Novel full-hardening cold-rolling working roller heat treatment process

A cold-rolled work roll, full hardening technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as easy damage of cold-rolled work rolls, shorten heating time, avoid bending or cracking, and reduce temperature differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

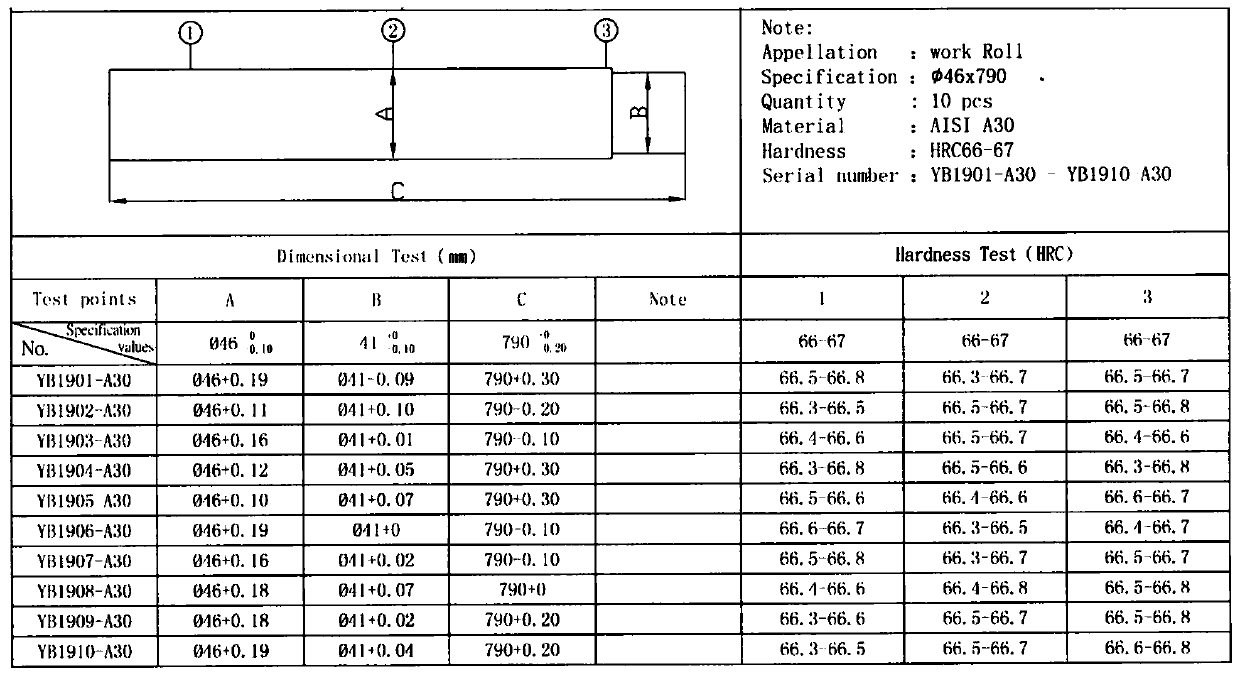

[0031] Such as figure 1 As shown, take the 46*790 work roll as an example:

[0032] A new heat treatment process for fully hardened cold-rolled work rolls, including the following heat treatment steps:

[0033] S1. Place the workpiece on the heating equipment, clamp and hoist it in for preheating. Preheat at 400°C, 600°C, and 800°C successively. The preheating time for the workpiece at 400°C is 3.5 hours. The preheating time is 2.5 hours, and the preheating time is 1.5 hours at 800°C;

[0034] S2. Hoist the preheated workpiece into a high-temperature quenching environment at 1120±10°C for heating, and the heating time for high-temperature quenching is 75 minutes;

[0035] S3, then hang the workpiece into a constant temperature quenching environment for constant temperature quenching treatment, the temperature of the constant temperature quenching environment is 180 ° C, and the constant temperature quenching time is 10 minutes;

[0036] S4. Oil cooling the quenched workpiec...

