Patents

Literature

41results about How to "Uniform cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

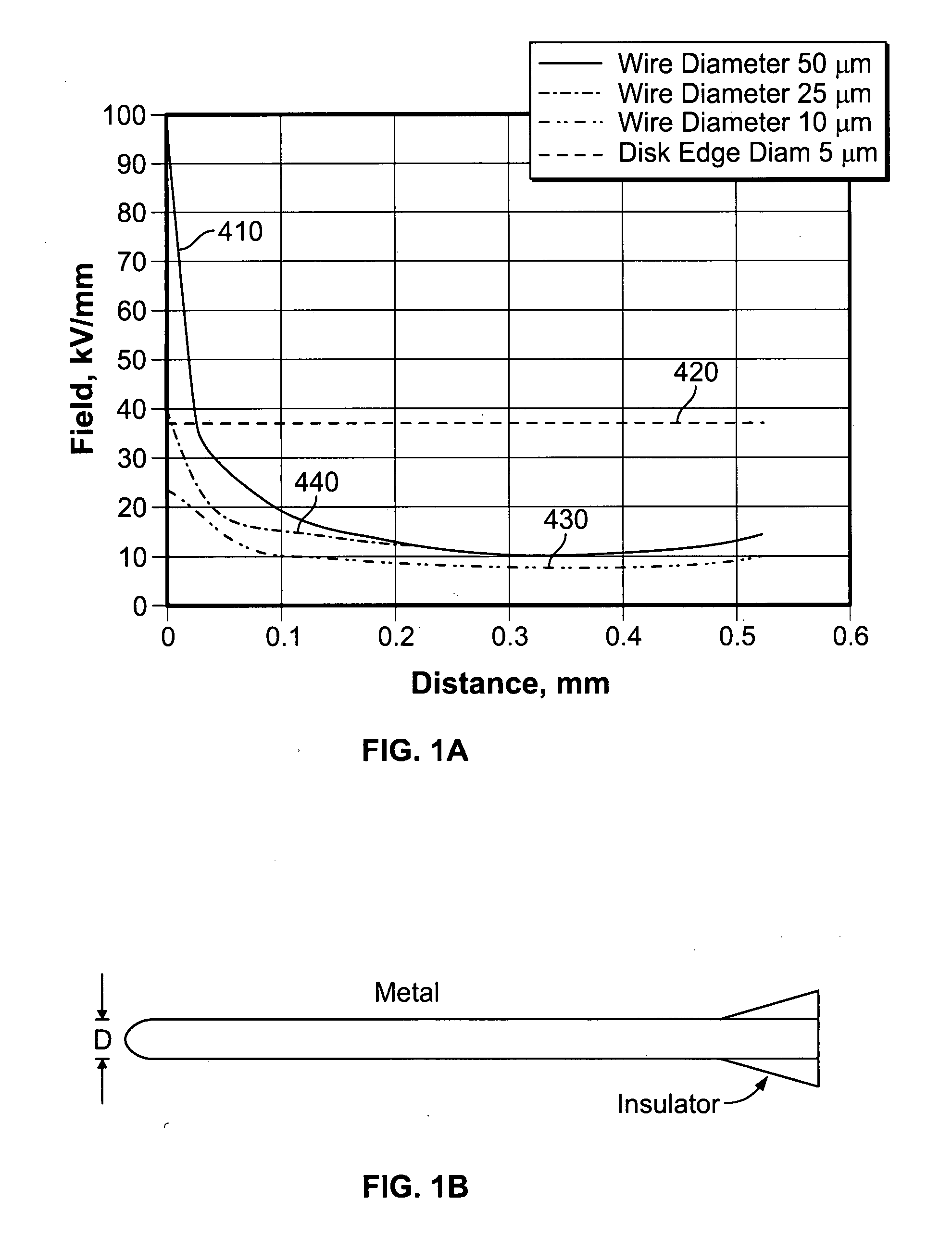

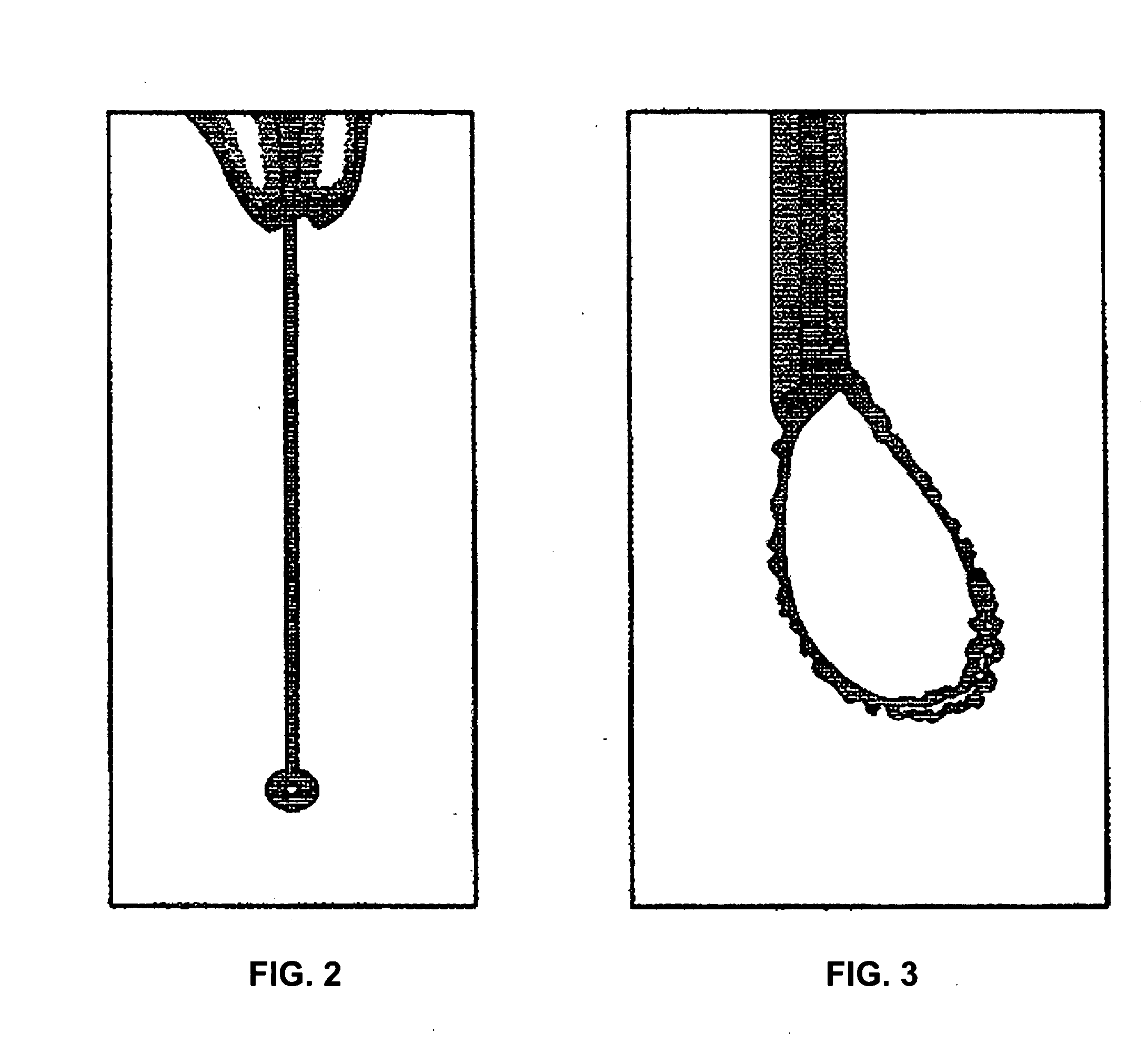

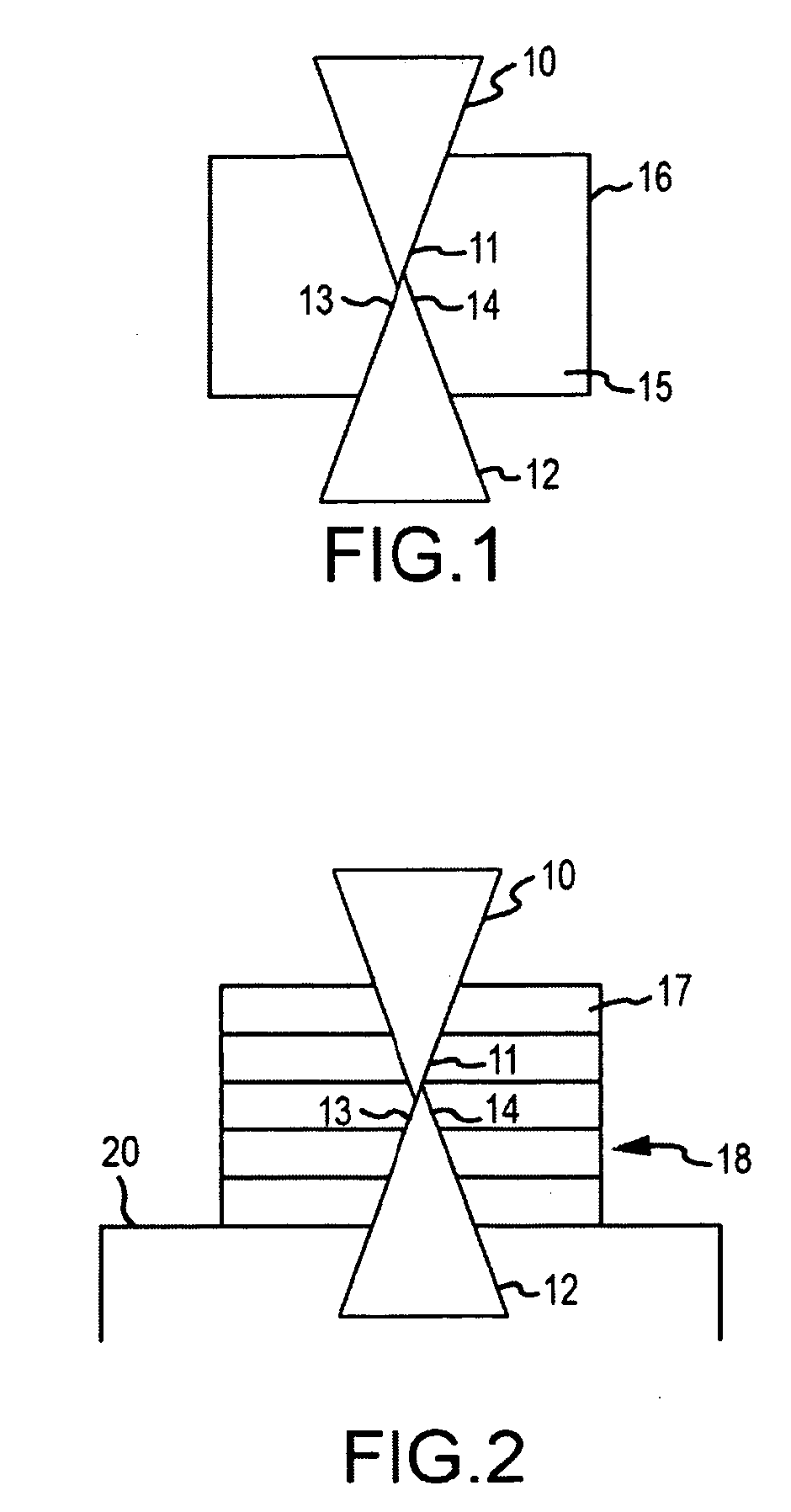

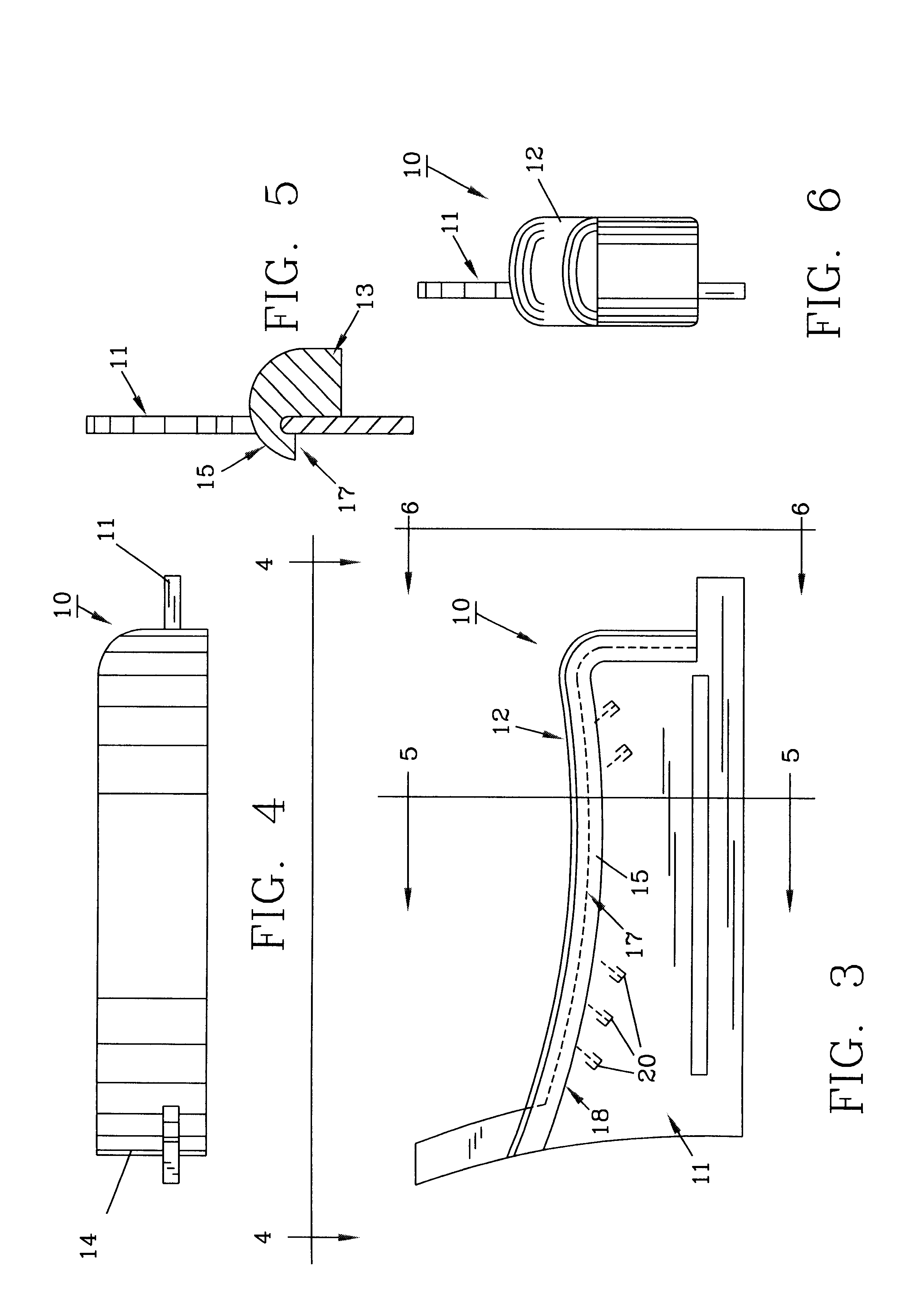

Electrosurgical system with uniformly enhanced electric field and minimal collateral damage

ActiveUS7736361B2High mechanical strengthUniform enhanced electric fieldSurgical instruments for heatingInsulation layerElectric field

