Patents

Literature

34results about How to "Avoid deformation and bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

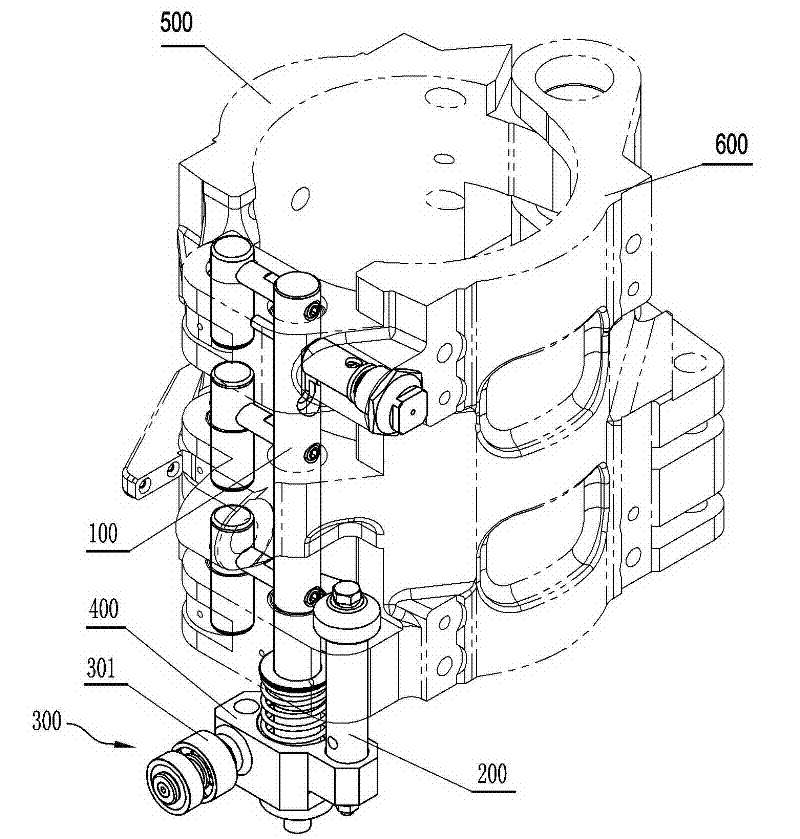

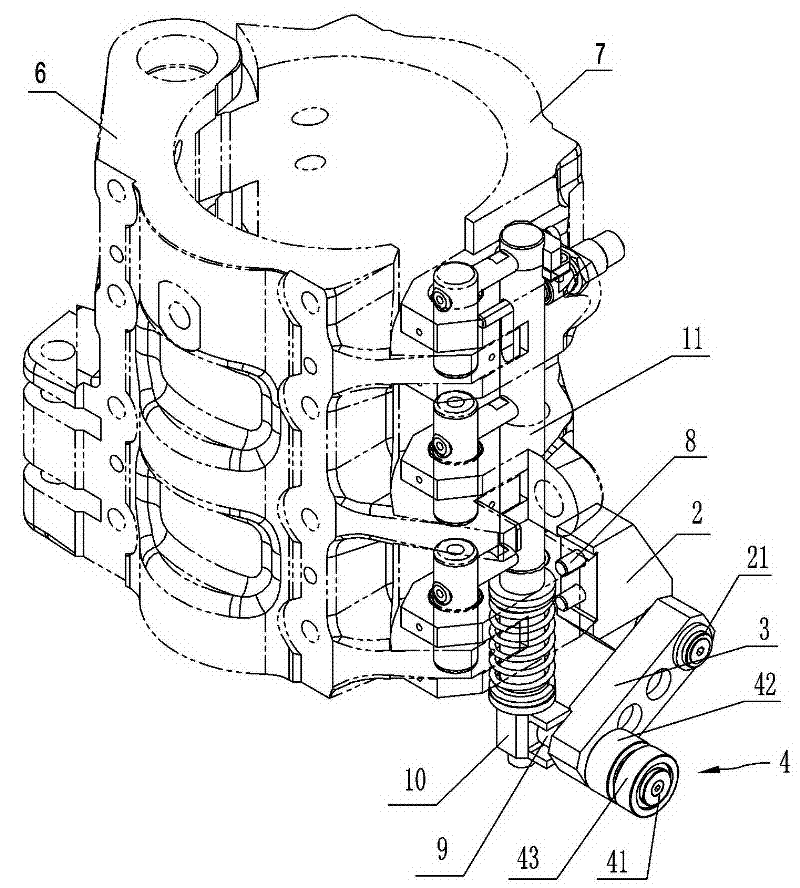

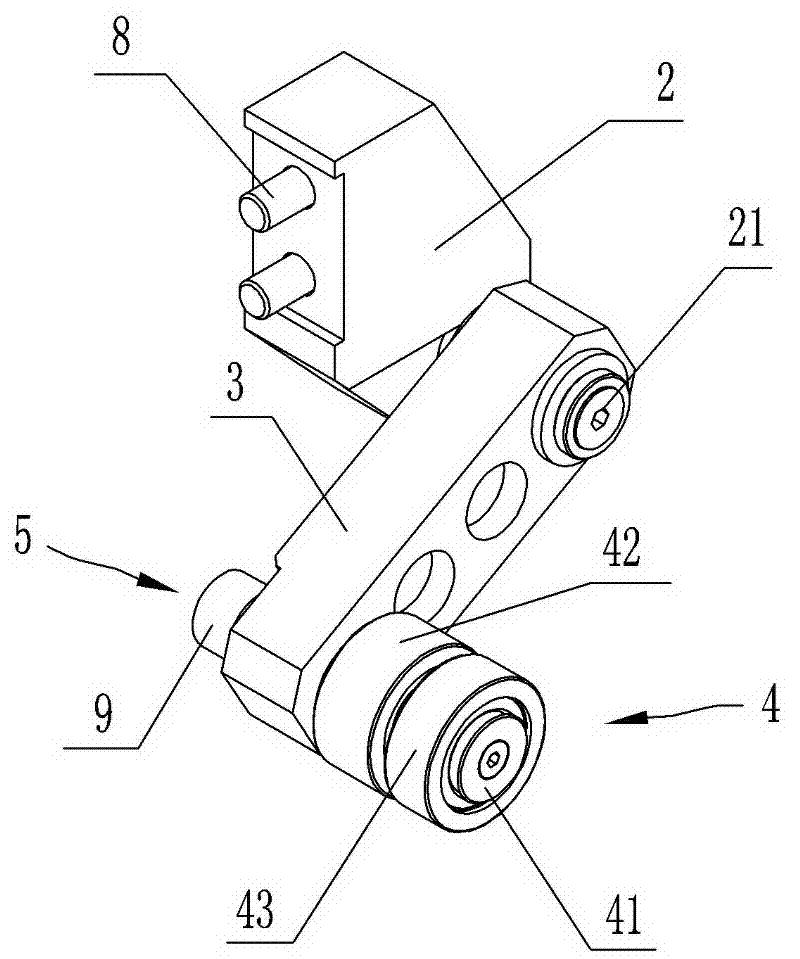

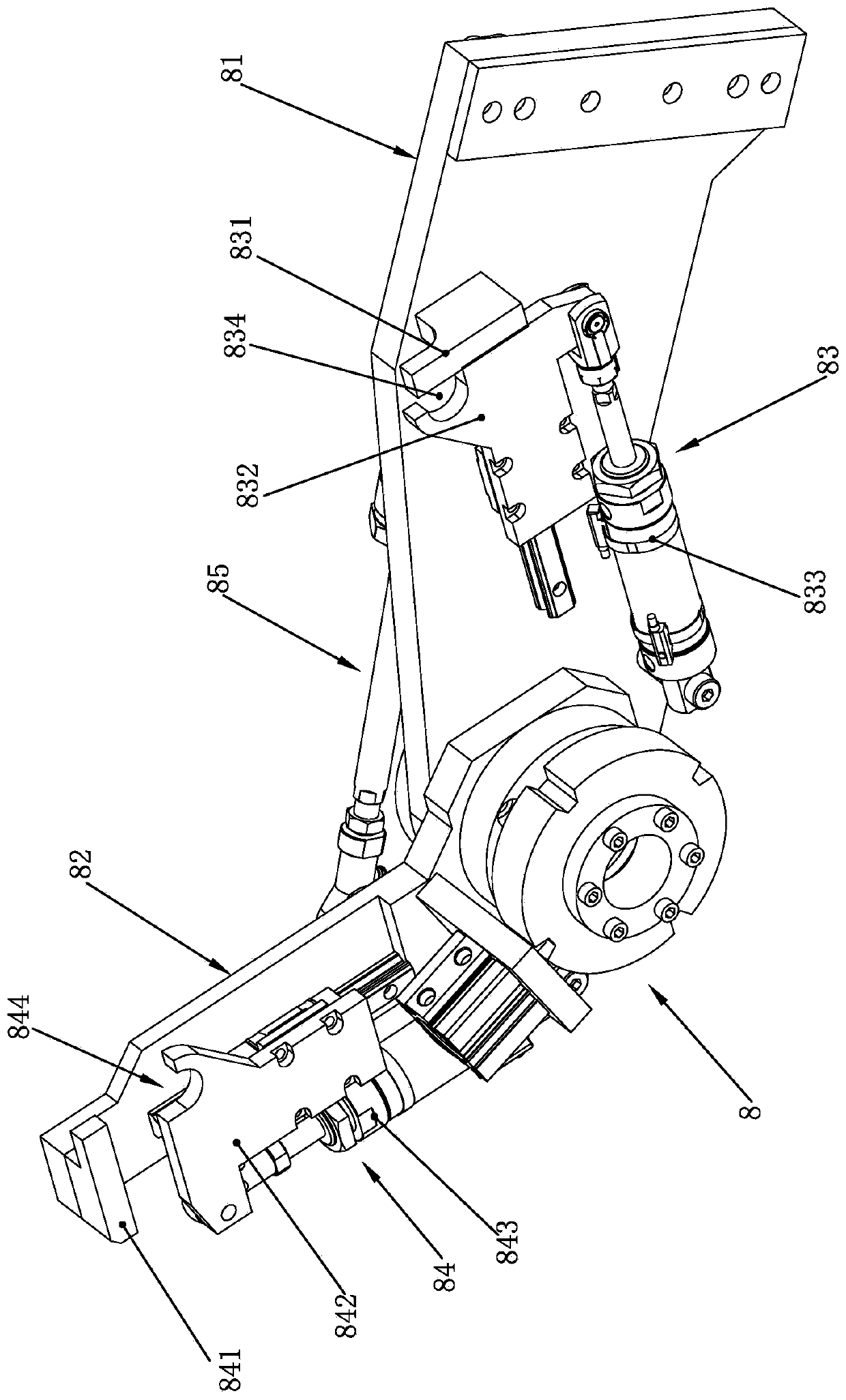

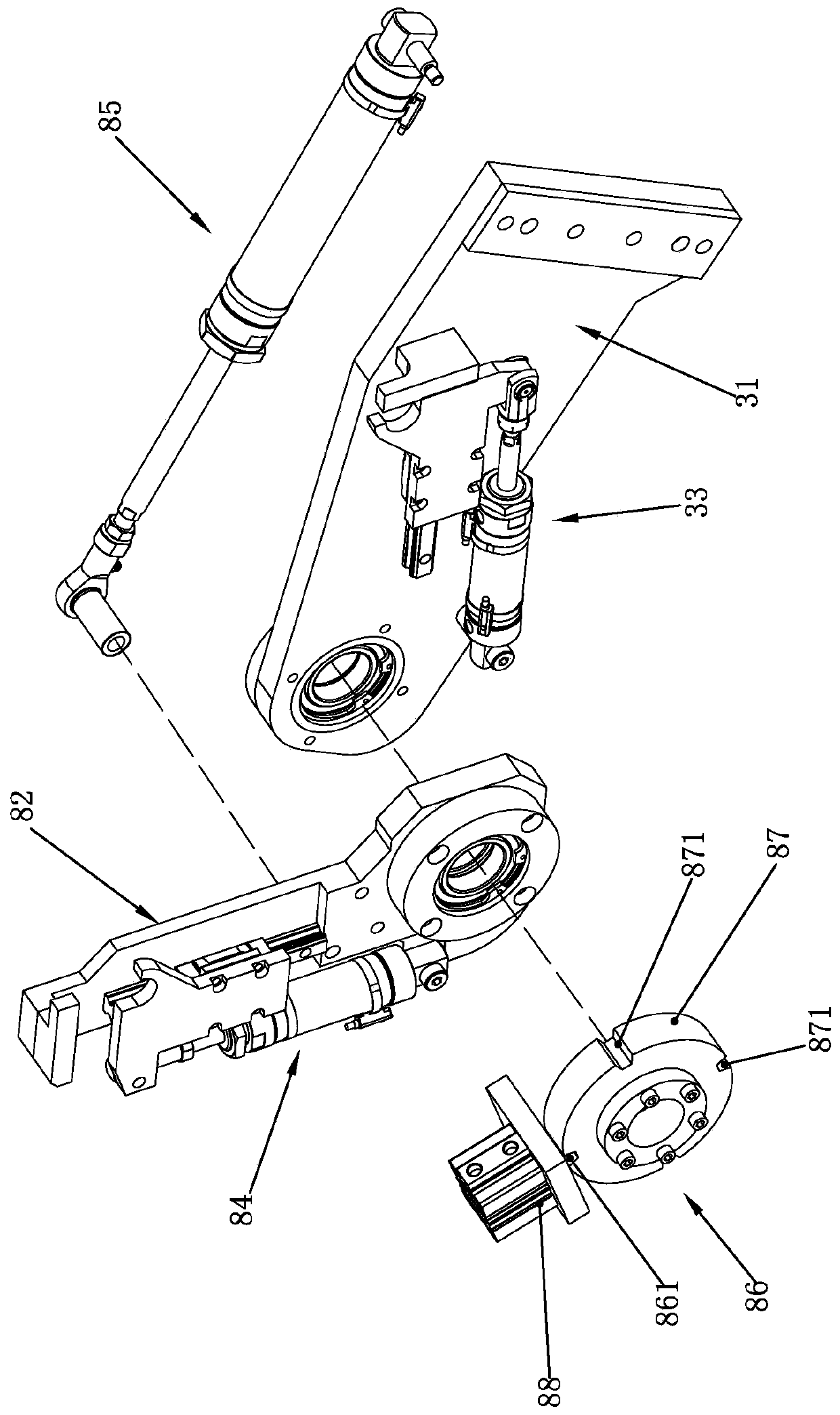

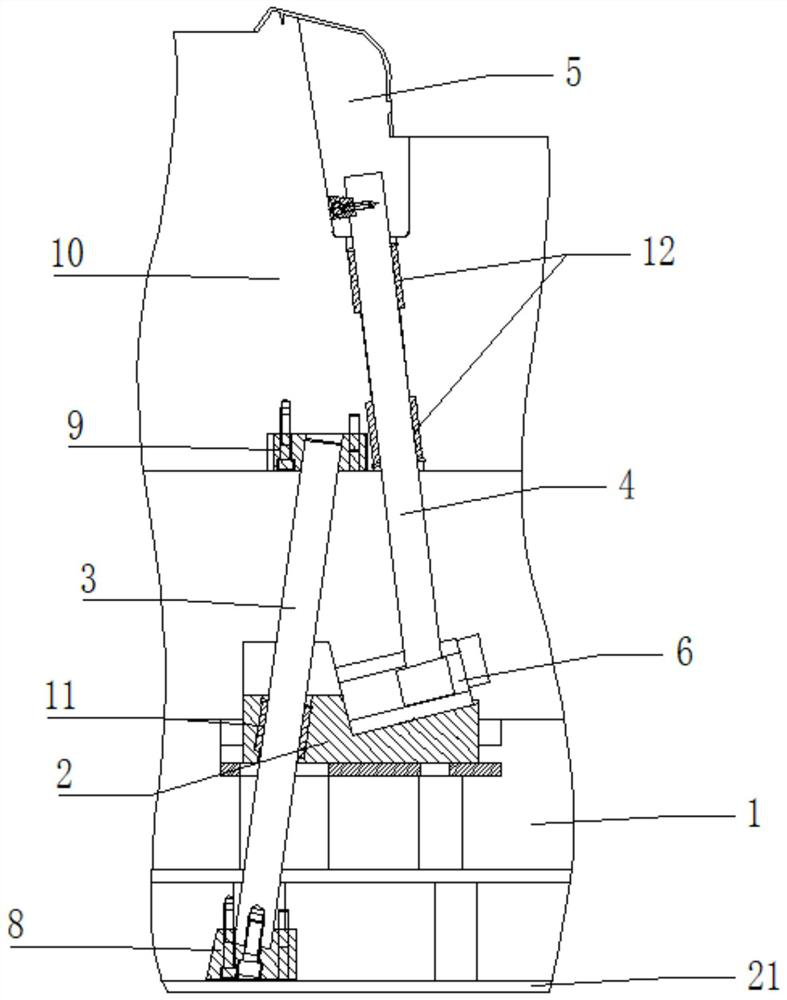

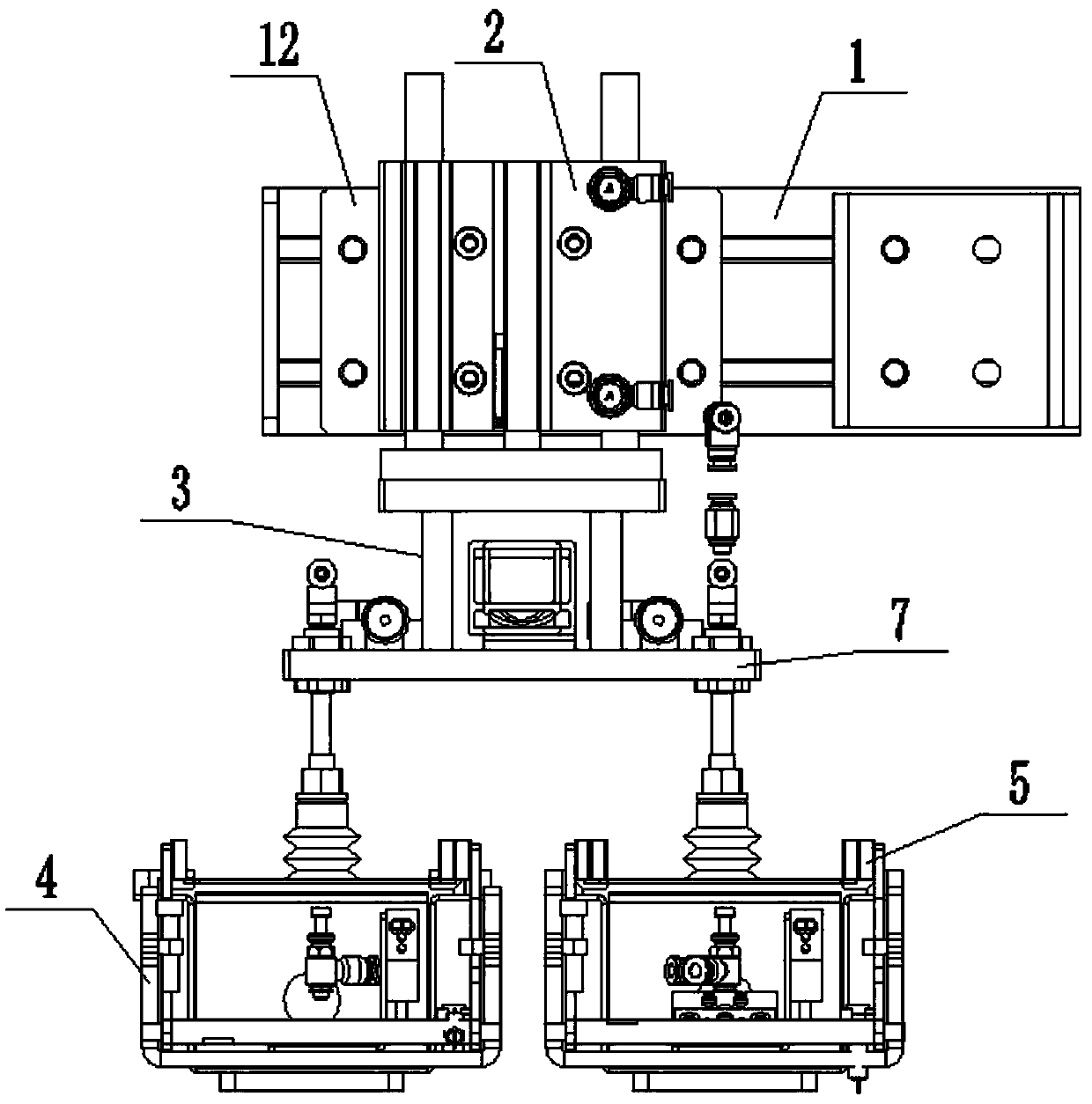

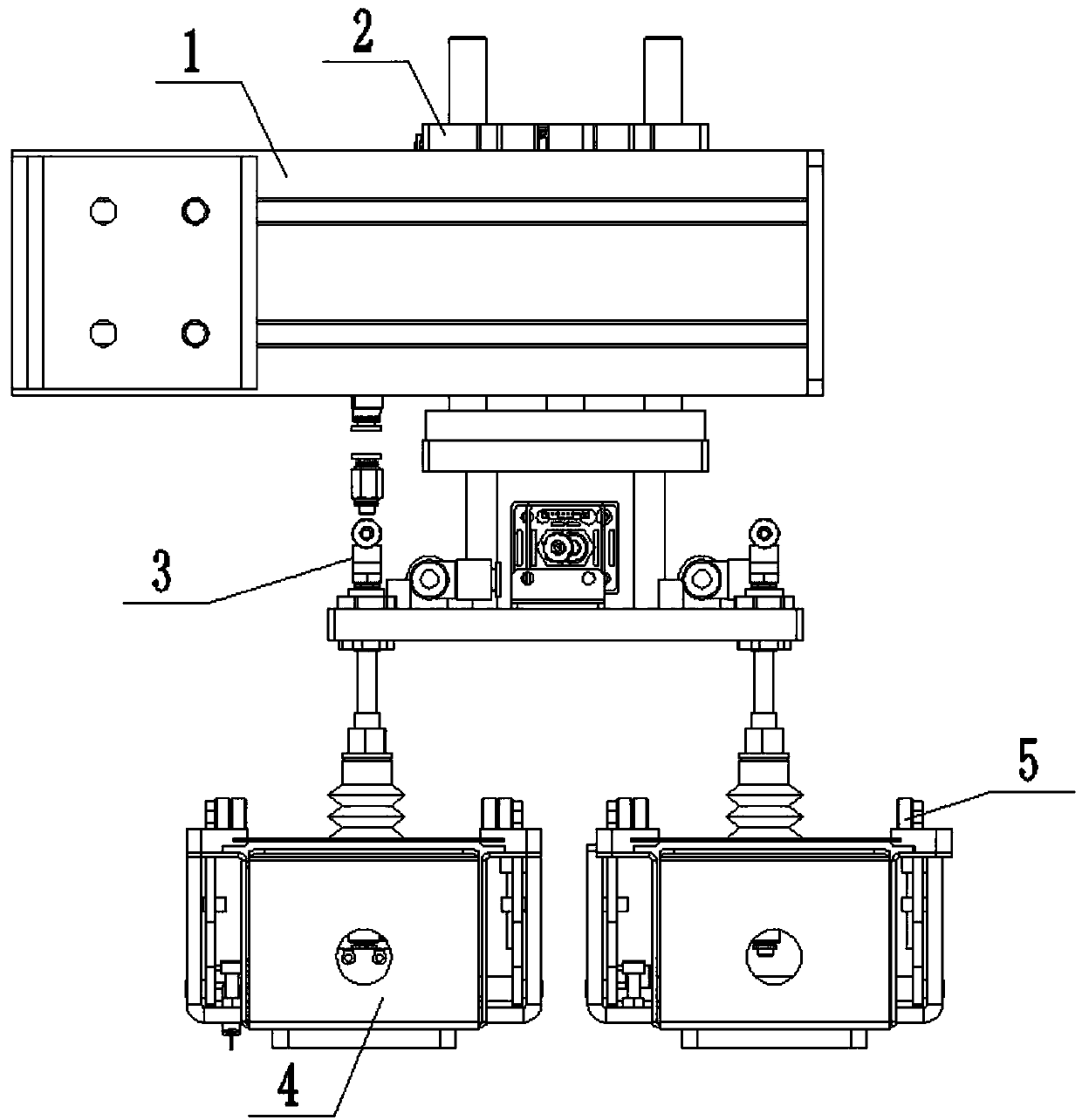

Mold locking shaft assembly lifting and shifting device

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

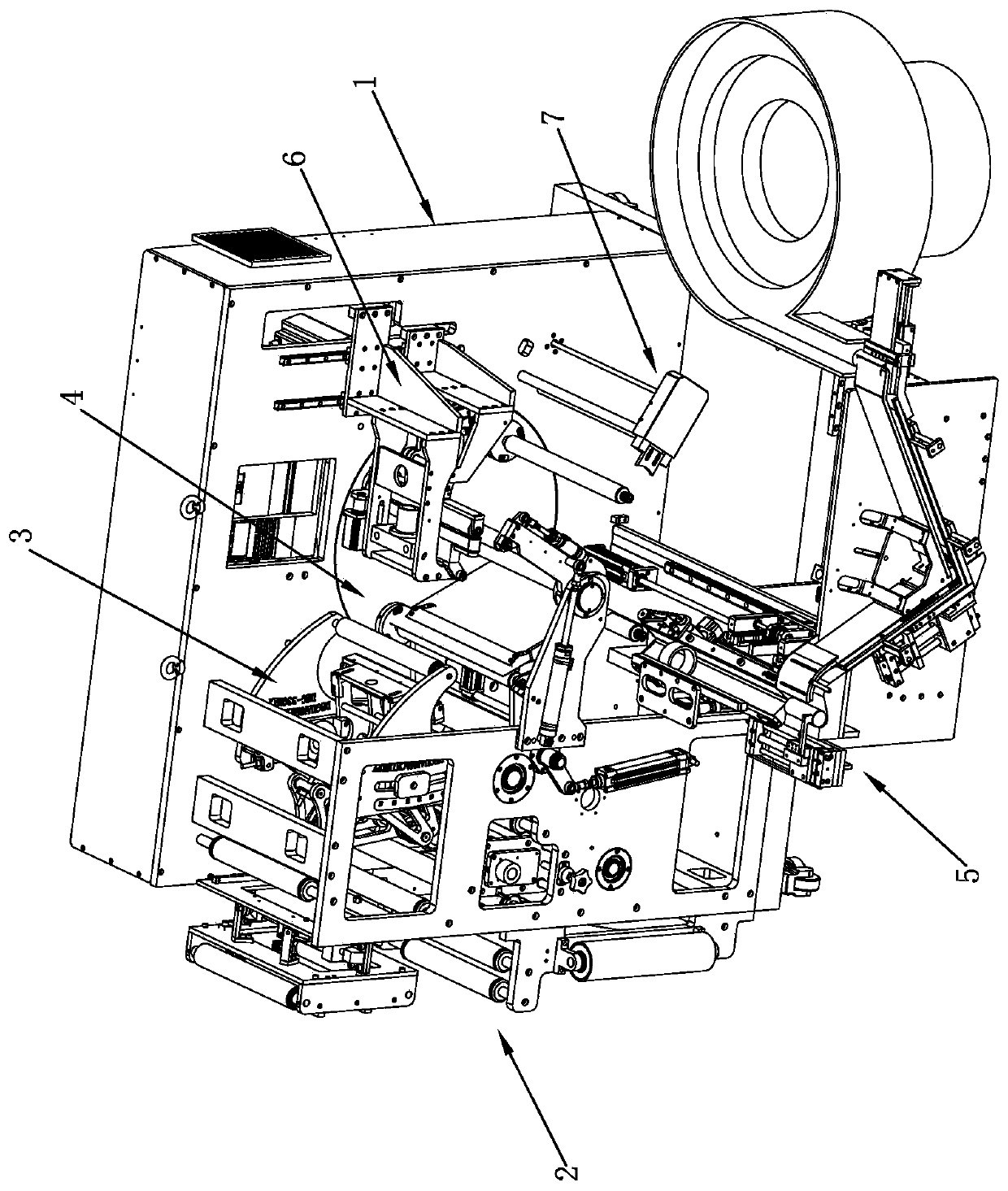

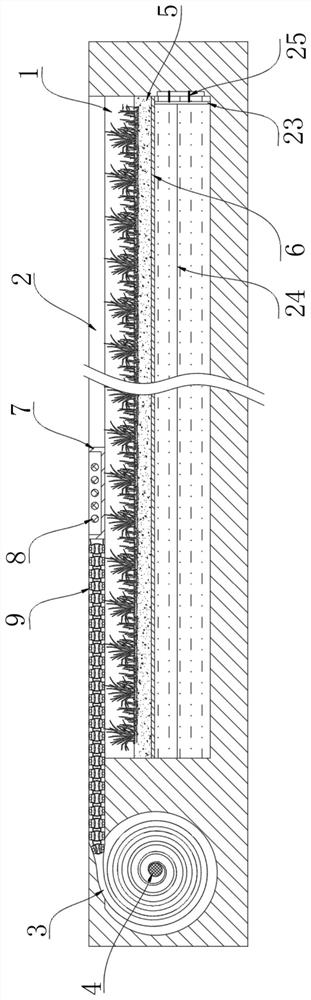

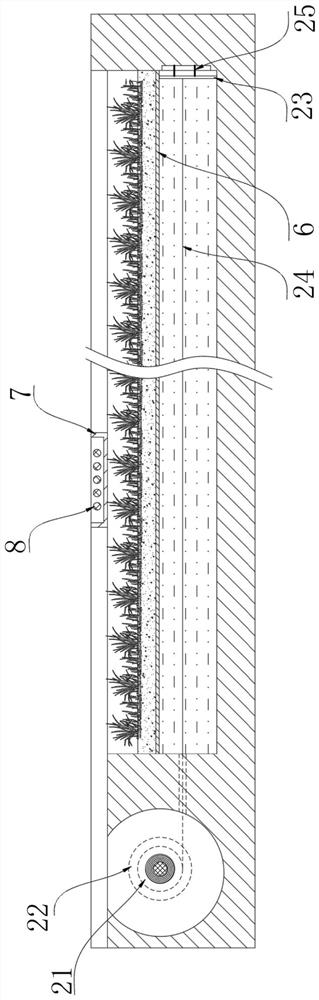

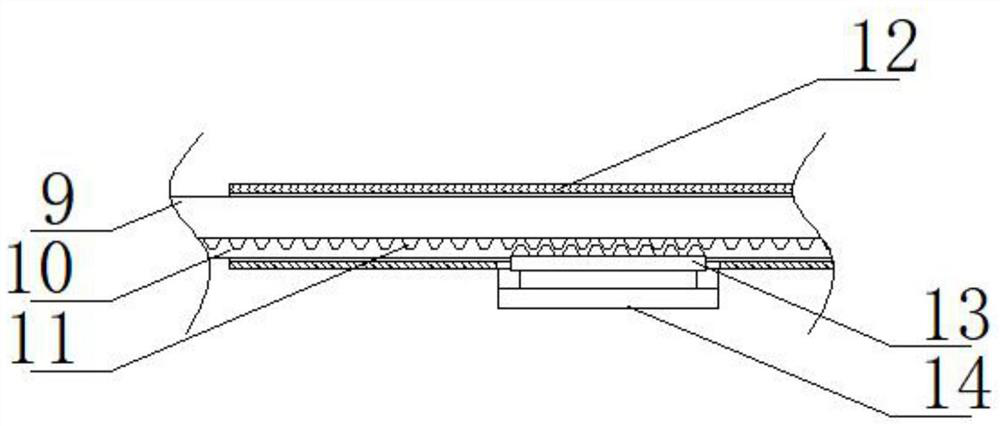

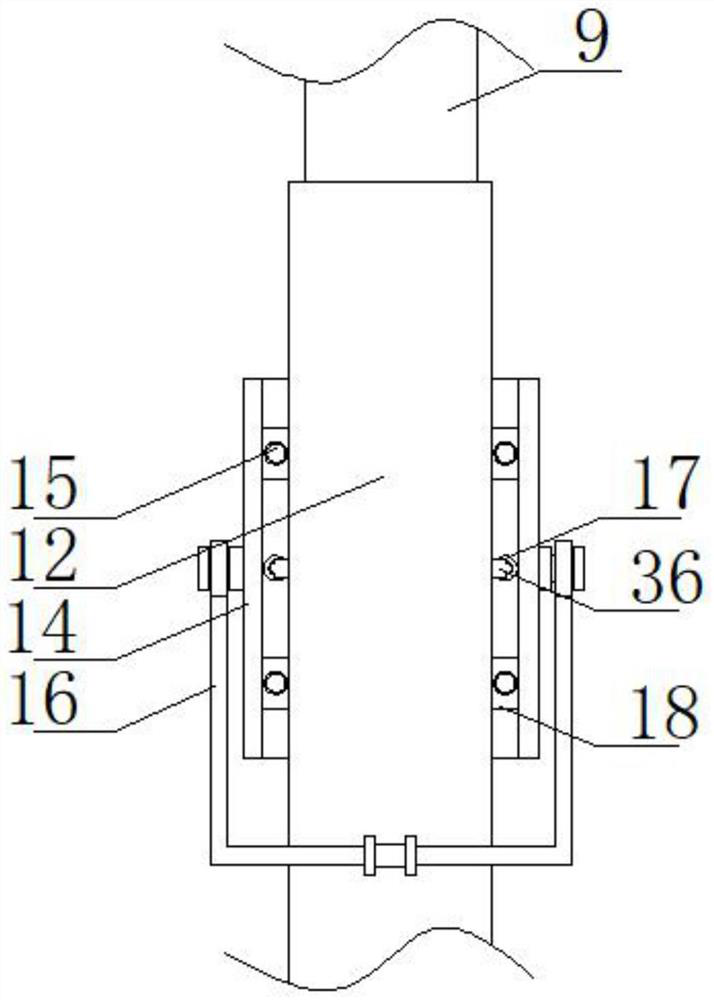

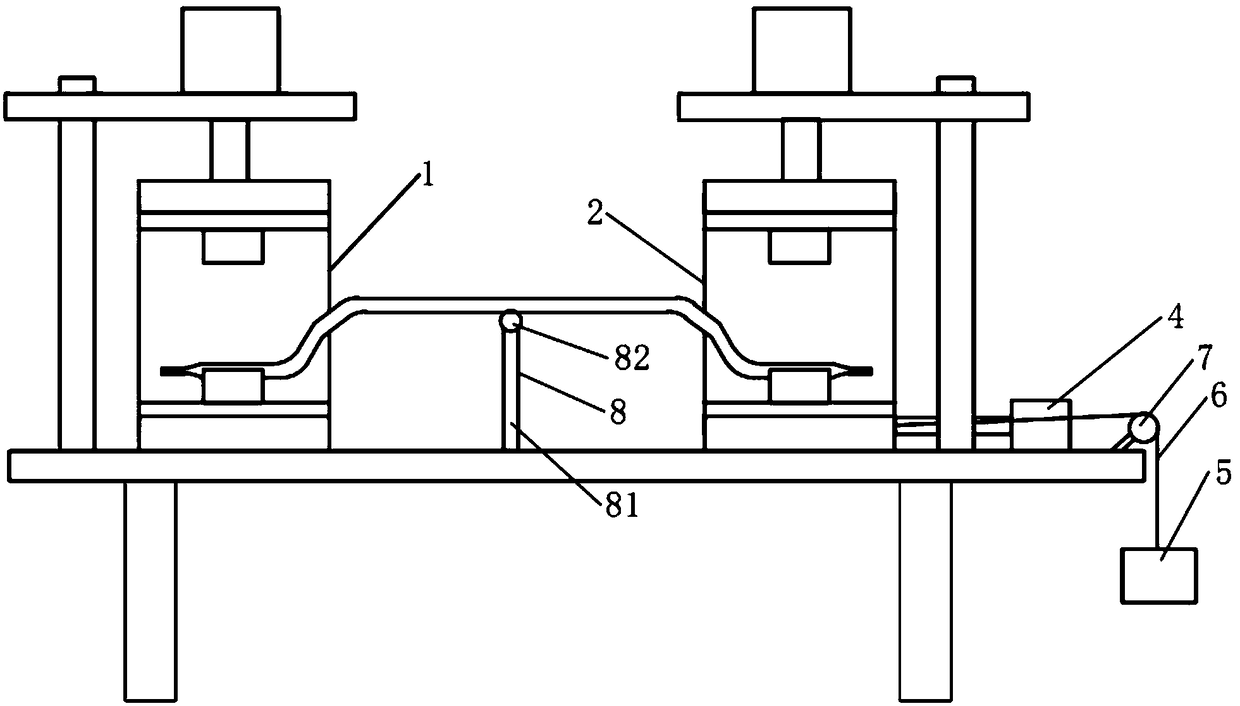

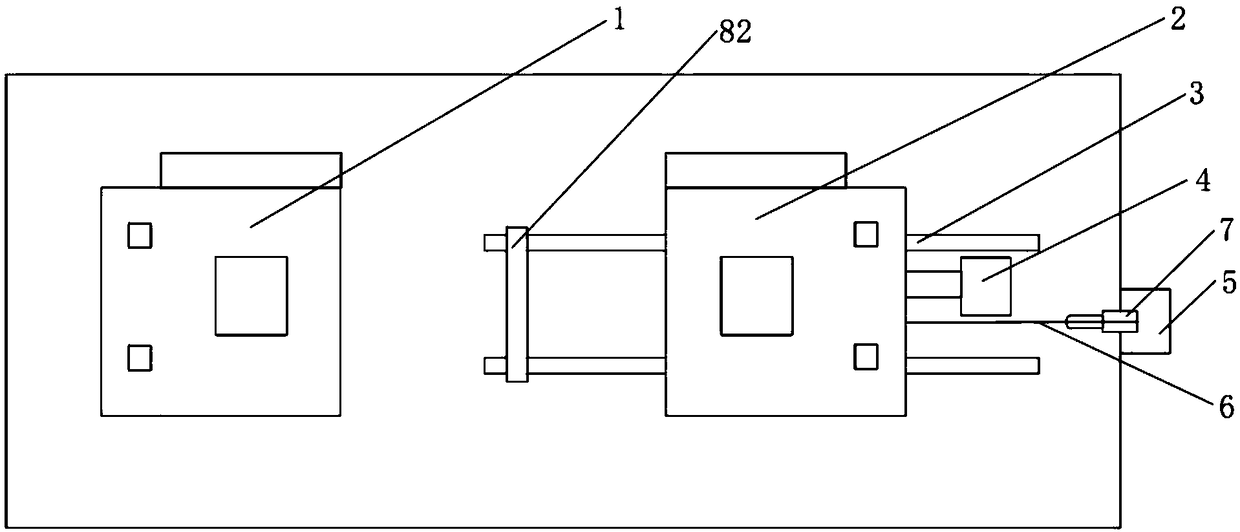

Full-automatic winding facility

PendingCN111017605AAvoid shakingAvoid bending deformationLabelling machinesWebs handlingMachineMachining process

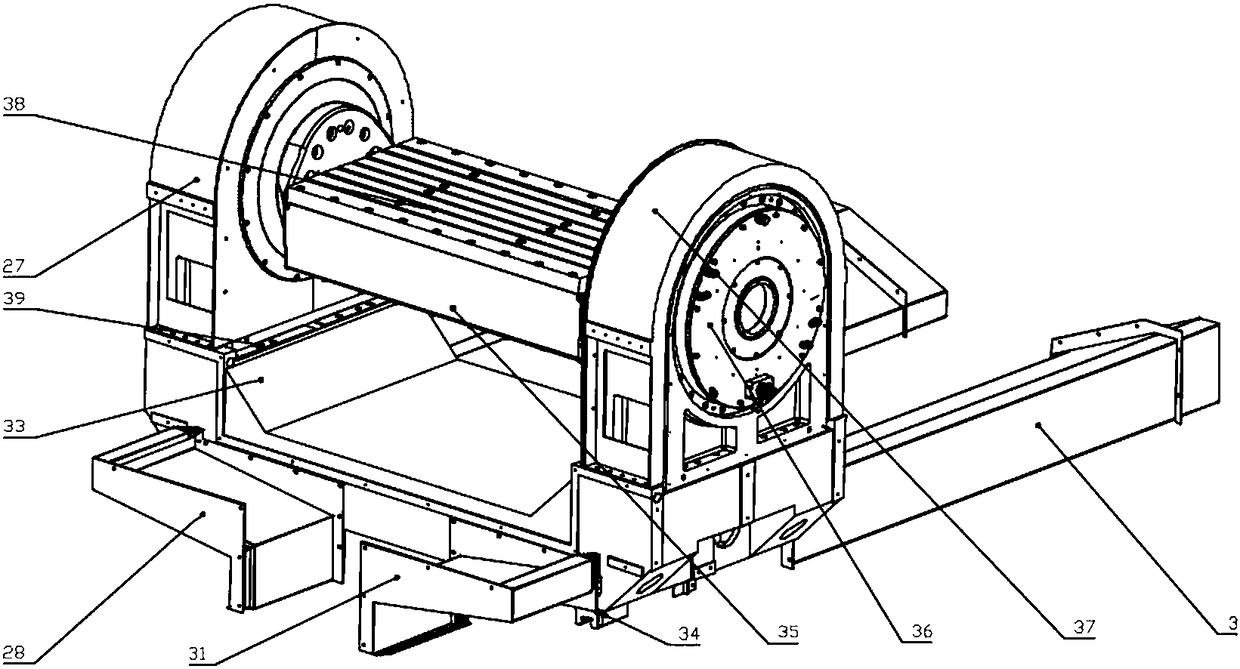

The invention relates to a full-automatic winding facility. The following technical scheme is provided. The full-automatic winding facility comprises a machine frame, a feeding device, a cutting device, a winding device, a paper tube core conveying device, a labelling device and a finished product output device. The feeding device, the cutting device, the winding device, the paper tube core conveying device, the labelling device and the finished product output device are arranged on the machine frame. The winding device comprises a rotating disc. The rotating disc can rotate in the circumferential direction. Multiple winding air expansion shafts which can run along with the rotating disc are arranged on the rotating disc. The cutting device comprises an upper cutter mechanism, a lower cutter mechanism and a paper press mechanism. The lower cutter mechanism and the upper cutter mechanism are correspondingly arranged, and the paper press mechanism is located on the upper cutter mechanism. A winding auxiliary clamping device is arranged between the winding device and the cutting device. Adjusting wallboards which are symmetrically arranged in pairs, are erected