Rotary scraper

A technology of rotating scraper and machine body, which is applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc. It can solve the problems of unreliable connection, poor cooperation, poor processing quality, etc., and achieve rapid replacement and cost saving , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

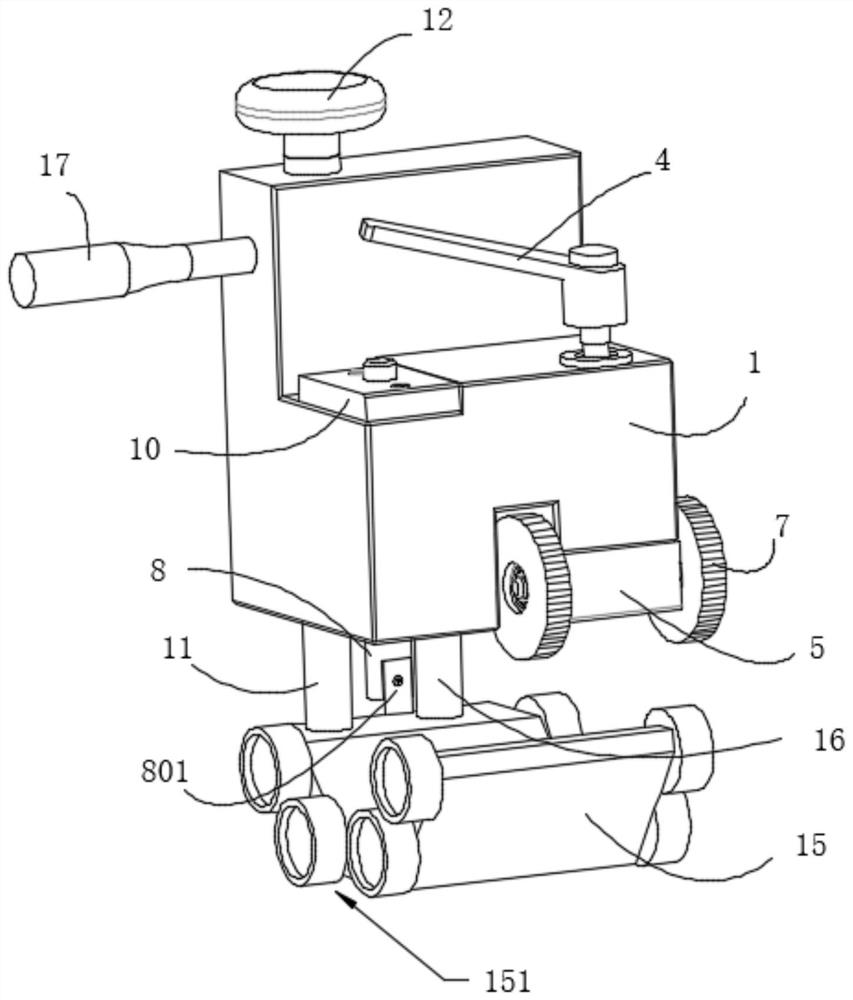

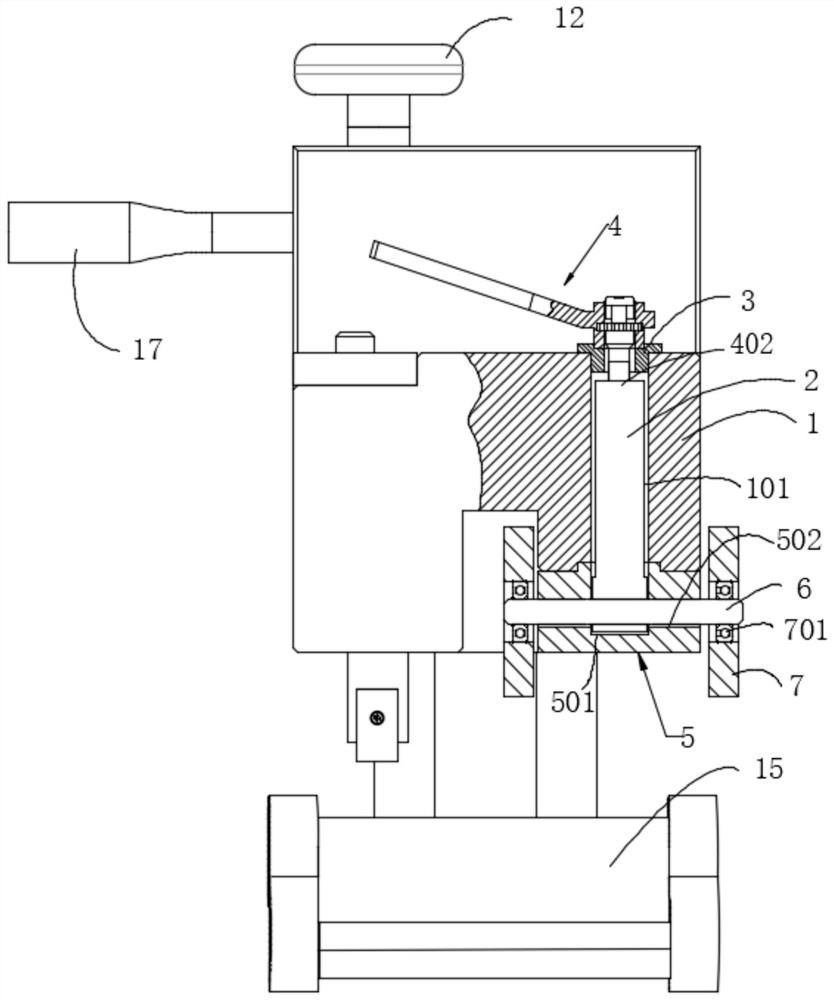

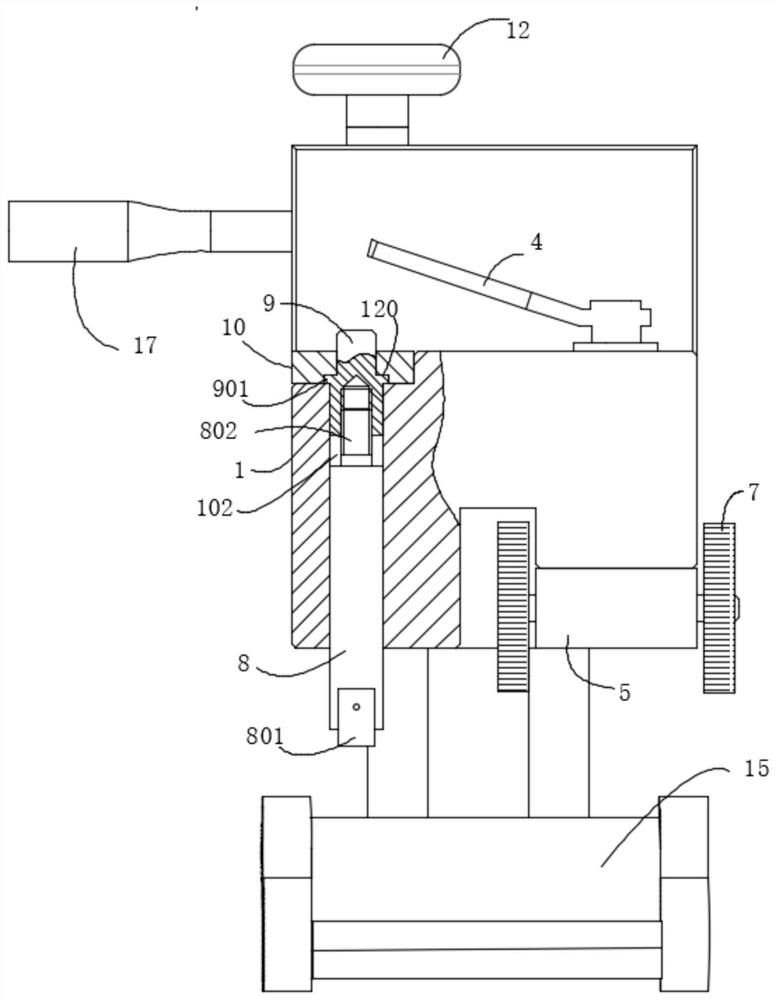

[0022] Embodiment: rotary scraper machine, constitutes as figure 1 As shown, including the body 1, the upper part of the body 1 is provided with a first through hole 101, the first through hole 101 is provided with a driving wheel locking rod 2, and the inside of the driving wheel locking rod 2 is provided with a long channel internal thread, the first One side of the through hole 101 is provided with a positioning ring 3, and a ratchet directional locking handle 4 is provided outside the positioning ring 3, such as Figure 6 As shown, the ratchet directional locking handle 4 includes a handle 401, the handle 401 is provided with an external threaded rod 402, the external threaded rod 402 is connected with a slotted pan head screw 403, and the slotted pan head screw 403 is sleeved with a Spring, externally threaded rod 402 and slotted pan head screw 403 are threadedly connected, externally threaded rod 402 is screwed on the driving wheel locking pull rod 2, the inside of handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com