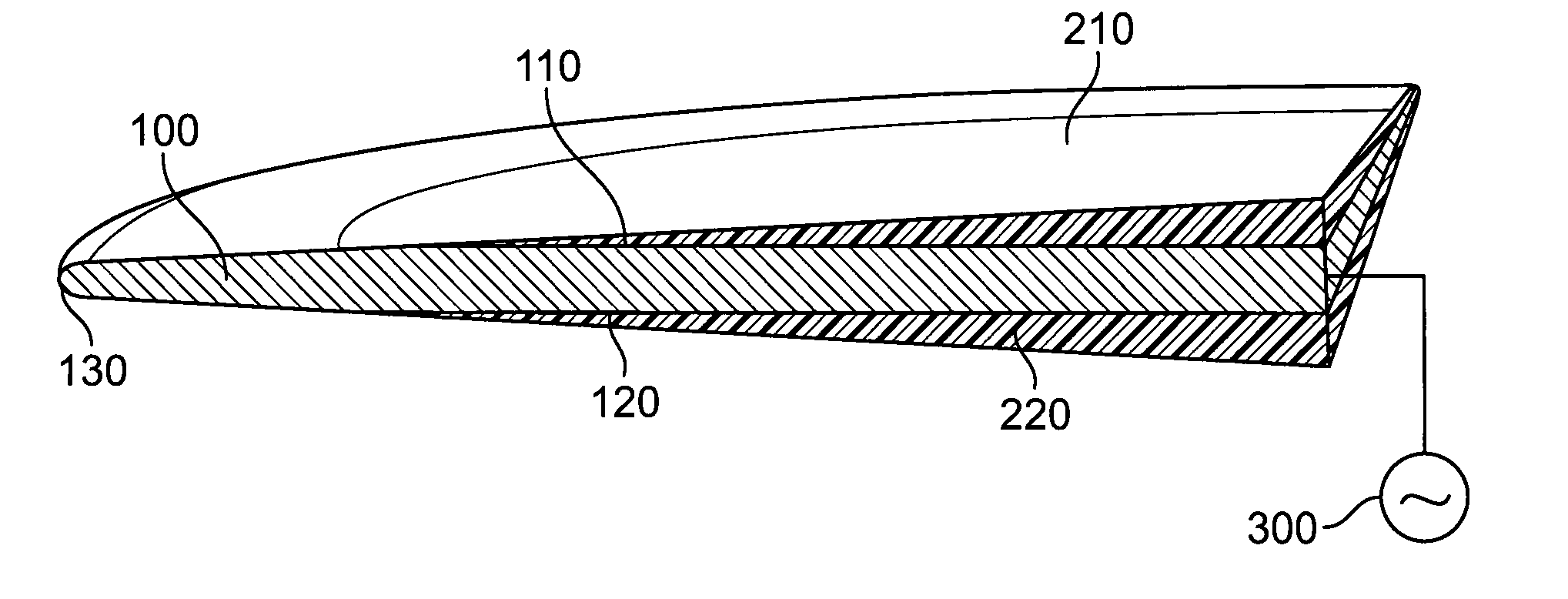

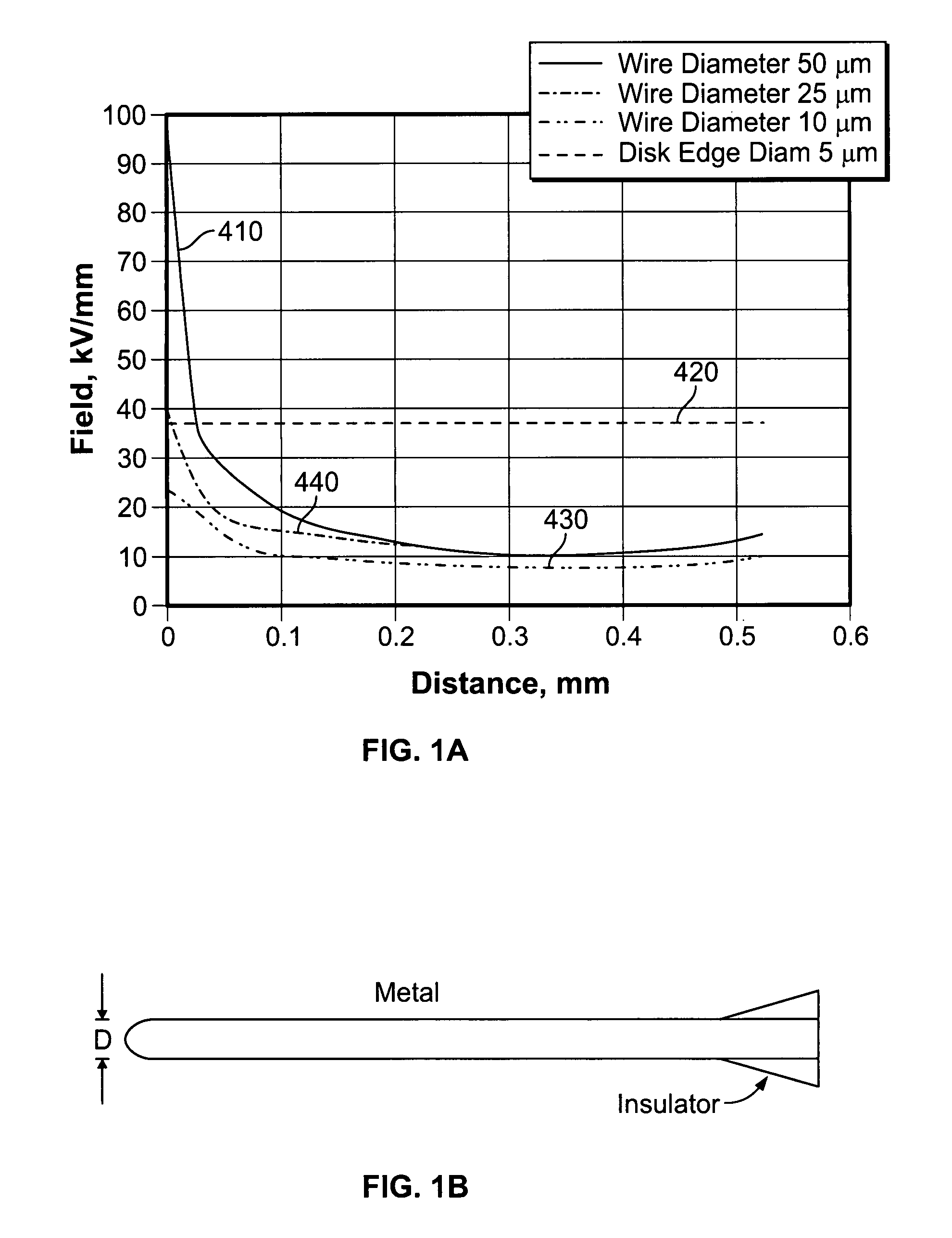

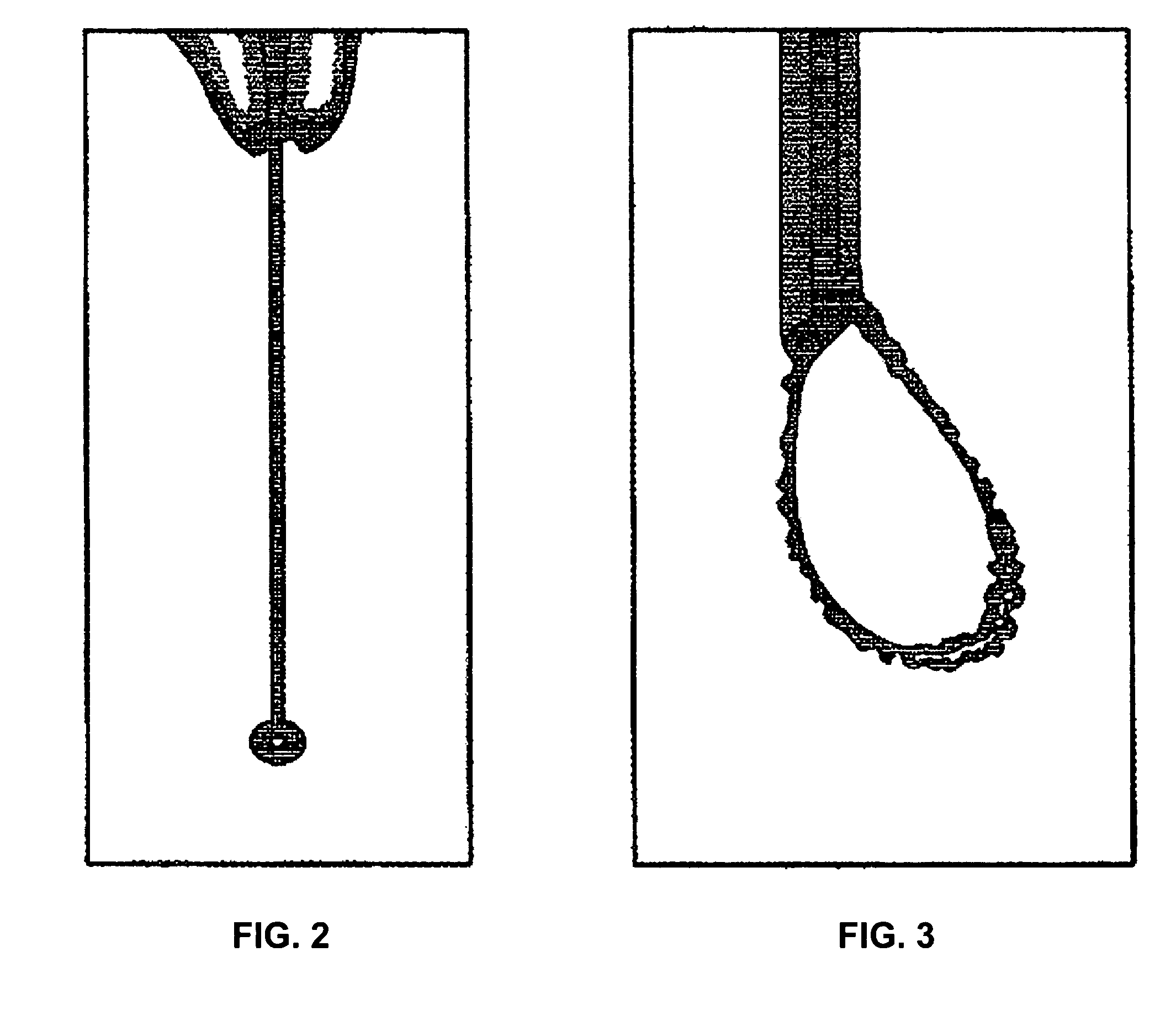

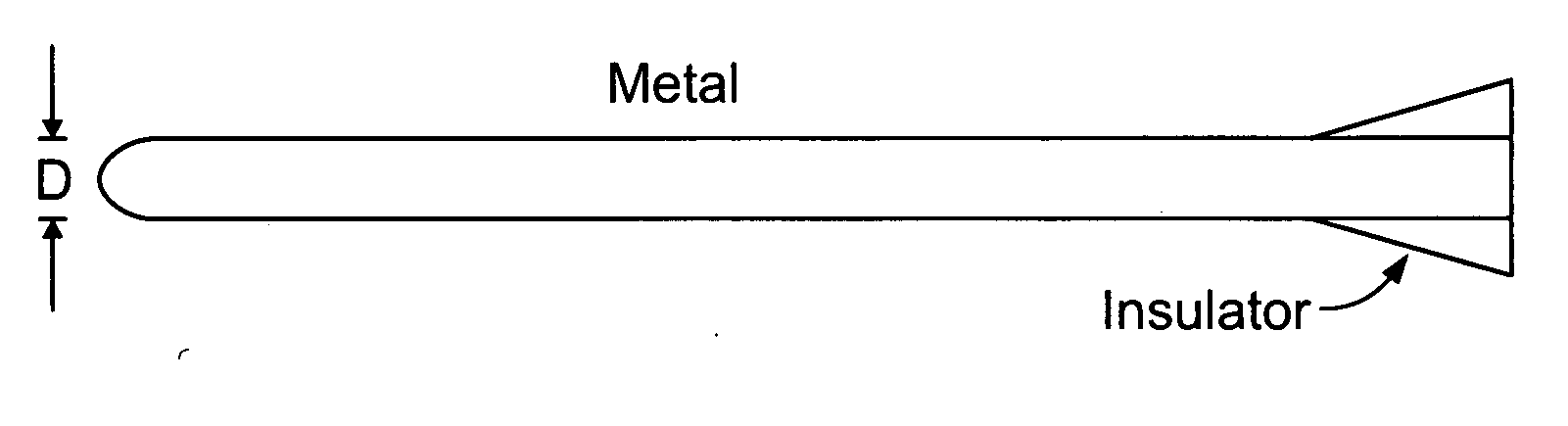

The present invention is directed towards an electrosurgical cutting system. The system comprises an electrically conductive blade, having an uninsulated cutting edge that is surrounded by an insulator. A source of pulsed electrical energy may be coupled to the electrically conductive blade to provide a substantially uniform and highly enhanced electric field along a cutting portion of the blade edge. The blade may have a uniform rate of erosion during use, so that both the conductive metal edge and the surrounding insulation layer erode at approximately the same rate. Also described are methods of fabricating insulated cutting electrodes, particularly blade electrodes.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Electrosurgical system with uniformly enhanced electric field and minimal collateral damage

ActiveUS20080027428A1Efficient methodReduce electroporation-related tissue damageSurgical instruments for heatingInsulation layerElectric field

The present invention is directed towards an electrosurgical cutting system. The system comprises an electrically conductive blade, having an uninsulated cutting edge that is surrounded by an insulator. A source of pulsed electrical energy may be coupled to the electrically conductive blade to provide a substantially uniform and highly enhanced electric field along a cutting portion of the blade edge. The blade may have a uniform rate of erosion during use, so that both the conductive metal edge and the surrounding insulation layer erode at approximately the same rate. Also described are methods of fabricating insulated cutting electrodes, particularly blade electrodes.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

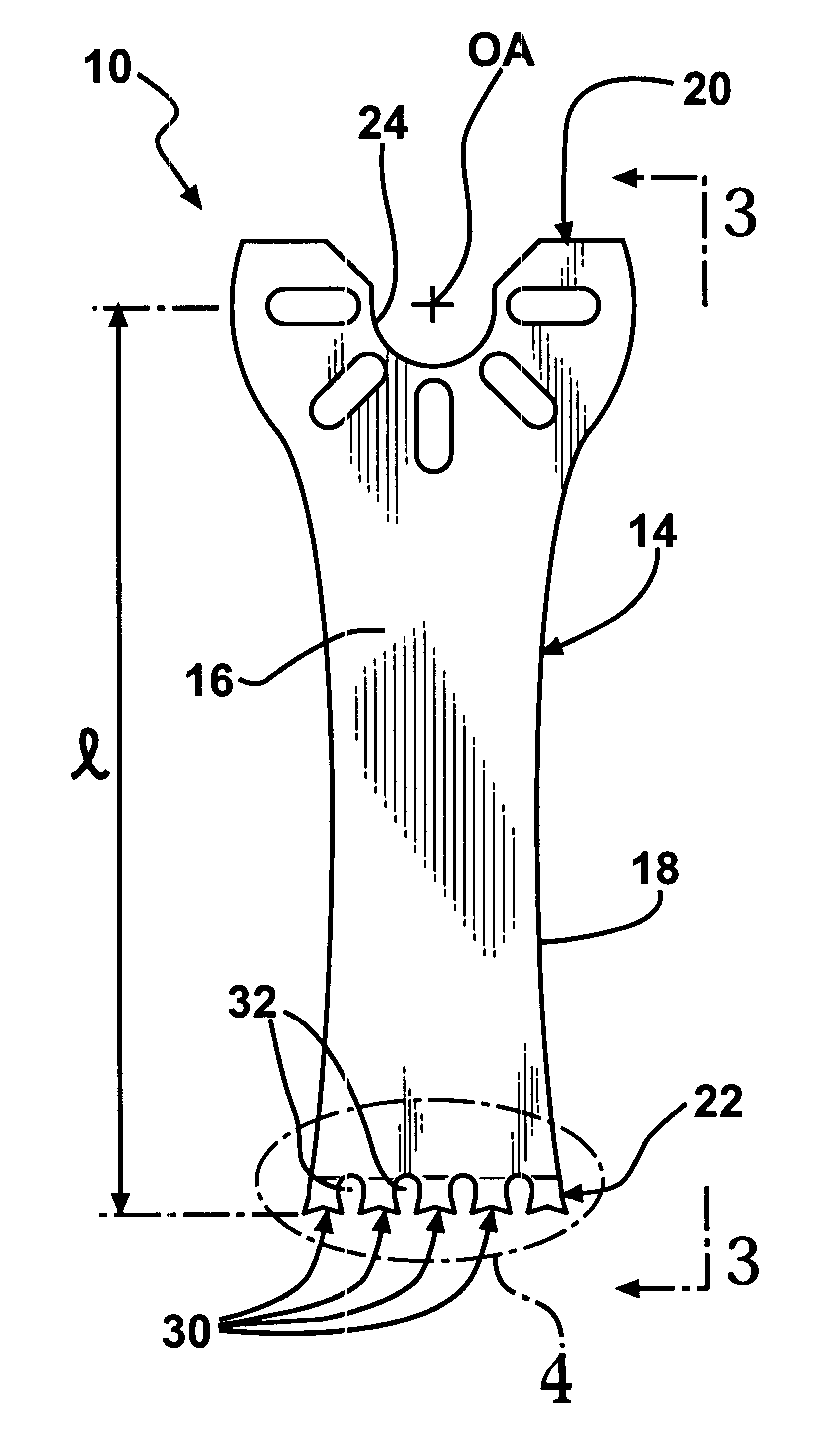

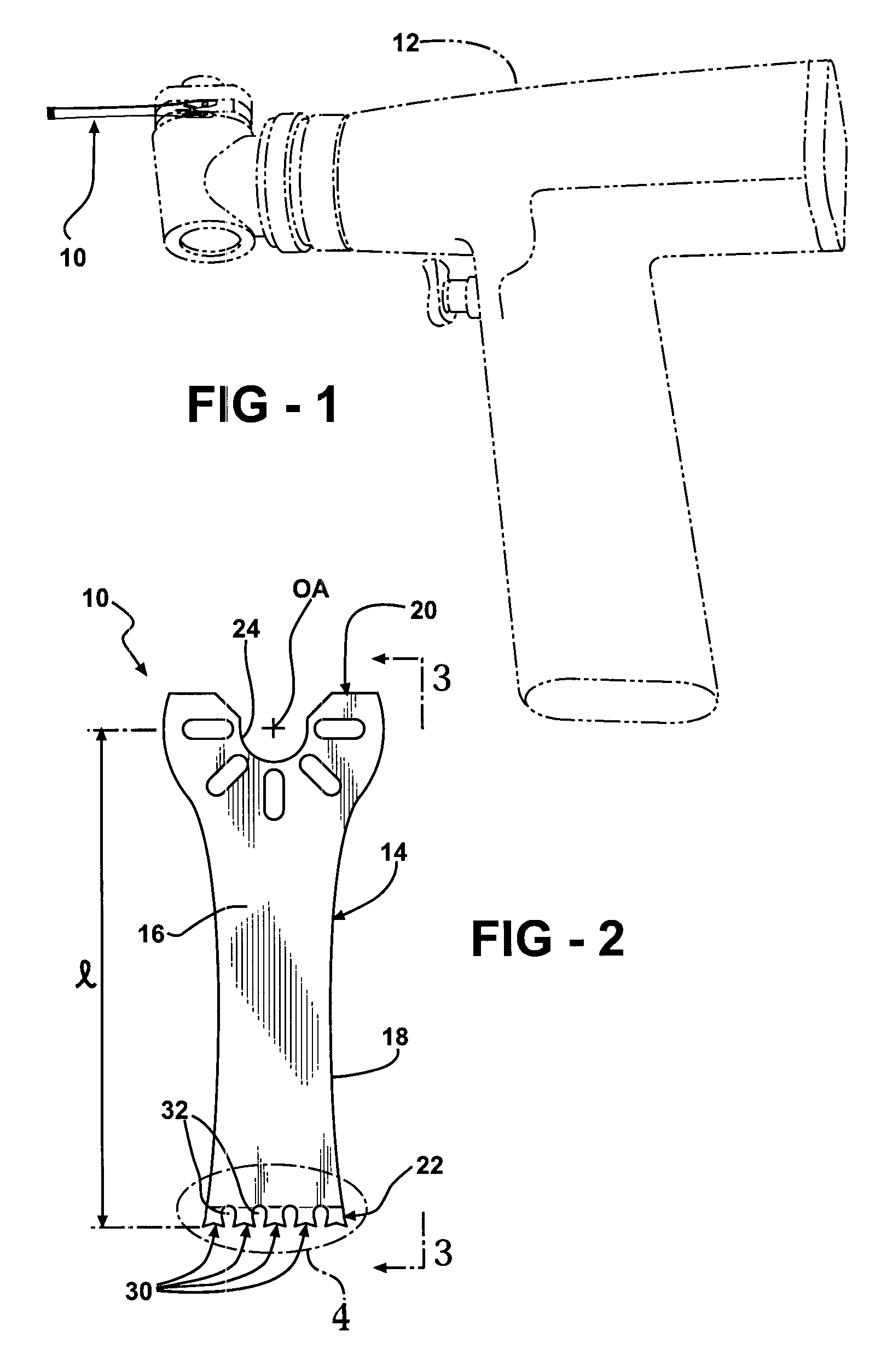

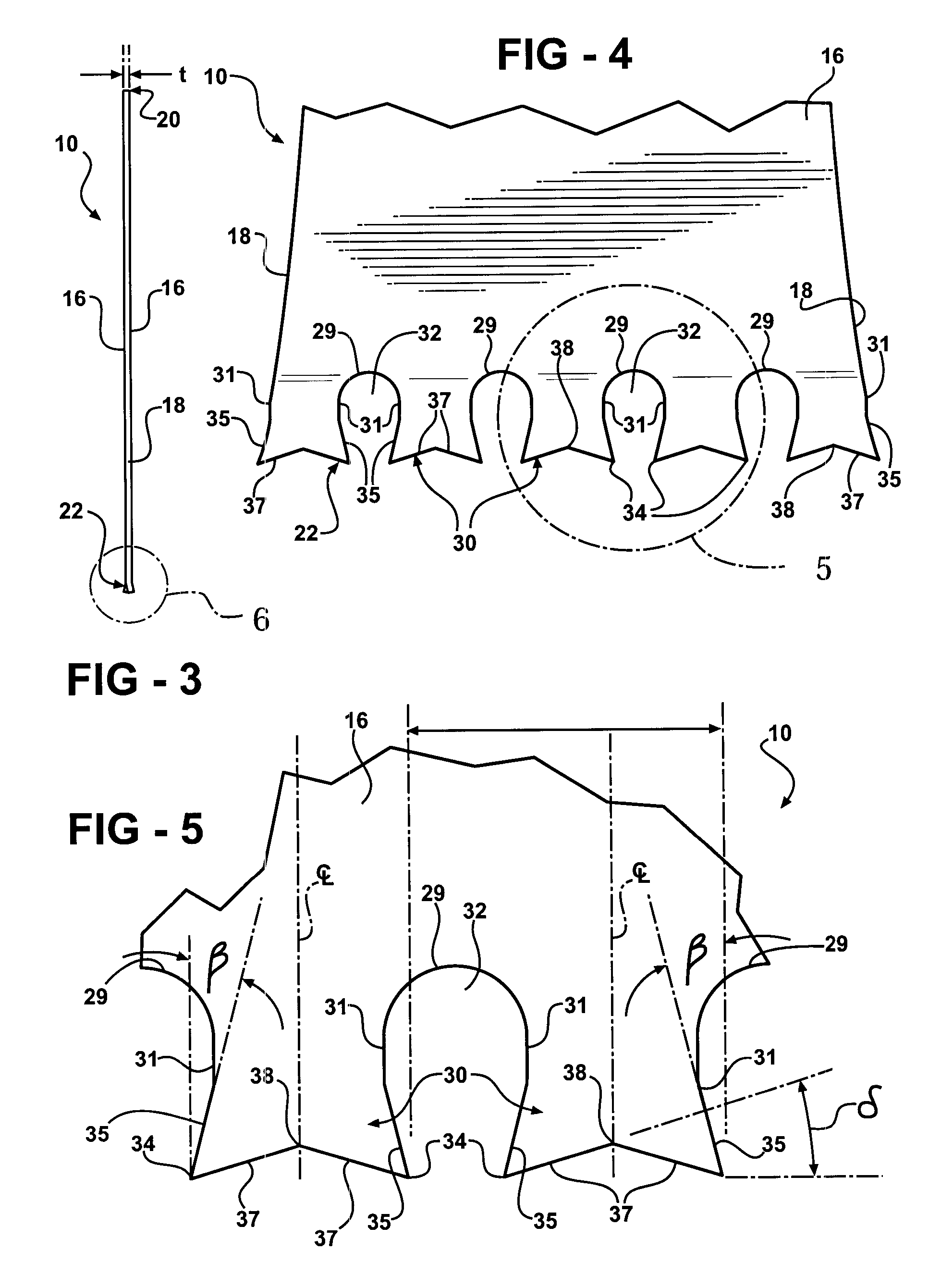

Dual cut surgical saw blade

InactiveUS20060272468A1Less stressEasy to controlMetal sawing devicesMetal sawing toolsEngineeringSurgical saw

A surgical saw blade operatively couples to an oscillatory power tool for oscillation about an oscillation axis (OA). The saw blade includes a plurality of cutting teeth separated from one another by a clean out opening along a distal end. The clean out opening comprises an arcuate closed end and straight side walls extending from the closed end. Each tooth comprises first and second rake surfaces and first and second relief surfaces intersecting to define first and second cutting edges, respectively. The first and second cutting edges are oppositely disposed from one another. One cutting tooth protrudes a distance (de) from one side face of the blade and the next adjacent cutting tooth protrudes the same distance (de) from the other side face of the blade to cut a groove having a width (dg) wider than the thickness (t) of the blade.