on the machine frame and enable the upper cutter mechanism to be integrated are arranged on the upper cutter mechanism. By the adoption of the technical scheme, the full-automatic winding facility which can adjust the cutting distance according to winding drums with different thicknesses, prevents the winding air expansion shafts against bending deformation in the machining process, is stable in clamping and supportingmovement and improves the winding efficiency is provided.

Owner:瑞安市德冠机械有限公司

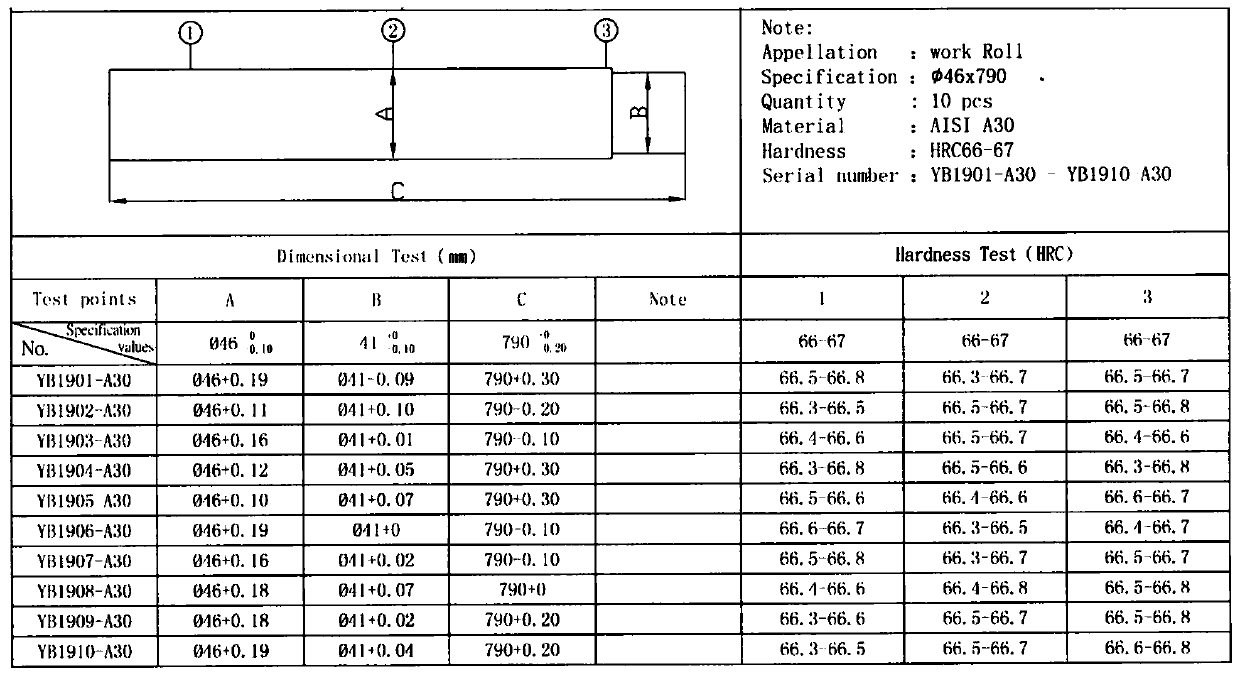

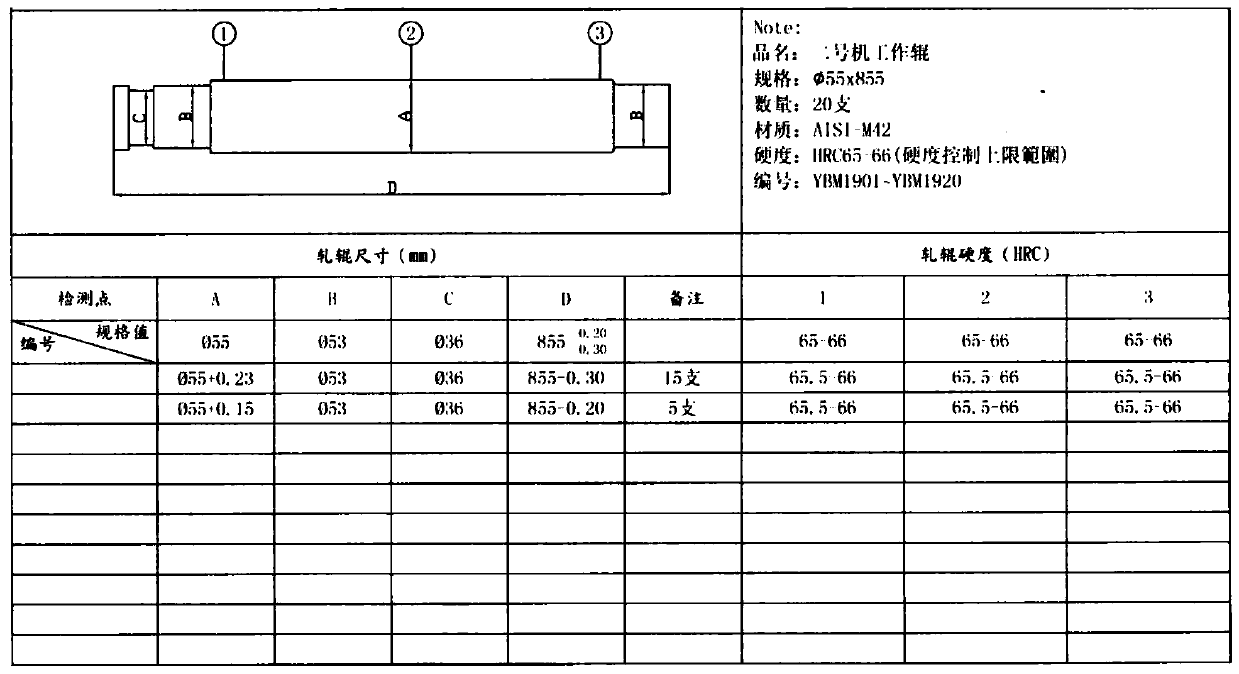

Novel full-hardening cold-rolling working roller heat treatment process

PendingCN111020127AReduce temperature differenceReduce deformationFurnace typesHeat treatment furnacesPhysicsQuenching

The invention relates to the technical field of full-hardening cold-rolling working roller heat treatment processing, and discloses a novel full-hardening cold-rolling working roller heat treatment process. Preheating treatment is performed on a workpiece first, then high-temperature quenching and heating are performed at 1080-1180 DEG C, and then the workpiece is hung into a constant-temperaturequenching environment to be subjected to constant-temperature quenching treatment. By means of the novel full-hardening cold-rolling working roller heat treatment process, heating and heat preservingare performed at each stage with the purposes of ensuring that the workpiece moves to a higher-temperature environment and finally reaches a quenching temperature after internal and external metal texture reaches a set temperature, reducing the deformation of the workpiece to a certain extent, shortening the heating time of the workpiece at the quenching temperature, improving the heat treatment efficiency of the workpiece, improving the metallographic phase texture distribution compactness, thermal shock resistance and abrasive resistance of a working roller, ensuring that hanging and air-cooling are performed after the parts, with different sizes, of the cold-rolling working roller reach the same temperature, effectively reducing the deformation of the cold-rolling working roller and preventing the working roller from being bent or broken.

