Process burner structure of gasification furnace

A technology of process burners and gasifiers, applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of high heat flux density, non-stationary air flow, and large temperature gradient of cooling coils, so as to improve service life and reduce heat flow Density, the effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

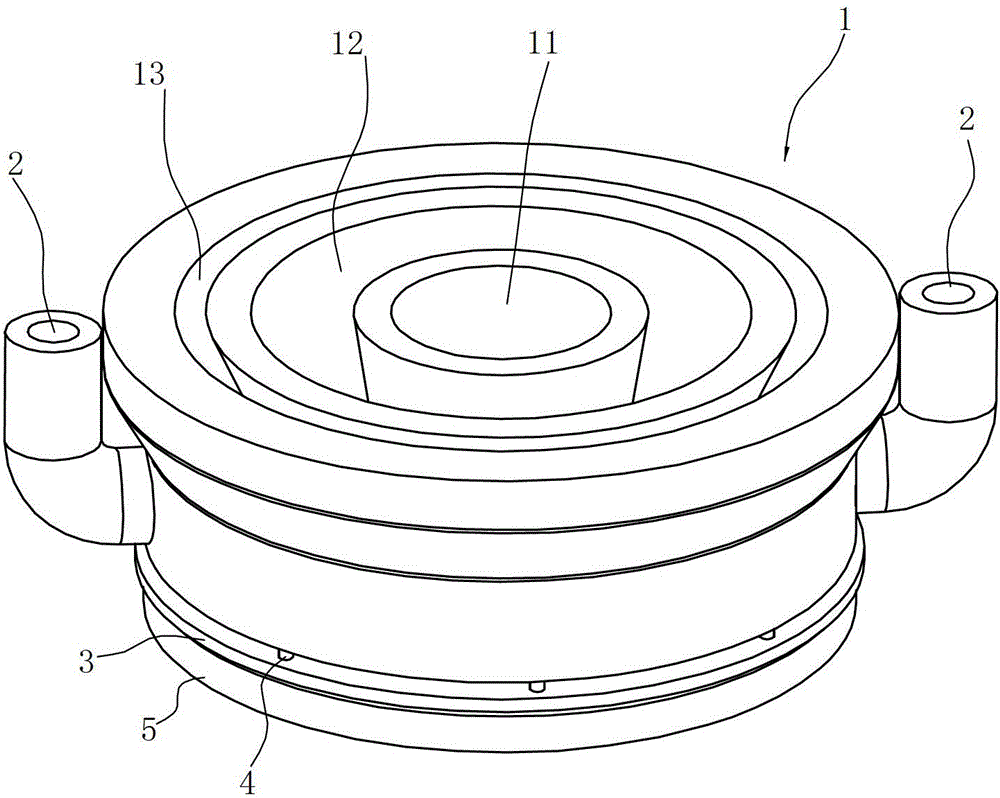

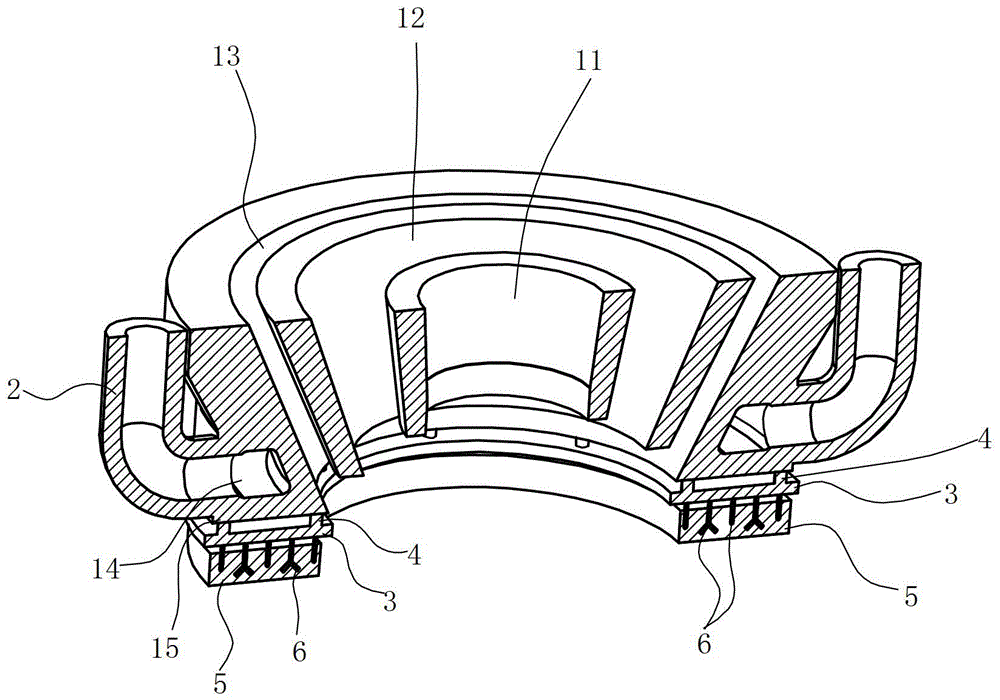

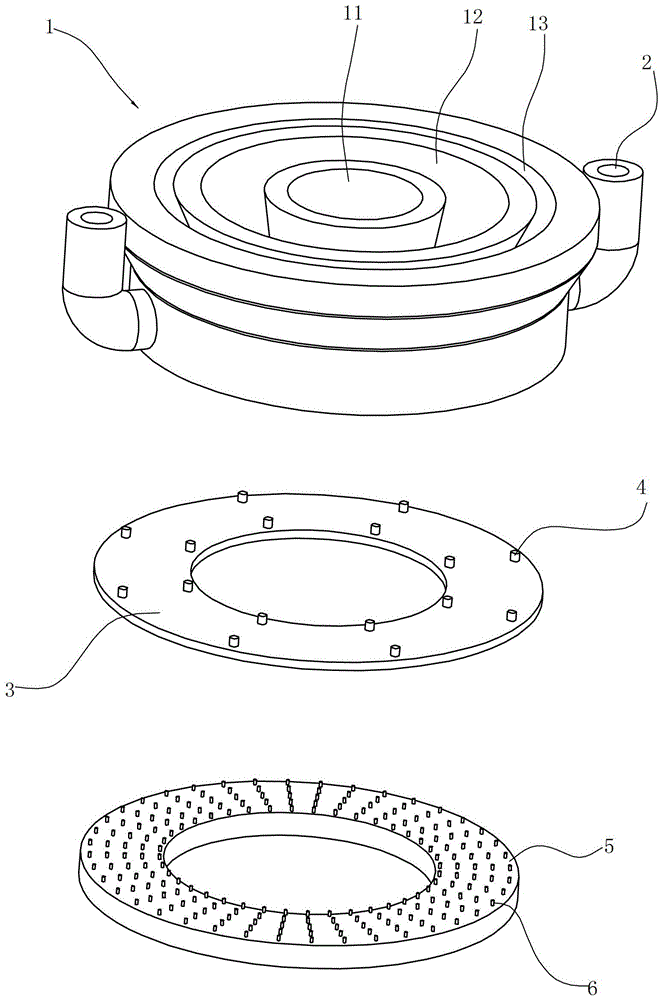

[0023] Such as Figure 1 to Figure 3 As shown, the process burner structure of the gasifier includes a burner body 1, on which there are pulverized coal channel 11, oxygen channel 12, steam channel 13 and cooling water connected with external water pipe 2 from inside to outside. Cavity 14.

[0024] The heat-shielding ring 3 is arranged in front of the front end face 15 of the burner, and the heat-shielding ring 3 is welded on the front end face of the burner through a plurality of connecting nails 4 arranged at intervals. The heat-shielding ring in this embodiment is made of N06600 material, the size of the through hole in the middle of the heat-shielding ring is equal to the diameter of the steam channel 13, and the thickness of the heat-shielding ring is 2 mm. The connecting nail 4 is made of N06600 material, one end of the connecting nail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com