Owner:STRYKER CORP

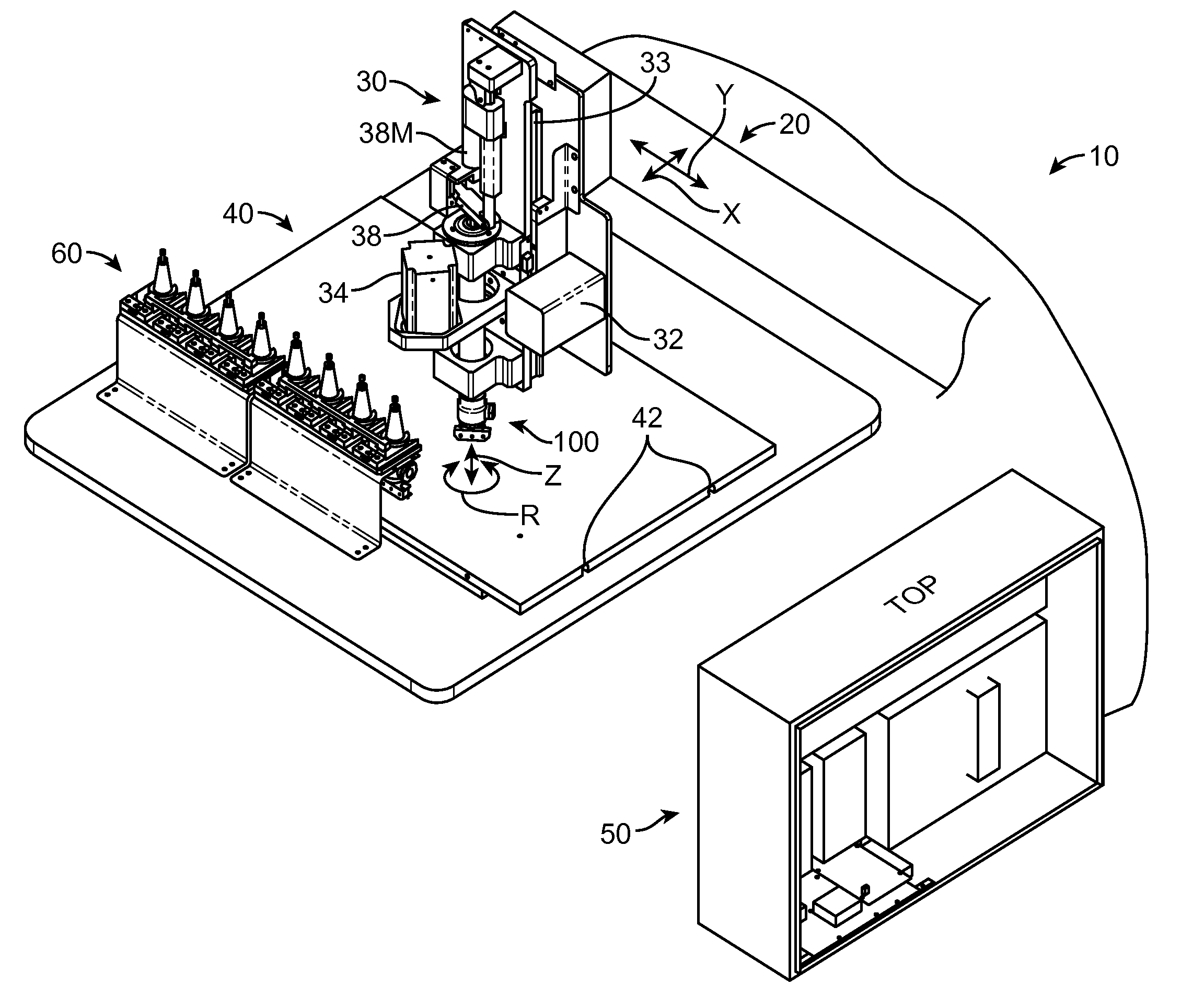

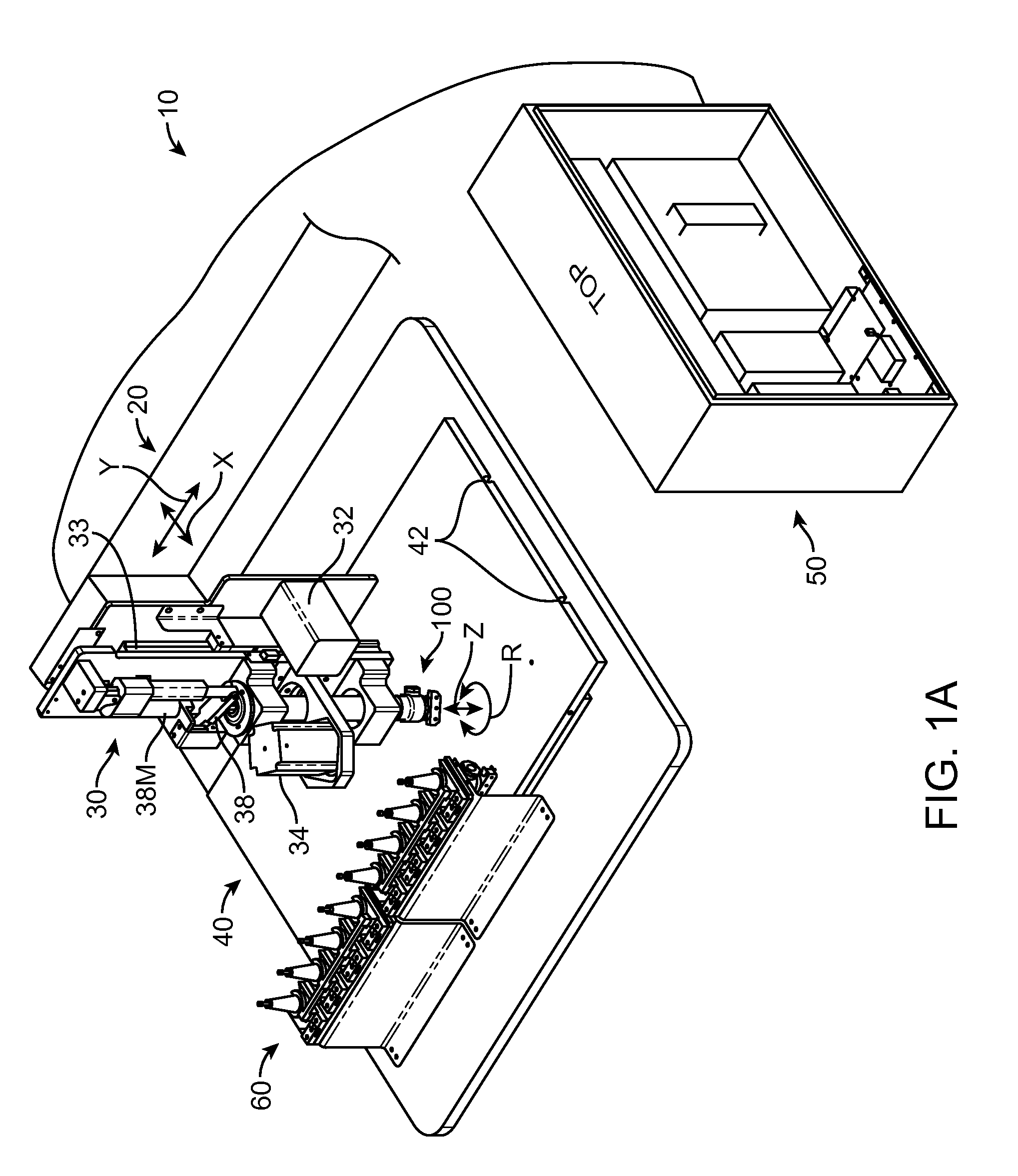

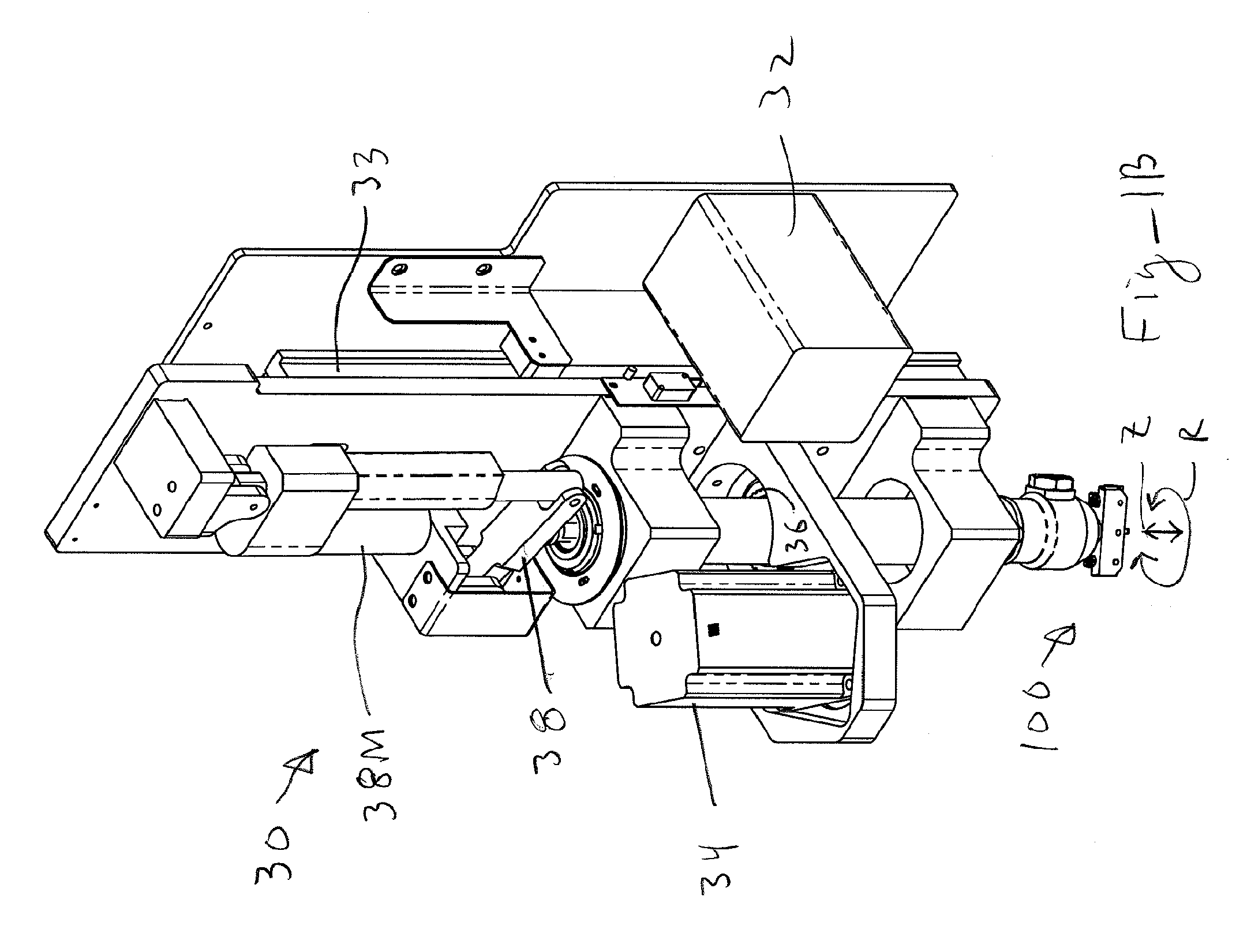

Rapid converting of sheet material methods and apparatus

InactiveUS20120330449A1Speed up the conversion processEasy to understandMetal working apparatusSpecial data processing applicationsEngineeringMachining process

Methods and apparatus provide an input for a user located remote from a cutting machine to cut a part. The user can instruct the cutting machine to cut the part to the user's specification in many ways, for example such that the user can instruct the cutting machine without having knowledge of the machine's cutting processes or construction. The methods and apparatus of the embodiments described herein can convert a machine processes into an image of the part to be cut such that the user can easily view and understand the image of the part to be cut remote from the cutting machine.