Owner:WUXI YIBAO MACHINERY EQUIP CO LTD

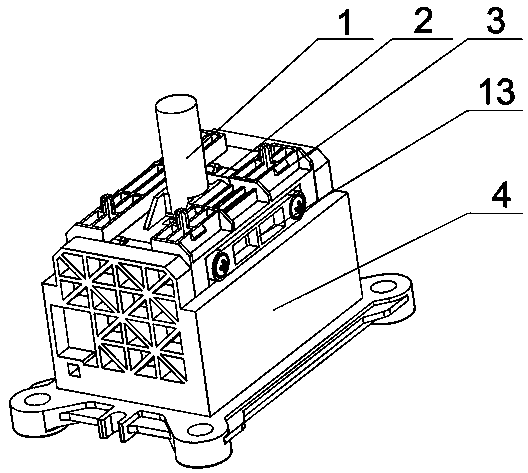

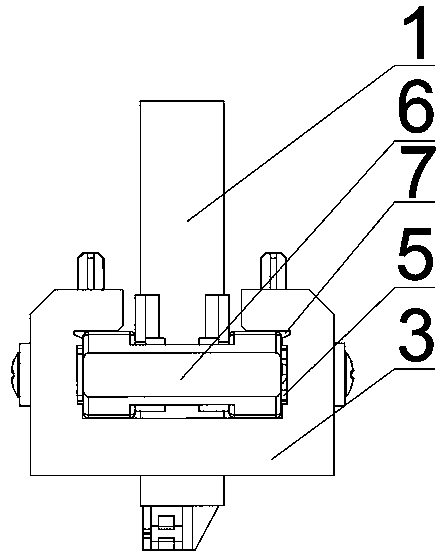

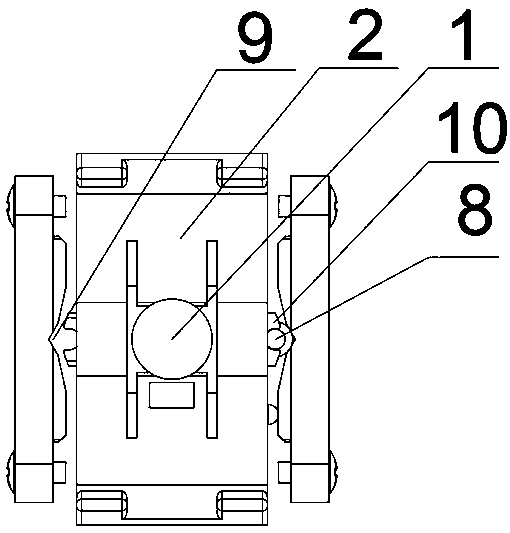

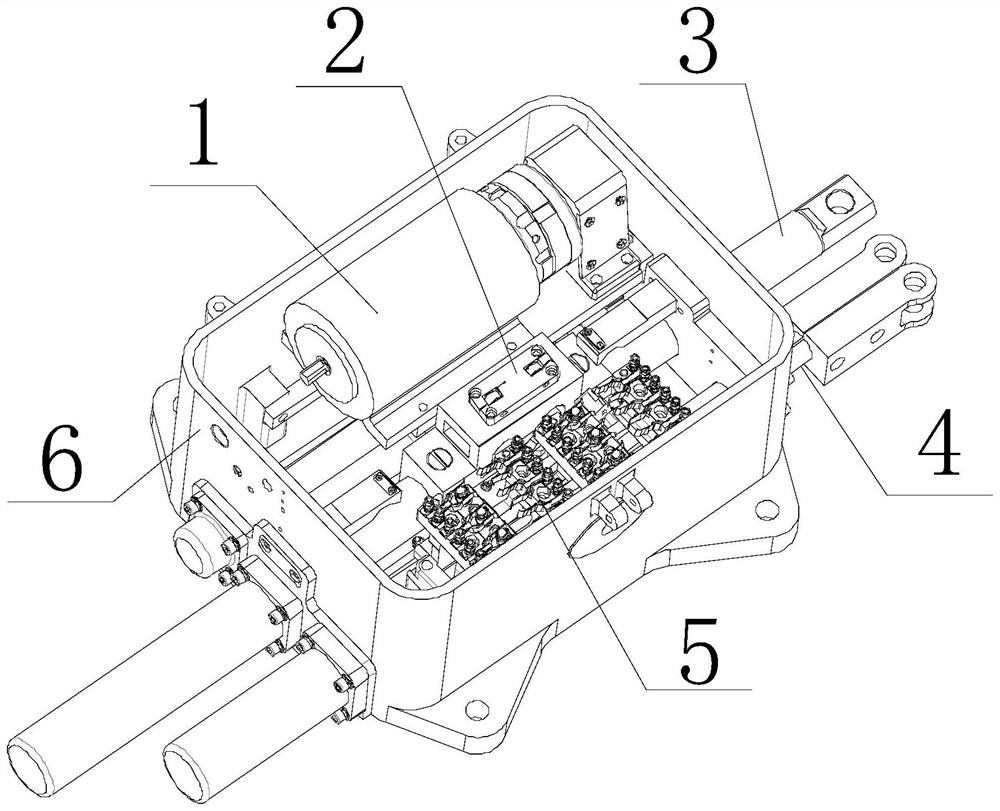

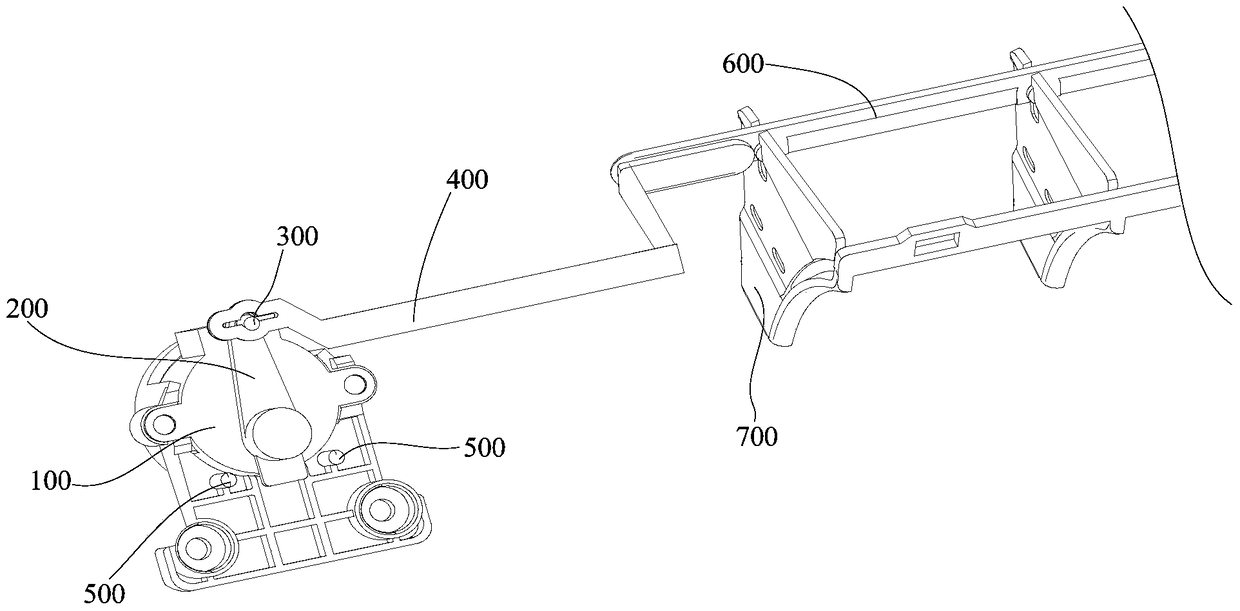

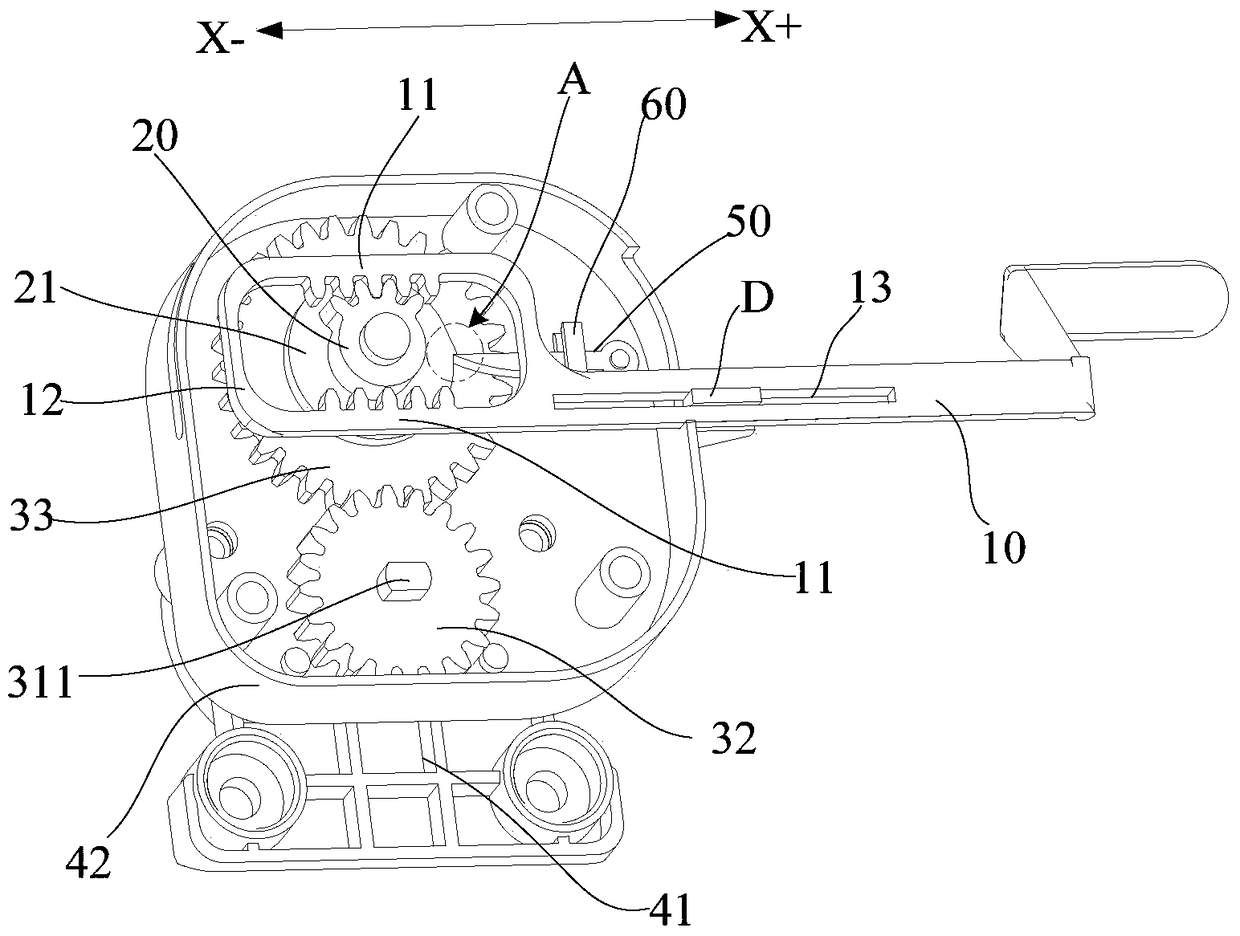

Sliding type gear shifter

Owner:宁波鹏程汽车系统有限公司

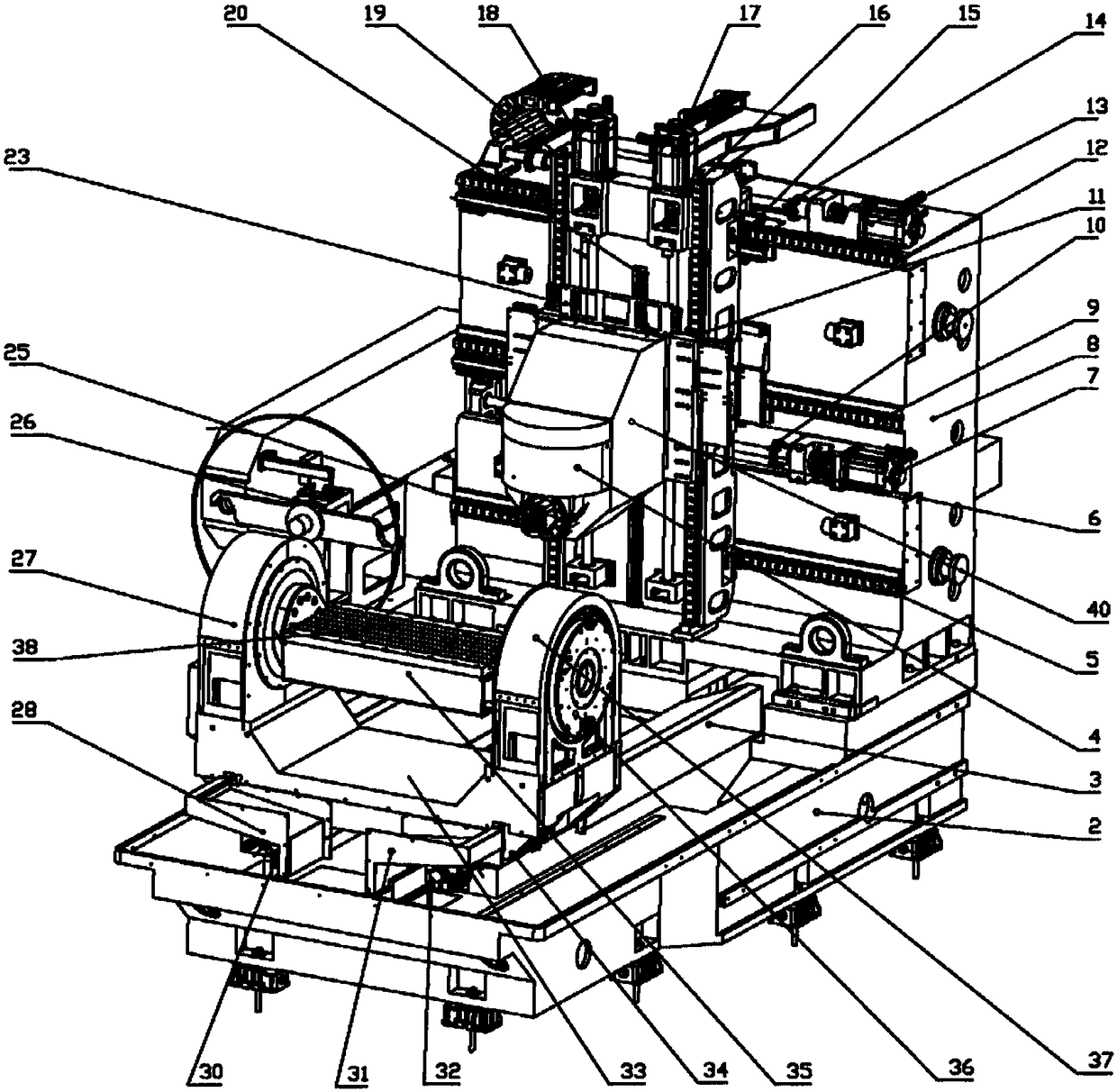

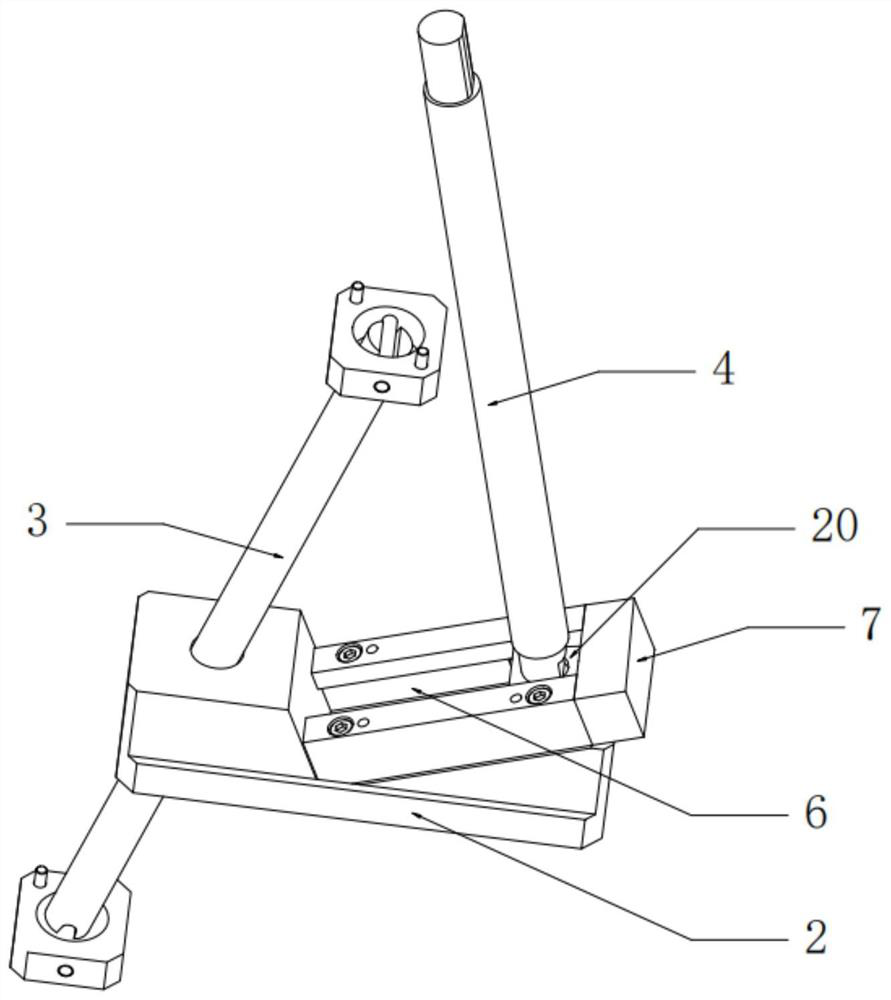

Horizontal type five-axis combined machining center with turning plate structure

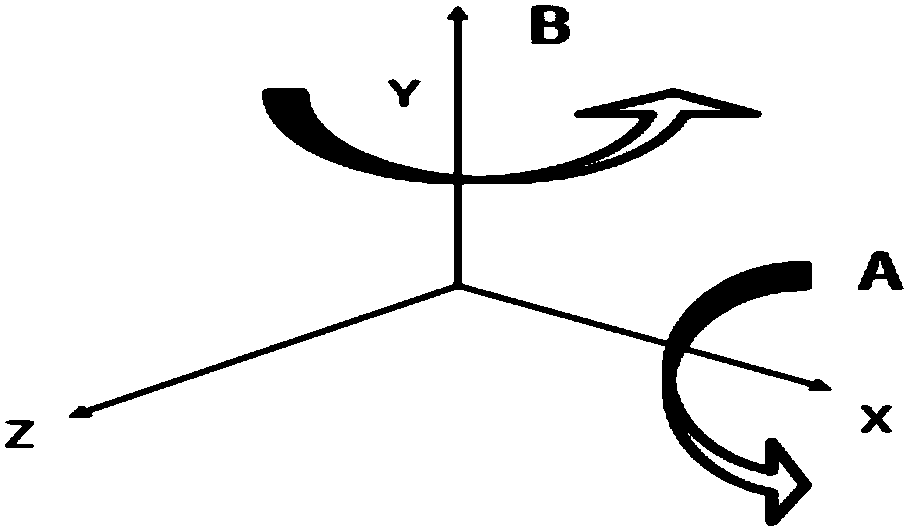

ActiveCN108311898AAvoid deformation and bendingHigh precisionLarge fixed membersManipulatorEngineering

The invention discloses a horizontal type five-axis combined machining center with a turning plate structure. A bed body is arranged horizontally, and front-back movemenet of a turning plate working table on the bed body is Z-axis movement; a stand column is mounted at the rear part of the bed body, and a saddle moves left and right on the stand column to realize X-axis movement; a spindle box drives a spindle to move up and down on the saddle to realize Y-axis movement; the turning plate working table moves around the X axis to realize A-axis movement; the spindle box moves around the Y axisto realize B-axis movement. By means of linkage of the X axis, the Y axis, the Z axis, the A axis and the B axis, efficient cutting machining for aircraft structural parts can be realized; a tool magazine and a tool changing manipulator are distributed on the left side of the bed body, automatic tool change of the machining center is realized, and production efficiency is improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

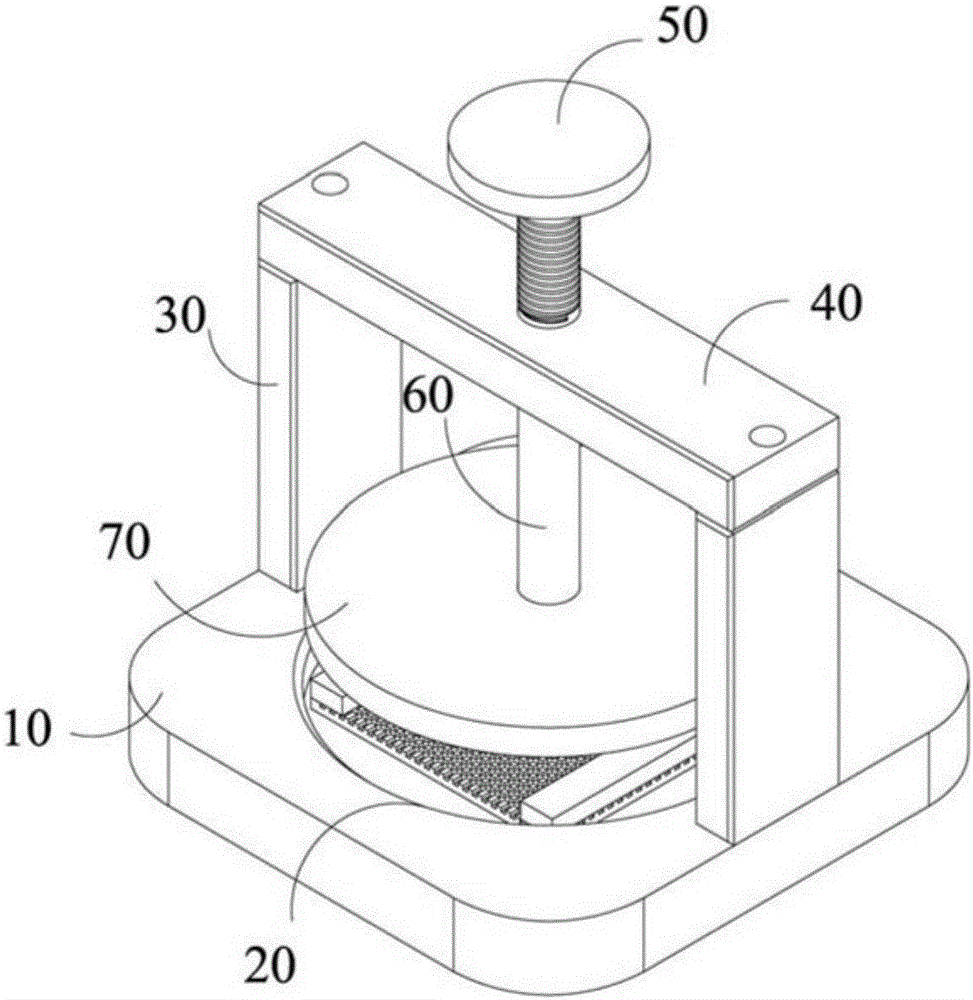

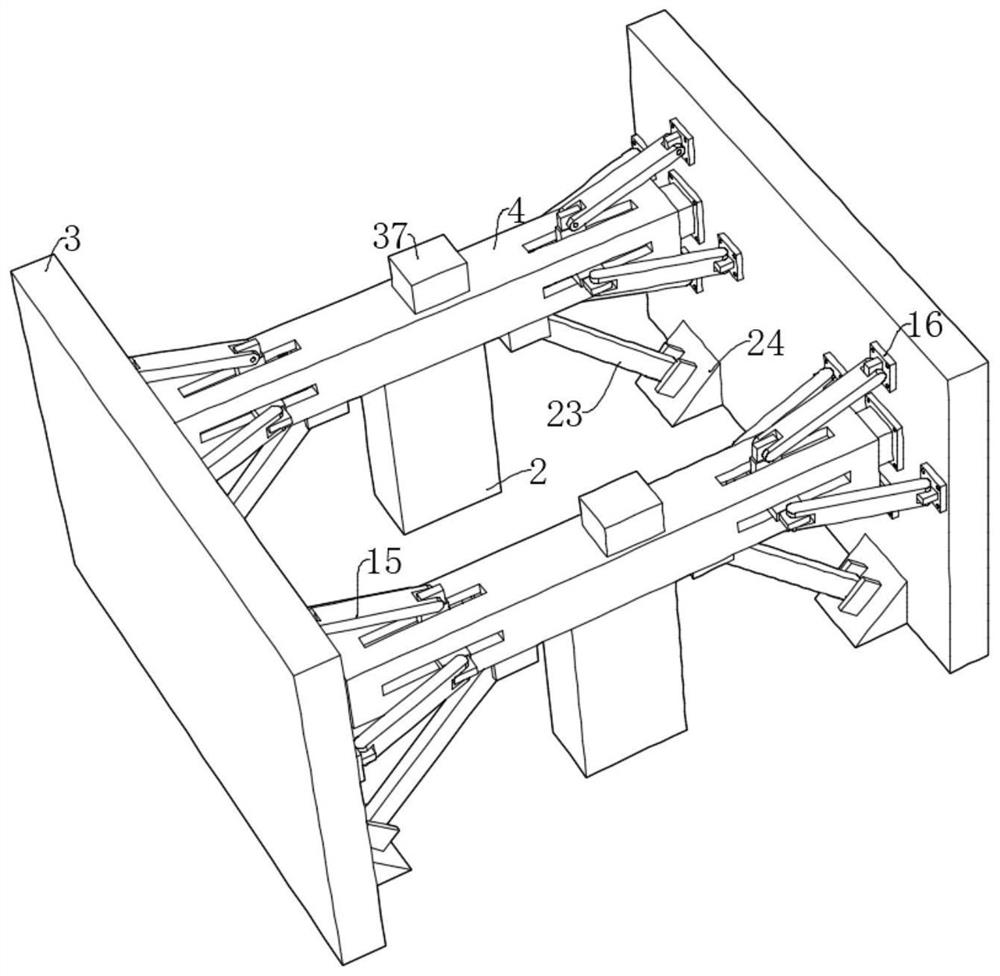

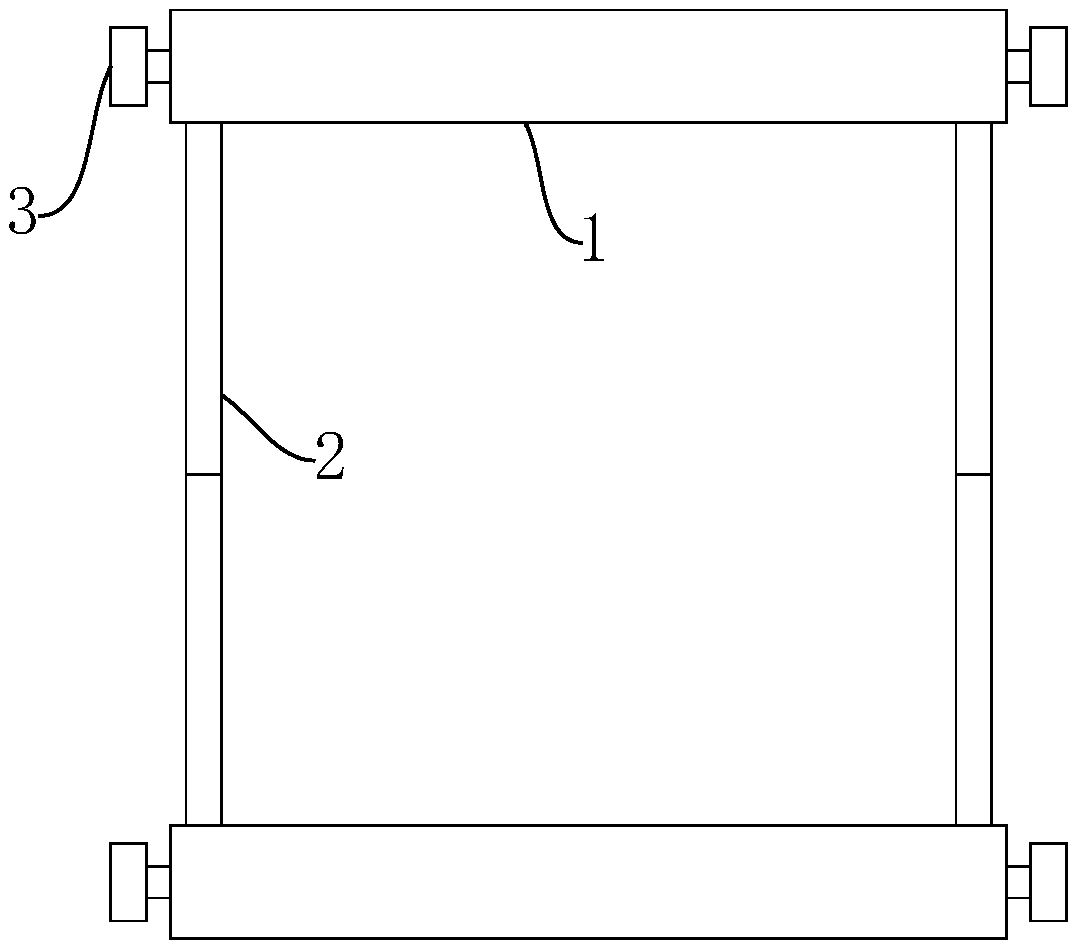

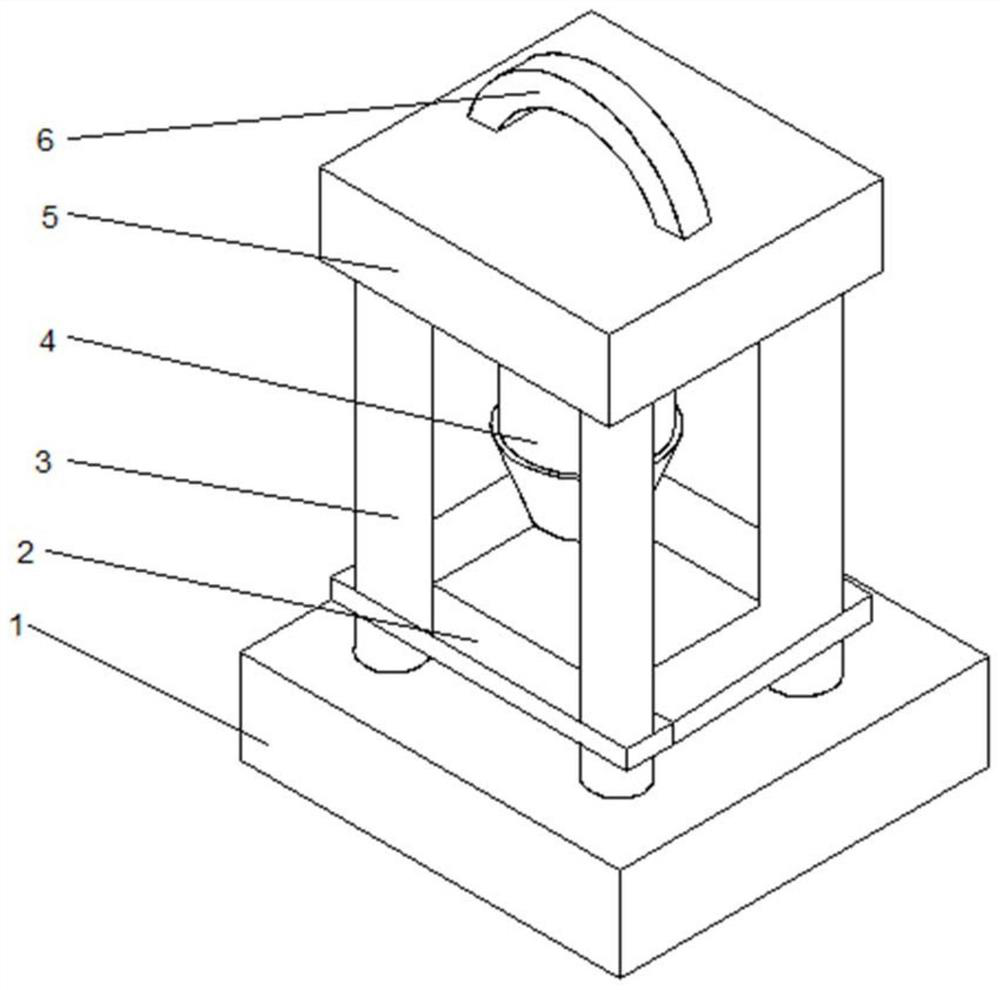

Fastening jig

ActiveCN105742482ASimple structureEven by forcePiezoelectric/electrostrictive device manufacture/assemblyEngineeringMechanical engineering

The invention provides a fastening jig, which comprises a base, a pressure lever base and a plurality of pressure levers, wherein each of two sides of the base is connected with a support part; the pressure lever base is connected between the upper ends of two support parts; the pressure lever base and the base are arranged in parallel; a plurality of slide chutes which penetrate up and down are formed in the pressure lever base; the plurality of slide chutes are arranged along the periphery of the central line of the pressure lever base; and the plurality of pressure levers pass through the slide chutes and can slide in the slide chutes. According to the fastening jig provided by the invention, pressing stabilization is carried out on piezoelectric ceramic chips placed on the base through the plurality of pressure levers; the piezoelectric ceramic chips are stressed uniformly; bending deformation of the piezoelectric ceramic chips due to solidification of a high-molecular polymer can be effectively prevented; and meanwhile, the pressure levers can move in the slide chutes, so that the fastening jig provided by the invention can be compatible with the piezoelectric ceramic chips with different sizes.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

