Mold locking shaft assembly lifting and shifting device

A technology of a toggle device and a shaft assembly is applied in the field of the lifting and toggle device of the clamping shaft assembly, which can solve the problems of increased moment of inertia and centrifugal force, shutdown of the blowing machine, bending deformation of the clamping shaft, etc., so as to reduce the moment of inertia, The effect of reducing centrifugal force and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

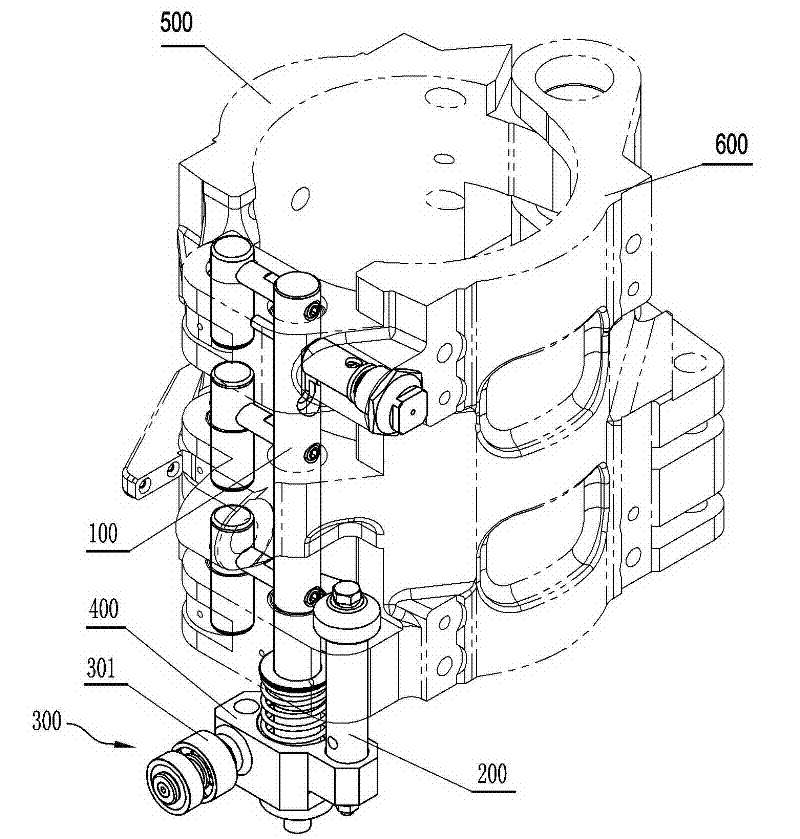

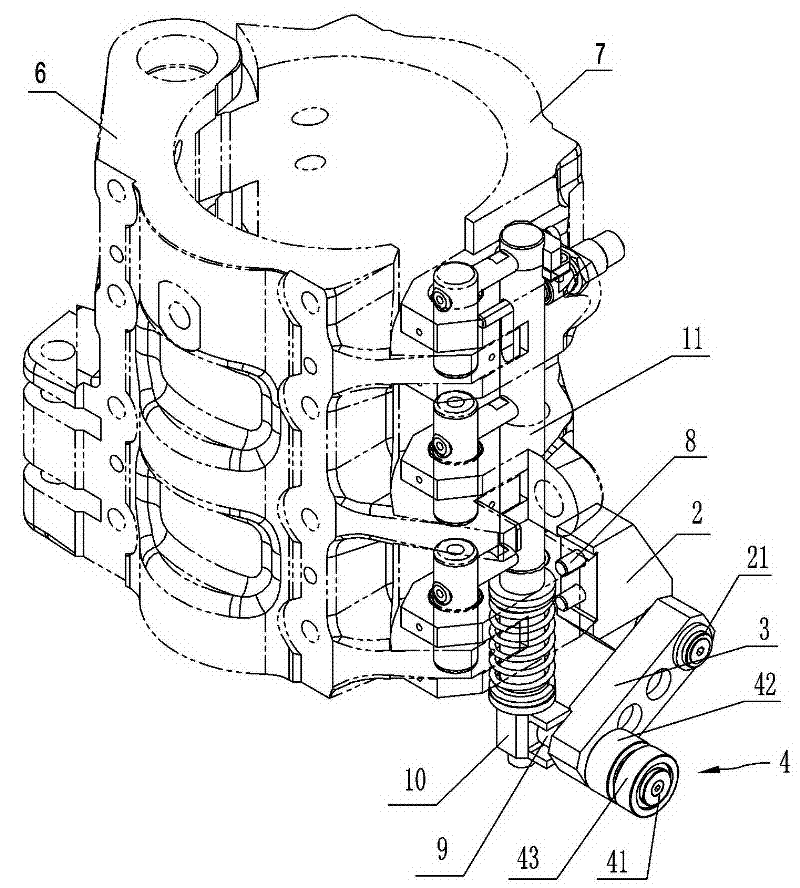

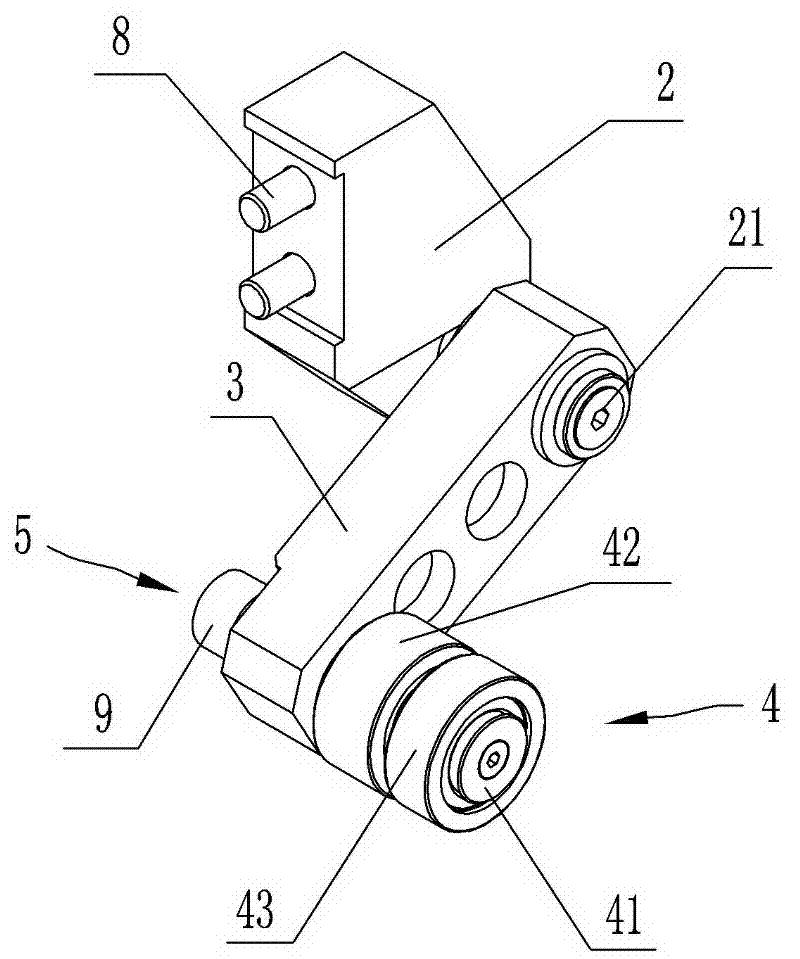

[0012] Such as Figures 2 to 5 As shown, the clamping shaft assembly lift toggle device according to the present invention includes a toggle block 10 fixed at the lower part of the clamping shaft 11 of the clamping shaft assembly 1, and a swing arm member for driving the toggle block 10 up and down , the swing arm component includes a base 2 fixed on the formwork, a swing arm 3 is hinged on the base 2, and a roller assembly 4 is installed on one side of the swing arm 3. This roller assembly 4 is a prior art, and its main Including the roller shaft 41 installed on the swing arm 3, and the first roller 42 and the second roller 43 installed on the roller shaft 41, wherein the first roller 41 is connected with the clamping guide rail (not shown in the figure) on the bottle blowing machine Cooperate, the other side of the swing arm 3 extends the toggle shaft 5, and the opposite surface of the toggle block 10 and the toggle shaft 5 has a slideway 101 for the toggle shaft 5 to stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com