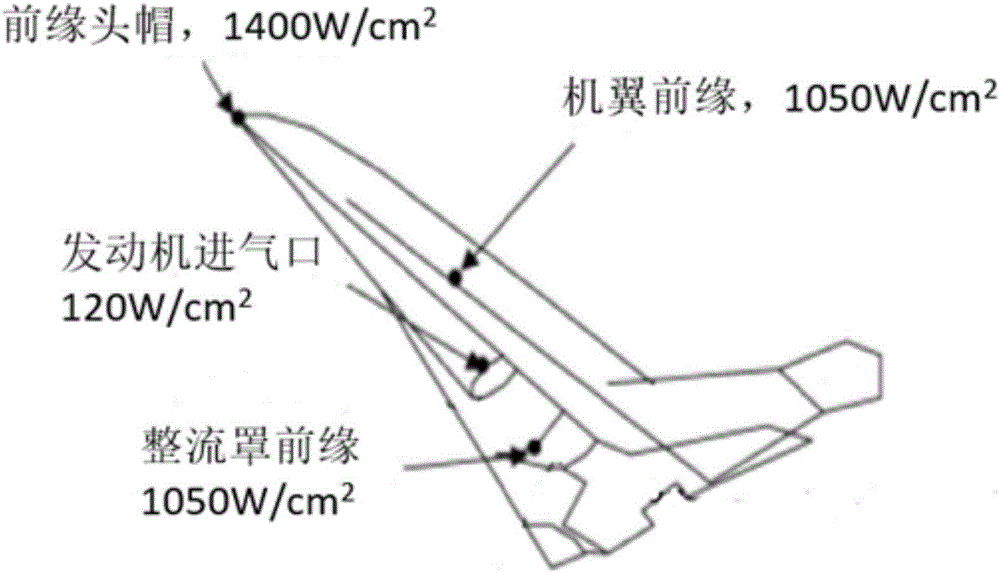

Thermal protection structure for leading edge of hypersonic vehicle

A technology of thermal protection structure and aircraft, applied in aircraft parts, fuselage, transportation and packaging, etc., can solve the problem of difficult cooling of leading edge parts, and achieve the effect of saving coolant, making up for weakening, and strengthening the overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