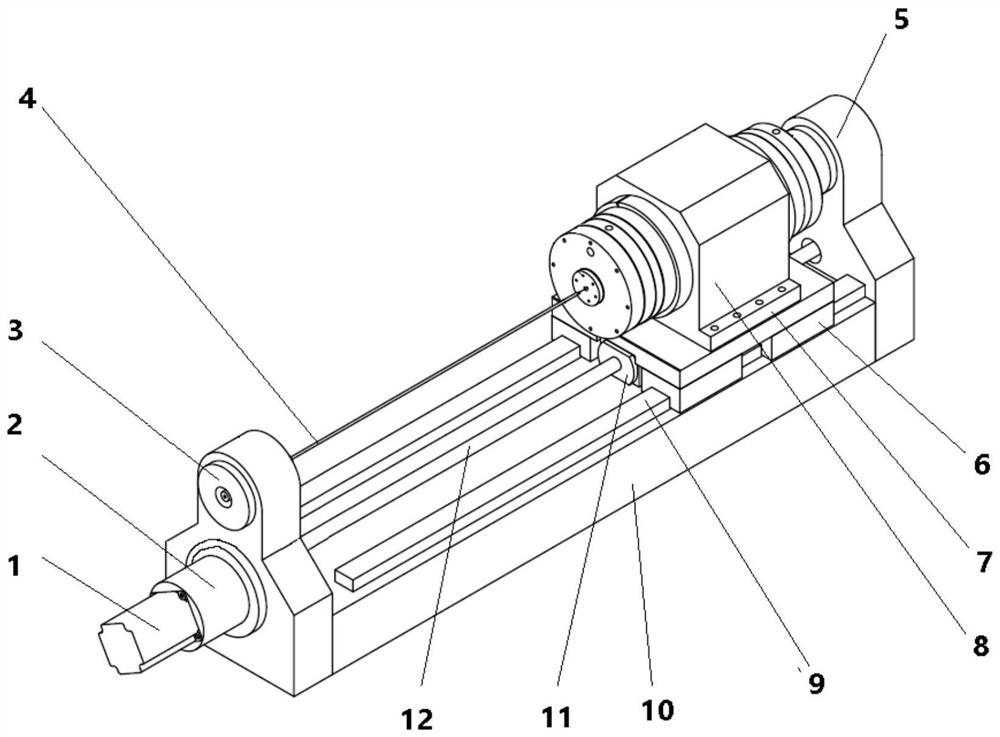

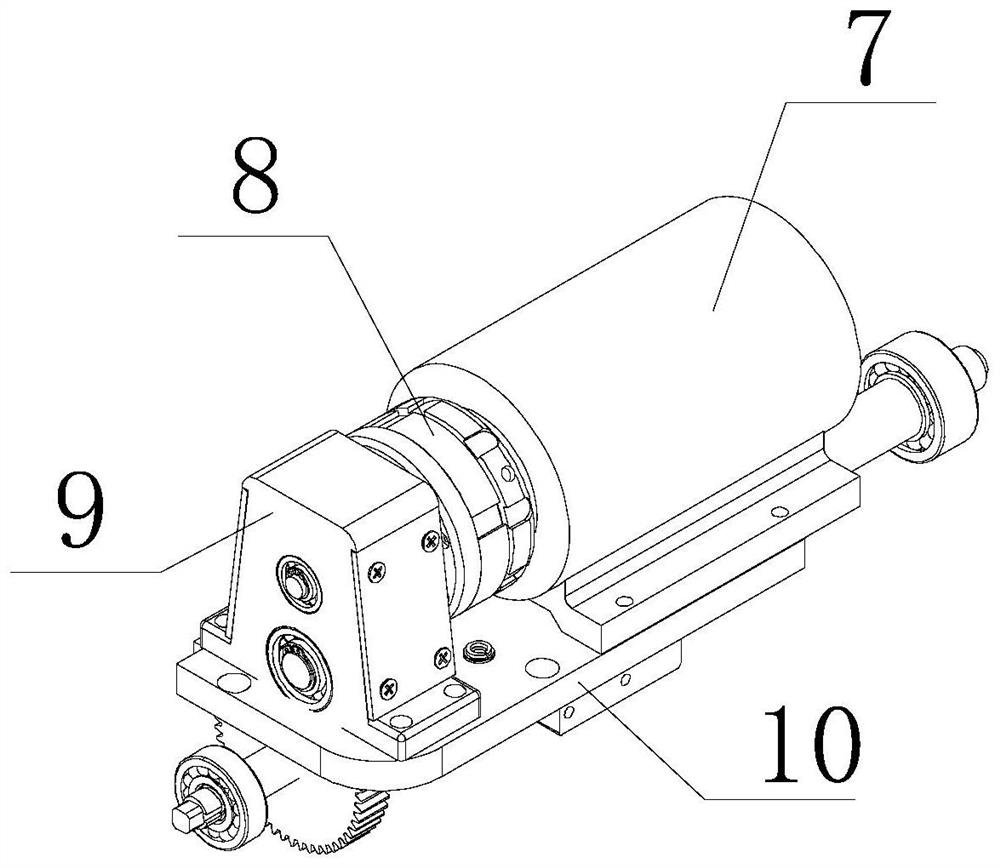

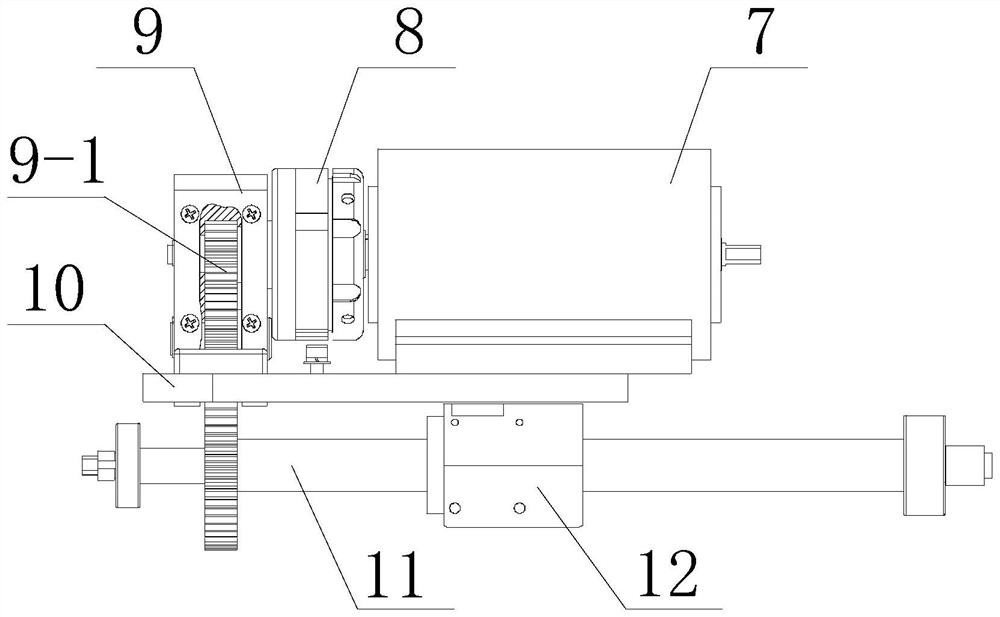

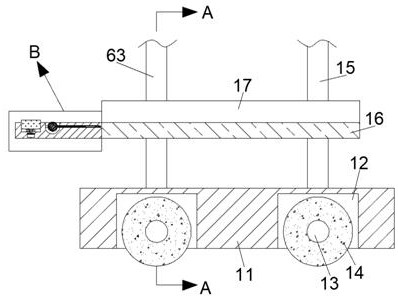

Multi-cutter progressive turning machine tool of slender shafts

PendingCN113579265AUniform cutReduce the amount of cuttingAuxillary equipmentTurning machinesReciprocating motionCentrifugal force

The invention discloses a multi-cutter progressive turning machine tool of slender shafts, belongs to the technical field of precision machining, counteracts one-way force of cutters on workpieces during machining, eliminates the deformation condition of slender shaft workpieces caused by centrifugal force generated during centering and machining of the traditional lathe and solves the technical problem that the machining size of the workpieces is limited at the same time. The machine tool comprises a machine tool body unit, a multi-tool machining unit, a left pre-tightening force unit and a right pre-tightening force unit, wherein the left pre-tightening force unit and the right pre-tightening force unit are distributed at the two ends of the machine tool body unit and drive the multi-tool machining unit to reciprocate in the axial direction; and the multi-cutter machining unit is arranged on the machine tool body unit and does reciprocating motion on the machine tool body unit to machine the slender shafts. The main motion of the traditional lathe is workpiece rotation; weak-rigidity tiny slender shafts can generate centrifugal force during rotation to cause workpiece deformation; the main motion of the lathe is improved from traditional workpiece rotation to cutter set rotation by the device; workpiece deformation is avoided; and the machining precision is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

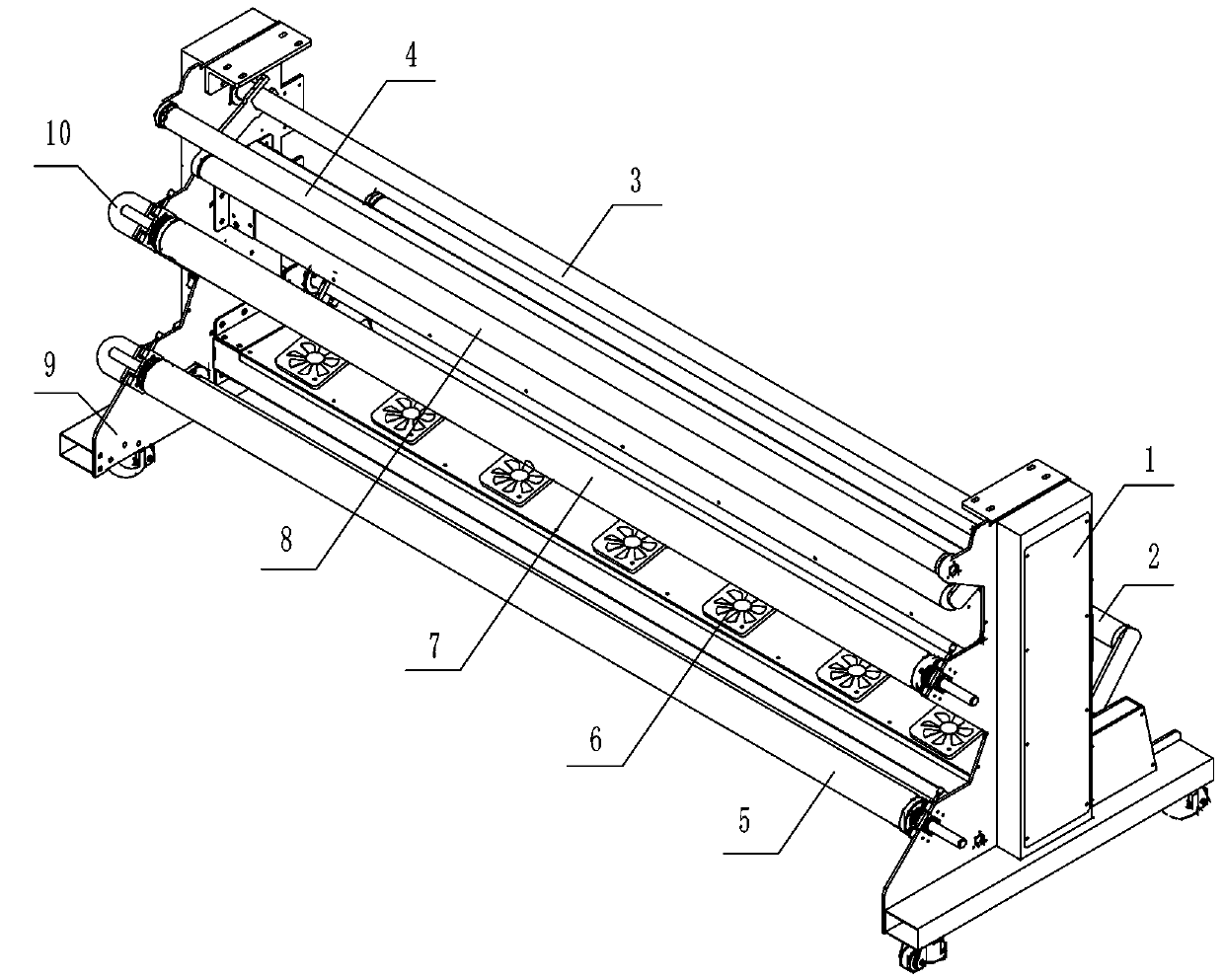

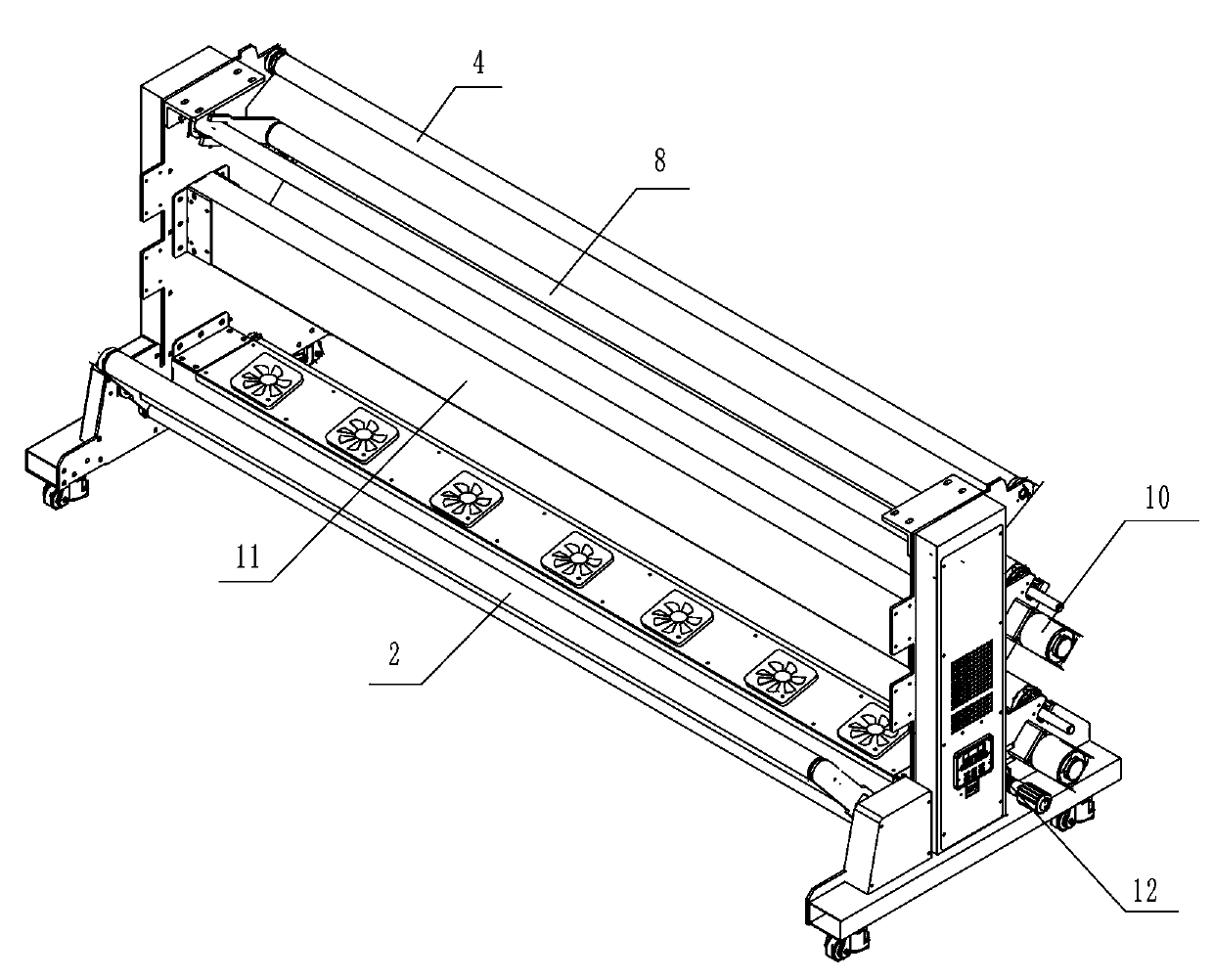

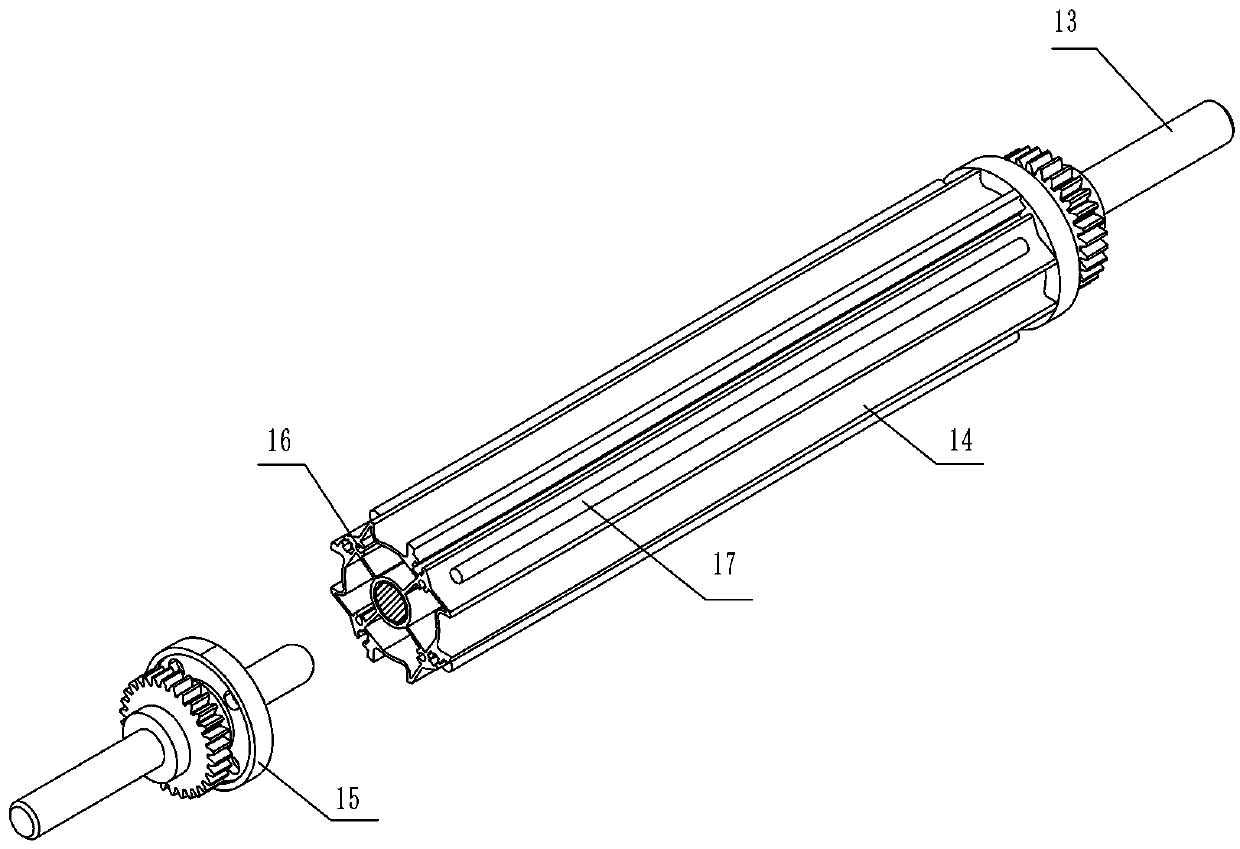

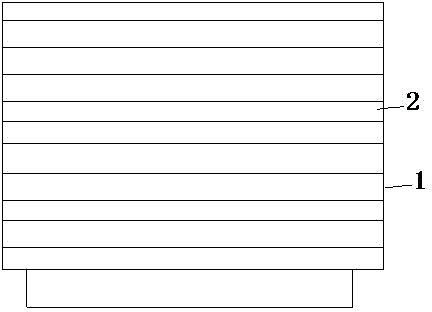

Double-head supporting winding and unwinding system for printing machine

The invention provides a double-head supporting winding and unwinding system for a printing machine. The double-head supporting winding and unwinding system comprises a machine frame, wherein an unwinding roller, a winding roller, a cloth winding roller, a swing rod supporting rod, an unwinding swing rod, a winding swing rod and a damping roller are rotationally arranged on the machine frame through an integral positioning installing plate, and the cloth winding roller, the swing rod supporting rod, the unwinding swing rod, the winding swing rod and the damping roller are used for supporting aprinting medium to achieve winding and unwinding; and the unwinding roller and the winding roller each comprises a rotating shaft and a supporting profile which sleeves the circumferential surface ofthe rotating shaft, a plurality of rubber strips are clamped on the surface of each supporting profile, and each rotating shaft is in transmission connection with a winding and unwinding motor. According to the system, all the rollers are installed on the integral positioning installing plate, and the winding roller and the unwinding roller are designed into a complete rotating shaft, so that thewhole paper tube can be uniformly supported during winding and unwinding, and the phenomena such as staggering, inclining or wrinkling in the winding and unwinding process are effectively avoided.

Owner:NEW CENTURY DIGITAL PRINT TECH

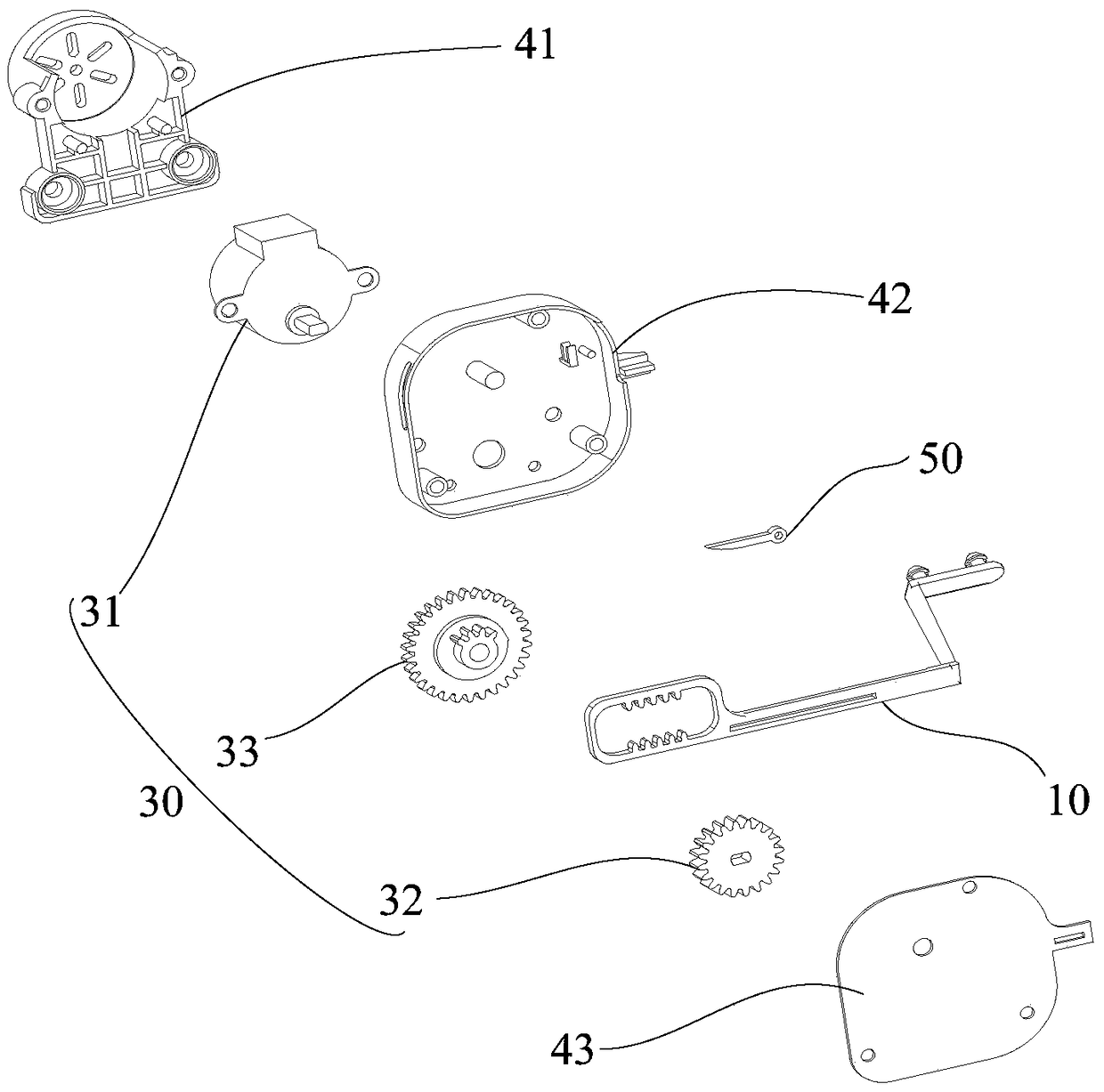

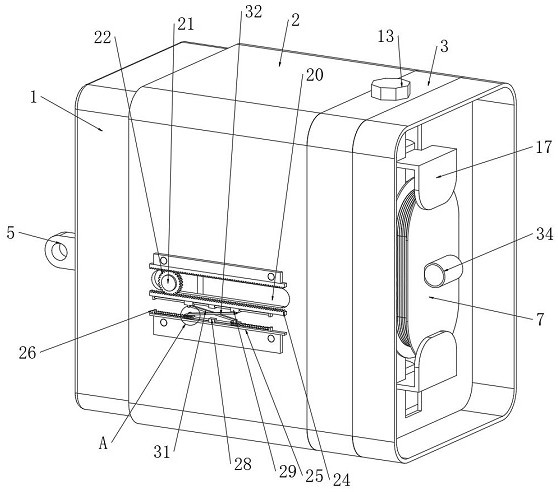

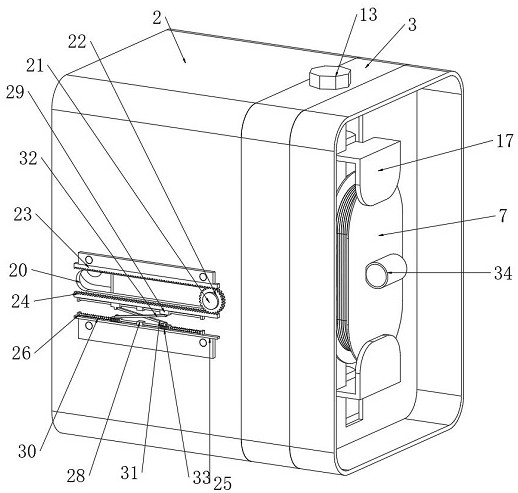

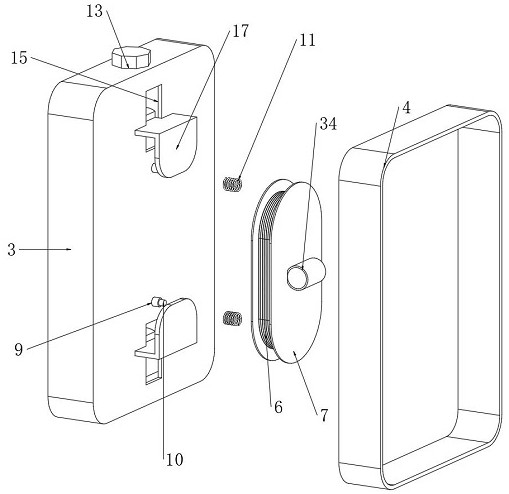

Electric switch machine

PendingCN114475704APlay a protective effectAvoid damageElectric devices for scotch-blocksLocking mechanisms for pointsElectric machineEngineering

The invention discloses an electric switch machine, which belongs to the technical field of switch machines and comprises an indication rod, an action rod and a power assembly, a locking mechanism is arranged on the action rod, a contact assembly is arranged on the indication rod, and the power assembly comprises a shifting plate, a motor for driving the shifting plate to move and a transmission system; the locking mechanism comprises a locking body and a lock hook; an inserting hole is horizontally formed in the locking body in the movement direction of the action rod, a through hole is formed in the locking body, the inserting hole and the through hole are communicated through a communicating hole, a locking roller is arranged in the communicating hole, a check block is arranged in the locking body and located above the locking roller, and a groove matched with the locking roller is formed in the front end of the lock hook. Effective and reliable locking action of the action rod is guaranteed, the extrusion cutting pin is protected, and the phenomenon of abnormal breakage is avoided; the transmission stability and precision are guaranteed, the structure is compact, and the more stringent limit requirement can be met; and the conversion efficiency and stability of movable and static contacts are improved.

