Full-automatic winding facility

A fully automatic and equipment technology, applied in the direction of winding strips, labels, packaging, etc., can solve the problems of cumbersome disassembly and assembly, cumbersome operation process, reducing production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

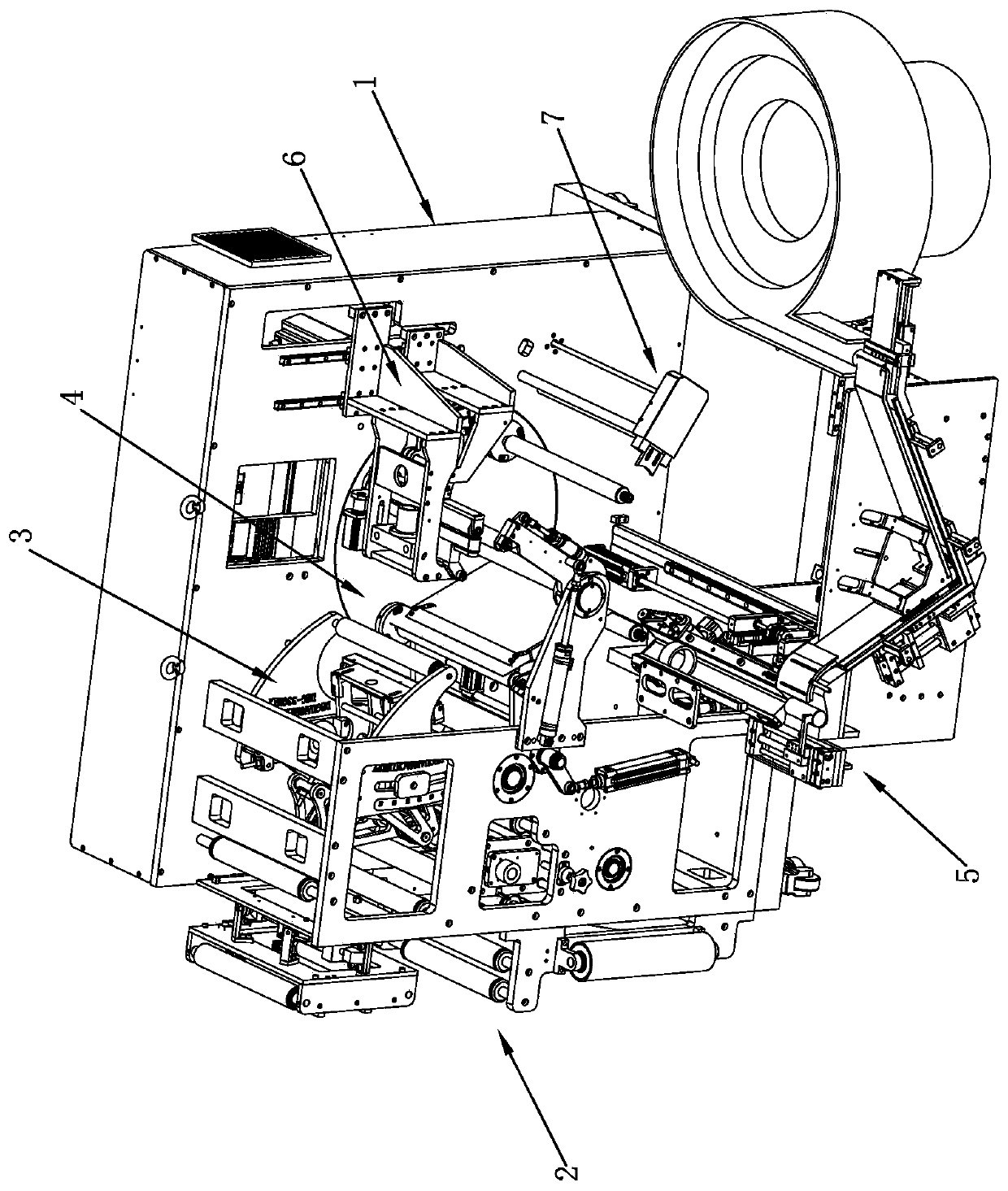

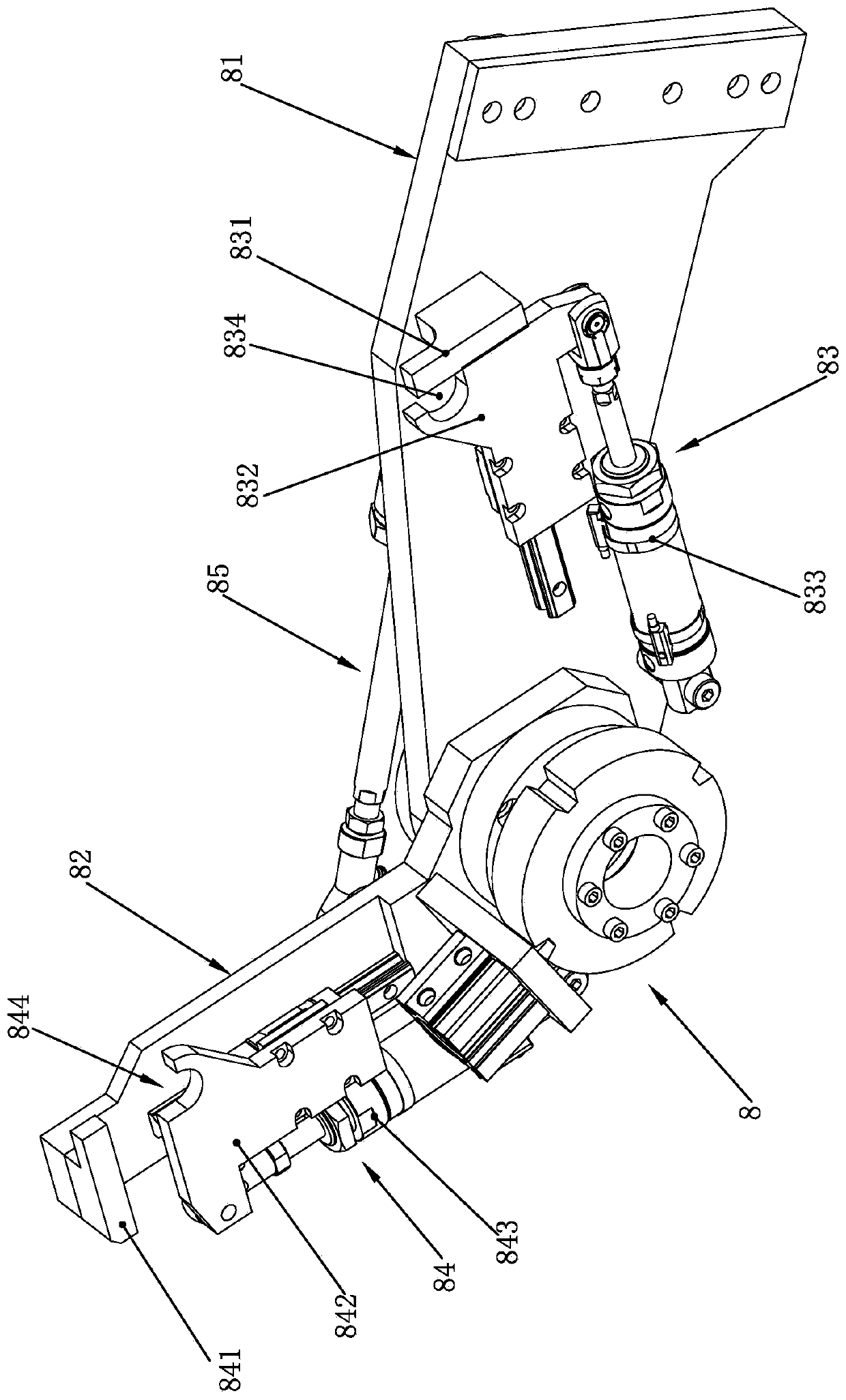

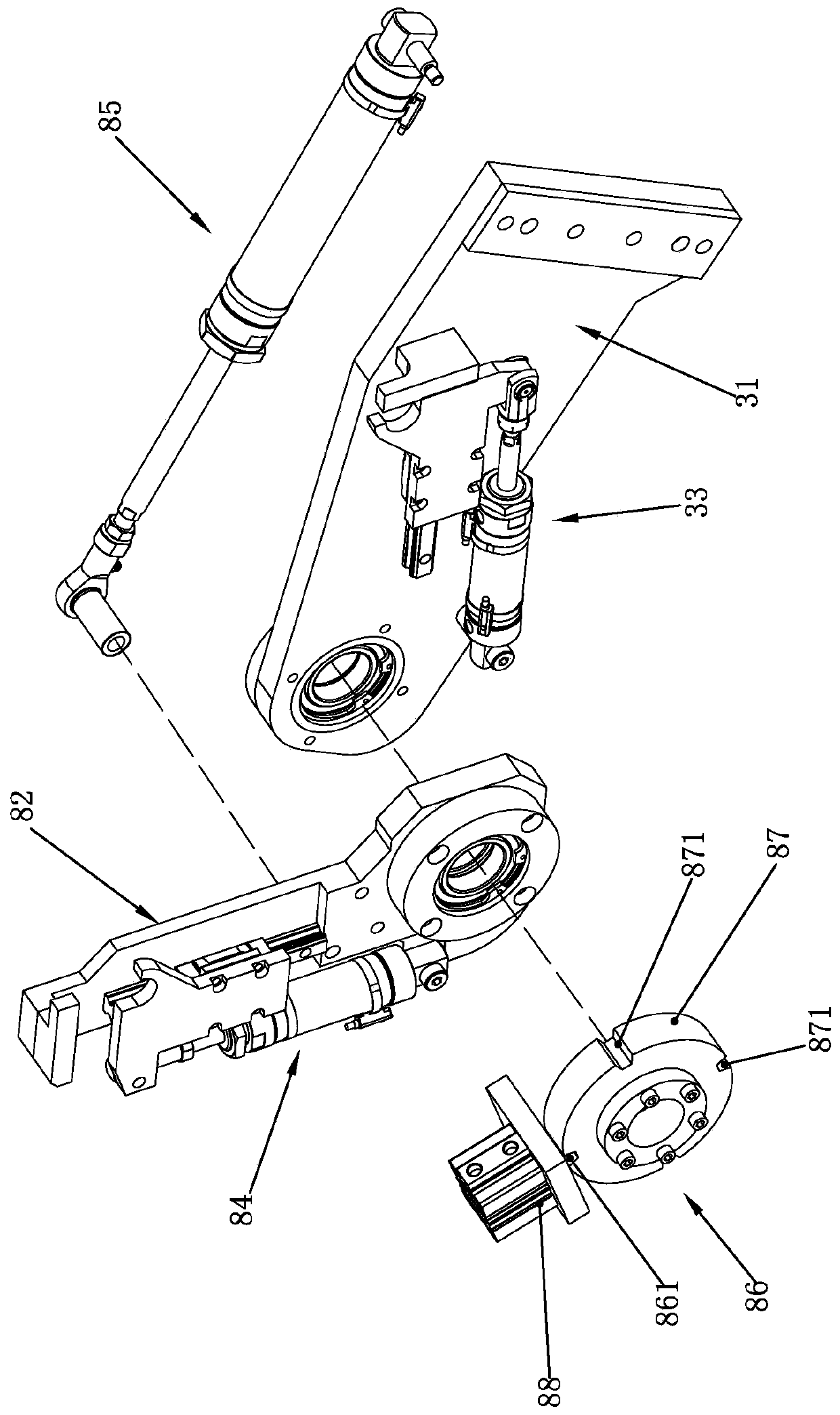

[0034] Such as figure 1 — Figure 12 A kind of fully automatic winding equipment shown, comprises frame 1, is located at the feeding device 2 on frame 1, cutting device 3, rewinding device 4, paper feeding pipe core device 5, labeling device 6 and The finished product output device 7, the winding device 4 includes a turntable 42 that is driven by the drive source and the main drive shaft 41 and can rotate in the circumferential direction. The drive source can be a motor. Rolling station 422, labeling station 423 and finished product output station 424. The turntable 42 is provided with a number of rewinding air shafts 43 that can run to each station along with the turntable 42. The cutting device 3 includes a knife mechanism. 31. The lower knife mechanism 32 corresponding to the upper knife mechanism 31 and the paper pressing mechanism 33 located at the upper knife mechanism 31, there is a pre-cutting station 34 between the upper knife mechanism 31 and the lower knife mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com