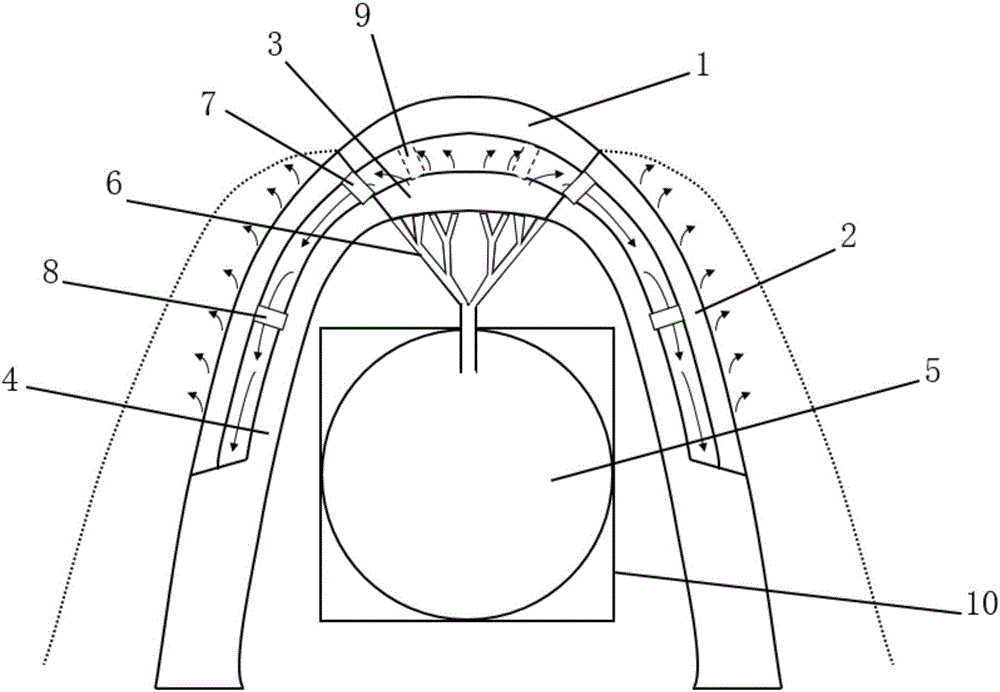

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

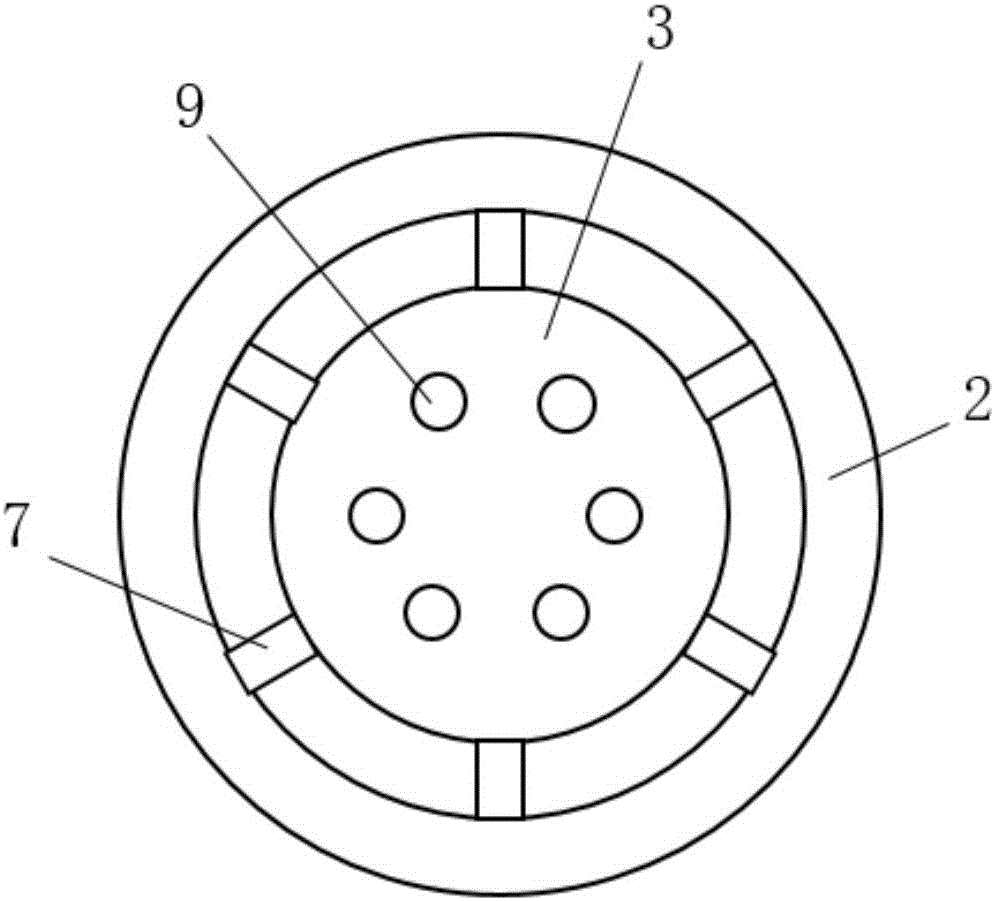

[0018] Such as figure 2 As shown, the present invention proposes a thermal protection structure at the leading edge of a hypervehicle, the thermal protection structure consists of an outer shell layer and an inner wall layer from outside to inside. The shell layer includes a head cover 1 at the top of the front edge and a front edge side wall shell 2 fixedly connected to the head cover 1, wherein the head cover 1 is made of a high temperature resistant material (such as carbon / carbon composite material), and the front edge side The wall shell 2 is made of a steel based porous material. The inner wall layer includes a head cover 3 arranged corresponding to the head cover 1 and a metal shell 4 fixedly connected with the head cover 3 and arranged corresponding to the front edge side wall shell 2, wherein the head cover 3 is made of a steel-based porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com