Owner:天津铁科铁路信号有限公司

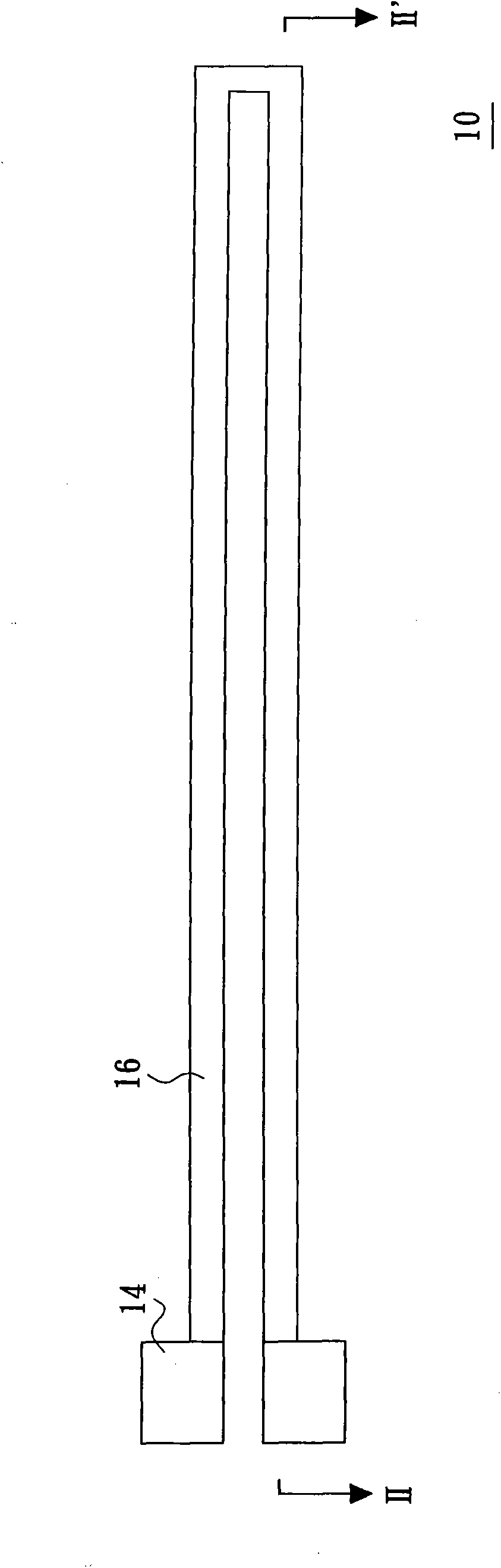

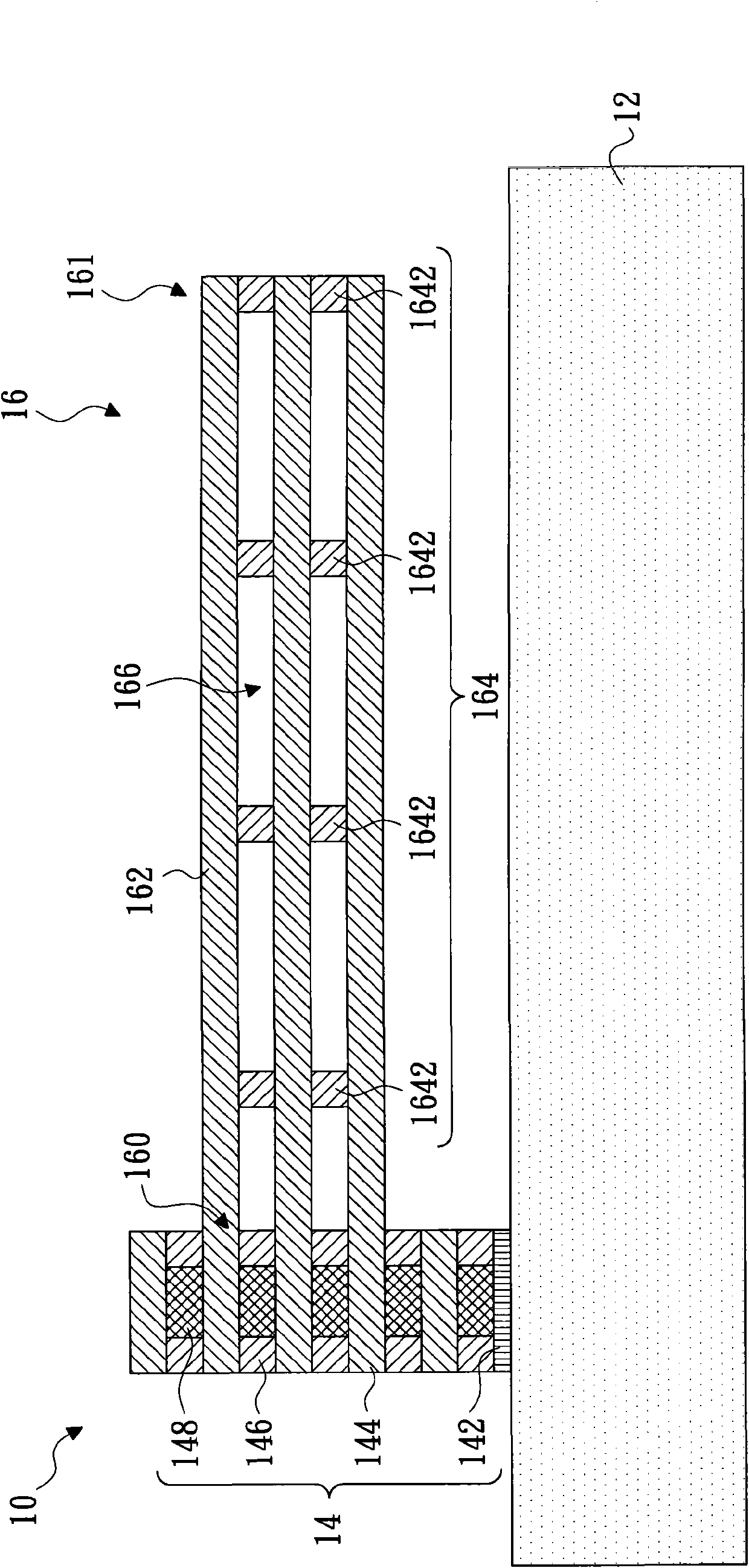

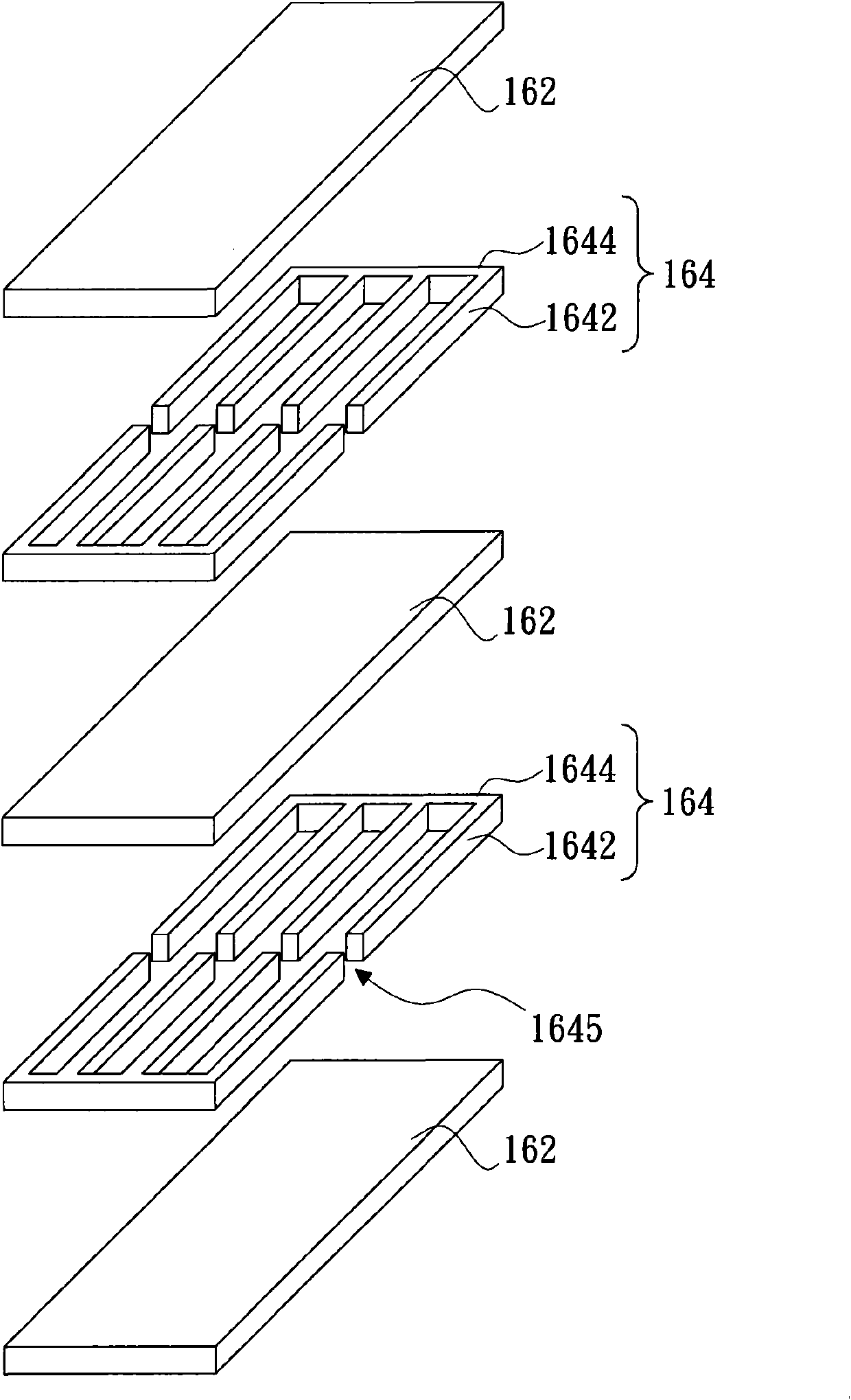

Micro electronmechanical element and micro electronmechanical spring element

ActiveCN102086017AImprove workabilityAvoid deformation and bendingSolid-state devicesFluid speed measurementThermal expansionEngineering

The invention relates to a micro electronmechanical element and a micro electronmechanical spring element. The micro electronmechanical element comprises a substrate, a fixed part and a movable part, wherein the fixed part is fixed on the substrate; the movable part is provided with a first end connected with the fixed part and a second end suspended above the substrate and comprises a plurality of metal layers and supporting layers connected between adjacent metal layers; and a hollow area is formed between each supporting layer and each connected metal layer. Because the micro electronmechanical spring element is in a hollow structure, the movable part can prevent bending and deforming caused by different thermal expansion coefficients of the metal layers and the film layers between the metal layers when the micro electronmechanical spring element is changed by the environment or the encapsulating temperature so that the micro electronmechanical spring element has favorable working performance.

Owner:PIXART IMAGING INC

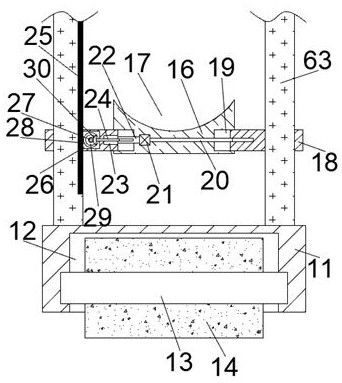

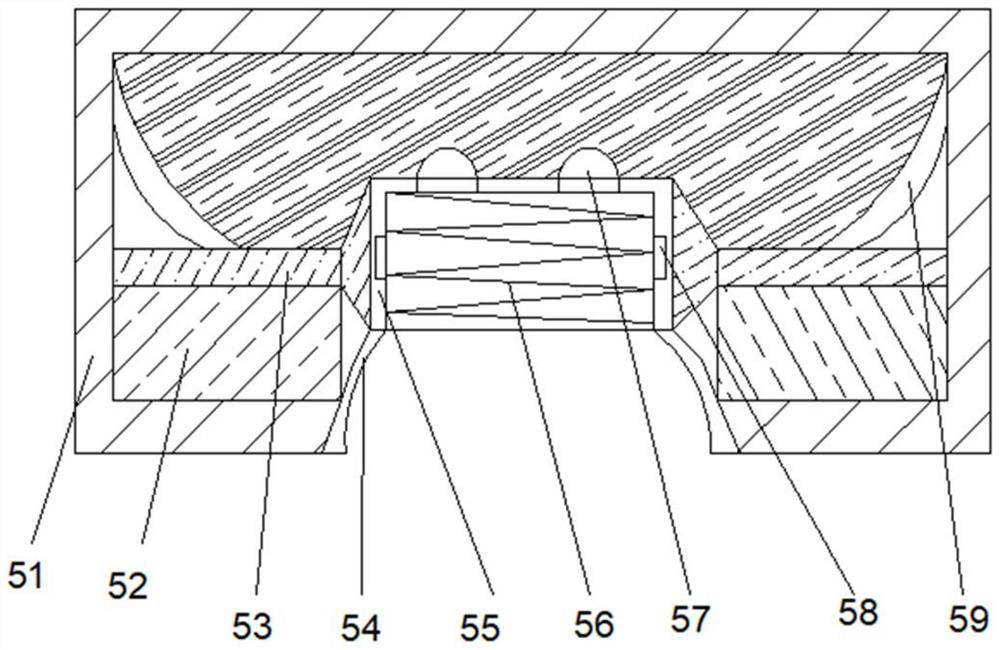

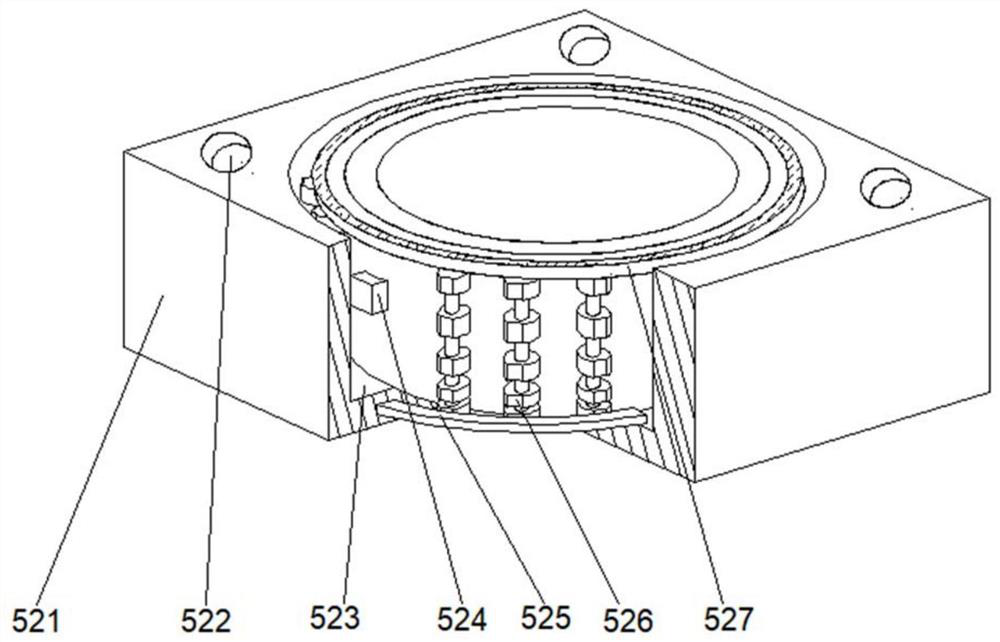

Inclined-ejector demoulding mechanism

The invention discloses an inclined-ejector demoulding mechanism, which comprises an ejector plate, an inclined-ejector base arranged on the ejector plate, a guide rod obliquely penetrating through the inclined-ejector base, an inclined-ejector rod with the lower end movably connected with the inclined-ejector base and an inclined-ejector block arranged at the upper end of the inclined-ejector rod; an included angle between the guide rod and the inclined-ejector rod is an acute angle; an inclined guide sliding groove is arranged on the inclined-ejector base, and the lower end of the inclined-ejector rod is connected with a sliding block matched with the inclined guide sliding groove; and the guide rod inclines towards the side where the inclined guide sliding groove is located. By using the inclined-ejector demolding mechanism, the situation that inclined-ejector self-locking occurs due to the fact that the inclined-ejector climbing or downhill angle is large can be avoided, the situation the inclined-ejector rod is bent and deformed during inclined-ejector ejecting out can be avoided, the structural stability of the inclined-ejector demolding mechanism is improved, the problem that an inverted buckle in a product inclines downwards or inclines upwards by an excessively large angle is solved, and the inclination angle of the inclined guide sliding groove can be designed to be smaller.

Owner:FOSHAN POLYTECHNIC

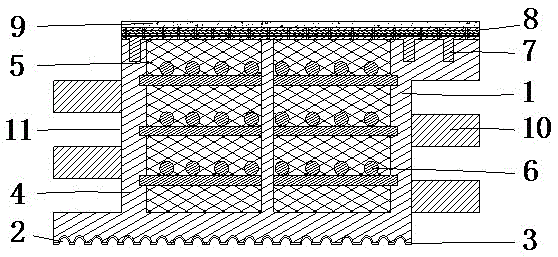

Durable high-strength energy-saving and environment-friendly wall board

InactiveCN105625605AImprove integrityStrong integrity, strong structureWallsSound proofingBreakage rateHigh intensity

The invention discloses a durable high-strength energy-saving and environment-friendly wall board.The durable high-strength energy-saving and environment-friendly wall board comprises a wall board body, a color steel layer, a rock wool layer and a sound insulation noise reduction board.The wall board is formed by press fitting of the color steel layer, the rock wool layer and the sound insulation noise reduction board into a whole.The rock wool layer is placed into a notch formed in the middle of an inner cavity of the color steel layer.At least two reinforcing layers are arranged in the middle of an inner cavity of the rock wool layer.The durable high-strength energy-saving and environment-friendly wall board is good in energy-saving and environment-friendly effect, high in integral strength, solid and durable; by adopting the arrangement of the color steel layer and the rock wool layer, the wall board can have the durability, energy-saving performance, environment-friendly performance and other performances; by applying the reinforcing layers, the integral wall board can bear larger pressure and higher pressure intensity, and the seismic resistance, the perpendicular fracture resistance and the load capacity of the wall board can be improved; the phenomenon that the wall board is deformed and bent is avoided, the breakage rate of the wall board in the conveying and using process is reduced, and the service life of the wall board is prolonged.

Owner:林丽芳

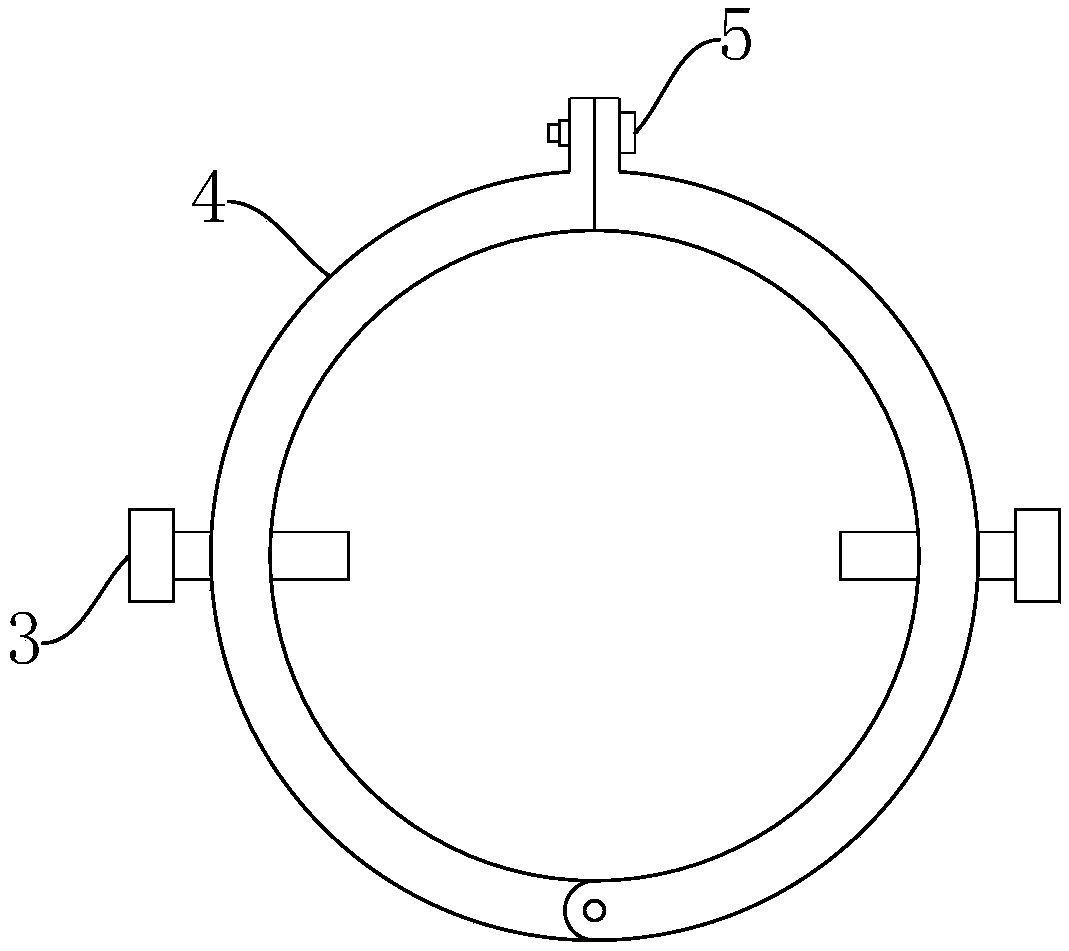

Self-adaptive anchoring device for deformed side slope and construction method of self-adaptive anchoring device

InactiveCN112761145AInhibit sheddingFit firmlyExcavationsBulkheads/pilesArchitectural engineeringStress strength

The invention relates to the field of slope protection, and particularly discloses a self-adaptive anchoring device for a deformed slope and a construction method of the self-adaptive anchoring device. The self-adaptive anchoring device for the deformed side slope comprises a rotatable rotation adjusting disc of an fixing anchor rod, an anchor rod sleeve and a bottom rod. The self-adaptive anchoring device stably matches slope protection, the situations that the anchoring device falls off and the fixing capacity is reduced can be avoided, the fixing anchor rod is located inside a hole to form an arch through the arrangement of a stress strip, and therefore when the side wall of the anchoring device has bending stress, through the arch-shaped stress strip, the bending stress is distributed to the fixing anchor rod, so that the stress strength of the side wall of the fixing anchor rod is greatly reduced, a bending stress resistance strength of the fixing anchor rod is greatly improved, and the situation that a steel pipe pile is bent and deformed due to the fact that the steel pipe pile cannot resist acting force of slope expansion deformation is avoided.