Owner:RAPID CONVERTING

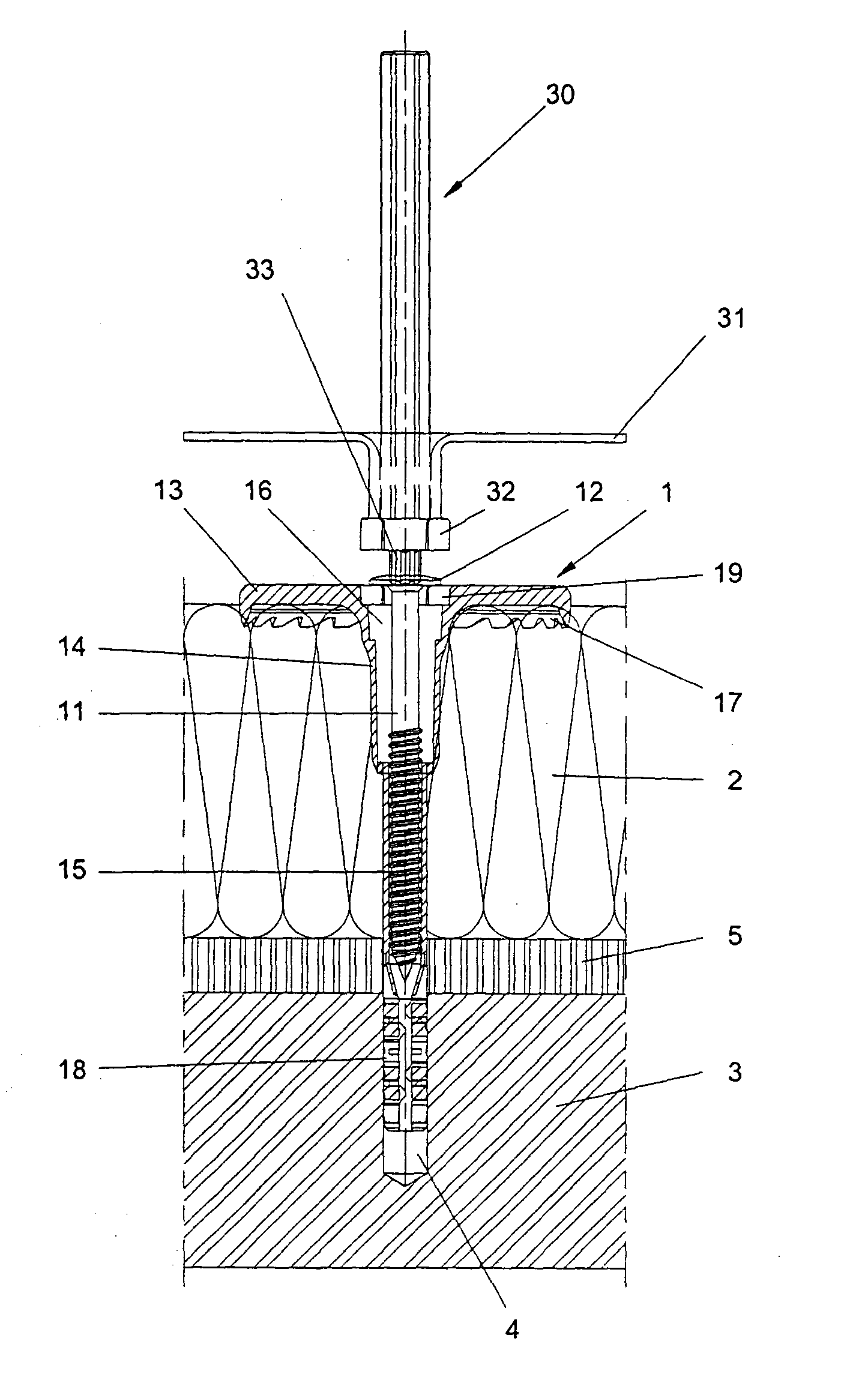

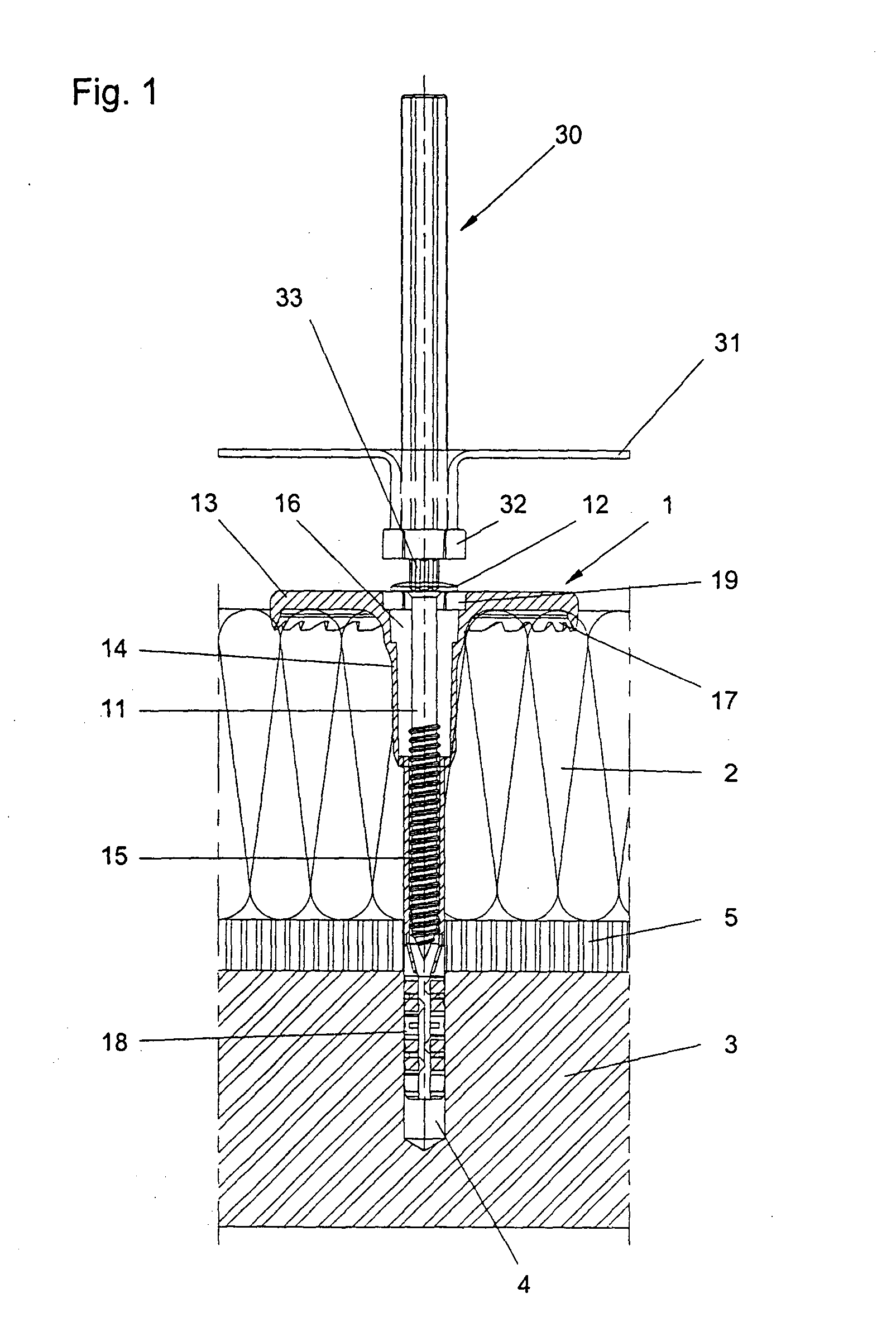

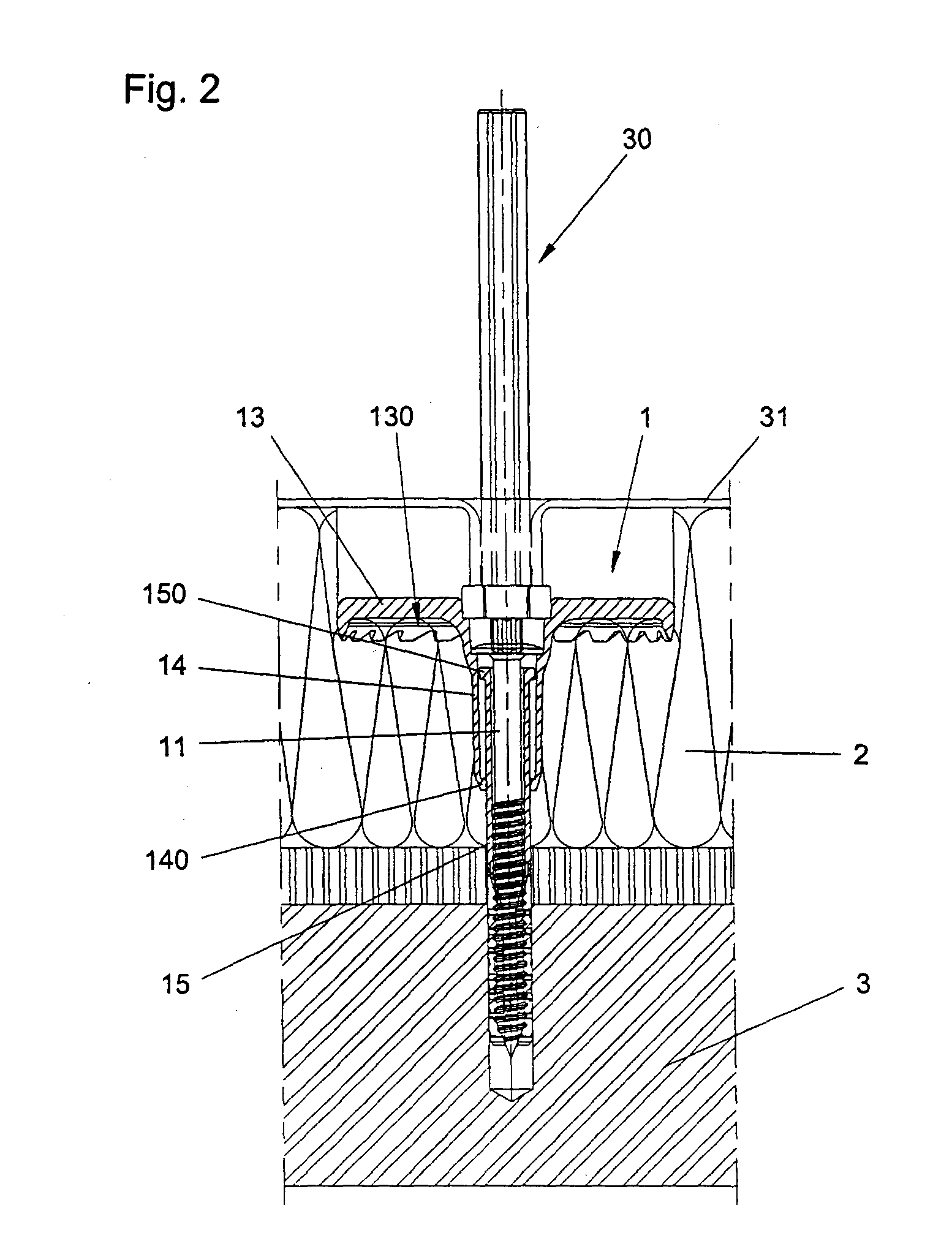

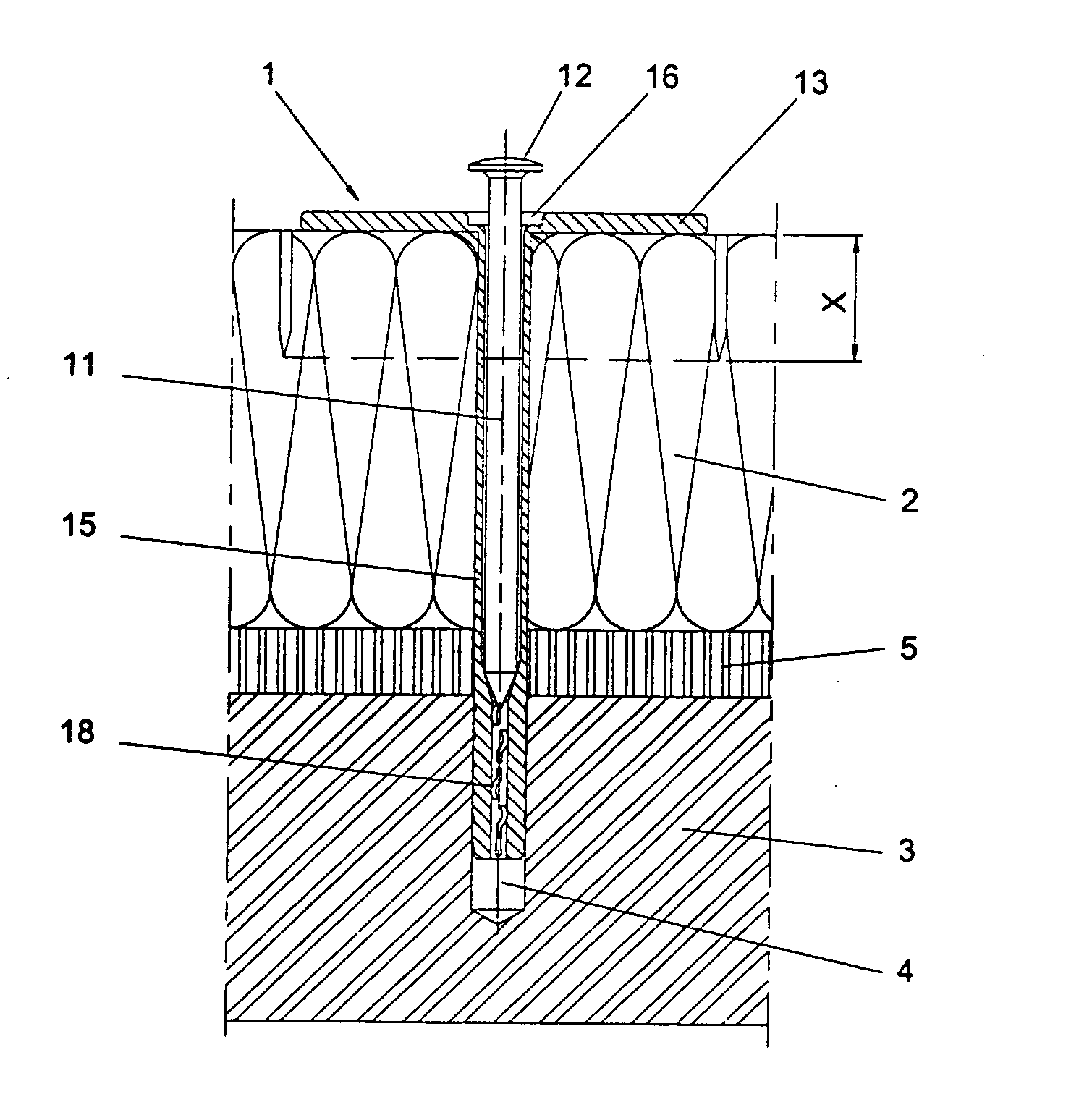

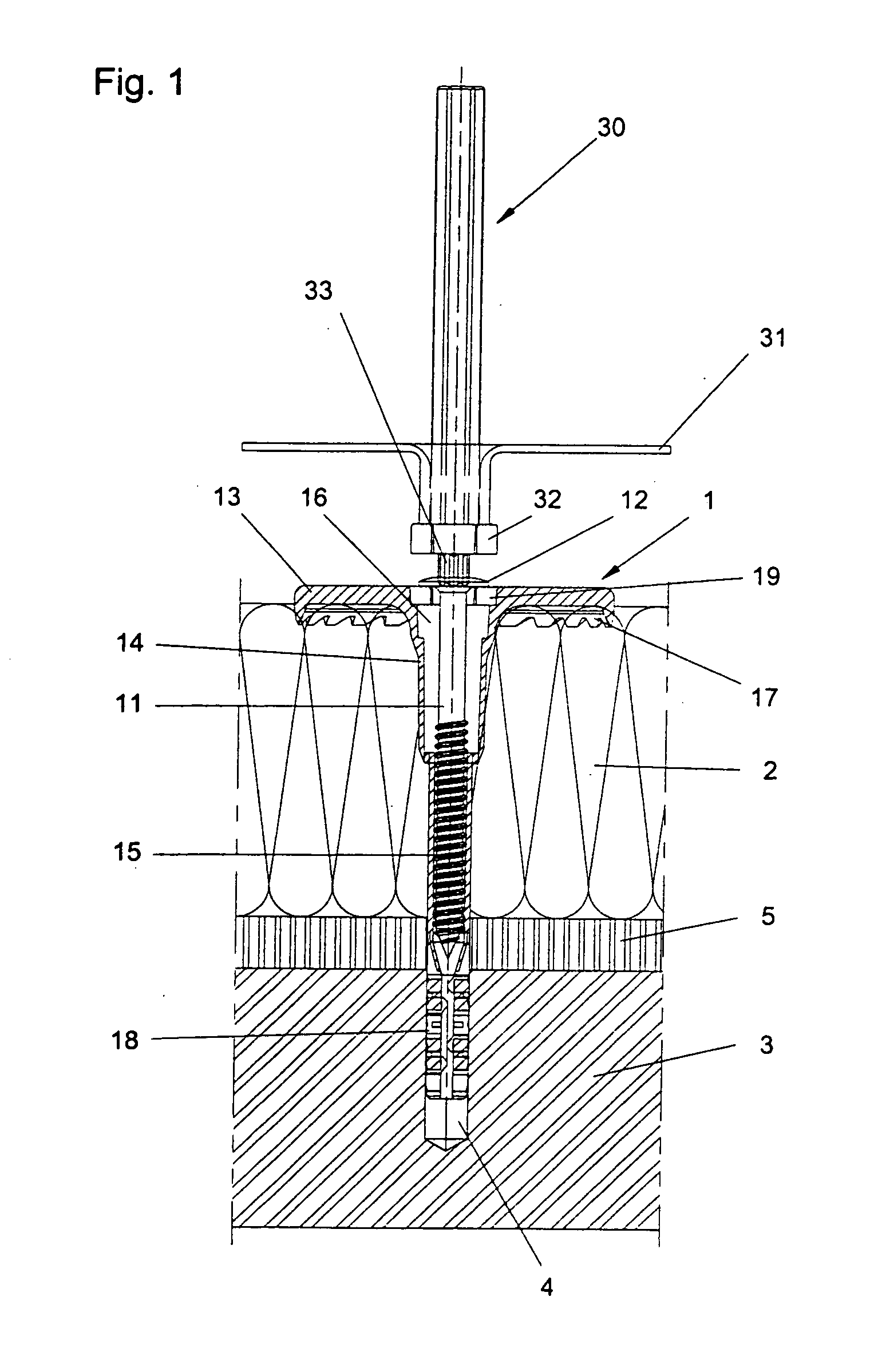

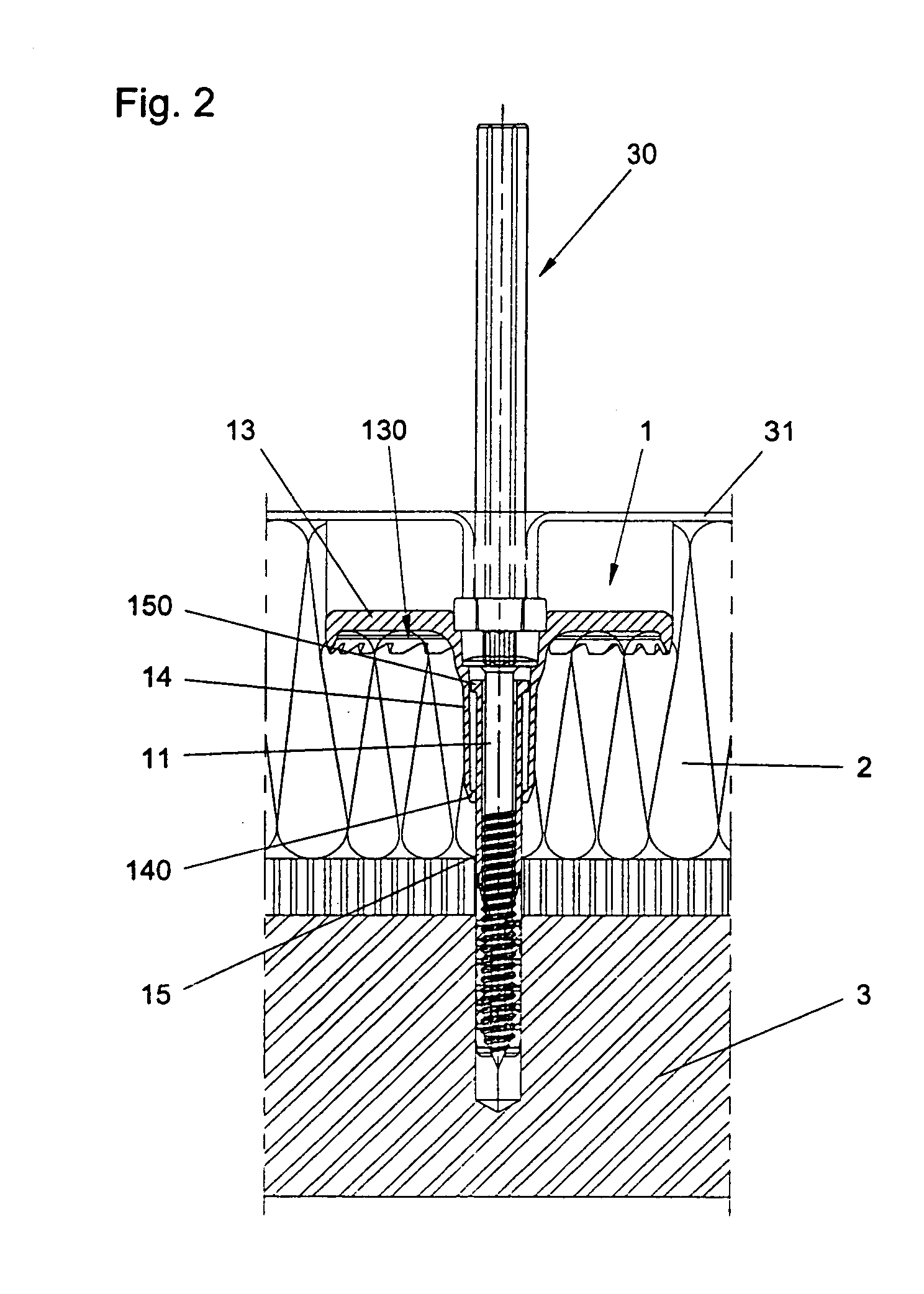

Dowels and methods for the assembly of insulating panels

ActiveUS20050055927A1Avoid environmental pollutionAvoid pollutionDrilling/boring measurement devicesRoof covering using tiles/slatesEngineeringSubstructure

The invention relates to a dowel having cutting devices at the lower side of the pressing plate at the circumference of said pressing plate for cutting into the insulating panel when the pressing plate is pulled into the insulating panel. The invention further relates to a method, in which a bore-hole is drilled through the insulating panel into the substructure, the dowel and the expansion element are inserted into the bore-hole, the expansion element is driven into the pressing plate and the dowel sleeve, and wherein simultaneously the pressing plate is pulled into the insulating panel under compression of the insulating panel, and the insulating panel is cut in at the circumference of the pressing plate by means of cutting devices. The invention further relates to a method in which a bore-hole is drilled trough the insulating panel into the substructure, a circle with at least the radius R is cut into the insulating panel by means of cutting devices, the dowel and the expansion element are inserted into the bore-hole, the expansion element is driven into the pressing plate and the dowel sleeve, and simultaneously the pressing plate is pulled into the insulating panel under compression of the insulating panel.

Owner:EJOT GMBH & CO KB

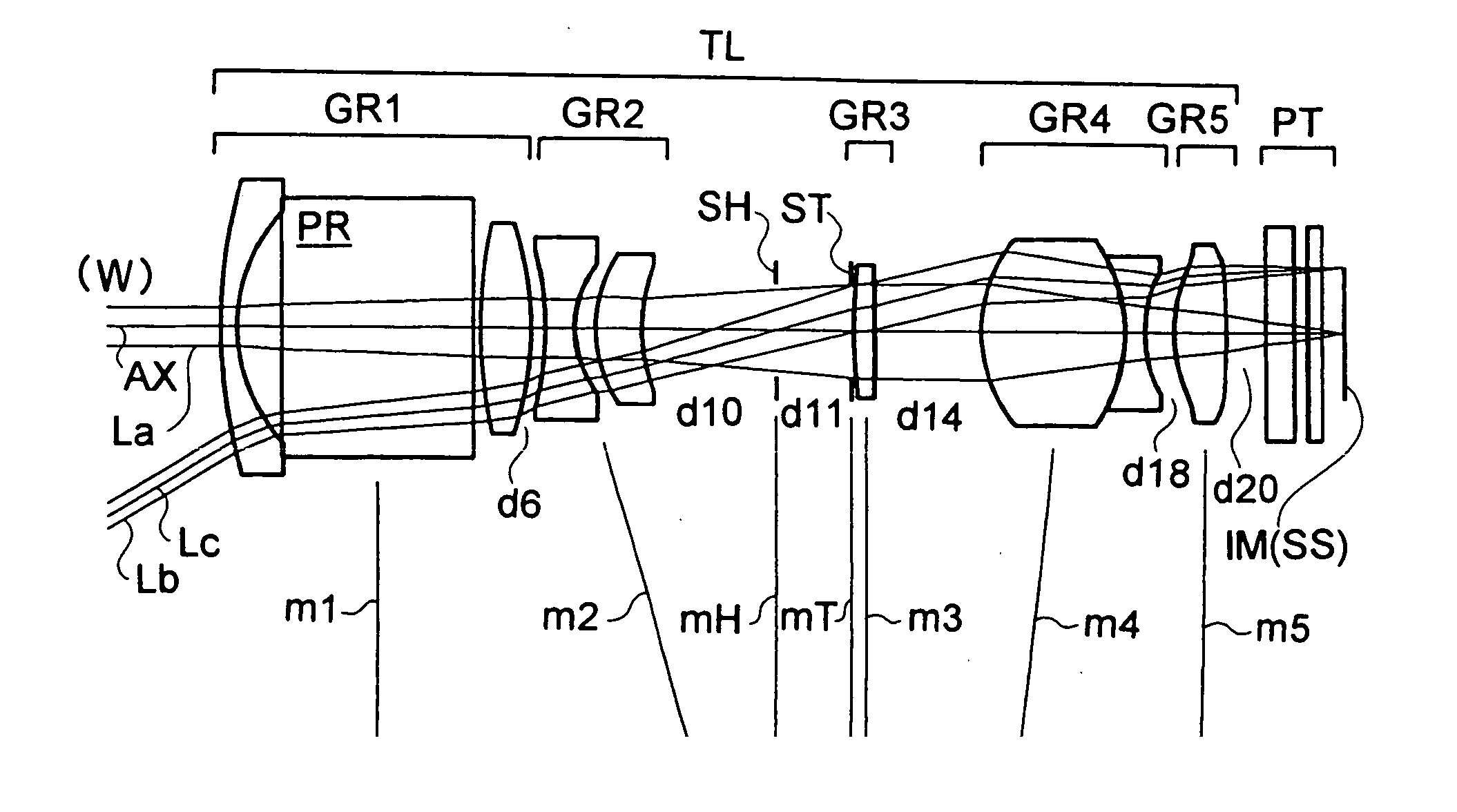

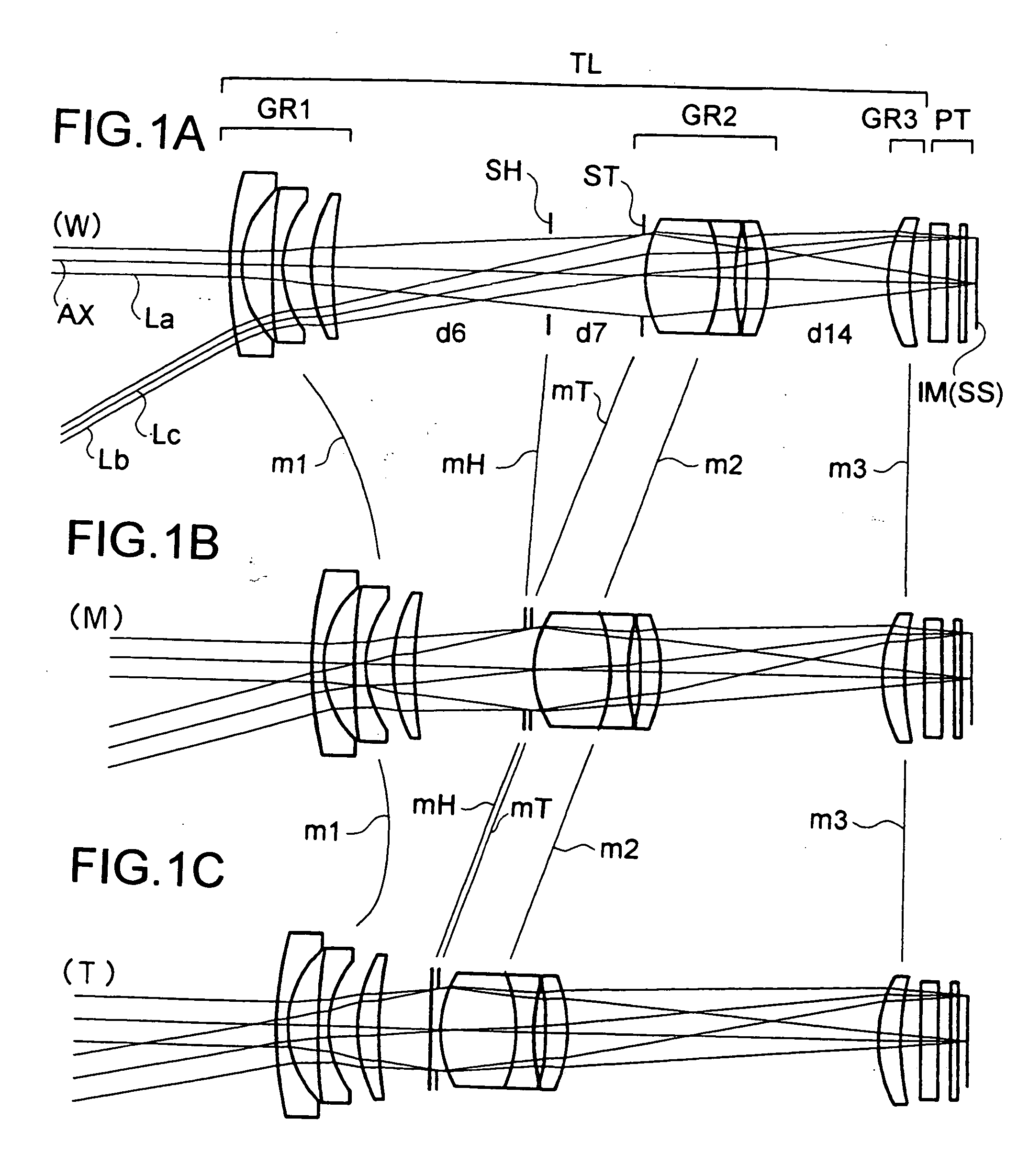

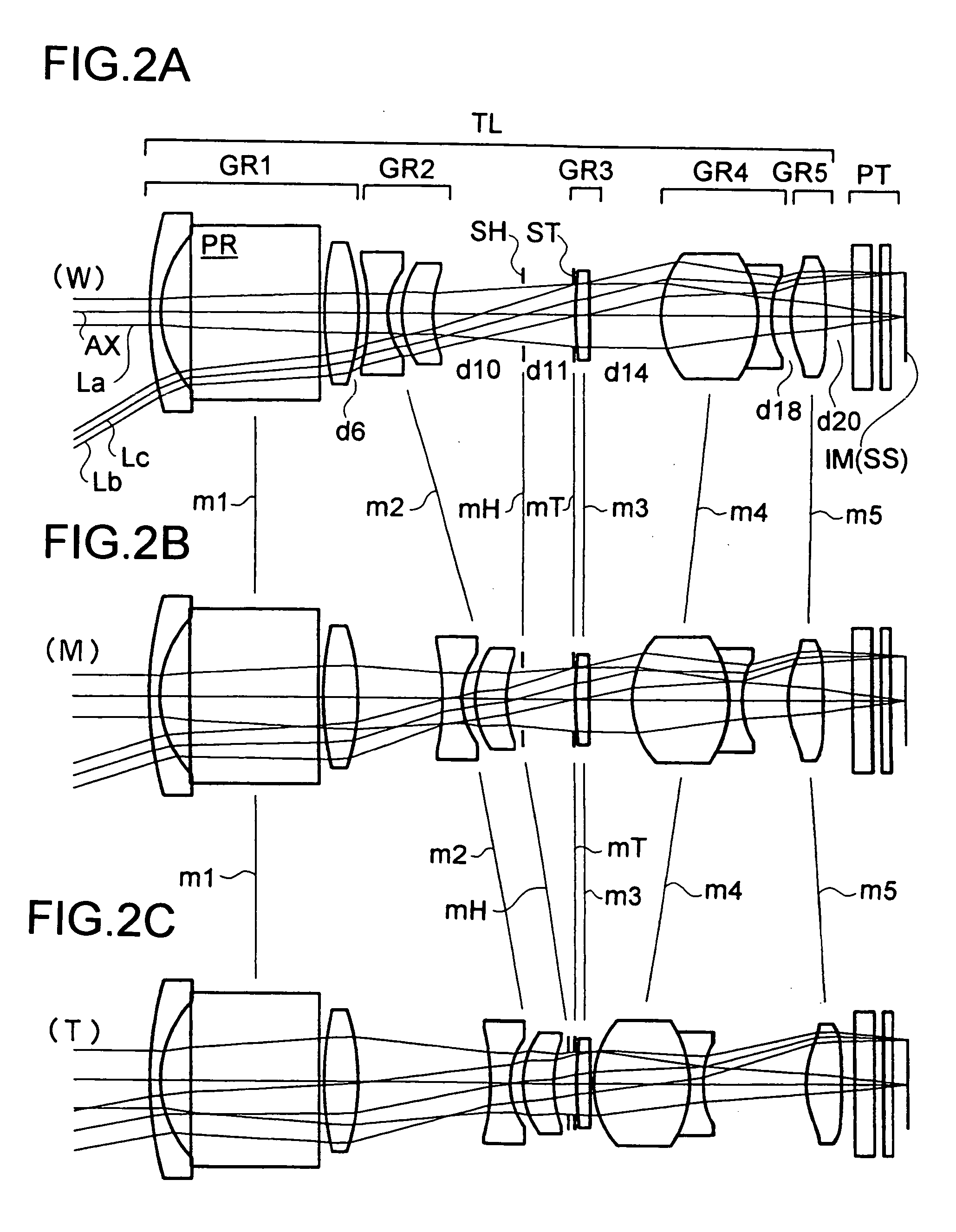

Optical apparatus

InactiveUS20050285970A1Uniform brightnessReduce thicknessTelevision system detailsPrismsOptical axisMagnification

In an optical apparatus provided with: a variable focal length lens system including a plurality of lens units and performing magnification variation by moving at least one lens unit along the optical axis; and an image sensor that converts an optical image formed by the variable focal length lens system into an electric signal, the shutter is disposed to the object side of the most image side lens unit, the aperture stop that determines the f-number is disposed separately from the shutter, and a magnification variation range where the distance between the shutter and the aperture stop varies with magnification variation is provided.

