Continuous casting method of aluminum-containing peritectic high-strength automobile steel

A high-strength technology for automobile steel, which is applied in the field of continuous casting of aluminum-containing peritectic high-strength automobile steel, and can solve problems such as water blocking, unstable pouring, and cracks in the billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

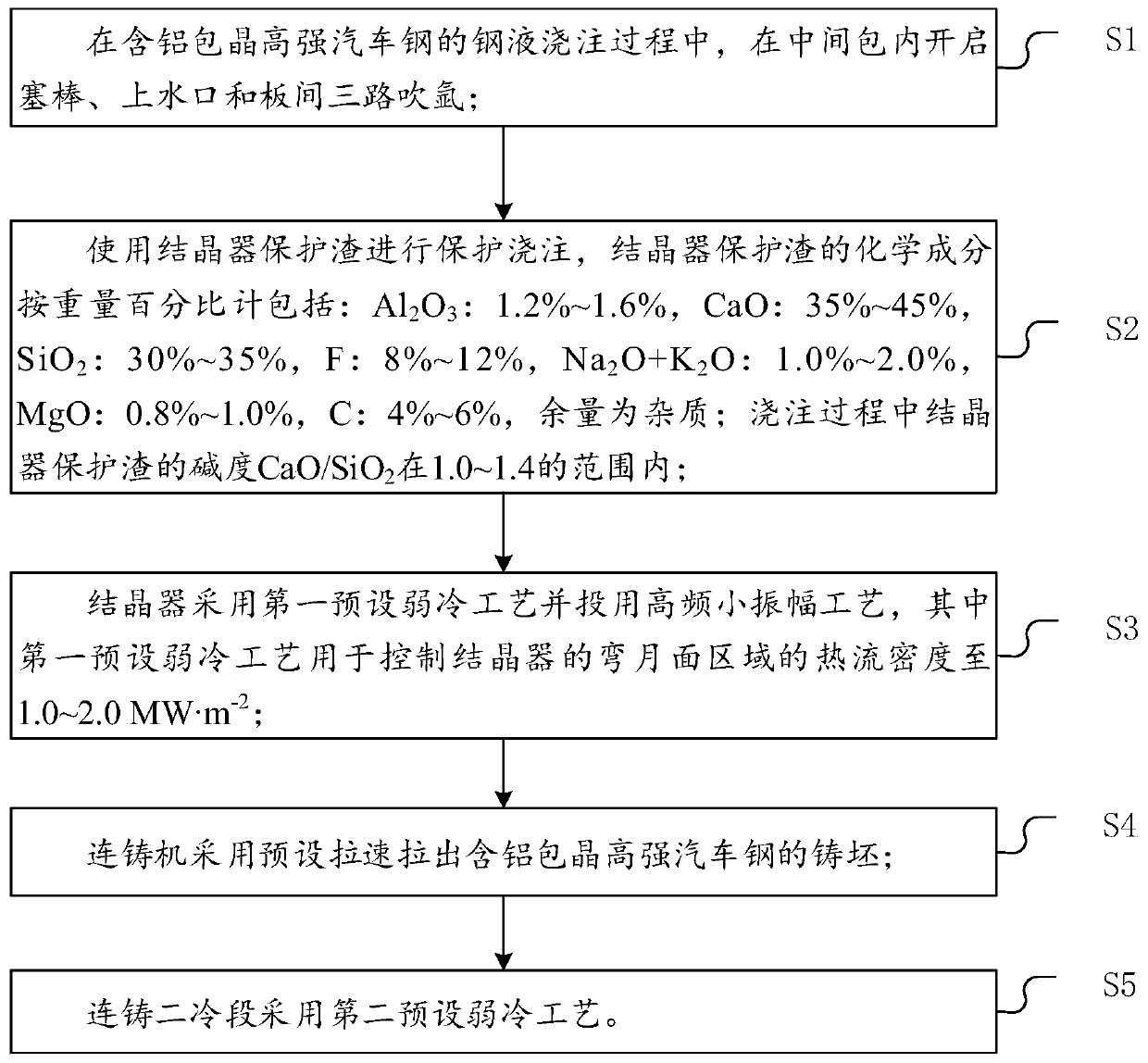

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0029] During slab continuous casting, the tundish receives the molten steel transferred from the ladle, and then distributes it to each crystallizer through the tundish nozzle; the molten steel forms a certain thickness in the crystallizer through the cooling process control of the cooling water in the crystallizer. The casting slab of the primary slab shell; then the slab is stably pulled out from the crystallizer according to a certain pulling speed, and the slab is further cooled when passing through the secondary cooling section of the continuous casting machine to solidify the inside of the slab; then it is drawn and straightened , cutting, and finally obtain the finished slab.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com