Multi-cutter progressive turning machine tool of slender shafts

A technology of turning machine tools and slender shafts, applied in turning equipment, turning equipment, accessories of toolholders, etc., can solve problems such as limiting the processing size of workpieces, eliminate dimensional deviation, avoid dynamic unbalance characteristics, and reduce dynamic deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

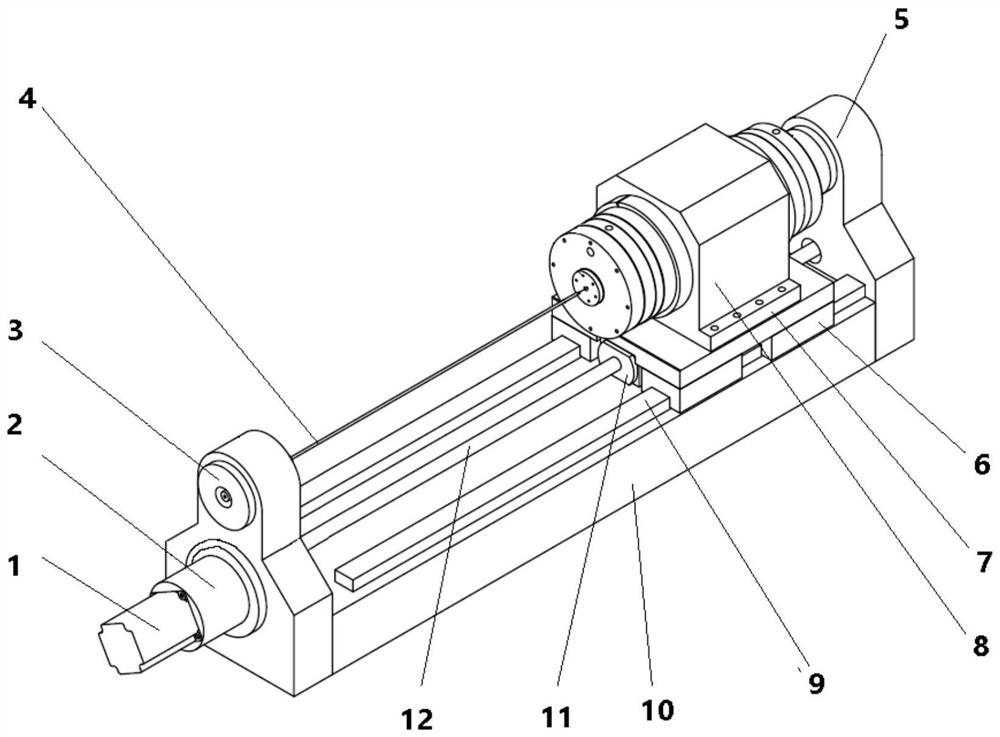

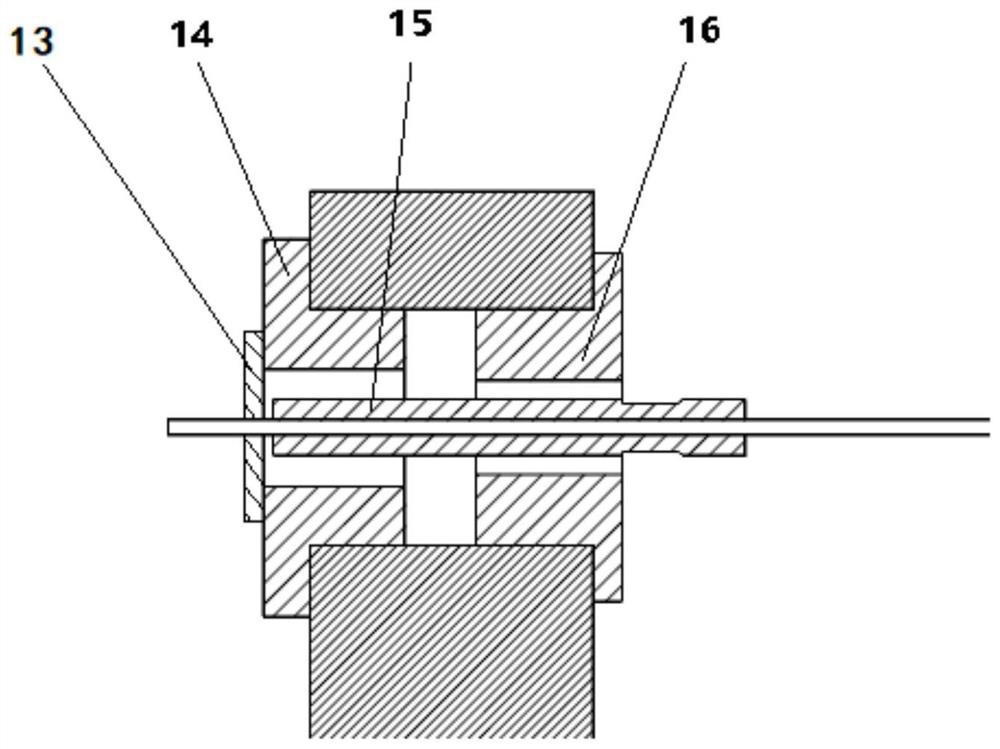

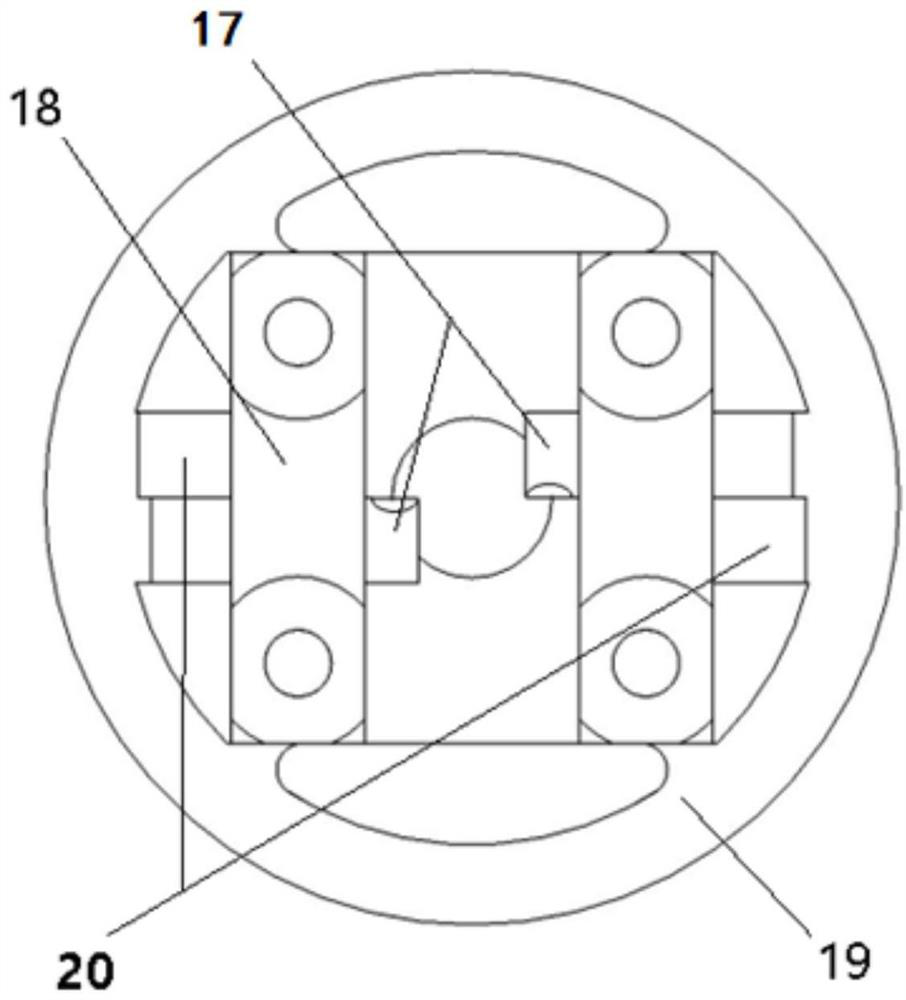

[0033] Such as figure 1 As shown, a slender shaft multi-tool progressive turning machine tool, the machine tool includes: machine tool main unit, multi-tool processing unit, left pre-tightening force unit and right pre-tightening force unit; said left pre-tightening force unit and right pre-tightening force unit The tightening force units are arranged at both ends of the main body unit of the machine tool to provide support for the slender shaft 4, prevent the slender shaft 4 from being deformed, and drive the multi-tool processing unit to reciprocate along the axial direction; The knife processing unit is arranged on the main body unit of the machine tool, and reciprocates on the main body unit of the machine tool to process the elongated shaft 4 .

[0034] Wherein, the main unit of the machine tool includes: a marble base 10, a screw nut 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com