Owner:JSTI GRP CO LTD

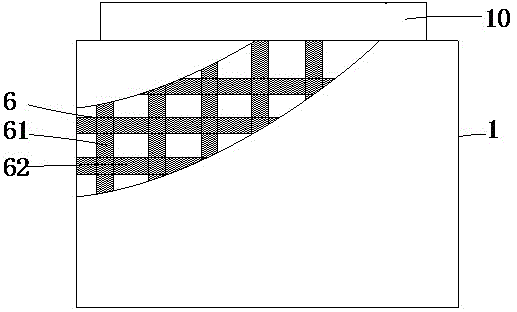

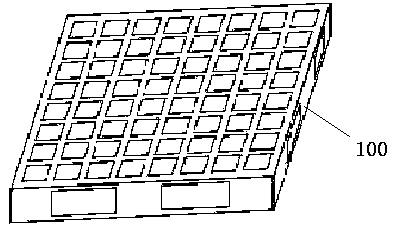

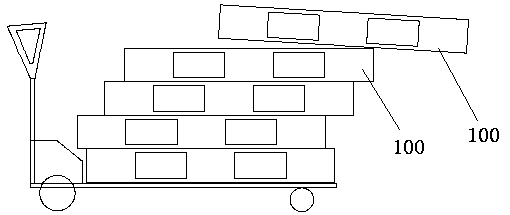

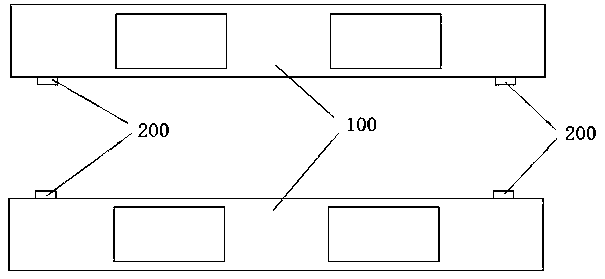

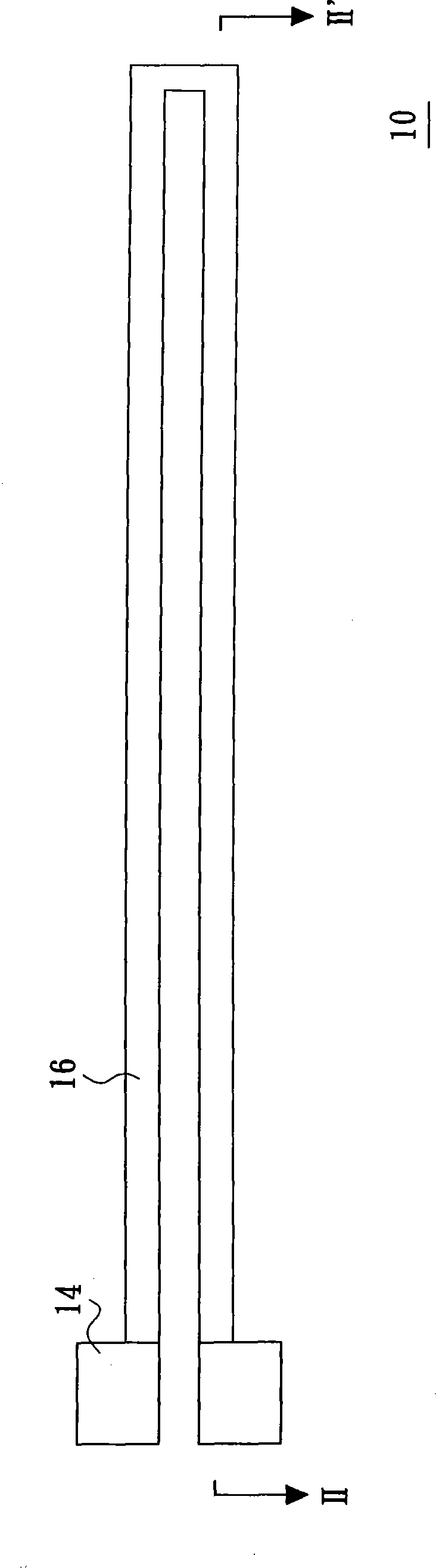

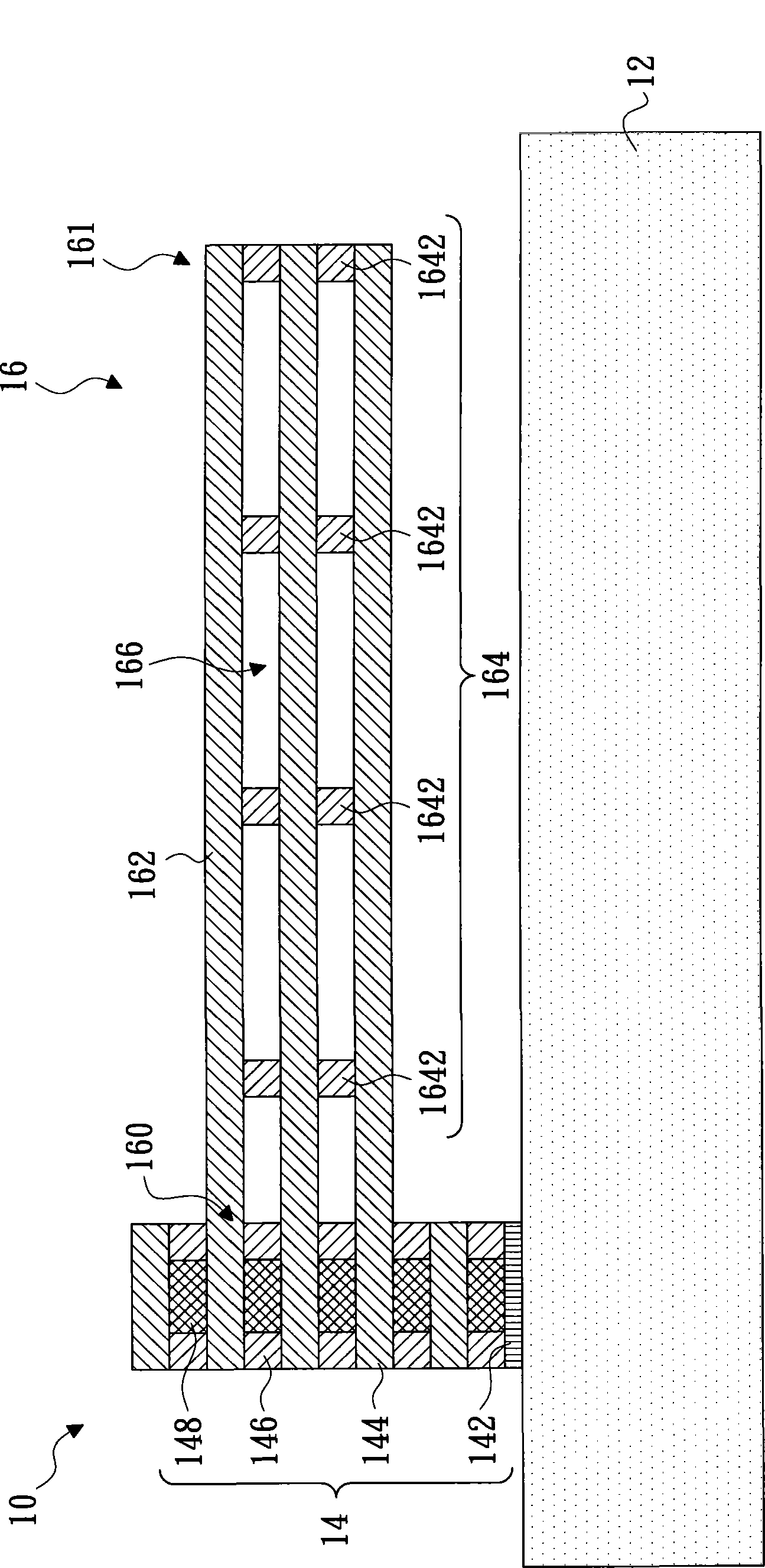

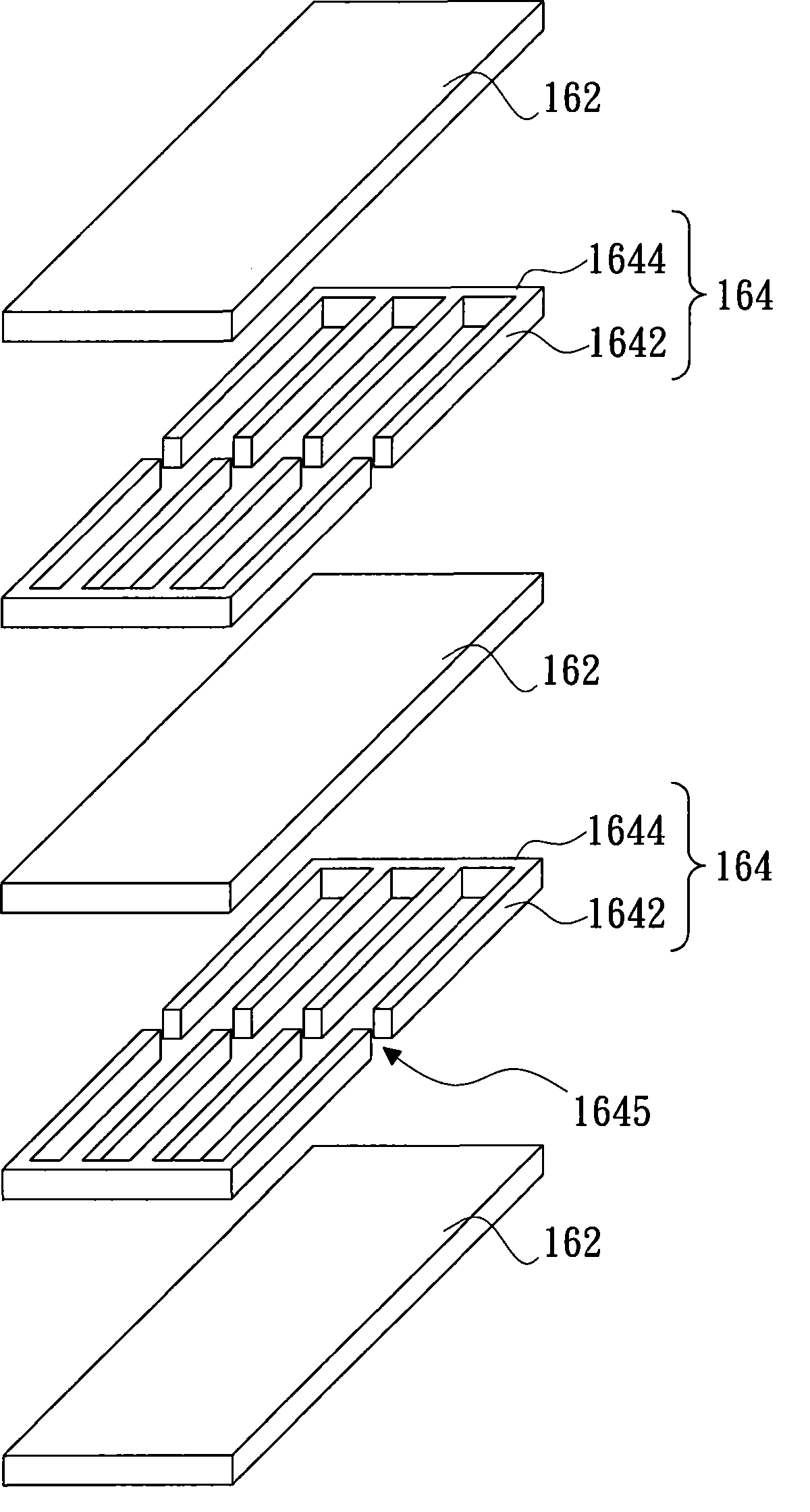

a pallet structure

ActiveCN109205003BReduce frictionCases to prevent slippingRigid containersEngineeringBoard structure

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

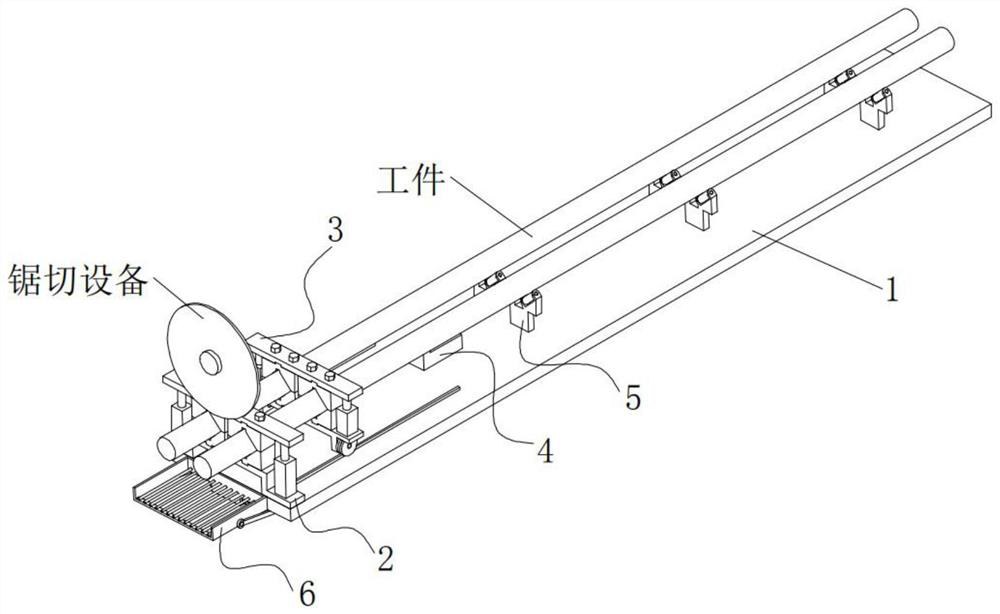

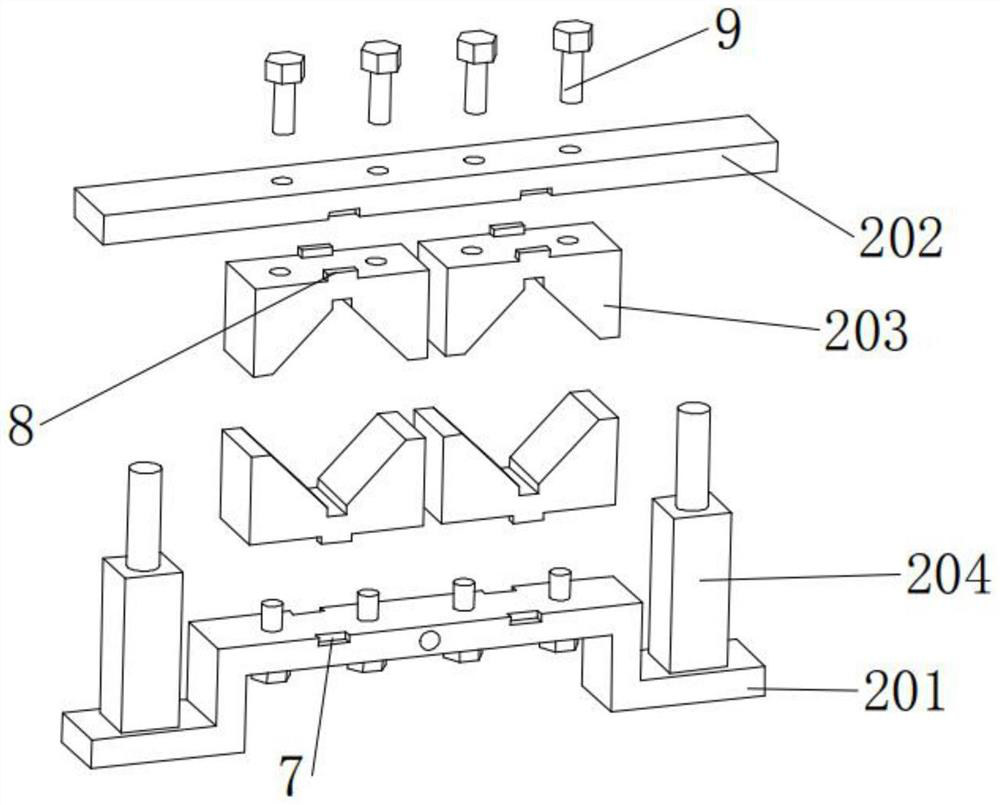

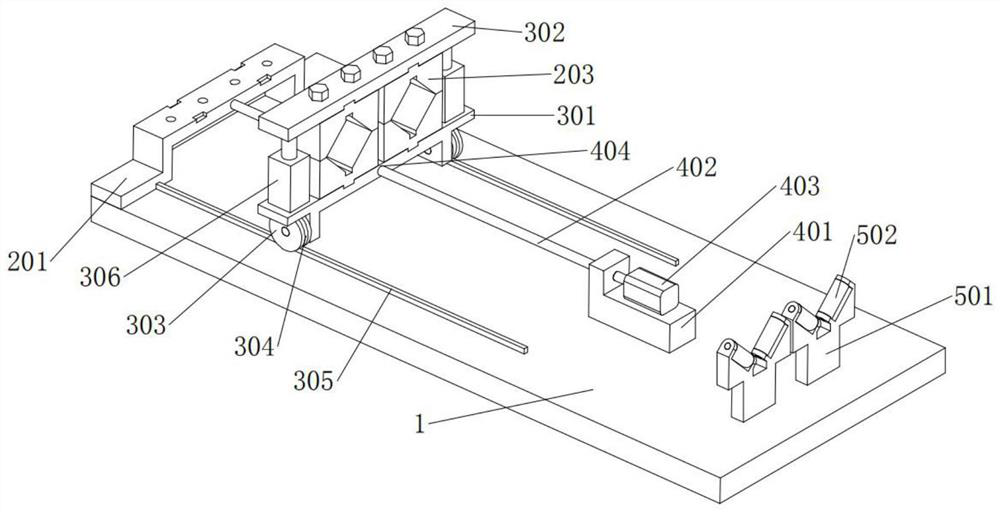

Clamping device

The invention provides a clamping device, and relates to the technical field of long material machining. The clamping device comprises a bottom plate, one end of the bottom plate is provided with an installing and clamping mechanism, the bottom plate is further provided with a clamping mechanism and a driving mechanism, the clamping mechanism clamps workpieces when the installing and clamping mechanism loosens the workpieces, and the workpieces are dragged to move to complete feeding under drive of the driving mechanism; supporting mechanisms are further arranged on the bottom plate and are arranged at the rear end of the driving mechanism, and the plurality of supporting mechanisms are evenly arranged according to the length of the workpieces so as to support the workpieces; and a collecting mechanism is arranged at the end of the bottom plate and used for collecting the machined workpieces and conveying the workpieces out. The clamping device has the advantages that the multiple workpieces can be clamped at a time, so that the multiple workpieces can be machined at a time by saw cutting equipment, the clamping device can automatically complete feeding of the workpieces, the feeding precision is high, and the processed products are stable in treatment.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Micro electronmechanical element and micro electronmechanical spring element

ActiveCN102086017BImprove workabilityAvoid deformation and bendingSolid-state devicesFluid speed measurementEngineeringThermal expansion

The invention relates to a micro electronmechanical element and a micro electronmechanical spring element. The micro electronmechanical element comprises a substrate, a fixed part and a movable part, wherein the fixed part is fixed on the substrate; the movable part is provided with a first end connected with the fixed part and a second end suspended above the substrate and comprises a plurality of metal layers and supporting layers connected between adjacent metal layers; and a hollow area is formed between each supporting layer and each connected metal layer. Because the micro electronmechanical spring element is in a hollow structure, the movable part can prevent bending and deforming caused by different thermal expansion coefficients of the metal layers and the film layers between the metal layers when the micro electronmechanical spring element is changed by the environment or the encapsulating temperature so that the micro electronmechanical spring element has favorable working performance.

Owner:PIXART IMAGING INC

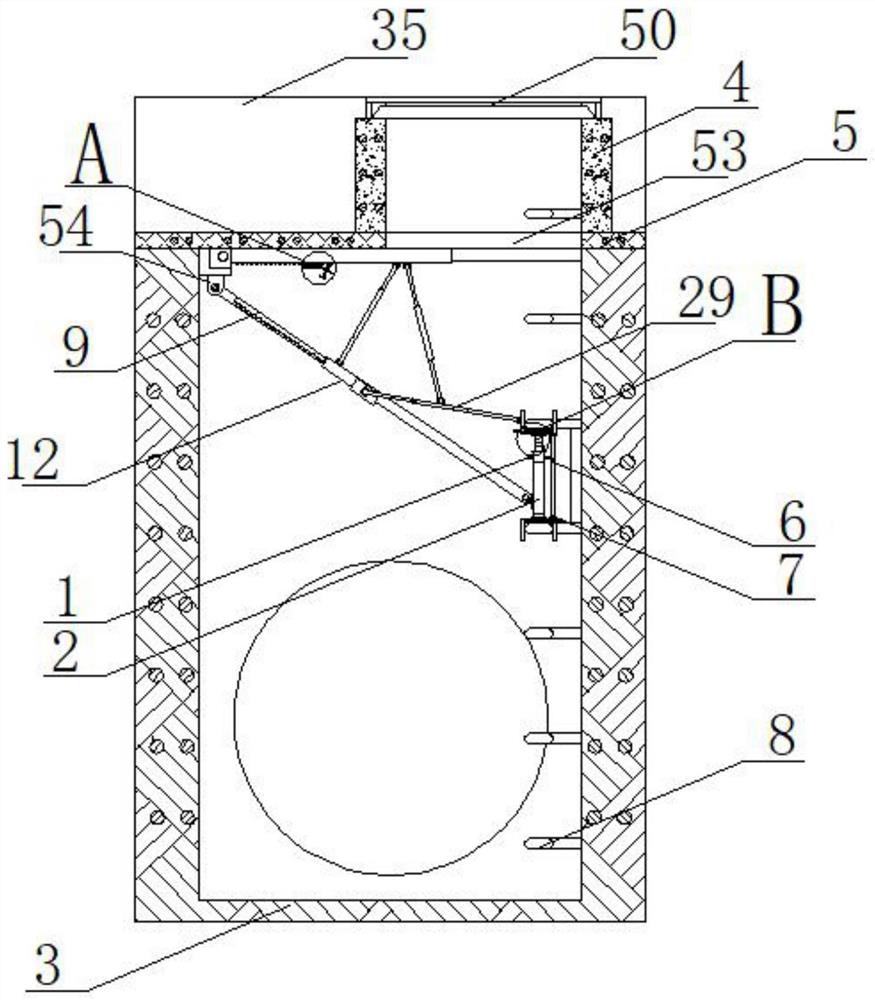

Deep foundation pit support structure capable of being excavated and supported at same time and supporting method thereof

PendingCN114197484AAvoid deformation and bendingAvoid reselectionFoundation testingExcavationsElectric machineryDrive motor

The foundation pit support structure comprises two symmetrical supporting columns fixedly connected to the inner wall of the bottom of a foundation pit, support plates are arranged on the inner walls of the sides, away from each other, of the foundation pit, a transverse rod is fixedly connected to the tops of the supporting columns through bolts, and a driving motor is fixedly connected to the top of the transverse rod; a first bevel gear fixedly sleeves the outer wall of the rotating shaft in the transverse rod, an output shaft of the driving motor extends into the transverse rod and is fixedly connected with the top end of the rotating shaft, two first enclosure assemblies used for enclosing a foundation pit are arranged in the transverse rod, a rectangular through hole is formed in the top end of the supporting column, and a circular ring is fixedly embedded in the inner wall of the bottom of the transverse rod; the bottom end of the rotating shaft rotationally penetrates through the circular ring and is fixedly connected with a straight gear, and two second enclosure assemblies used for enclosing the foundation pit are arranged at the bottom of the transverse rod. The problems that in the prior art, an enclosure structure is poor in recoverability, supporting cannot be conducted according to deformation of a foundation pit, and the deformation degree of the foundation pit cannot be monitored in real time are solved.

Owner:SHANGHAI NO 4 CONSTR

An outdoor parking space system based on the concept of sponge city

The invention discloses an outdoor parking space system based on a sponge city concept. The system comprises a square parking space groove formed in a foundation and is characterized in that two sidewalls of the parking space groove are each provided with a straight rail, the two straight rails are each communicated with a spiral rail, the spiral rails are arranged in the foundation, the centersof the two spiral rails are jointly provided with a center shaft, the two spiral rails are mutually communicated and are not communicated with the parking space groove, and the straight rails are eachslidably connected with a square wheel plate with a groove. The system has the advantages that winding pieces in initial states are located in the spiral rails, driving wheels continuously rotate toenable the winding pieces to gradually wind out of the spiral rails and be located on the straight rails, when the winding pieces slide to the straight rails, two conducting strips are disconnected toenable corresponding coils to be electrified without being short-circuited to generate a magnetic field, the magnetic field enables magnetorheological fluid to be changed into a solid-like state withextremely high shearing strength from an original liquid state, and the strength is enough to bear the weight of a vehicle.

