Die casting machine charging barrel good in cooling effect

A cooling effect and die casting machine technology, applied in the field of die casting machine barrels, can solve the problems of poor cooling effect, increased cost, and impact on production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

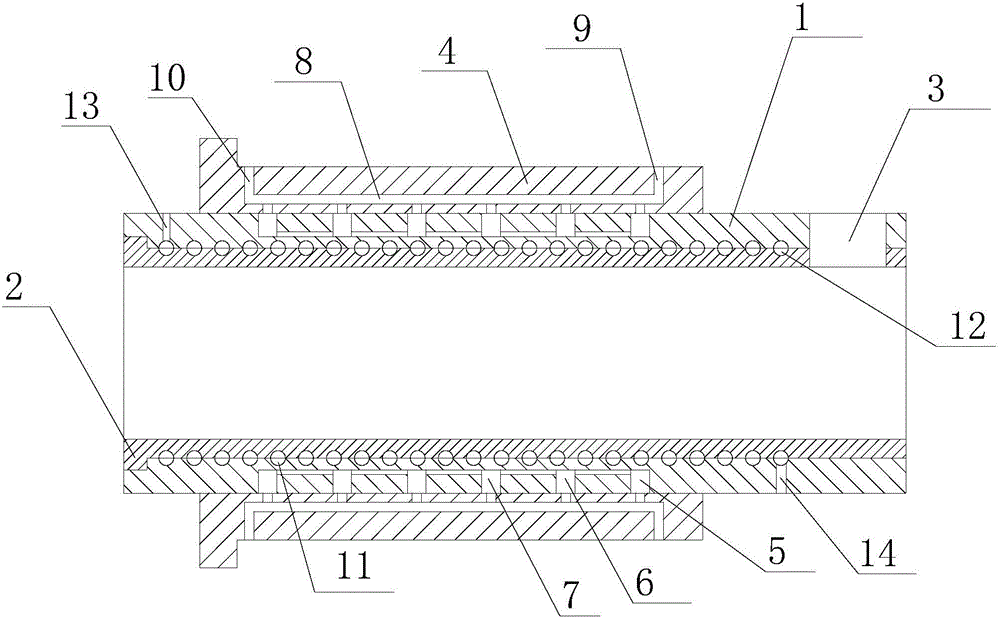

[0012] refer to figure 1 , the present invention proposes a die-casting machine barrel with good cooling effect, including a barrel body 1 and a bushing 2, the barrel body 1 is set on the bushing 2, and one end of the barrel body 1 is provided with a blanking port 3, and the material The barrel body 1 is covered with a cooling sleeve 4, and the contact part of the barrel body 1 and the cooling sleeve 4 is sequentially provided with a first annular groove 5, a second ring groove 5, and a second ring groove from the end close to the blanking port 3 to the end far away from the blanking port 3. Annular groove 6, the third annular groove 7, ..., the nth annular groove, the first annular groove 5 communicates with the second annular groove 6, the second annular groove 6 communicates with the third annular groove 7, ..., the n-1th annular groove communicates with the nth annular groove, the diameter of the first annular groove 5, the second annular groove 6, the third annular groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com