Fully antomatic starch kitchenware moulding machine

A molding machine, fully automatic technology, applied in the field of machinery and equipment, can solve the problems of low technical level and automation, low production efficiency, high labor intensity, etc., to achieve high automation and technical level, less floor space, and labor intensity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

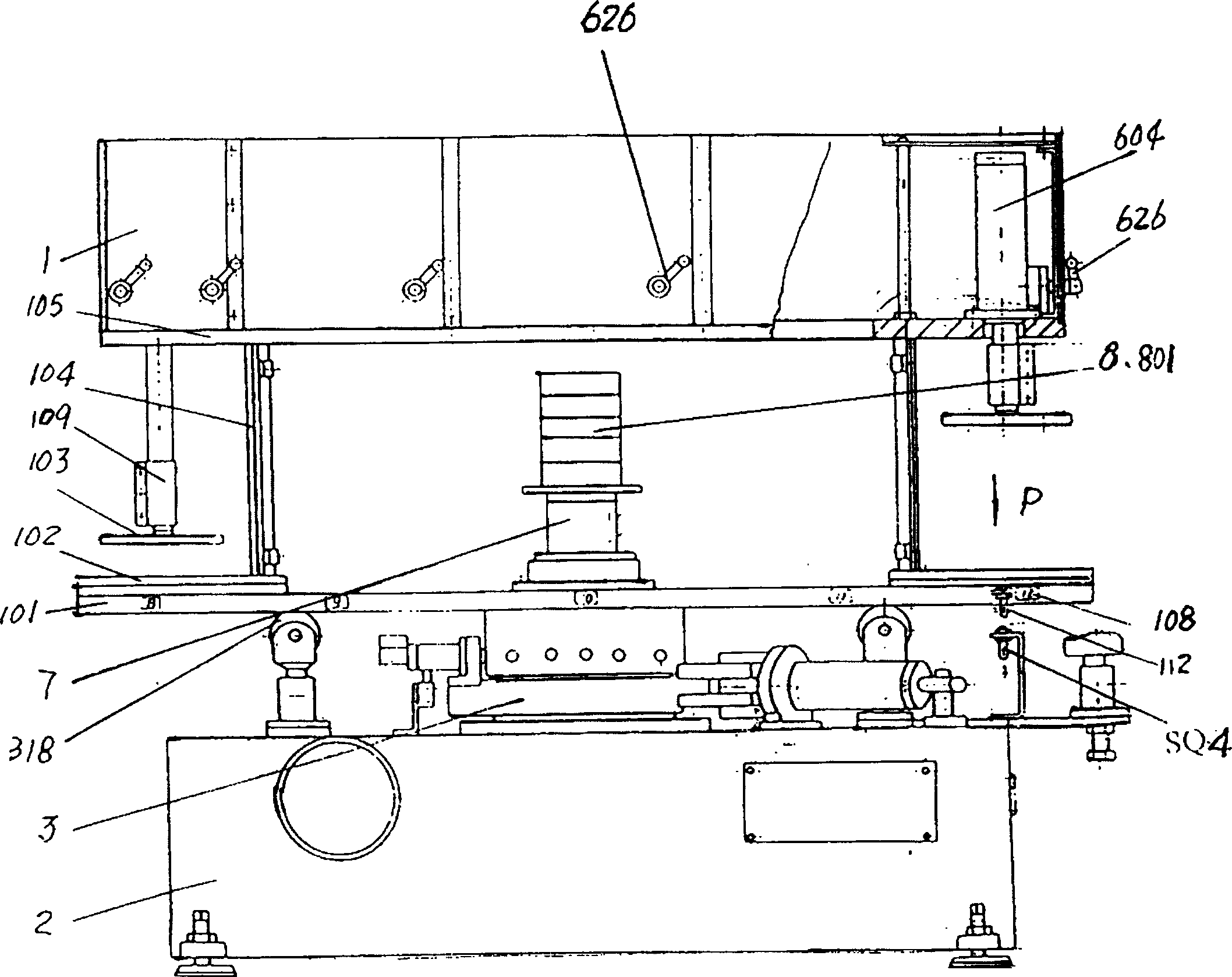

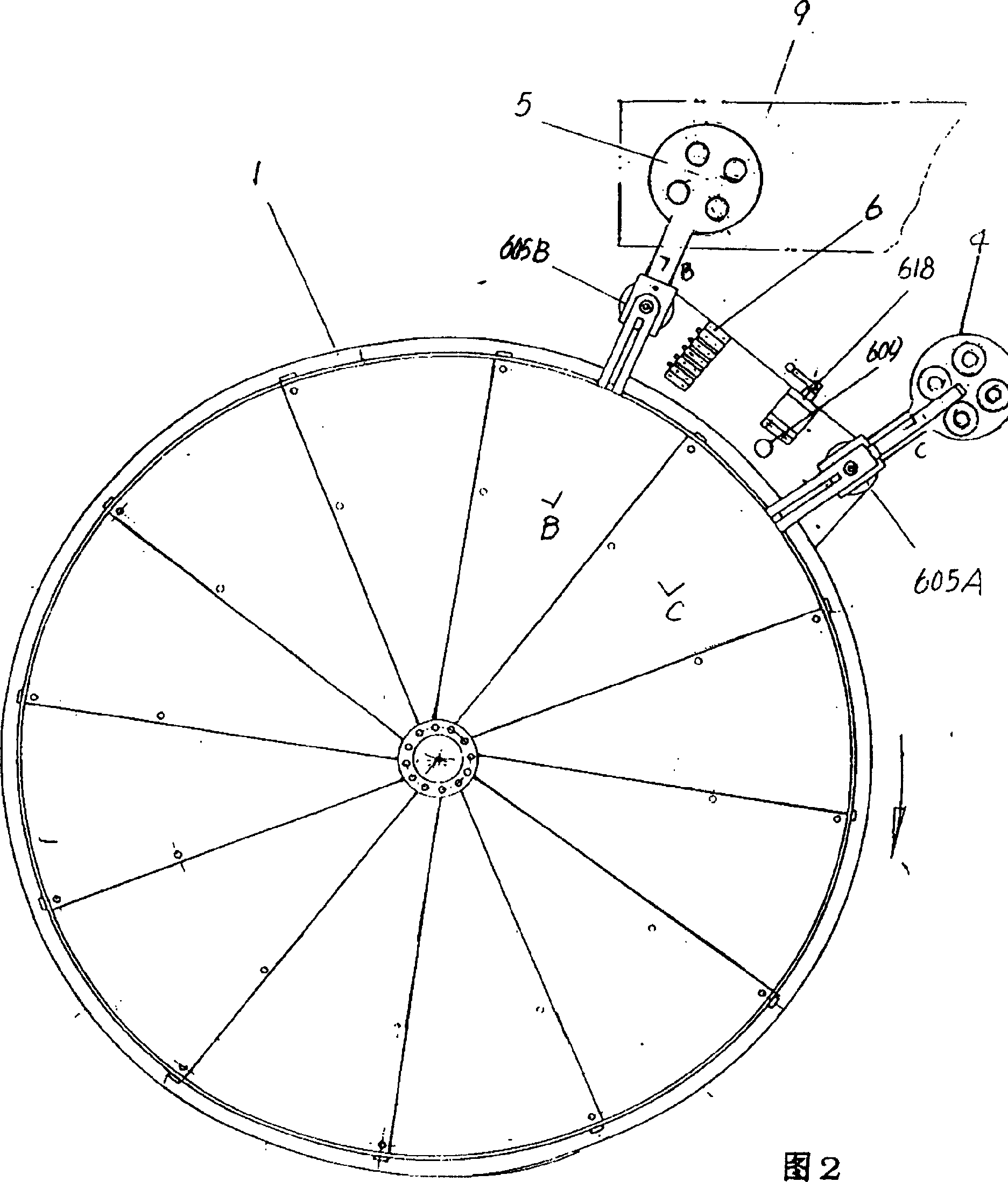

[0131] Please refer to figure 1 , Fig. 2, Fig. 5, the present invention is a kind of automatic starch tableware molding machine, comprises machine base, transposition part, upper and lower mold, feeding device, pick-up device and control device;

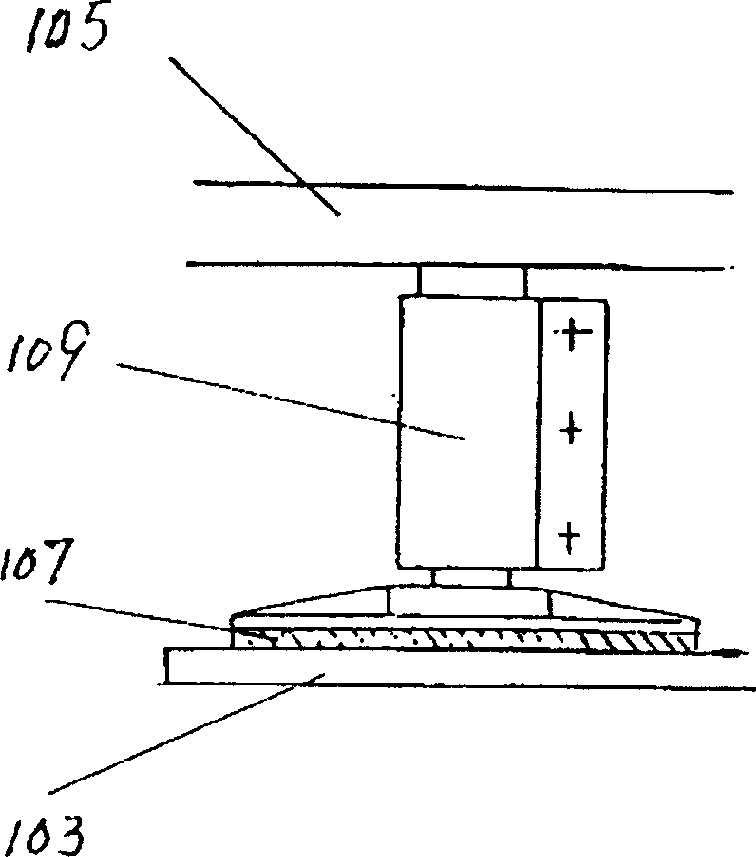

[0132] The center of the top surface of the machine base 2 is provided with an indexing part 3, and the indexing part includes an indexing body 311, the indexing number of the indexing body corresponds to the number of stations of the molding machine, and the indexing body is connected to an indexing point. Degree oil cylinder 601 realizes intermittent continuous rotation, and is contained on the traction ring 322 with bearing 316 and can rotate with the rotation bolt oil cylinder 602 of traction ring, and the immovable fixed bolt oil cylinder 603 that is installed on the base 2 realizes when indexing Staggered positioning, the fixed pin cylinder 603 runs synchronously with the dipping device cylinder 609 installed on the base 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com