Owner:SHANDONG CHENNENG ENERGY TECH CO LTD

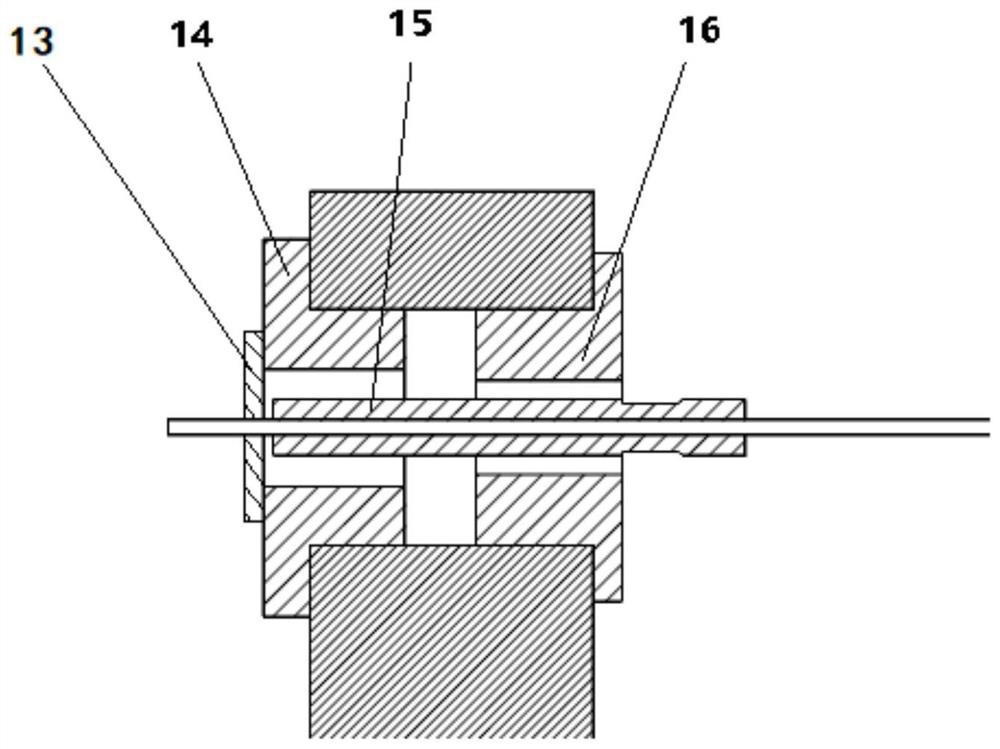

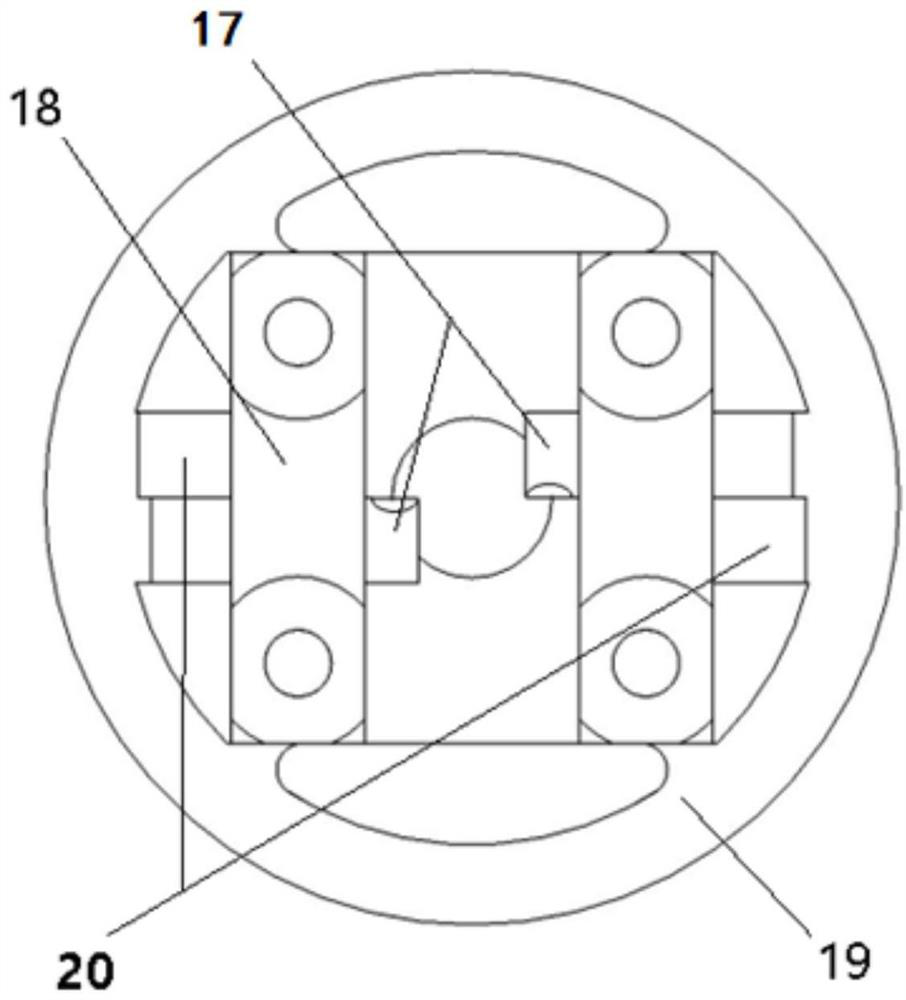

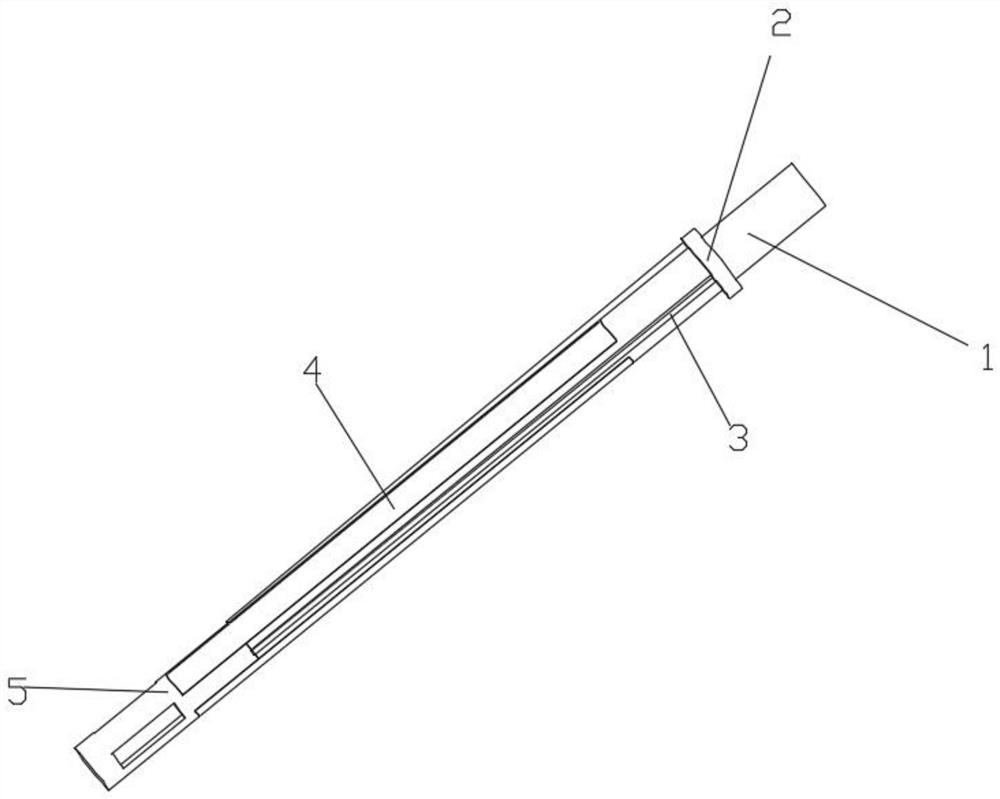

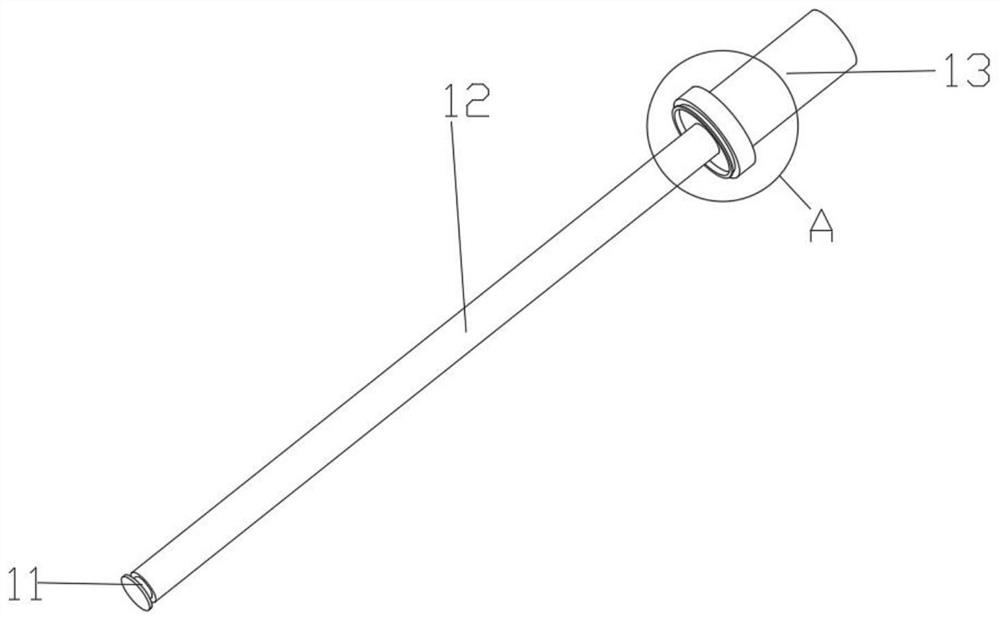

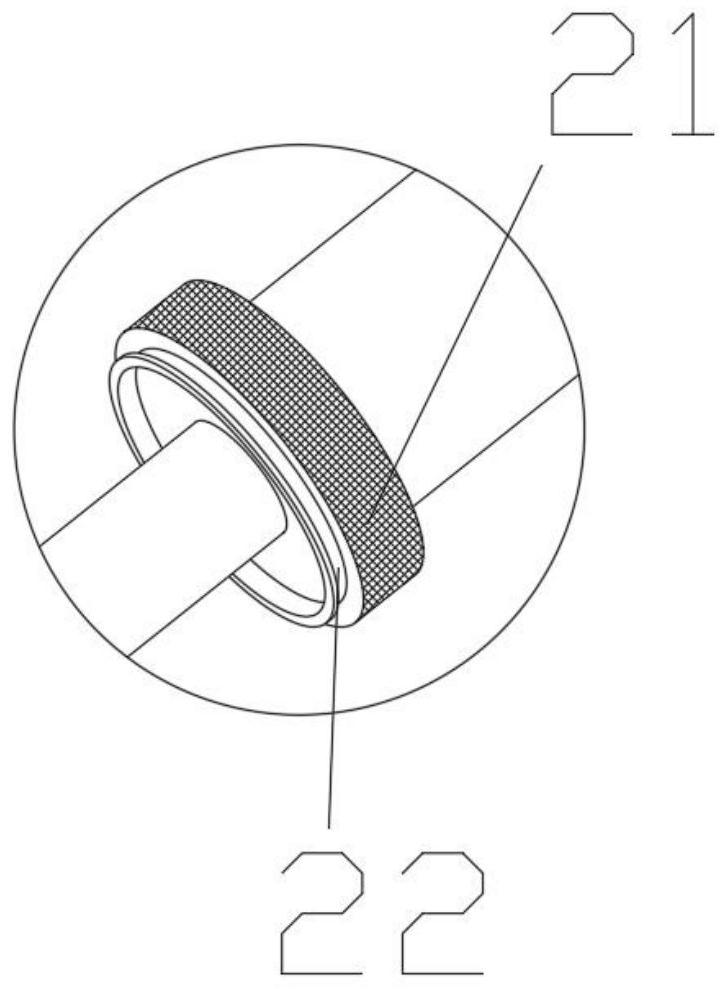

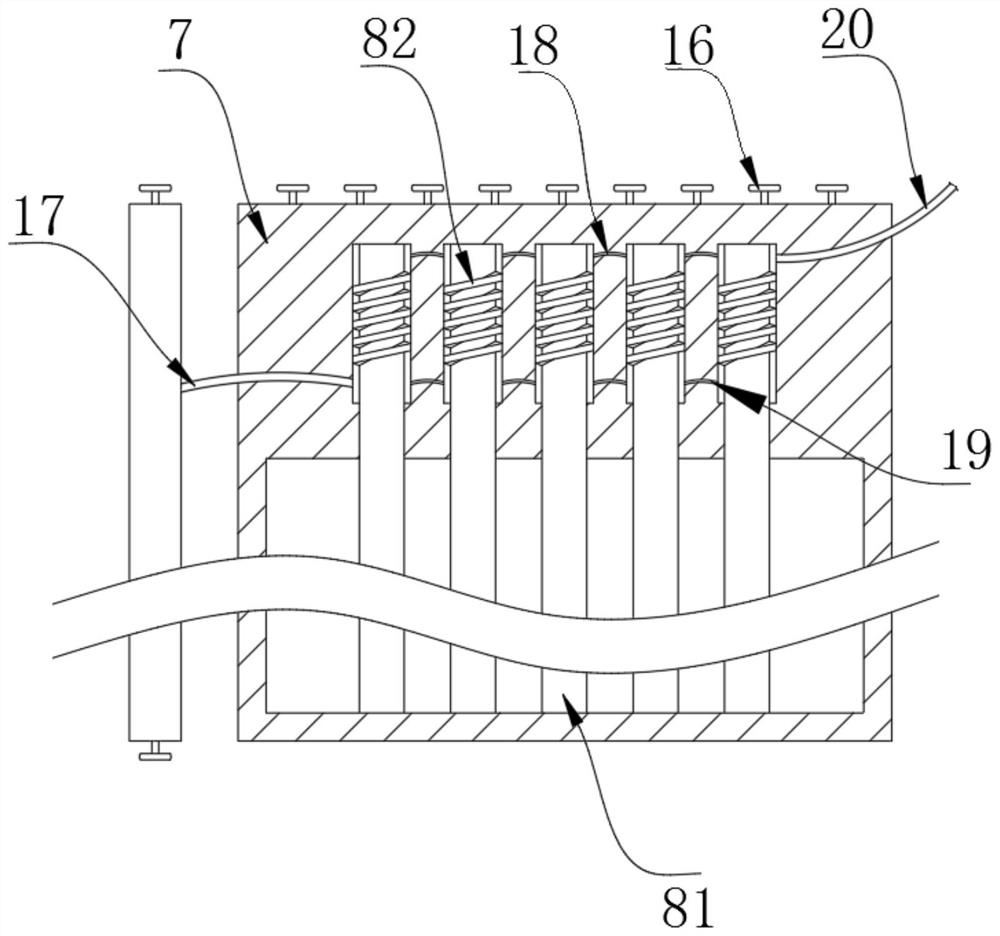

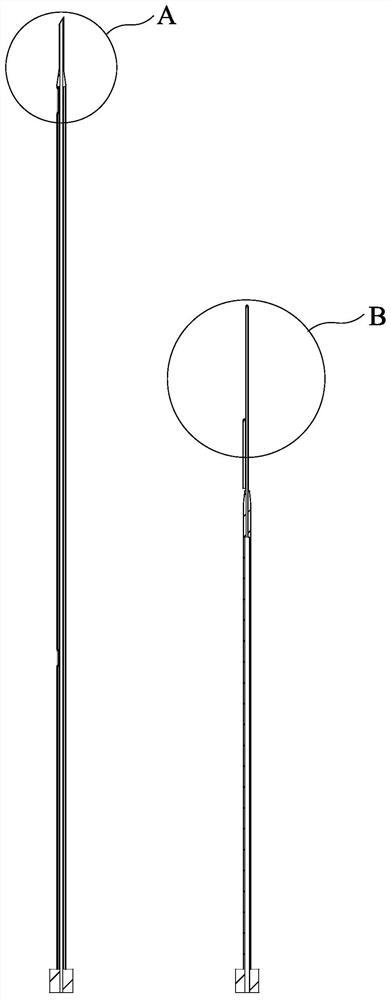

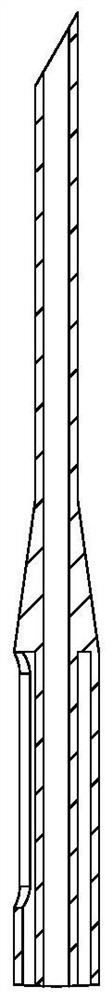

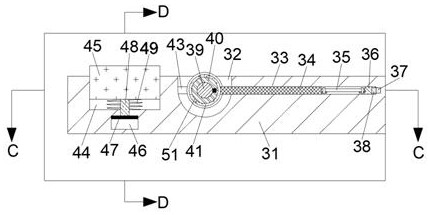

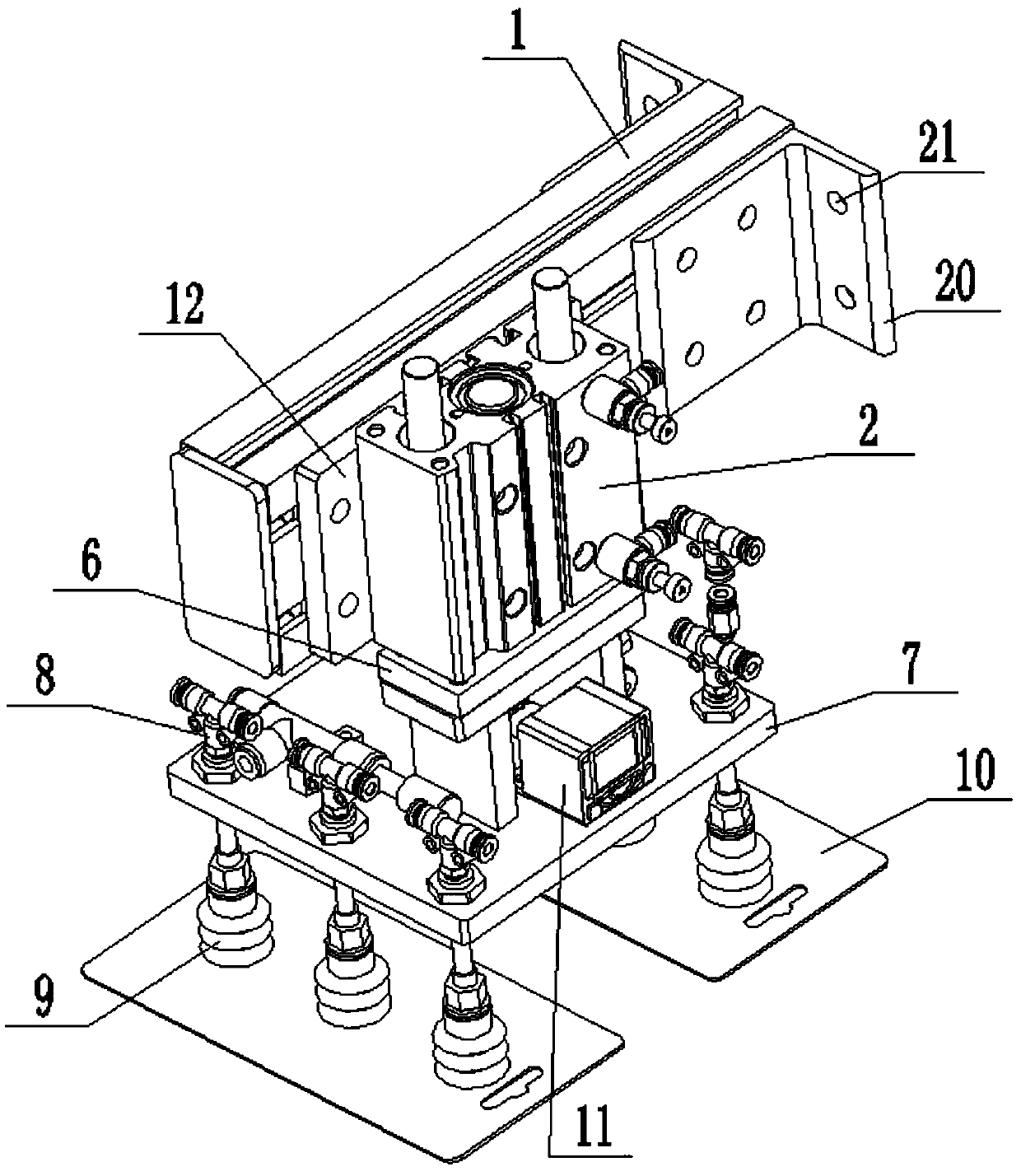

Secondary guide puncture needle device with bottle cap pressing function

ActiveCN113828370AAvoid deformation and bendingHigh strengthBurettes/pipettesEngineeringGeneral surgery

The invention discloses a secondary guide puncture needle device with a bottle cap pressing function. The secondary guide puncture needle device comprises a support, a puncture needle, a ventilation needle, a first driving mechanism, a second driving mechanism and a secondary guide mechanism. The first driving mechanism and the second driving mechanism are arranged on the upper portion of the support, the secondary guide mechanism comprises a guide block, a guide shaft, a ball bushing and a first guide sleeve, the puncture needle and the first guide sleeve are connected with the first driving mechanism, the first guide sleeve and the ball bushing are jointly arranged on the guide shaft in a sleeving mode, and the ball bushing is used for being connected with the first guide sleeve in a rolling friction sleeving mode. The length of the ball bushing is half of the descending stroke of the puncture needle, the ball bushing is fixedly connected with the guide block, the guide block is clamped on the guide shaft to balance the gravity of the guide block, and the middle part of the puncture needle is connected with the side part of the guide block in a penetrating manner. The ventilation needle is arranged on the guide shaft, and the second driving mechanism is connected with the guide shaft to control the ventilation needle to move up and down. The device can adapt to headspace bottles with different heights, the puncture and spit extraction function is effectively completed, and cross contamination is reduced.

Owner:RAYKOL GROUP XIAMEN CO LTD

Protecting and supporting device and protecting method for medium repair asphalt pavement inspection well construction

ActiveCN113863384AEasy to contradictAvoid deformation and bendingArtificial islandsClimate change adaptationArchitectural engineeringStructural engineering

The invention discloses a protecting and supporting device for medium repair asphalt pavement inspection well construction. The protecting and supporting device comprises a cover plate, the cover plate is connected with an inspection well assembly, and a plurality of U-shaped pedals are mounted in the inspection well assembly; the invention further provides a construction protecting method for a medium repair asphalt pavement inspection well. The construction protecting method comprises a plurality of steps. According to the protecting and supporting device and protecting method for medium repair asphalt pavement inspection well construction, workers can conveniently and quickly assemble, access of the workers is not affected during overhaul and maintenance, normal overhaul work is ensured, and when large-scale mechanical equipment runs, force can be well transmitted to the side wall in a concrete groove. Therefore, the bearing capacity of the cover plate is improved through the supporting force of the side wall of the concrete groove, the situation that the cover plate is damaged and collapsed due to small bearing capacity is avoided, and normal operation of a large machine on the cover plate can be effectively guaranteed.

Owner:广州市市政工程机械施工有限公司

Swing vane drive and air conditioner

ActiveCN105222307BAvoid deformation and bendingGuaranteed reliabilityLighting and heating apparatusAir-flow control membersPeriodic alternatingEngineering

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Tree trunk straightener

InactiveCN110731193AAchieve fixationGuaranteed normal growthCultivating equipmentsHorticulture methodsTree trunkStructural engineering

The invention particularly relates to a tree trunk straightener, which comprises two clamping parts. A plurality of connection rods in length-adjustable telescopic structures are arranged between thetwo clamping parts, and fixing devices for fixing a tree trunk are arranged on the clamping parts respectively. By arrangement of the two clamping parts, tree trunk fixing can be realized; by arrangement of the connection rods, vertical upward growth of the tree trunk can be guaranteed, and bending deformation of the tree trunk is avoided. In addition, the tree trunk straightener has advantages ofsimple structure, low cost, convenience and quickness in operation and high practicality.

Owner:成都锦蕊丝路贸易有限公司

A self-aligning plastic pipe lifting installation support frame

ActiveCN112607651BAvoid deformation and bendingEasy to installLifting framesClassical mechanicsSupport plane

A self-aligning plastic pipe lifting installation support frame disclosed by the present invention includes a mobile base, and the left and right symmetrically provided moving drum chambers with downward openings are respectively arranged in the mobile base, and the front and rear walls of the mobile drum chambers on the left and right sides are The moving roller shafts are respectively rotated between them, the moving rollers are fixed on the outer surface of the moving roller shafts, the left lifting guide pillars are respectively fixed on the left side of the upper end surface of the moving base symmetrically, and the upper end surface of the moving base and On the right side of the left lifting guide column, the right lifting guide column is respectively fixed symmetrically front and rear. The present invention can lift the plastic pipe to be installed to a high place through the bracket, avoiding the bending and deformation of the pipe during the hoisting and lifting process, and then lift it to the same level as the pipe. When the fixed pipe is at the same height, it will automatically stop lifting, and the butt joint correction of the installation pipe and the fixed pipe will be carried out, which is convenient for workers to install and avoids installation problems caused by offset.