Owner:KONICA MINOLTA PHOTO IMAGING

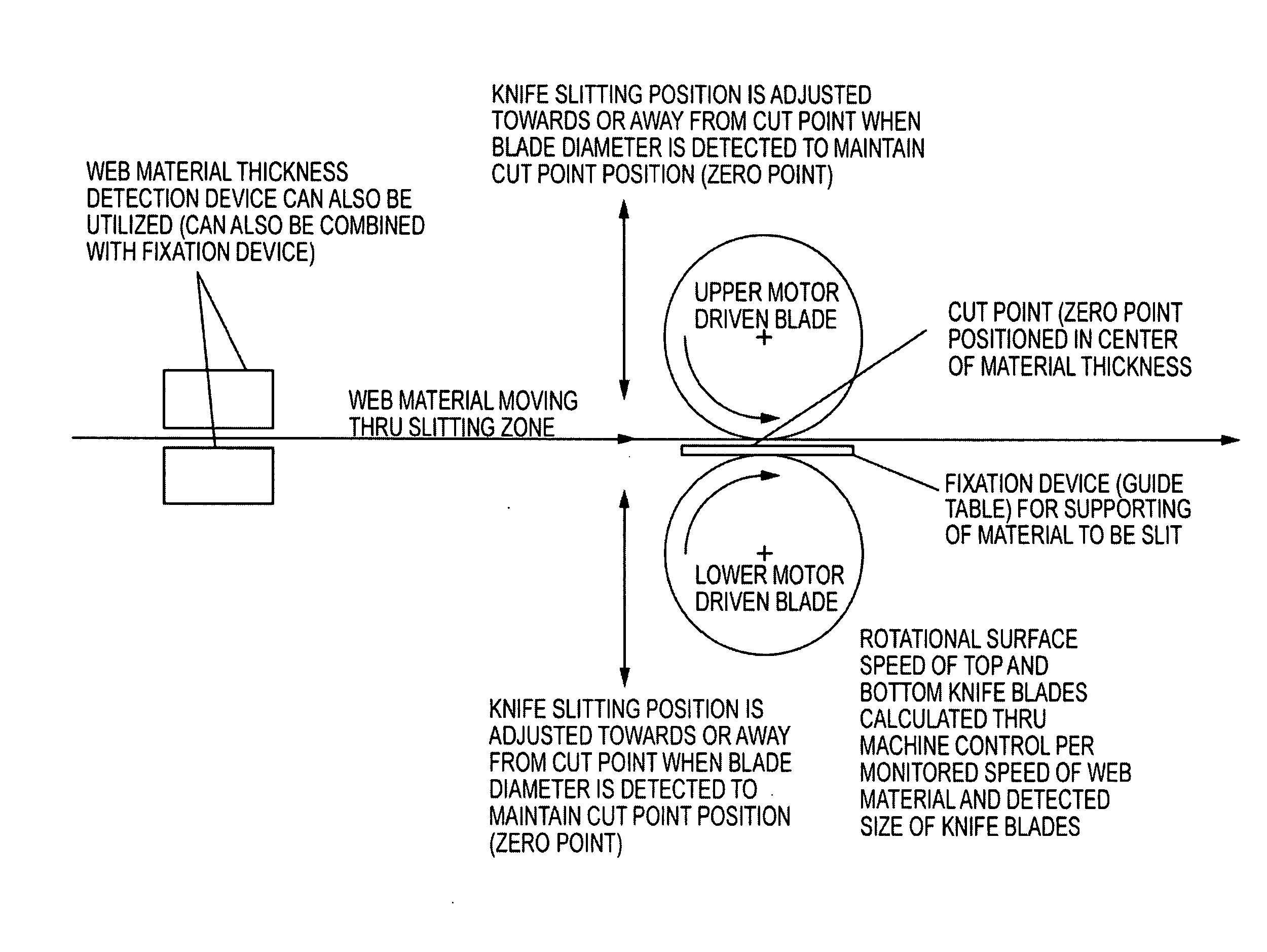

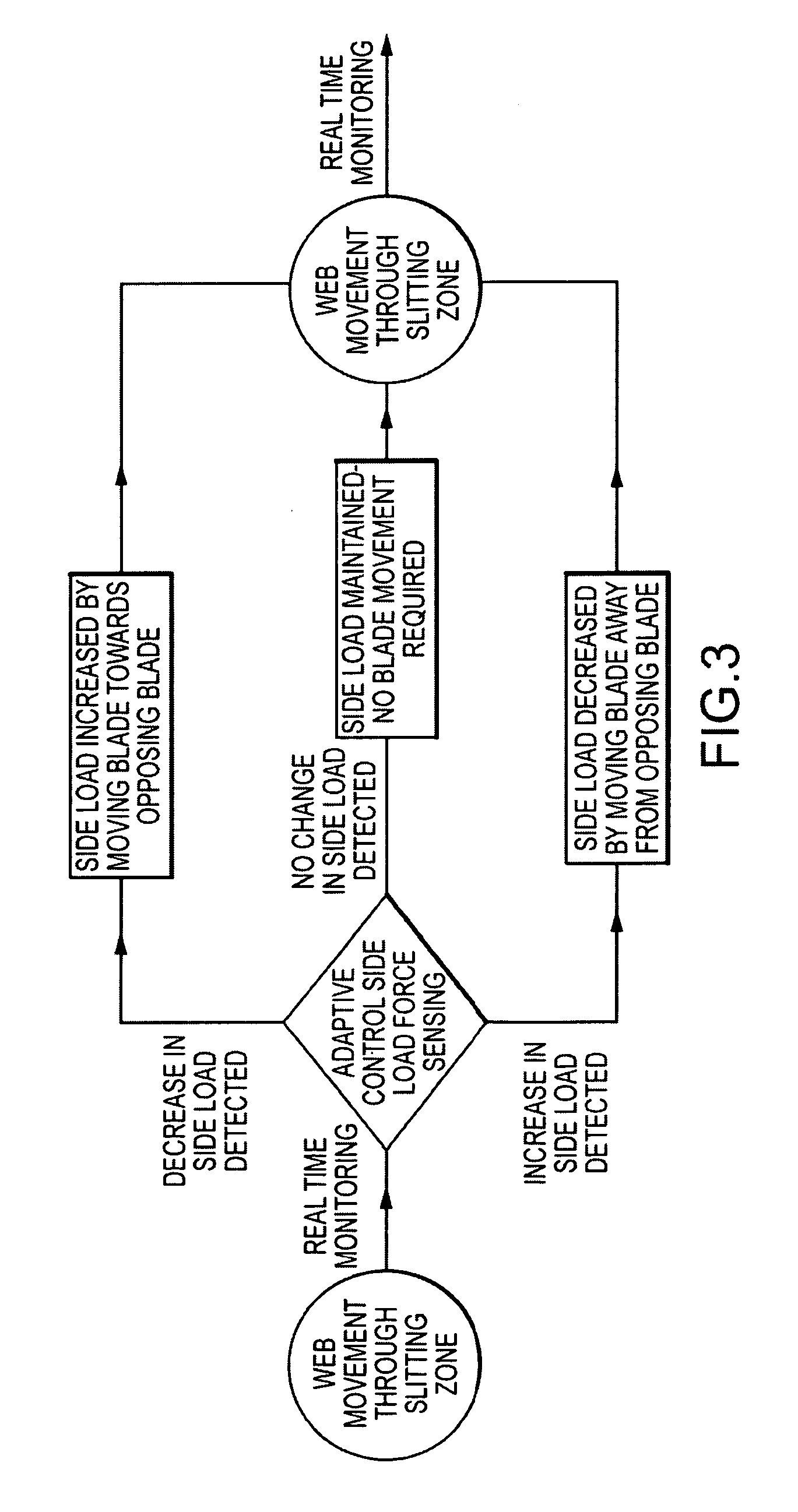

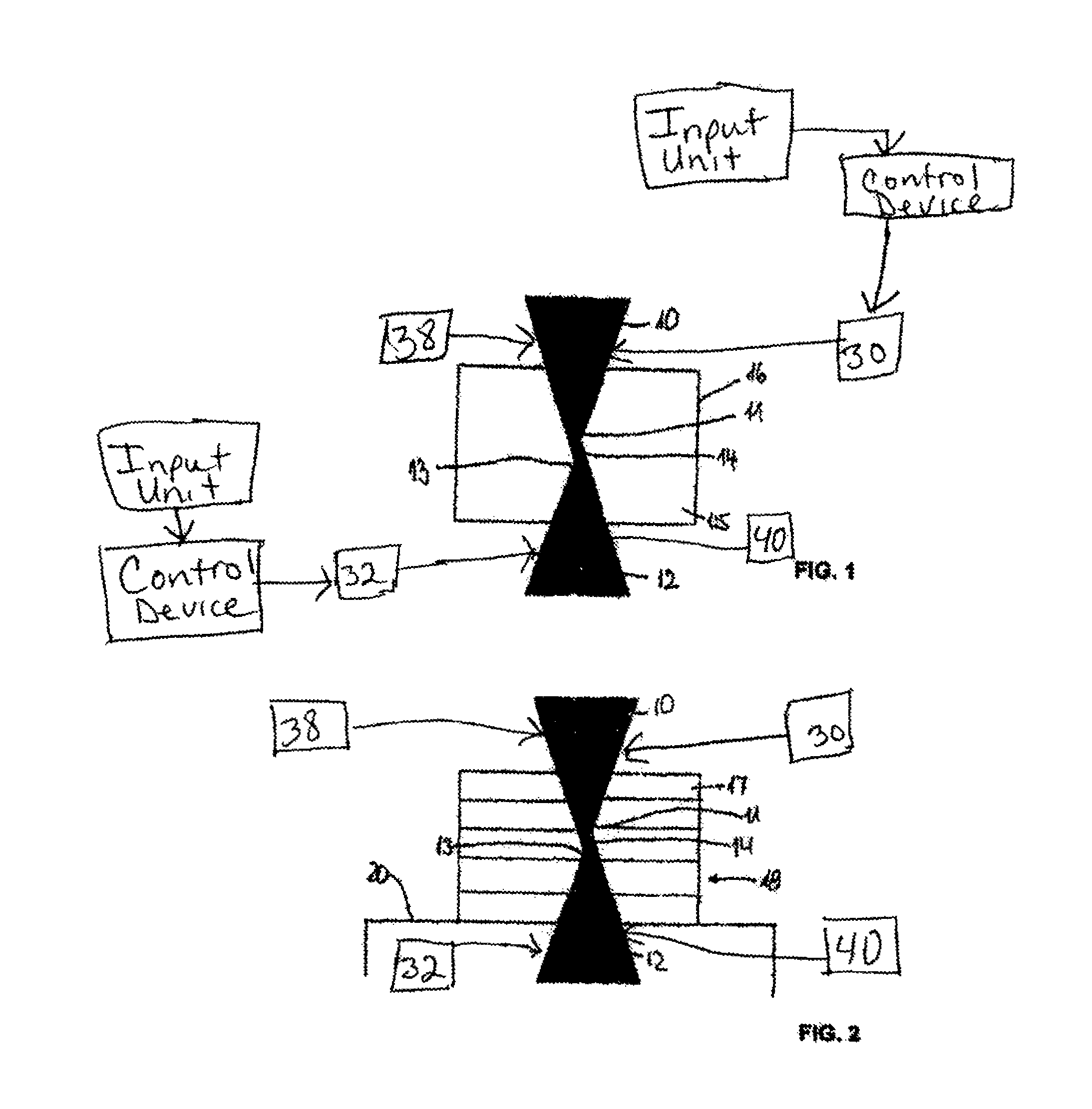

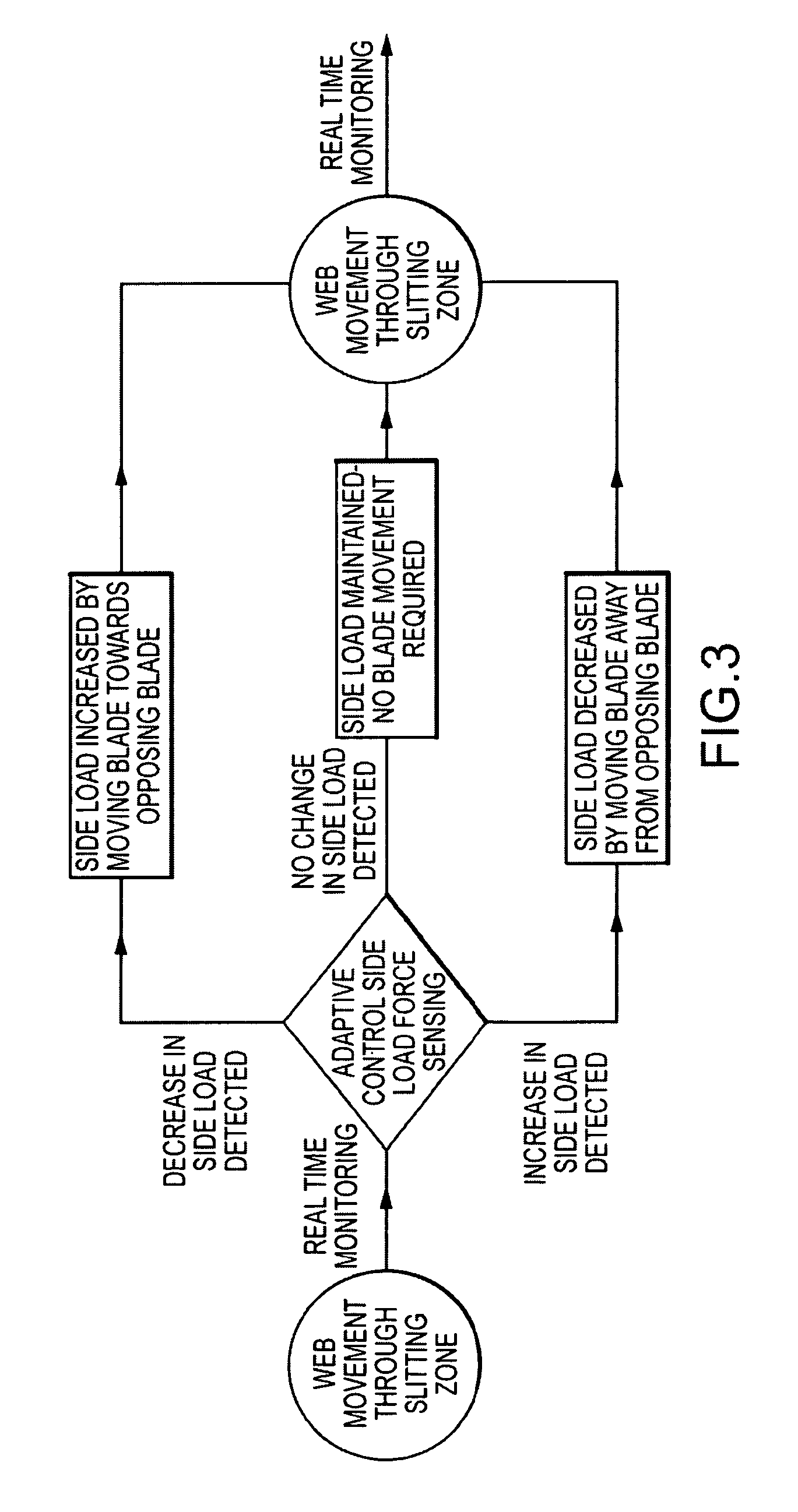

Cutting Arrangement Having a Tip-to-Tip Blade Arrangement

InactiveUS20120132046A1Increasing the thicknessUniform cutAutomatic control devicesShearing machinesDrive motorAdaptive control

A cutting arrangement for longitudinally cutting material includes two blades disposed across from one another and which cooperate during cutting. Each blade is embodied as a circular blade having a sharp cutting edge and supported by an adjusting or placement mechanism. During the cutting process, the circular blades are positioned by the adjusting or placement mechanisms so that the cutting edges overlap one another to form an overlap zone, the center of which coincides with the middle of the material that is to be cut. An adaptive control assembly includes individual drive motors for driving each blade and enables constant side load force control for each blade, such that side load pressures are adjustable in response to changes in web sped, web tension, and blade condition in real time. Automatic blade diameter sensors calculate the zero point of the cut, determine the appropriate blade speed and automatically set the overlap.