Embodiment 2

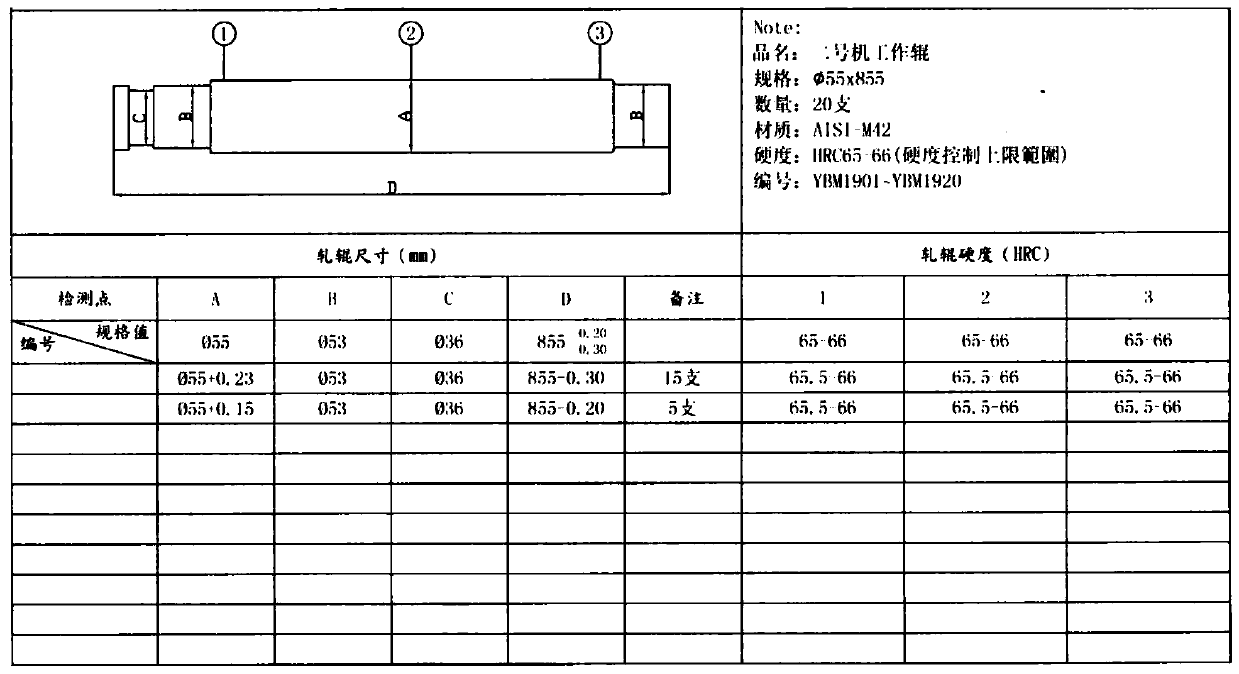

[0042] Such as figure 2 As shown, take the 55*855 work roll as an example:

[0043] A new heat treatment process for fully hardened cold-rolled work rolls, including the following heat treatment steps:

[0044] S1. Place the workpiece on the heating equipment, clamp and hoist it in for preheating. Preheat at 400°C, 600°C, and 800°C successively. The preheating time for the workpiece at 400°C is 3.5 hours. The preheating time is 2.5 hours, and the preheating time is 1.5 hours at 800°C;

[0045] S2. Hoist the preheated workpiece into a high-temperature quenching environment at 1160±10°C for heating, and the heating time for high-temperature quenching is 95 minutes;

[0046]S3, then hang the workpiece into a constant temperature quenching environment for constant temperature quenching treatment, the temperature of the constant temperature quenching environment is 190 ° C, and the constant temperature quenching time is 10.5 minutes;

[0047] S4. Oil cooling the quenched workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com