Owner:浙江常山顺飞工贸有限公司

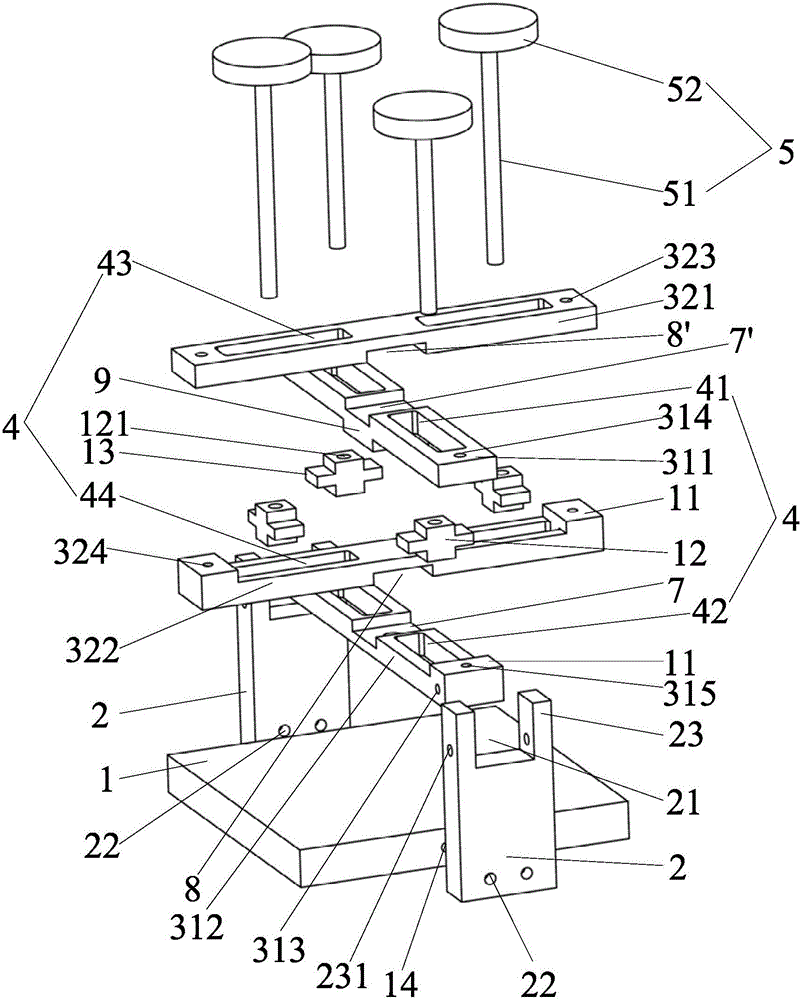

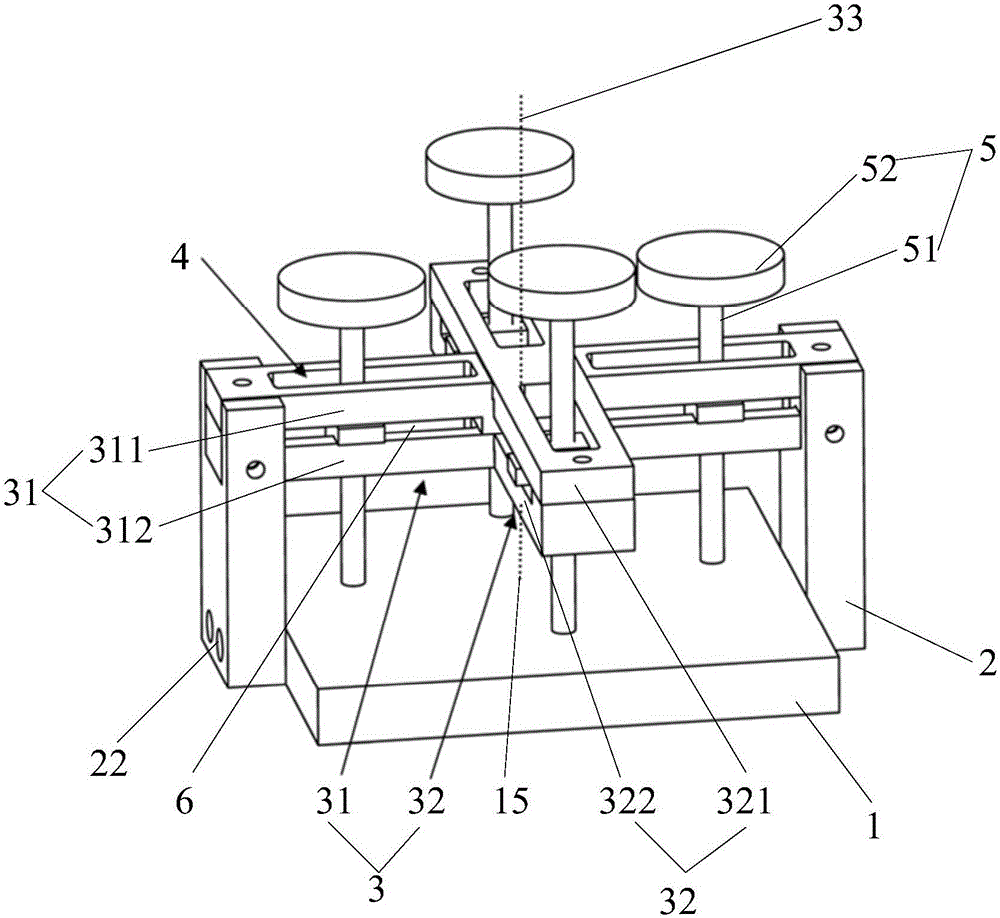

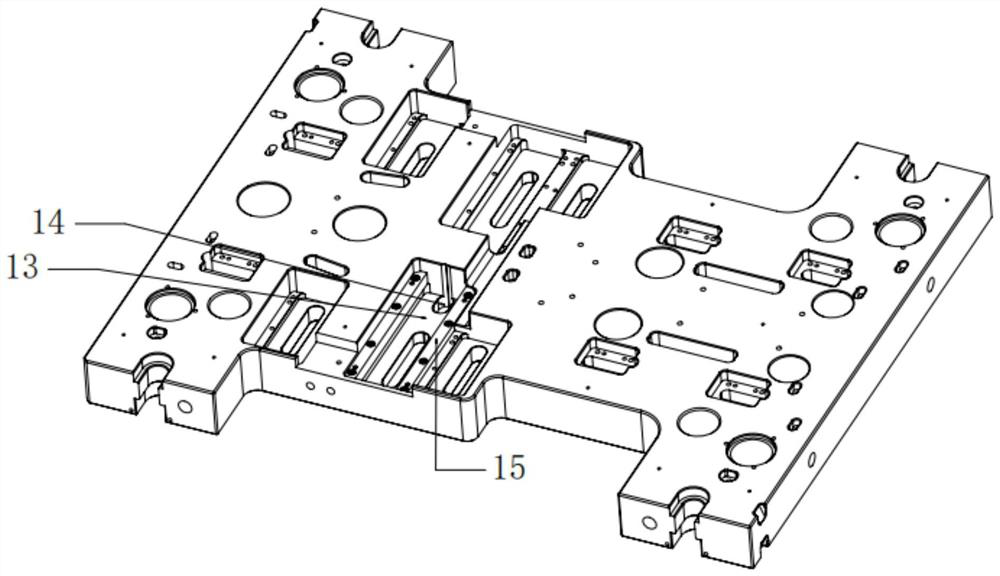

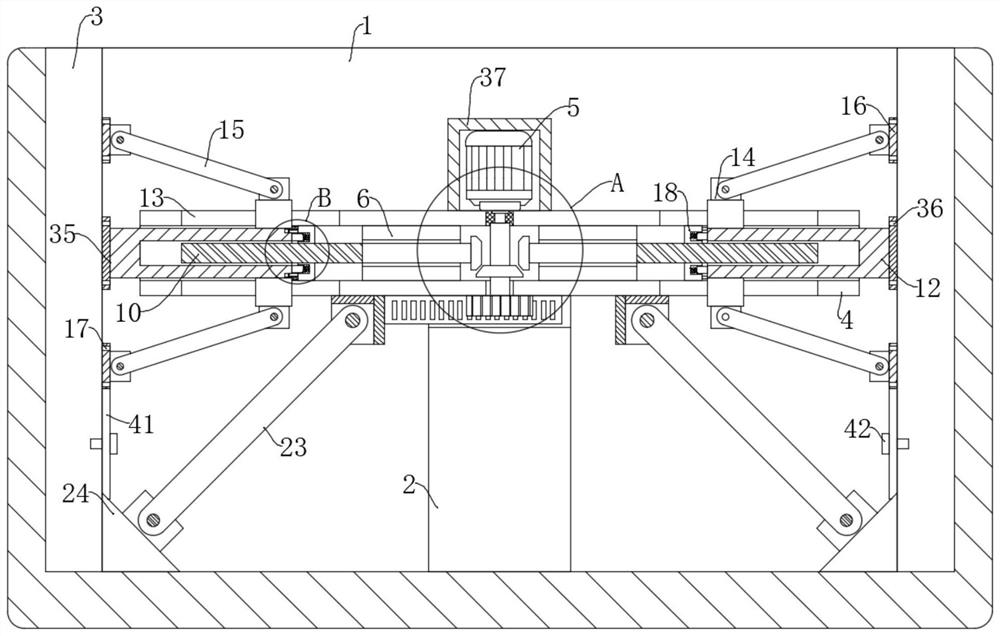

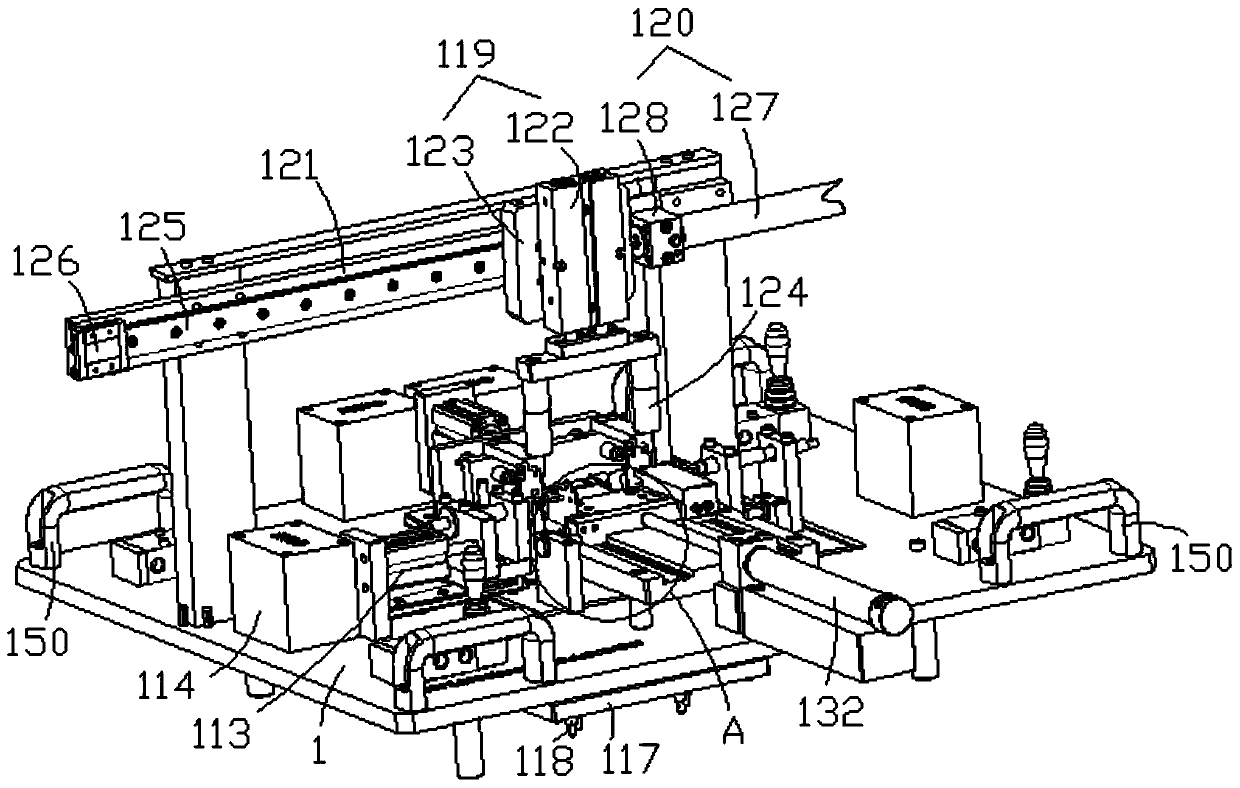

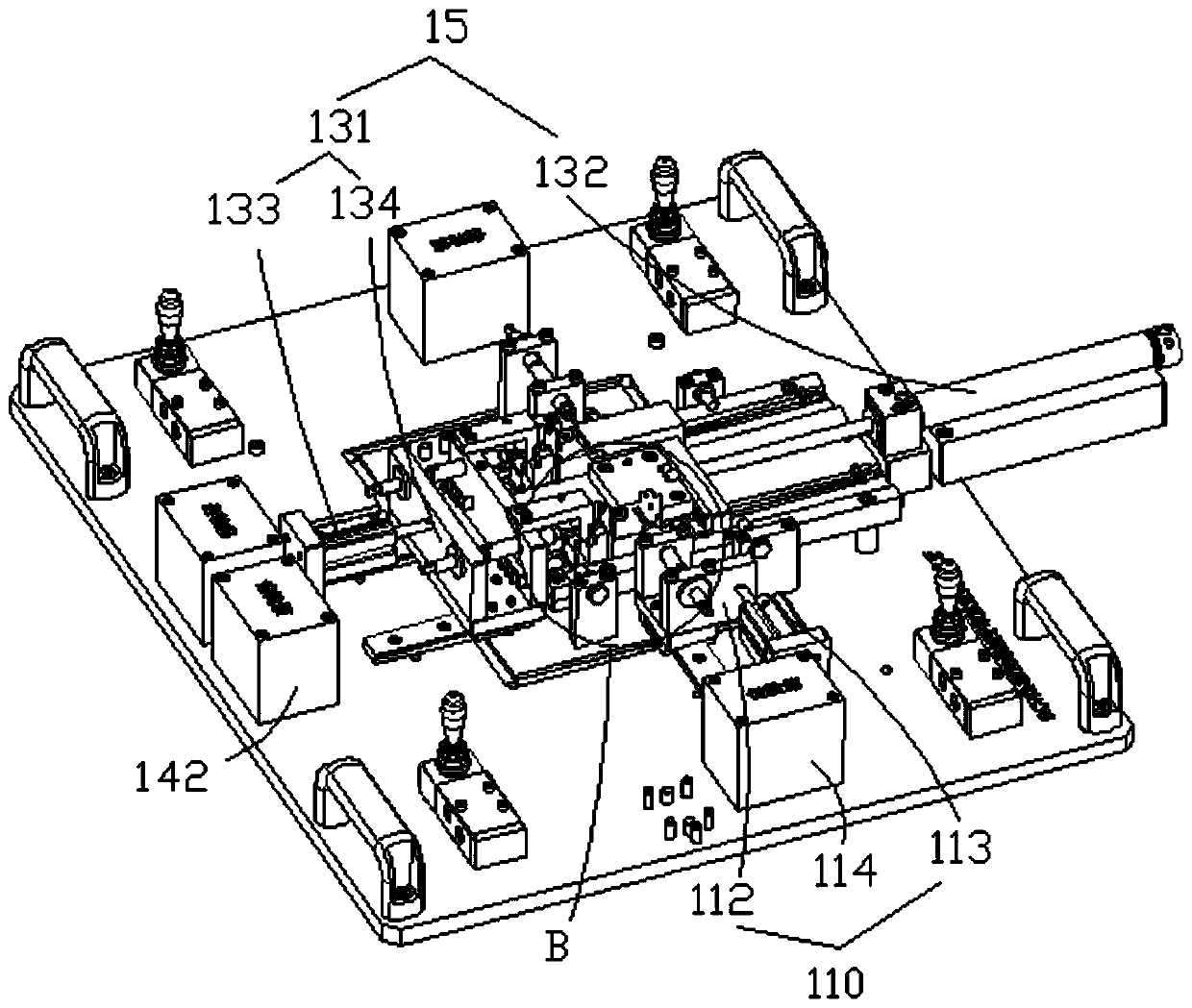

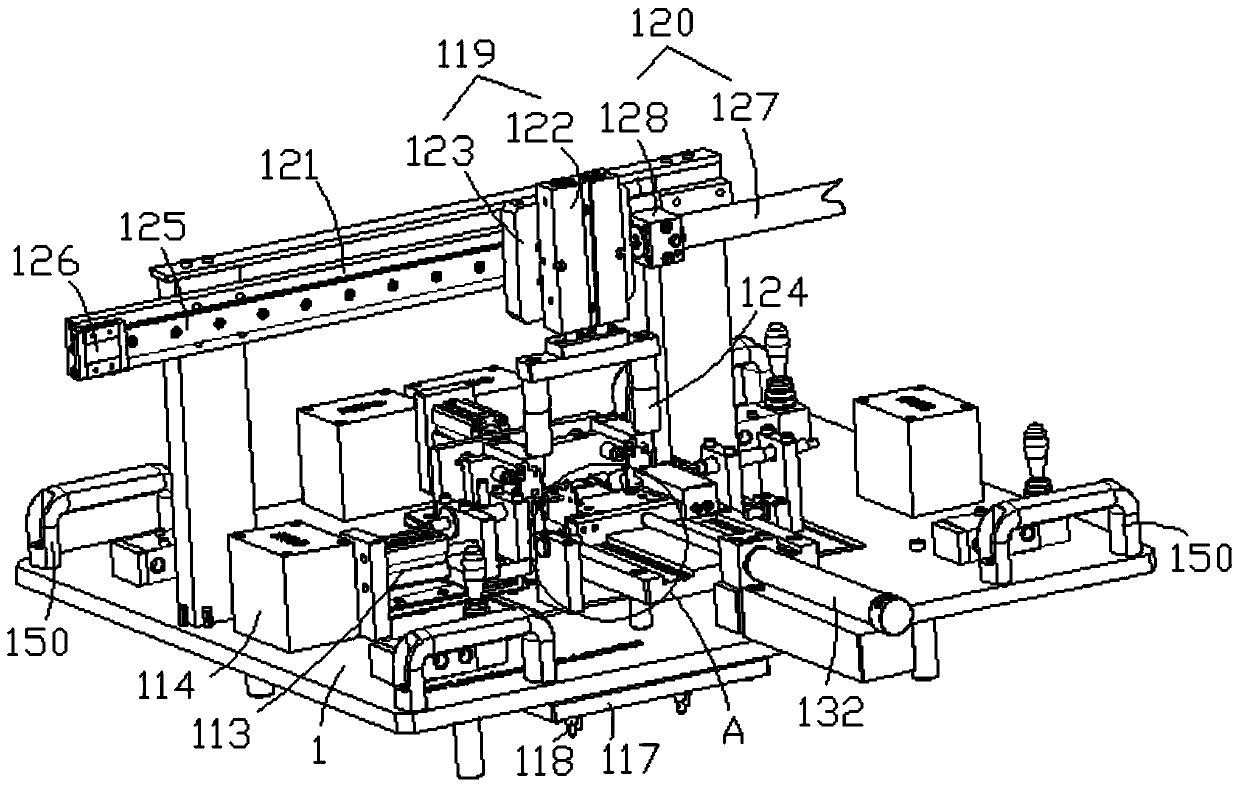

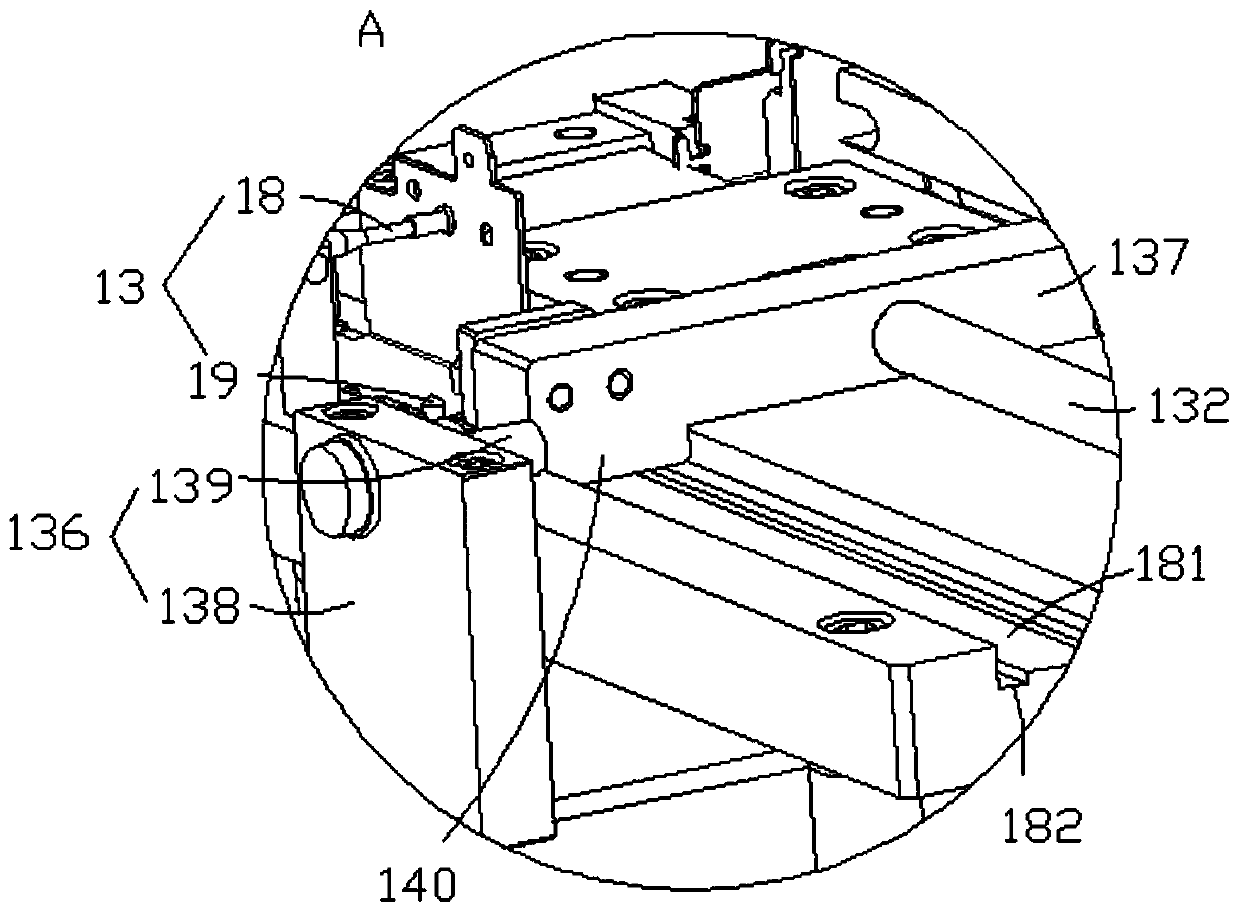

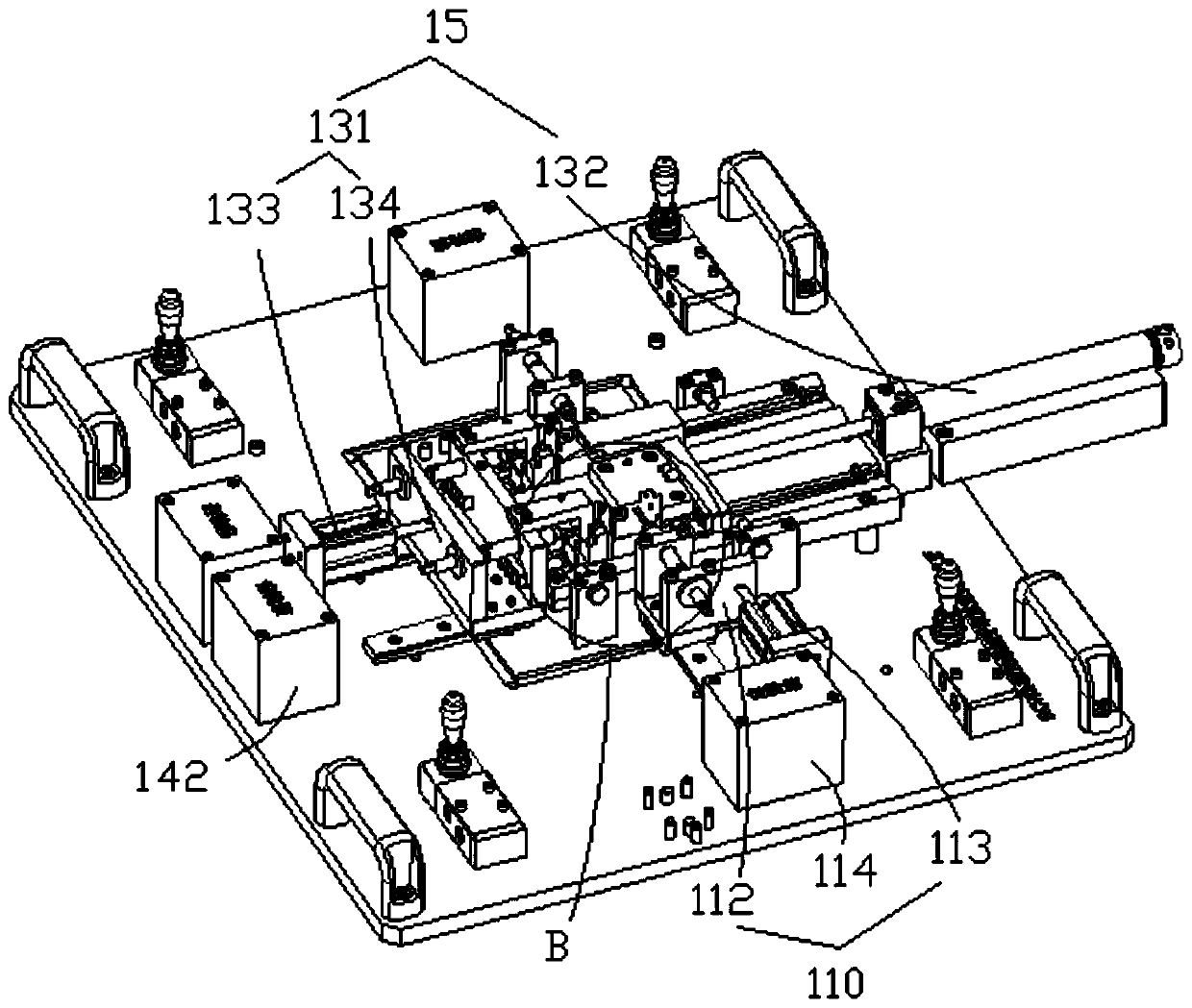

A multi-faceted three-dimensional automatic tapping equipment

ActiveCN110270722BAvoid deformation and bendingReduce turnaround timeThread cutting feeding devicesThread cutting machinesStructural engineeringMachining

The invention relates to multi-surface three-dimensional automatic tapping equipment. The equipment comprises a machining table and a control host, wherein a tapping station and a first detection assembly are arranged on the machining table; a workpiece comprises a bottom plate and a first vertical plate; the machining table is further provided with an anti-slip assembly used for preventing slip of the bottom plate of the machining table during tapping, a first anti-tilt assembly used for preventing the first vertical plate from tilting during tapping, a tapping assembly used for tapping the bottom plate and the first vertical plate, a first driving assembly used for driving the tapping assembly to move towards or away from the workpiece, and a second driving assembly used for driving the anti-slip assembly to move towards or away from the workpiece. According to the equipment, the situation of tilted tapping or bending and deformation of the first vertical plate can be avoided, and multi-surface tapping can be carried out by one-time clamping, so that the turnround and clamping time is shortened, and the production benefit is improved.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

Stabilizer bar electrode heating equipment with supporting mechanism

InactiveCN109082511AAccurate shapeAvoid deformation and bendingFurnace typesHeat treatment furnacesDesign standardEngineering

The invention discloses stabilizer bar electrode heating equipment with a supporting mechanism. The stabilizer bar electrode heating equipment with the supporting mechanism comprises a workbench. A fixed heating electrodes and a sliding heating electrode are separately arranged on both sides of the worktable. The workbench is further provided with a sliding device, and the sliding heating electrode is arranged on the sliding device. The stabilizer bar electrode heating equipment further comprises an air cylinder, a balancing weight, a connecting wire and a supporting mechanism. The air cylinder is fixed to the workbench to limit the forward or backward distance of the sliding heating electrode. The balancing weight is connected with the sliding heating electrode through the connecting wire. The supporting mechanism comprises a vertical bar and a cross bar, wherein the bottom end of the vertical bar is fixed to the workbench, and the cross bar is fixed to the top end of the vertical bar. The upper surface of the cross bar is in contact with the lower surface of a bar body of the stabilizer bar. According to the stabilizer bar electrode heating equipment with the supporting mechanism, downward deformation, caused by gravity, of the bar body of the stabilizer bar in the heating process can be avoided, the shape of the stabilizer bar can be ensured to reach the design standard, andthe use requirement can be met.

Owner:滁州硕燊机械制造有限公司

Energy-saving lamp

InactiveCN112923260ABrightness protectionEasy to replaceLighting support devicesCleaning using toolsDust controlLight fixture

The invention discloses an energy-saving lamp which comprises a base, supporting columns are fixedly connected to the two sides of the top of the base, a fixing frame is fixedly connected to the bottoms of the supporting columns, a fixing device is arranged at the tops of the supporting columns, and a handle is fixedly connected to the middle of the top of the fixing device. And an illuminating lamp is arranged in the middle of the bottom of the fixing device. The invention relates to the technical field of energy-saving lamps. According to the energy-saving lamp, the supporting column, the fixing device and the handle are arranged, dust can be cleaned through dust removal inside the fixing device, so that dust adsorbed on the surface after long-time use is convenient to remove, the brightness degree of the lamp is convenient to protect, the supporting column can be effectively fixed, meanwhile, the lamp is convenient to replace, place and take, the waste of resources can be effectively reduced, the moving direction can be better controlled, the dust removal strength is relieved, and the situation that the lamp is broken due to too large strength is prevented.

Owner:绍兴市载沣智能科技有限公司

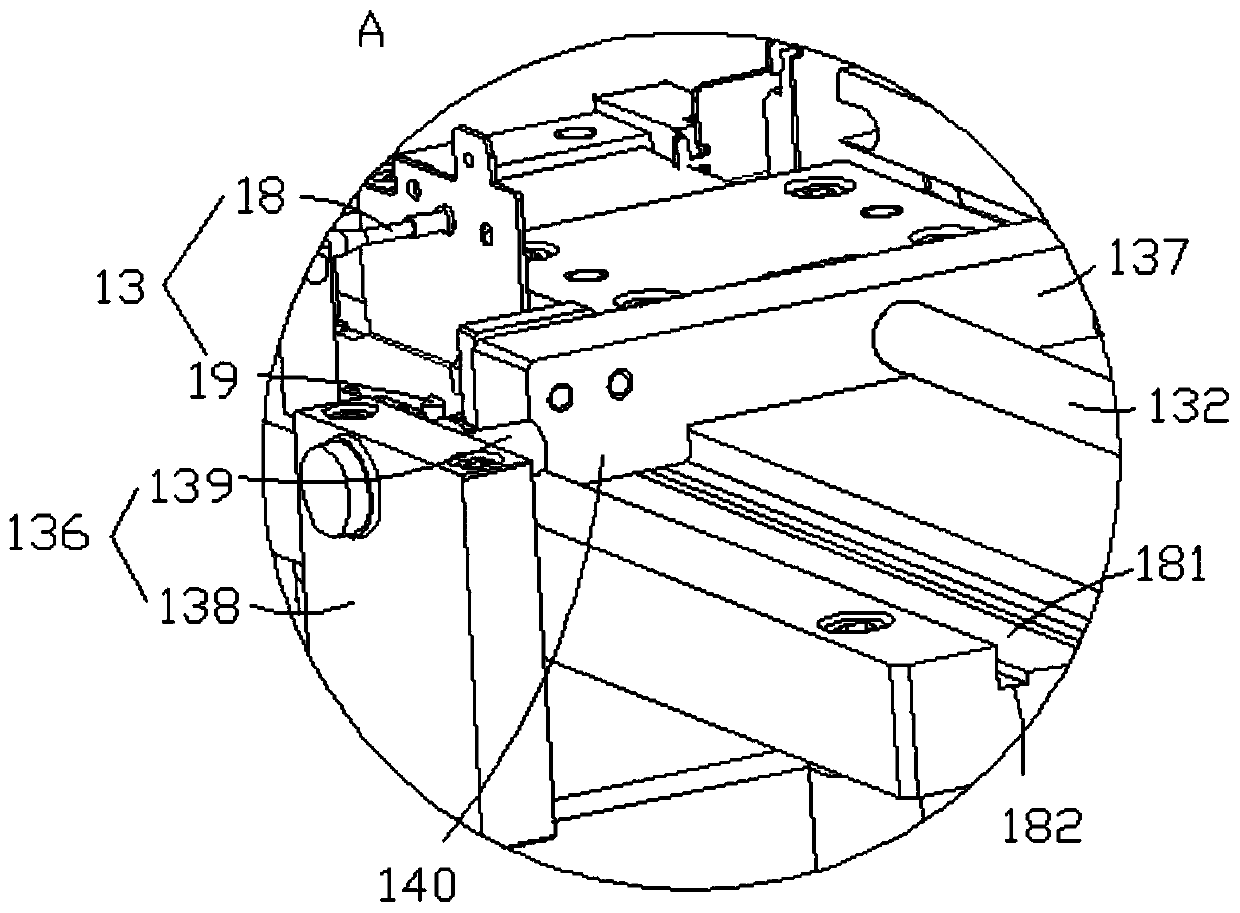

Colorful card assembling equipment and application method thereof

ActiveCN109664082AAvoid deformation and bendingReasonable designMetal working apparatusEngineeringCantilever

The invention discloses colorful card assembling equipment. A cantilever is included. An air cylinder is arranged on one side of the cantilever in a sliding manner. A colorful card clamp mechanism isarranged at the bottom of the air cylinder. Two blister positioning tools are arranged right in front of the colorful card clamp mechanism. Two blisters are inserted and placed in the blister positioning tools. A guiding mechanism is arranged at an inlet of each blister positioning tool. The invention further discloses an application method of the colorful card assembling equipment. The application method comprises the following steps that firstly, two sets of vacuum generators control two sets of vacuum suction cups correspondingly, wherein one vacuum generator controls the two vacuum suctioncups, and the front sections of two colorful card bodies are sucked; and the other vacuum generator controls the four vacuum suction cups, and the middle rear sections of the two colorful card bodiesare sucked. According to the colorful card assembling equipment and the application method thereof, design is reasonable, operation is convenient, the colorful card bodies can be rapidly inserted inthe blisters, the assembling time is short, the assembling success rate is increased, and the phenomena of colorful card body deforming and bending in the card inserting process are effectively avoided.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

Multi-surface three-dimensional automatic tapping equipment

ActiveCN110270722AAvoid deformation and bendingReduce turnaround timeThread cutting feeding devicesThread cutting machinesMachiningEngineering

The invention relates to multi-surface three-dimensional automatic tapping equipment. The equipment comprises a machining table and a control host, wherein a tapping station and a first detection assembly are arranged on the machining table; a workpiece comprises a bottom plate and a first vertical plate; the machining table is further provided with an anti-slip assembly used for preventing slip of the bottom plate of the machining table during tapping, a first anti-tilt assembly used for preventing the first vertical plate from tilting during tapping, a tapping assembly used for tapping the bottom plate and the first vertical plate, a first driving assembly used for driving the tapping assembly to move towards or away from the workpiece, and a second driving assembly used for driving the anti-slip assembly to move towards or away from the workpiece. According to the equipment, the situation of tilted tapping or bending and deformation of the first vertical plate can be avoided, and multi-surface tapping can be carried out by one-time clamping, so that the turnround and clamping time is shortened, and the production benefit is improved.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

Portable power adapter and charging method

PendingCN114552733AAdjustable positionExtended service lifeBatteries circuit arrangementsConversion constructional detailsComputer hardwarePortable power

The invention discloses a portable power adapter and a charging method, and belongs to the technical field of power adapters. The device comprises an adapter, a protective shell, a sliding box, a storage box and a plug, the protective shell slidably sleeves the outer wall of the adapter, the sliding box is arranged on the right side of the outer wall of the protective shell, the storage box is arranged on the right side of the outer wall of the sliding box, and the plug is arranged on the left side of the outer wall of the adapter. Position adjusting assemblies are arranged on the front side and the rear side of the protection shell correspondingly. According to the portable power adapter and the charging method, the problems that when the power adapter is used, due to the fact that a wire harness is too long and inconvenient to collect, the power adapter is very inconvenient to carry, the wire harness is often wound, a plug of the adapter cannot be protected when the power adapter is carried out, and the power adapter is inconvenient to use are solved. And the normal use of the adapter is affected due to the fact that the plug is often deformed.

Owner:肖礼芸

Semiconductor elongated strip and method for processing same

PendingCN110098114AReduce stressAvoid deformation and bendingSemiconductor/solid-state device manufacturingIonEtching

The method for processing a semiconductor elongated strip comprises the steps of: providing a semiconductor elongated strip; plating a predetermined surface of the semiconductor elongated strip with aprotective film; covering the protective film with a photosensitive film; covering the predetermined surface with a trench-shaped shielding cover for exposure and ion etching; and removing the photosensitive film. The method can reduce the bending and the deformation of the elongated strip during a cutting process, thereby ultimately improving the performance of a semiconductor product.

Owner:SAE TECH DELEVOPMENT DONGGUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com