Owner:DIENES CORP

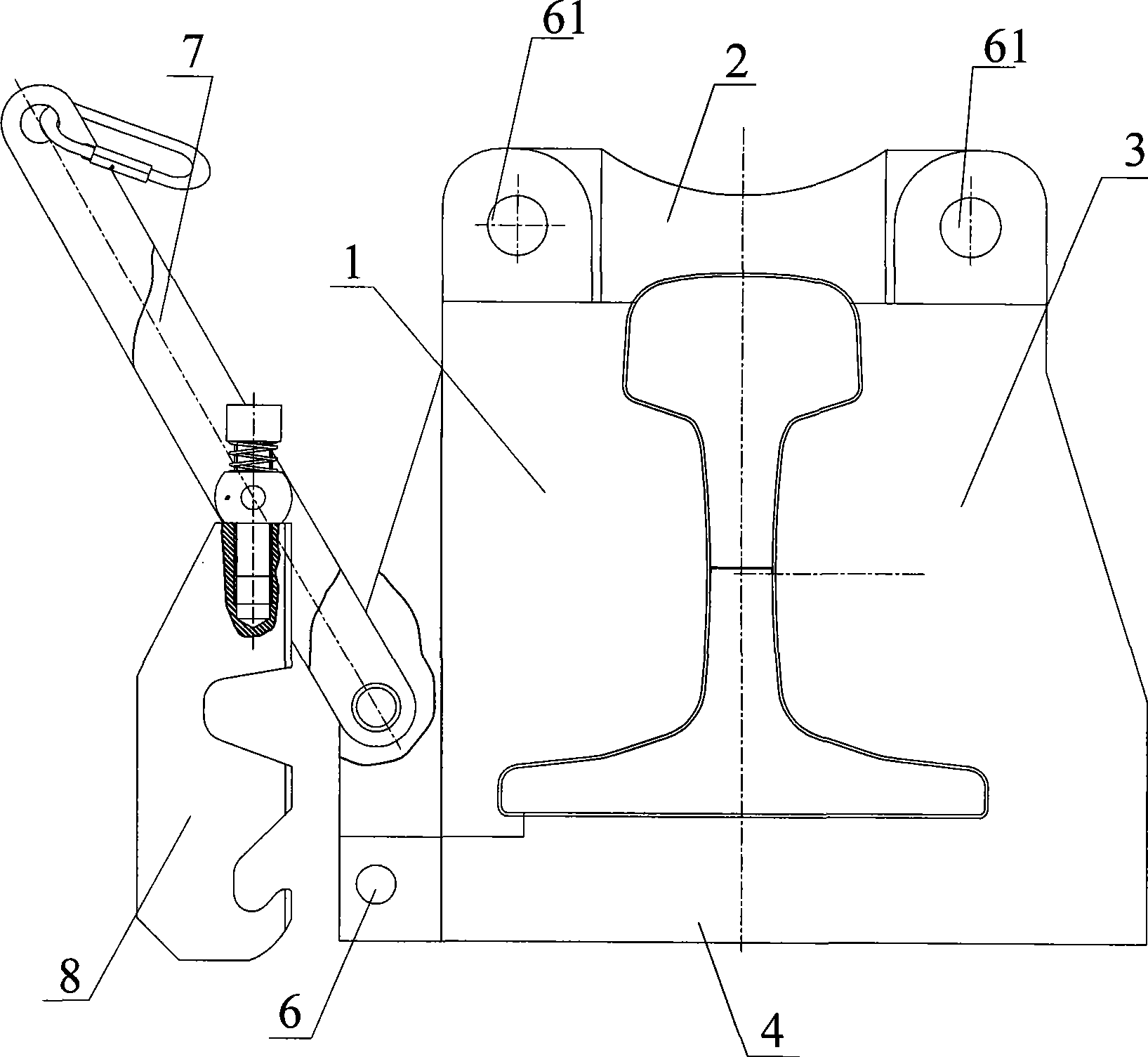

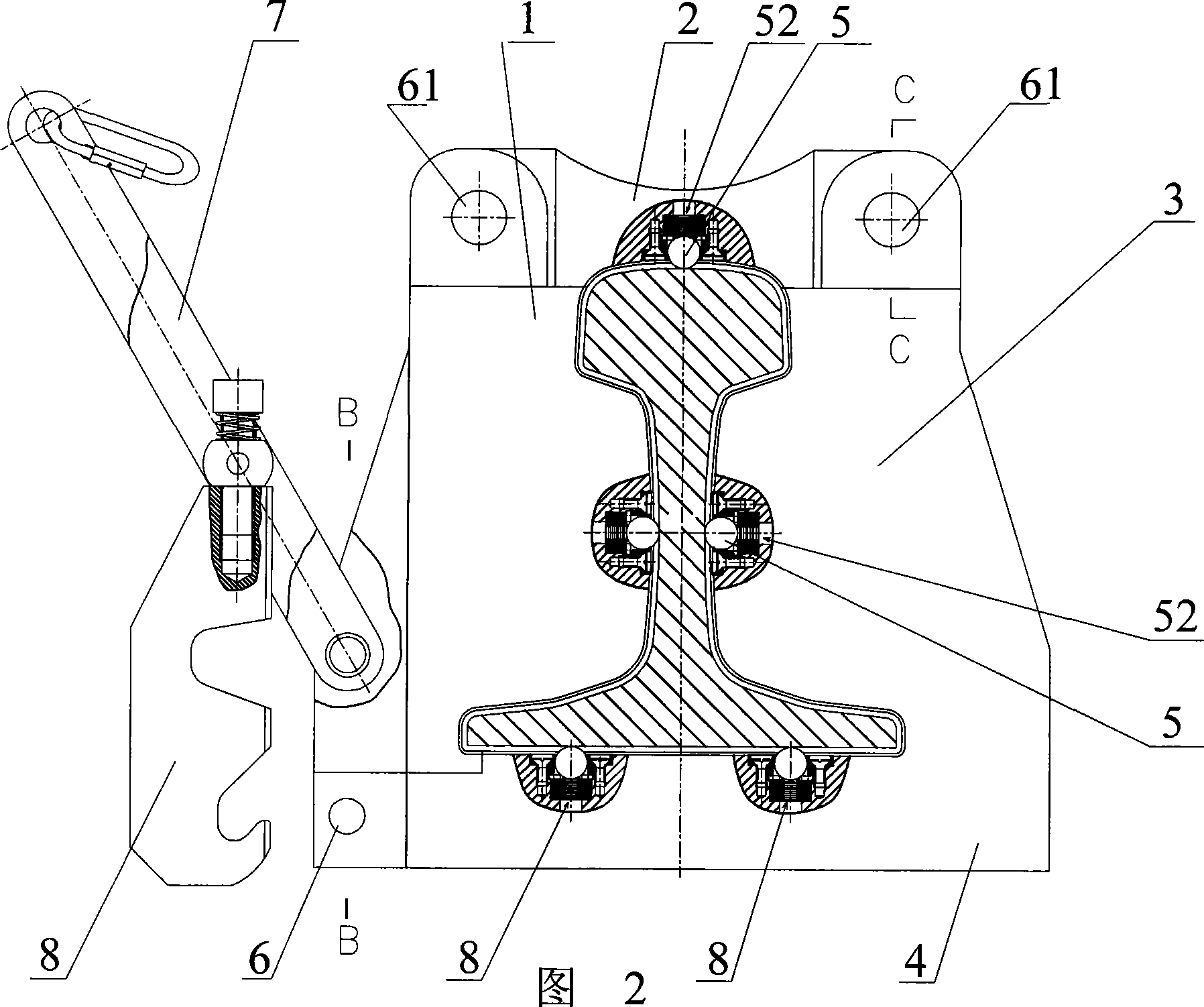

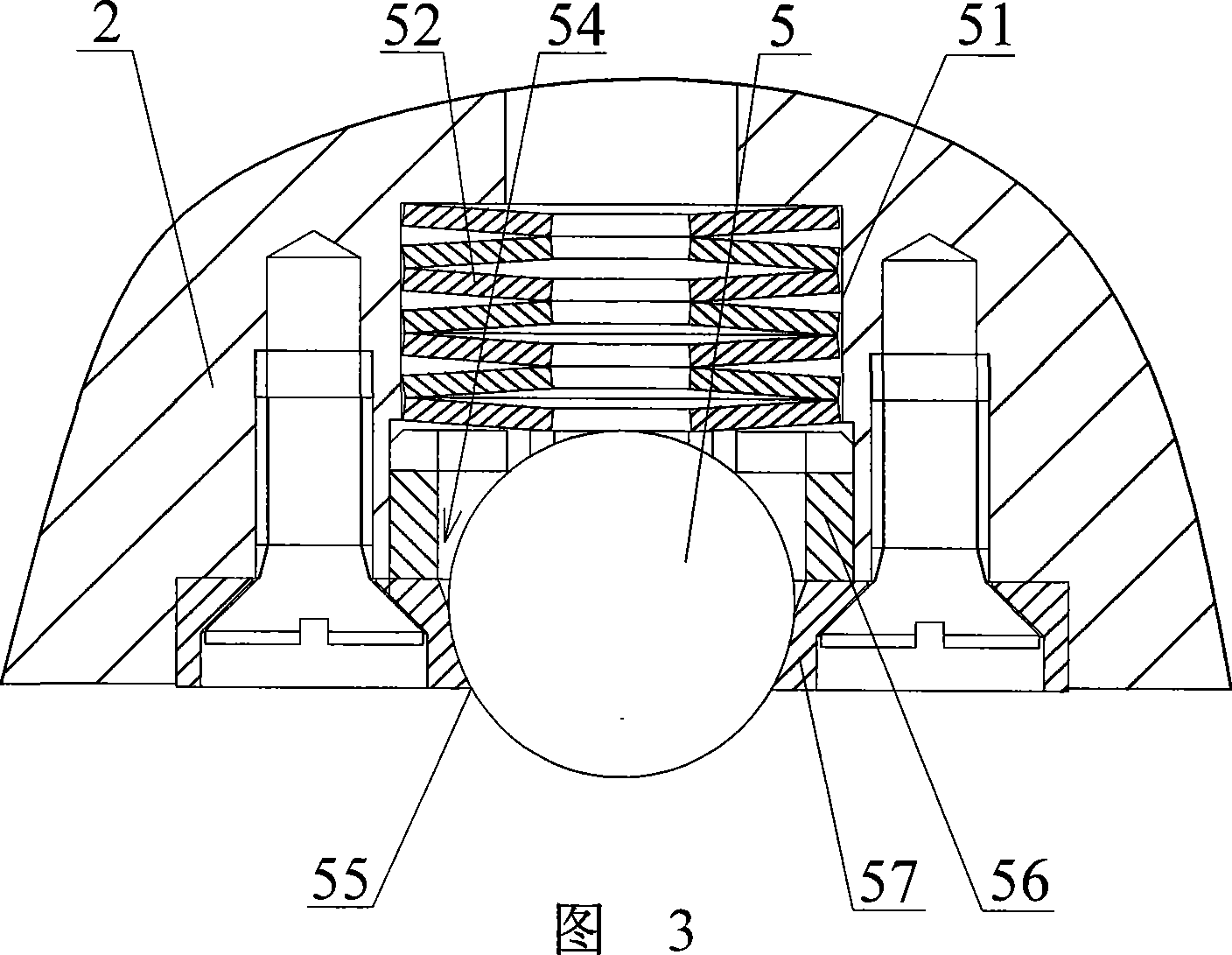

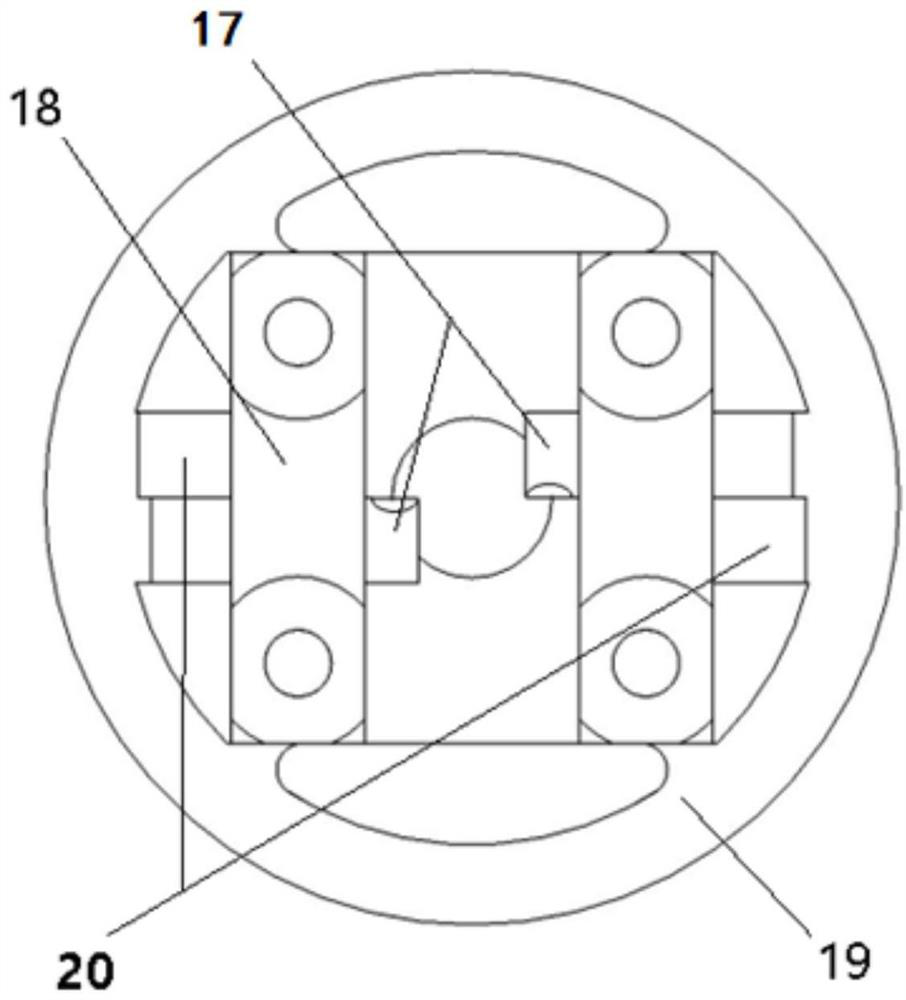

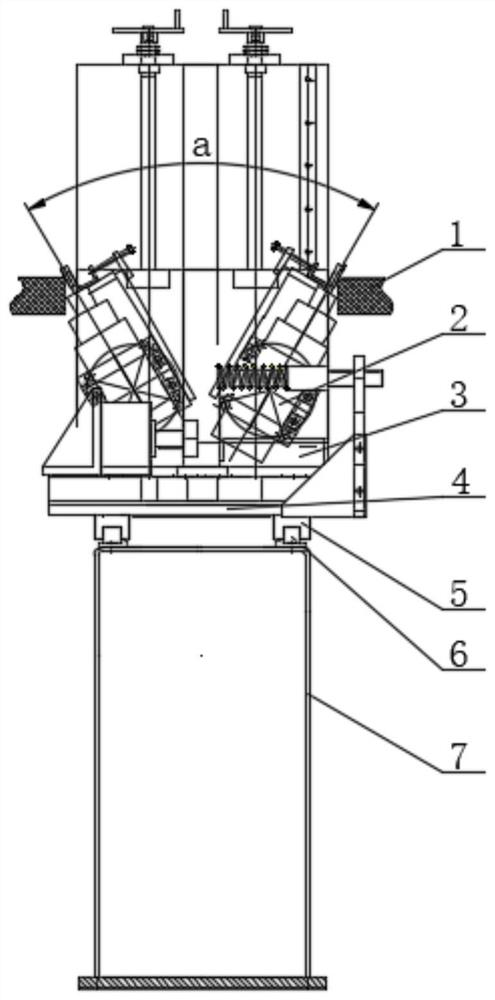

Tumour-pulling knife for removing steel rail welding beading

ActiveCN101428360AExtended service lifeWon't scratchWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismBody positions

The invention relates to a cutting tool, in particular to a knob removing tool used for removing rail welding beading. The invention provides the technical scheme that the knob removing tool for removing welding beading comprises a plurality of cutter bodies and locking mechanisms, which are connected end to end in sequence; wherein, the cutter bodies are mutually hinged end to end in sequence, or at least two adjacent cutter bodies therein are connected into an integrated body, and the other cutter bodies are mutually hinged; wherein, the locking mechanisms which are mutually matched and connected are arranged on the cutter bodies positioned at the front end and the rear end; cutting edges are arranged on the cutter bodies, after the cutter bodies positioned at the front end and at the rear end are mutually connected and locked, a section shape of the rail consists of the cutting edges of the cutter bodies, and the cutter bodies after locking comprise a left cutter body, a top cutter body, a right cutter body and a bottom cutter body. The knob removing tool is characterized in that a mounting hole is formed in the top cutter body, and a positioning component is mounted in the mounting hole, which is partially higher than the cutting edge of the top cutter body. The knob removing tool has the advantages that the main body of the rail can be not damaged in the knob removing process, the polishing quantity for workers is reduced, and the service life can be also prolonged.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Dowels and methods for the assembly of insulating panels

ActiveUS20050147465A1Avoid environmental pollutionAvoid pollutionDrilling/boring measurement devicesCovering/liningsSubstructureDowel

The invention relates to a dowel having cutting devices at the lower side of the pressing plate at the circumference of said pressing plate for cutting into the insulating panel when the pressing plate is pulled into the insulating panel. The invention further relates to a method, in which a bore-hole is drilled through the insulating panel into the substructure, the dowel and the expansion element are inserted into the bore-hole, the expansion element is driven into the pressing plate and the dowel sleeve, and wherein simultaneously the pressing plate is pulled into the insulating panel under compression of the insulating panel, and the insulating panel is cut in at the circumference of the pressing plate by means of cutting devices. The invention further relates to a method in which a bore-hole is drilled trough the insulating panel into the substructure, a circle with at least the radius R is cut into the insulating panel by means of cutting devices, the dowel and the expansion element are inserted into the bore-hole, the expansion element is driven into the pressing plate and the dowel sleeve, and simultaneously the pressing plate is pulled into the insulating panel under compression of the insulating panel.

Owner:EJOT GMBH & CO KB

Cutting arrangement having a tip-to-tip blade arrangement

InactiveUS8707838B2Increasing the thicknessUniform cutAutomatic control devicesShearing machinesOverlap zoneDrive motor

A cutting arrangement for longitudinally cutting material includes two blades disposed across from one another and which cooperate during cutting. Each blade is embodied as a circular blade having a sharp cutting edge and supported by an adjusting or placement mechanism. During the cutting process, the circular blades are positioned by the adjusting or placement mechanisms so that the cutting edges overlap one another to form an overlap zone, the center of which coincides with the middle of the material that is to be cut. An adaptive control assembly includes individual drive motors for driving each blade and enables constant side load force control for each blade, such that side load pressures are adjustable in response to changes in web sped, web tension, and blade condition in real time. Automatic blade diameter sensors calculate the zero point of the cut, determine the appropriate blade speed and automatically set the overlap.

Owner:DIENES CORP

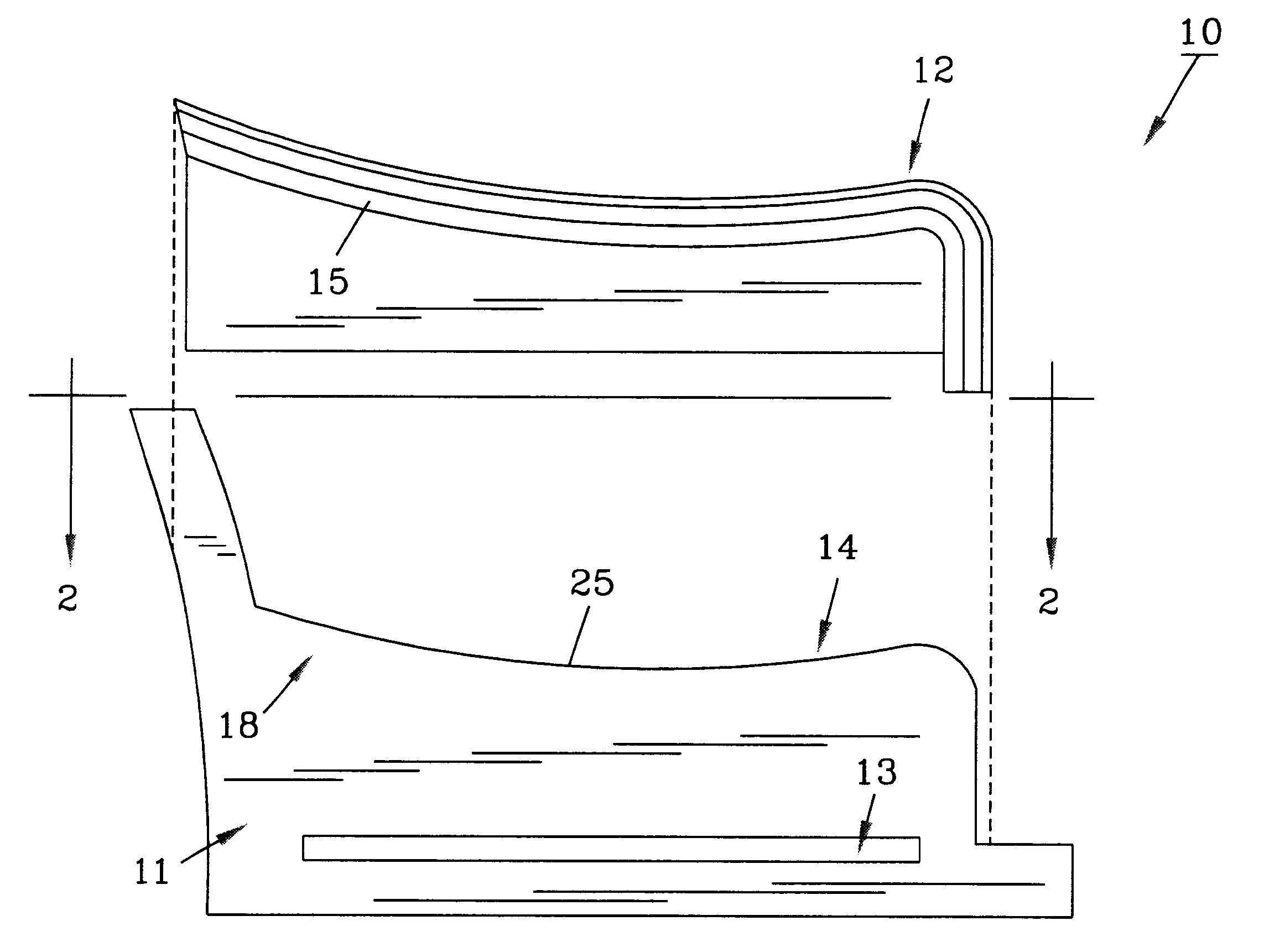

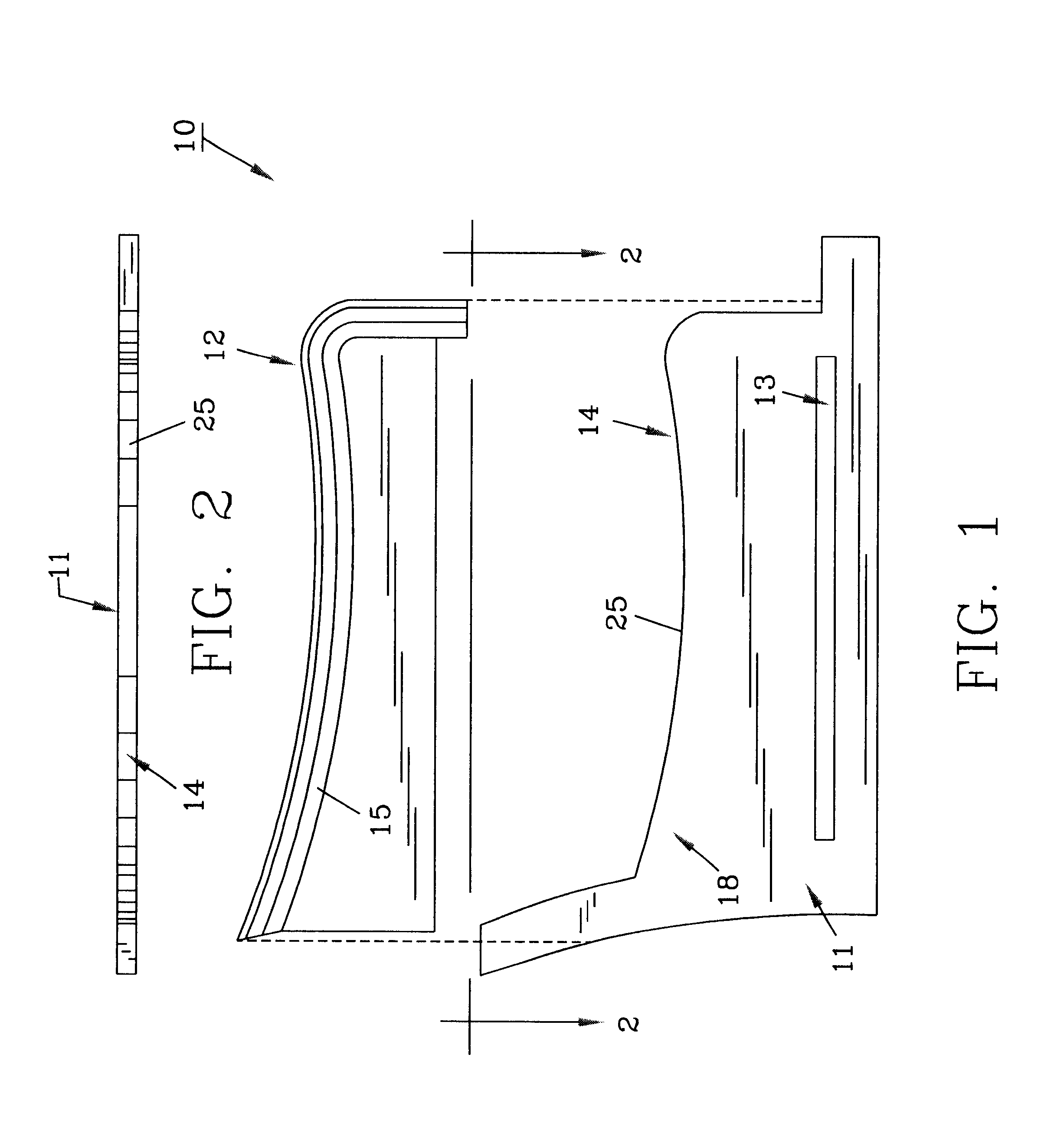

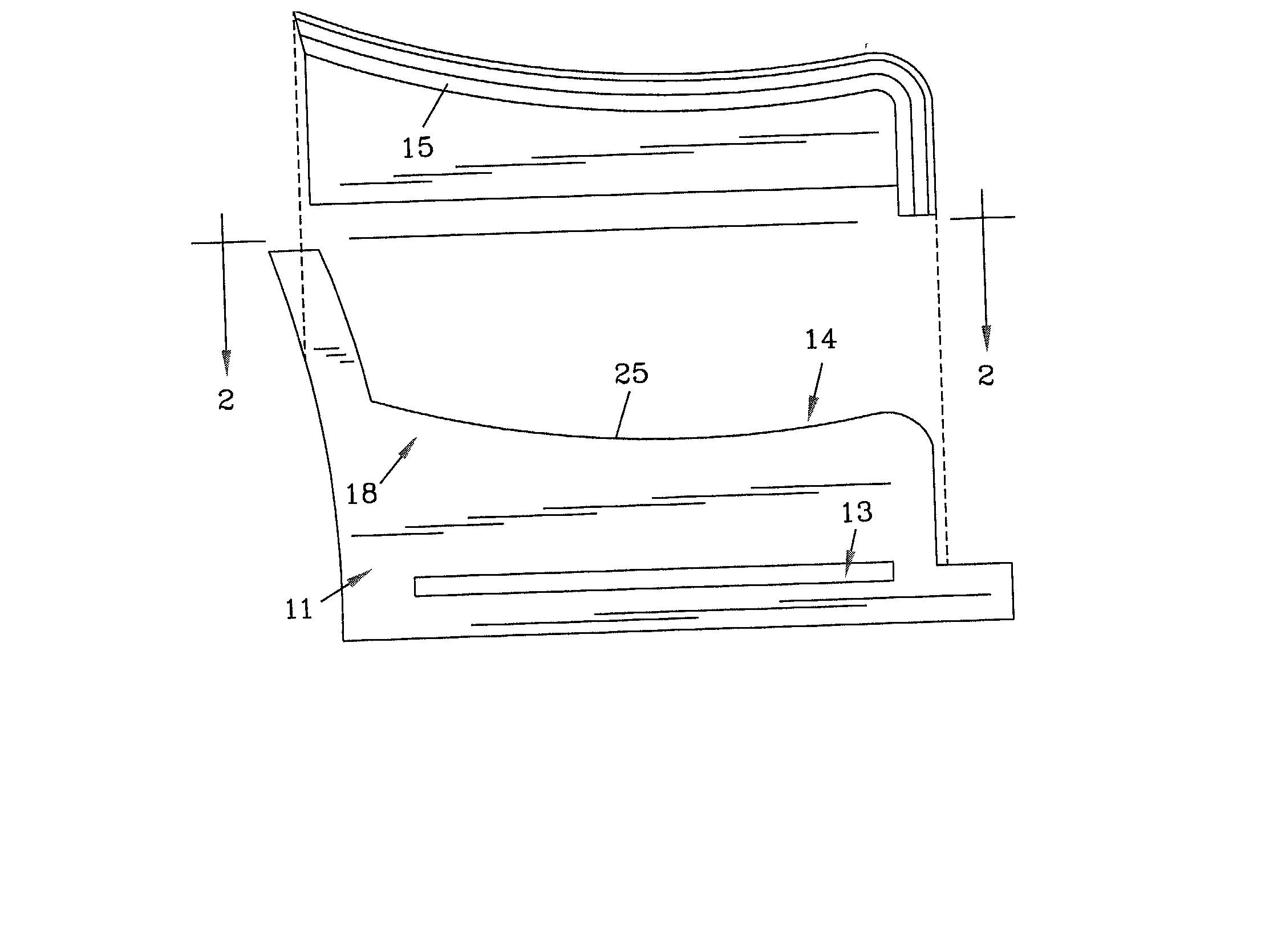

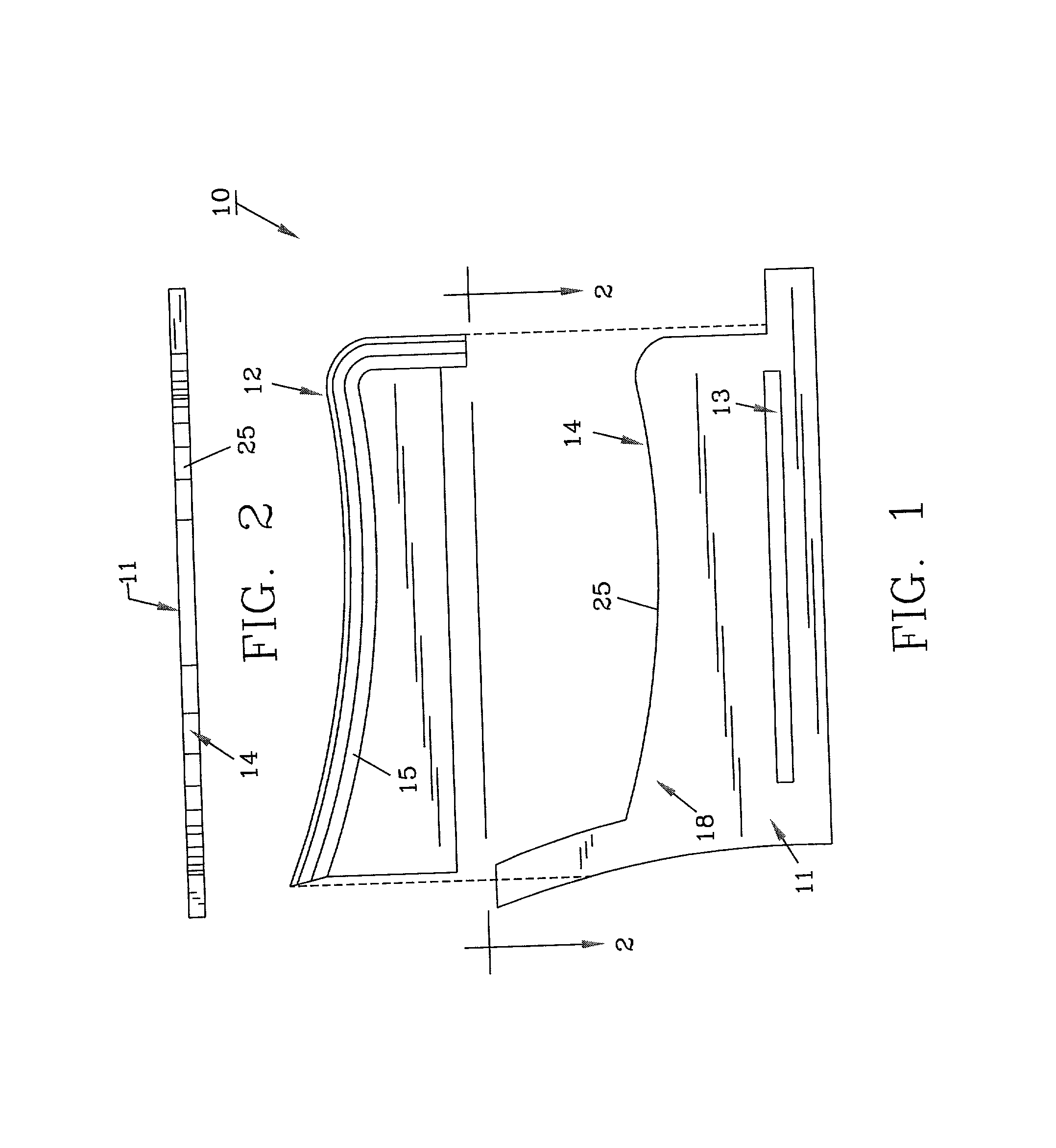

Furniture construction and method

InactiveUS6726284B2Different partEasy to installVehicle seatsStuffed mattressesEngineeringUpholstered furniture

Owner:CLEARY BOBBY D

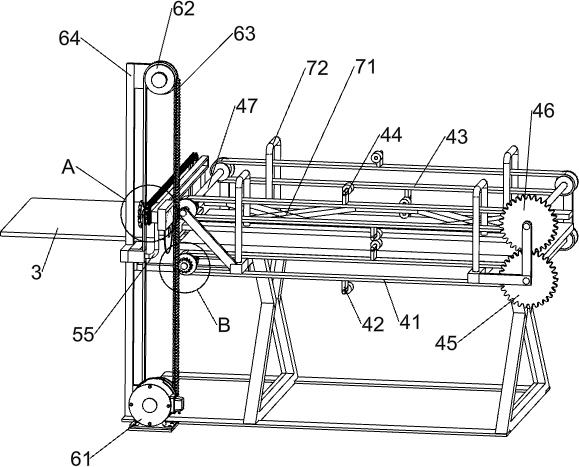

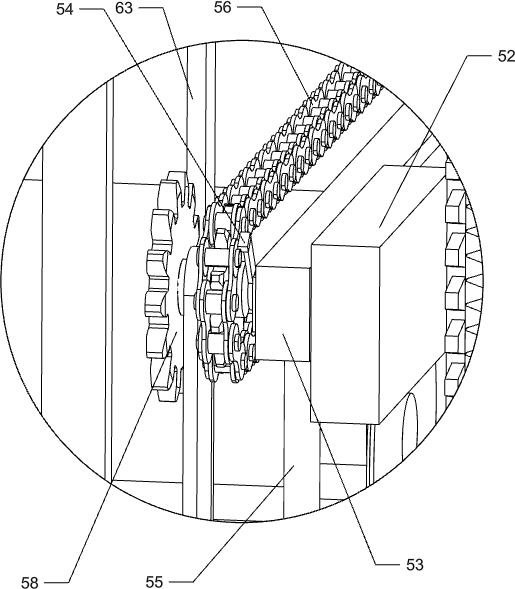

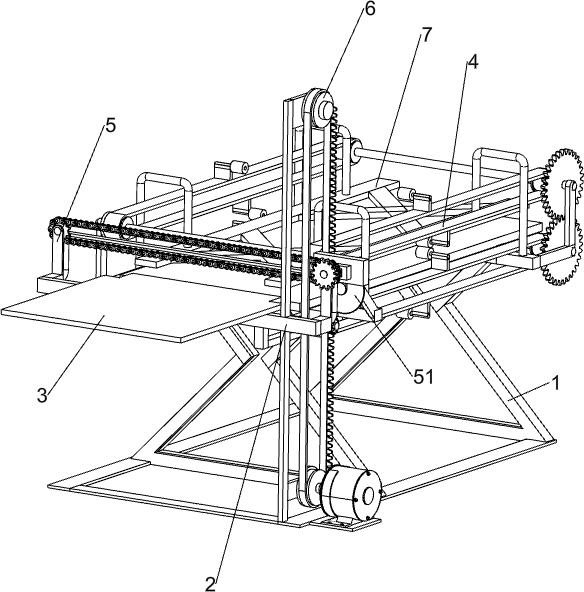

Cloth cutting device for garment processing

ActiveCN111749003AUniform cutImprove cutting efficiencySevering textilesConveyor beltCotton material

The invention relates to a cutting device, in particular to a cloth cutting device for garment processing. The technical problem to be solved by the invention is how to provide the cloth cutting device for garment processing, which is capable of uniformly cutting cloth, saving time and labor and improving the cutting efficiency. In order to above the technical problem, the invention provides a cloth cutting device for garment processing; the cutting device comprises a base, a material placing plate, a cutting mechanism, and a material moving mechanism, wherein the mounting frame is connected to one side of the upper portion of the base; the material placing plate is connected to the end part of the mounting frame; the cutting mechanism is arranged at one side of the mounting frame; and thematerial moving mechanism is arranged between the inner side surface at the upper portion of the base. The cloth can be clamped through mutual cooperation of a first material clamping rod and a second material clamping rod, a first conveyor belt rotates clockwise, a second conveyor belt rotates counter-clockwise, the cloth can be pulled out through the cooperation of the first material clamping rod and the first material clamping rod, and a cutting machine moves backward to cut the cloth.

Owner:东莞市珠峰信息科技有限公司

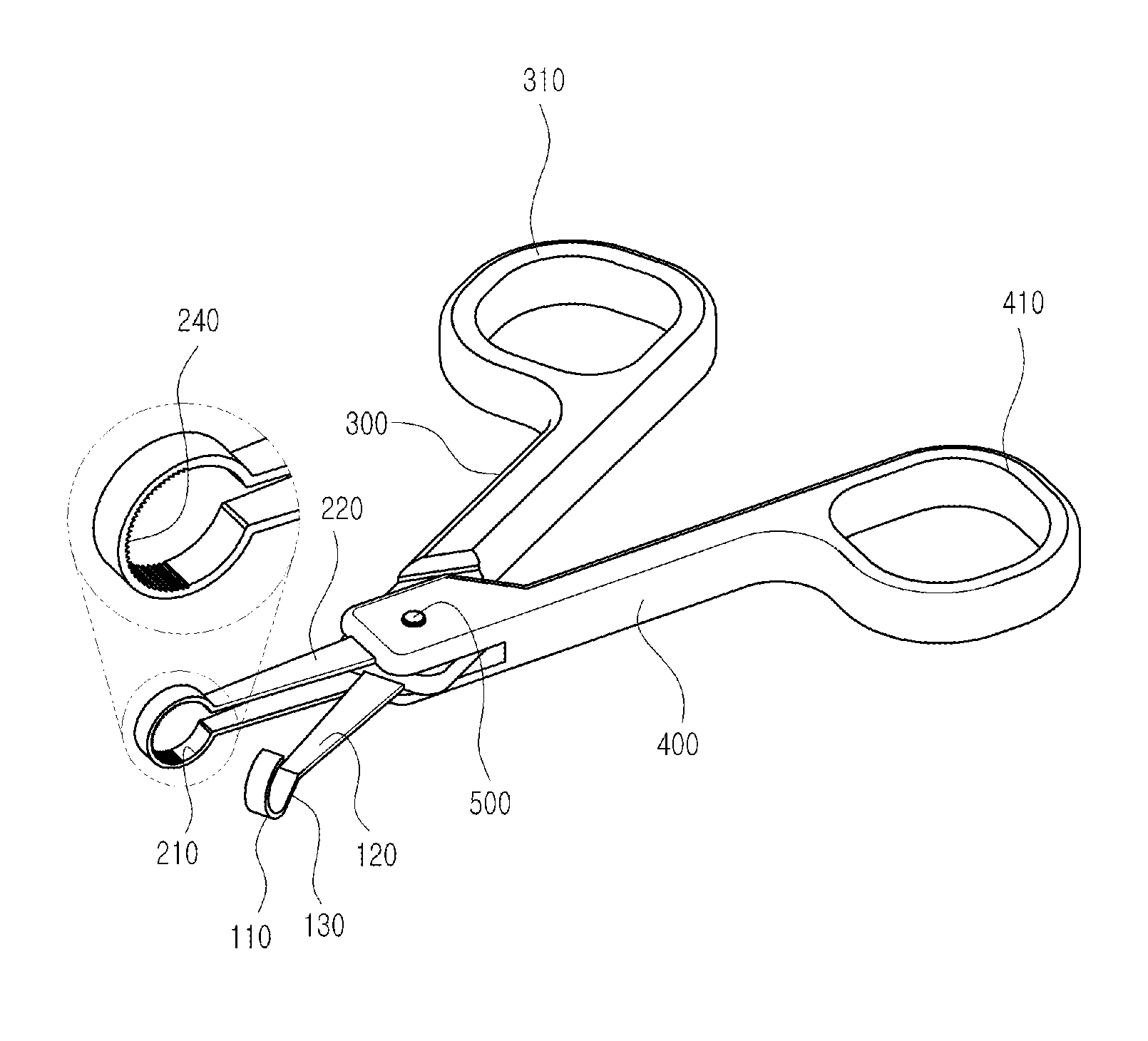

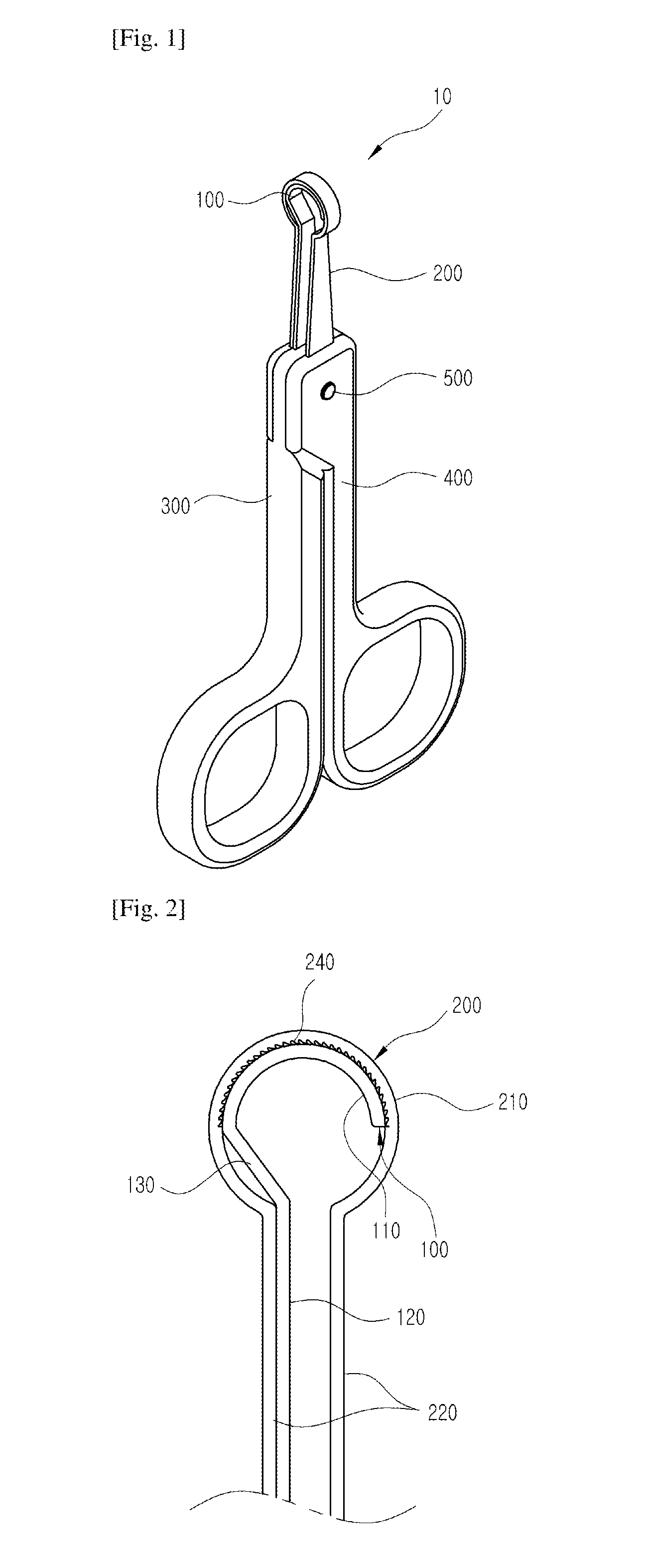

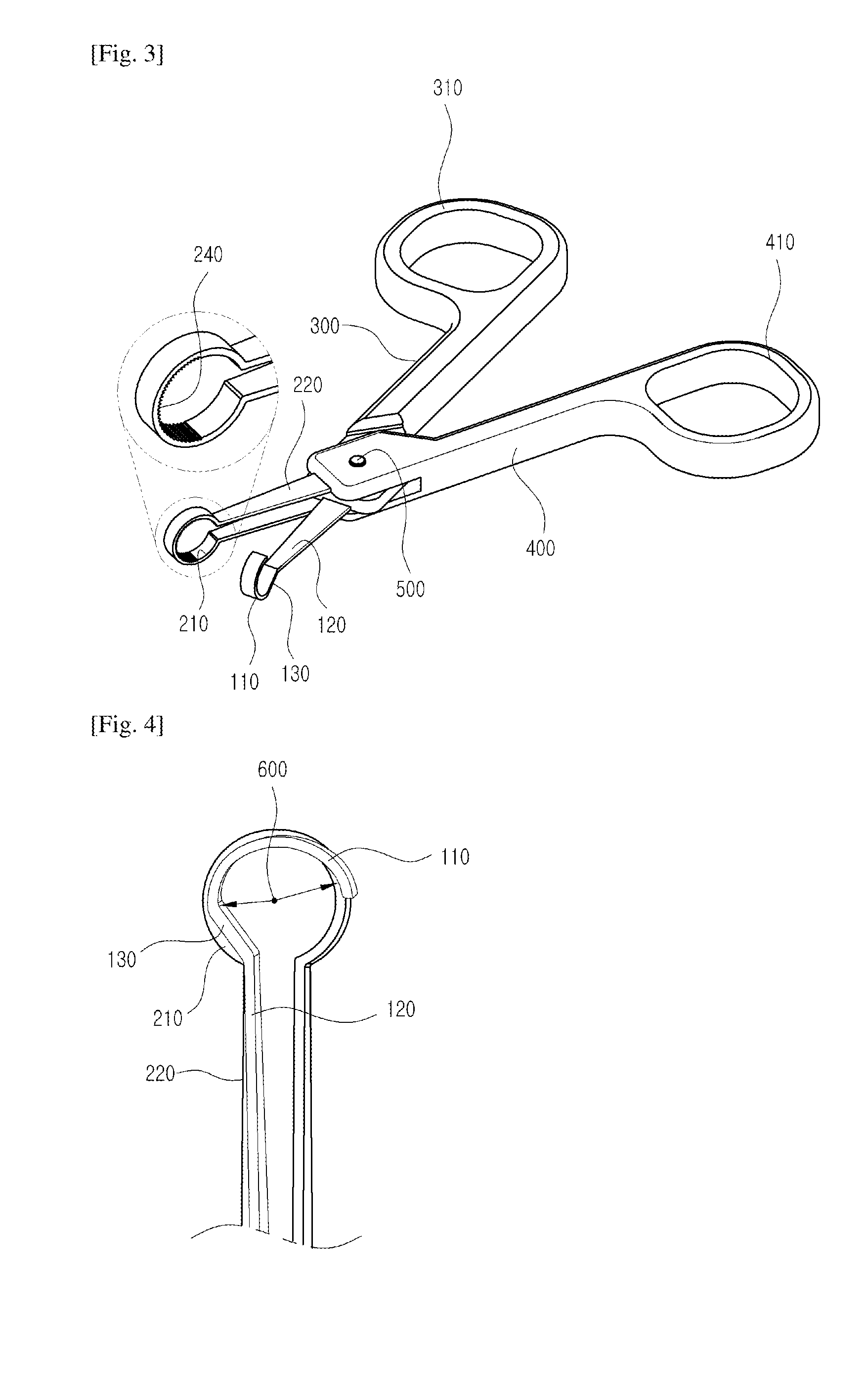

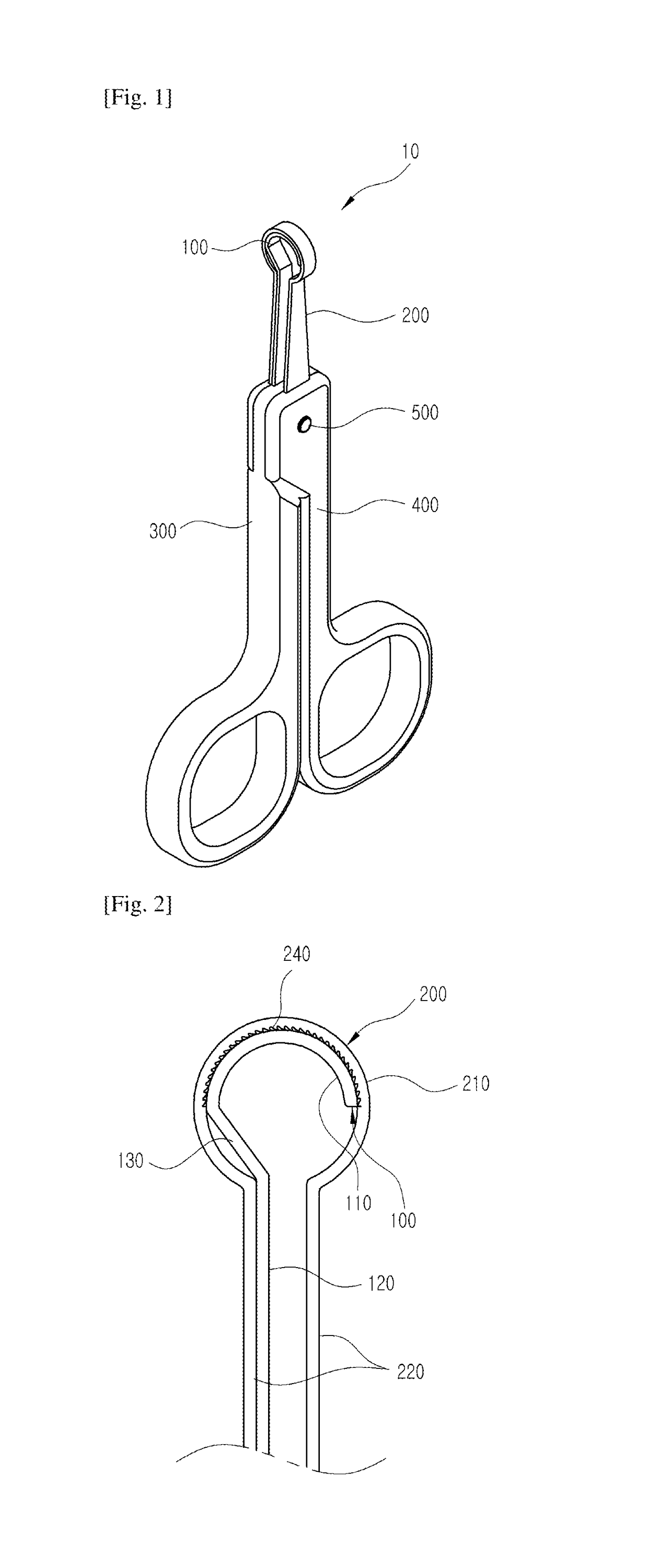

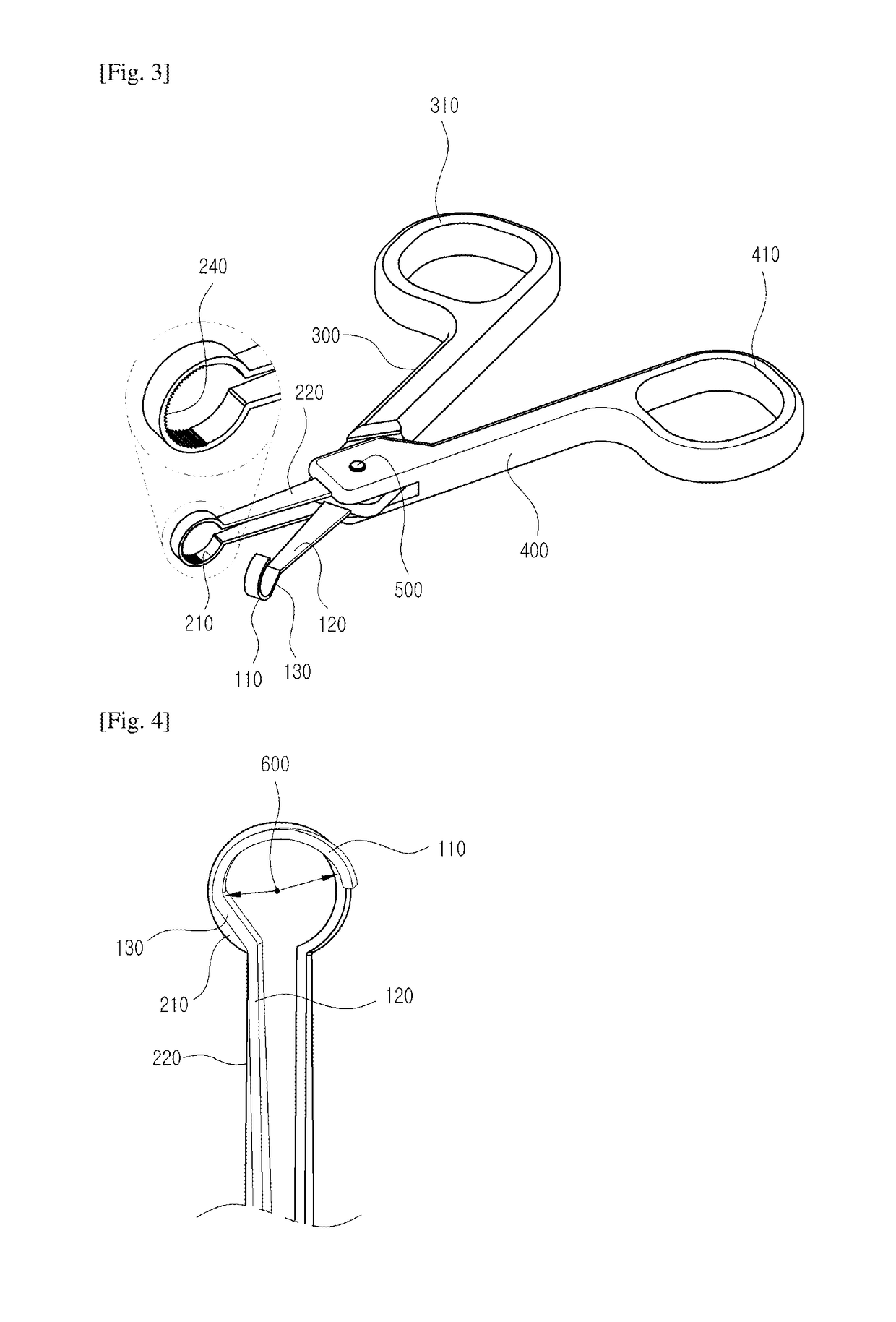

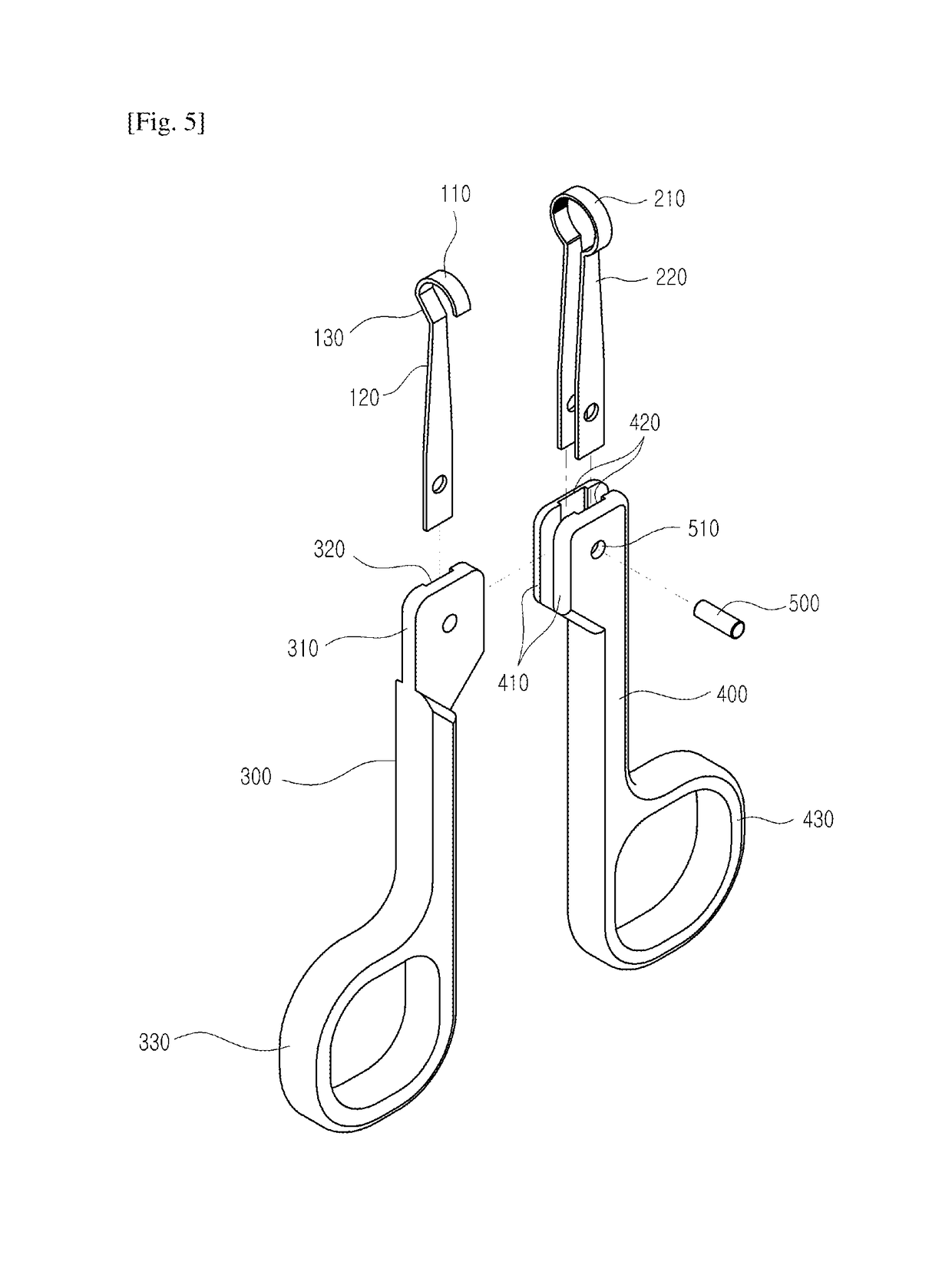

Rounded blade scissors

The present invention relates to rounded blade scissors. The rounded blade scissors according to one embodiment of the present invention comprise: a first cutting portion including a first cutting blade bent in one direction to cut a target; a second cutting portion including a second cutting blade having a closed annular or polygonal shape to surround the surface of the first cutting portion; a first frame portion supporting the first cutting portion on one side of the first cutting portion; a second frame portion supporting the second cutting portion on one side of the second cutting portion; and a coupling portion that hingedly couples the first frame portion with the second frame portion so that the first cutting portion comes into contact with the second frame portion through rotation. Therefore, the cutting can be performed in a safe and effective manner. According to the present invention, the cutting target can be cut in an easy, convenient, and safe manner.

Owner:KIM JEONG PYO

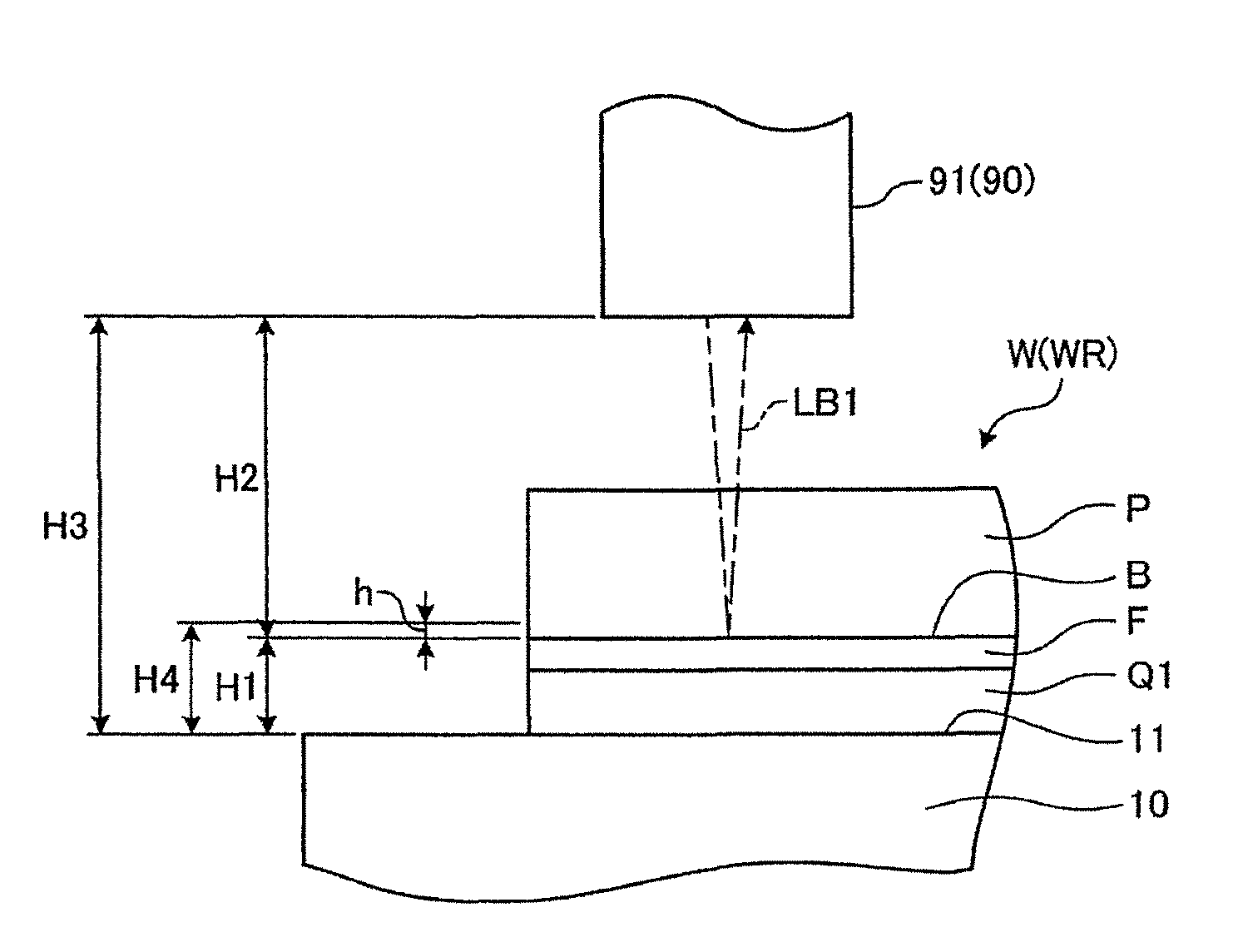

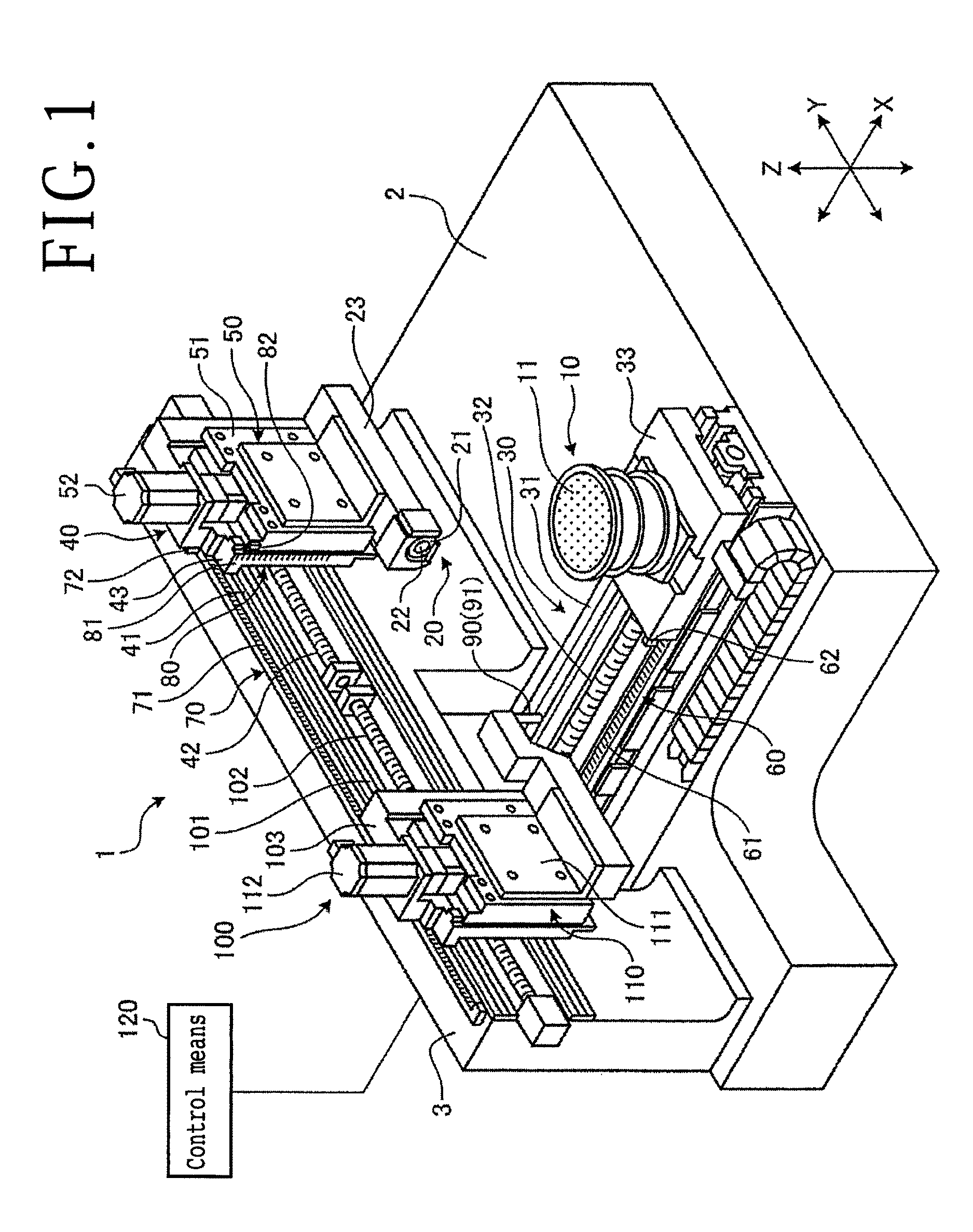

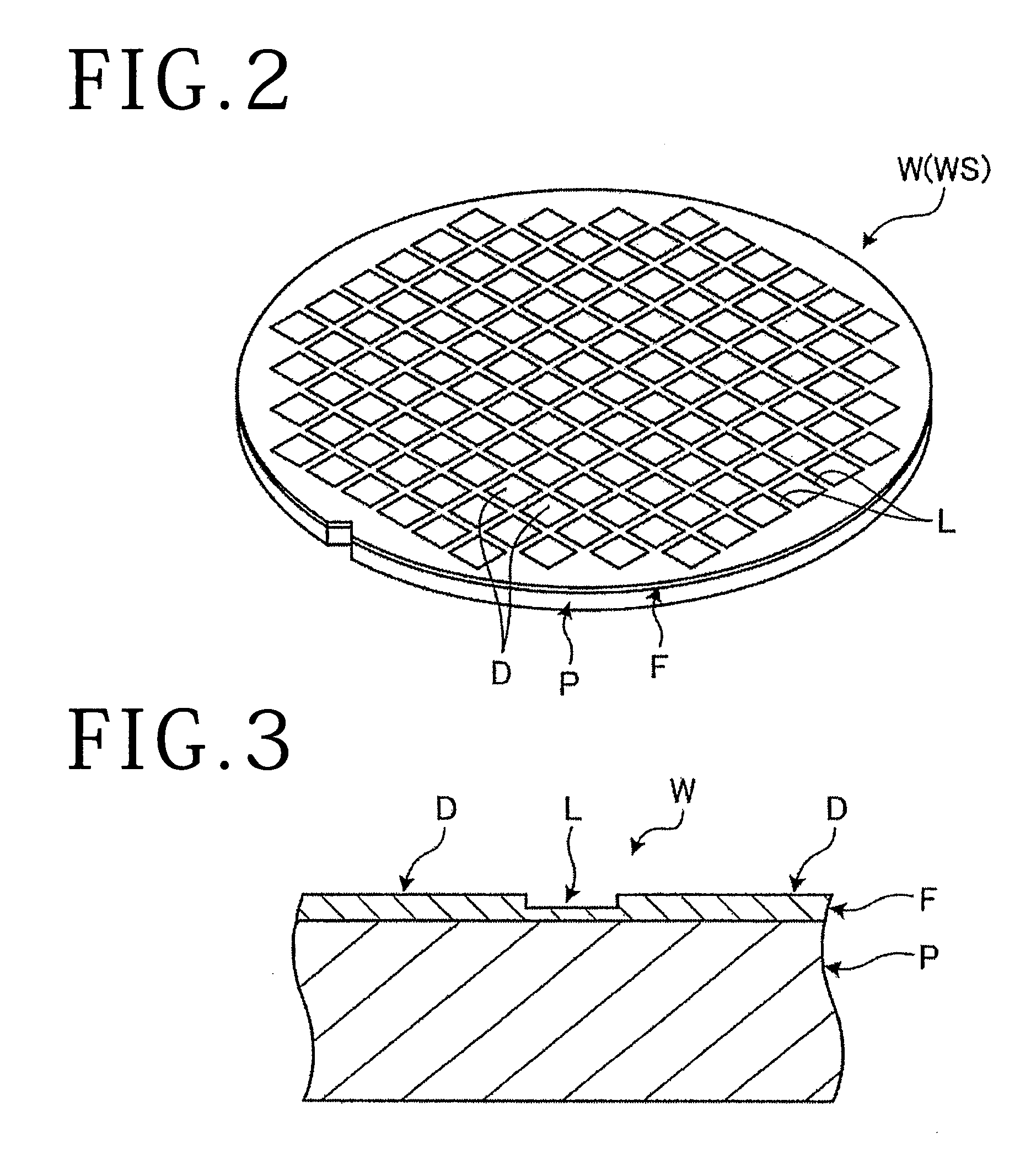

Wafer processing method

ActiveUS9536787B2Accurate divisionWafer can therefore be divided accuratelySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSplit linesEngineering

Disclosed herein is a wafer processing method for dividing a wafer into a plurality of individual devices along a plurality of crossing division lines. The wafer is composed of a substrate and a functional layer formed on the front side of the substrate. The division lines are formed on the front side of the functional layer. A laser beam having a transmission wavelength to the substrate is applied to the wafer from the back side thereof to detect the height of an interface between the functional layer and the substrate in an area corresponding to each division line. The depth of cut by a cutting blade for cutting the substrate is next set according to the height detected above. The back side of the substrate is next cut by the cutting blade according to the depth of cut set above to thereby form a cut groove having a depth not reaching the functional layer with a remaining part of the substrate left between the bottom of the cut groove and the functional layer along each division line, the remaining part having a uniform thickness. Thereafter, the remaining part and the functional layer are cut along each division line to thereby divide the wafer.

Owner:DISCO CORP

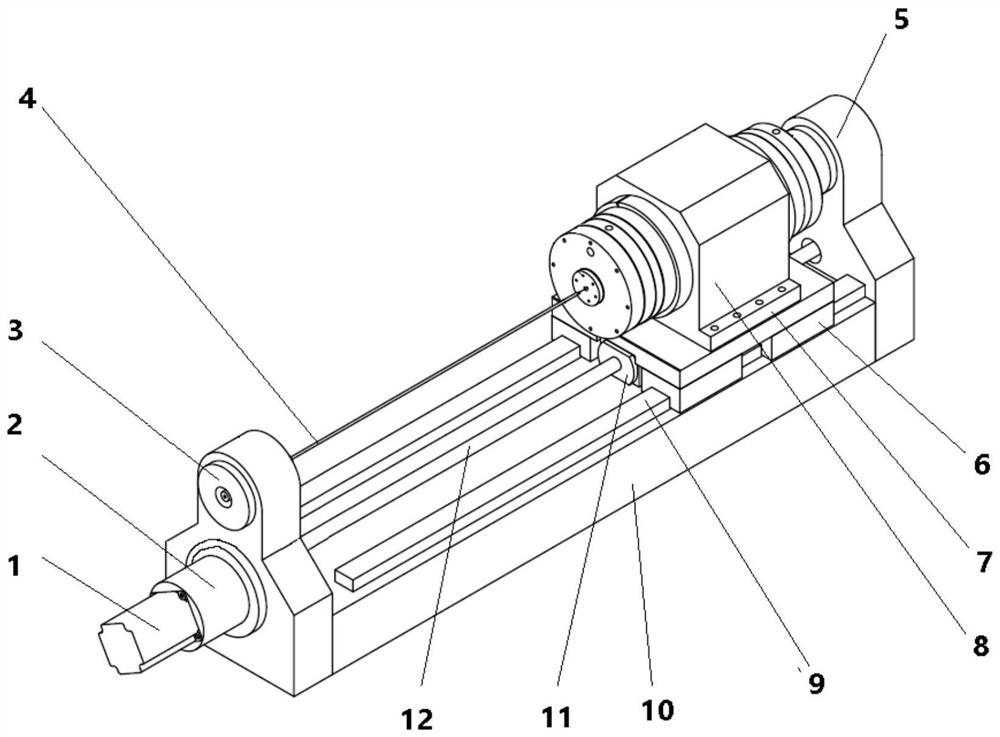

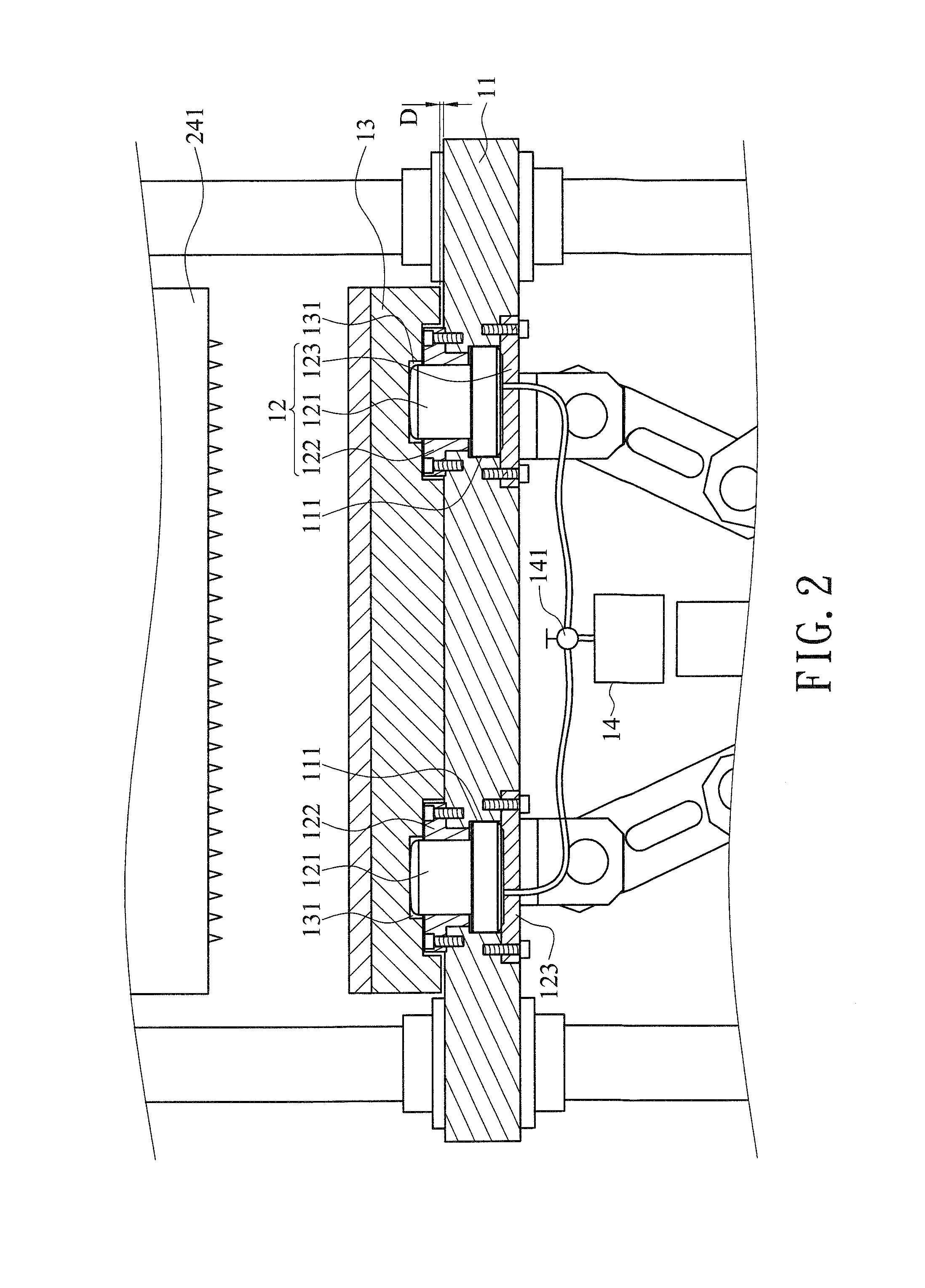

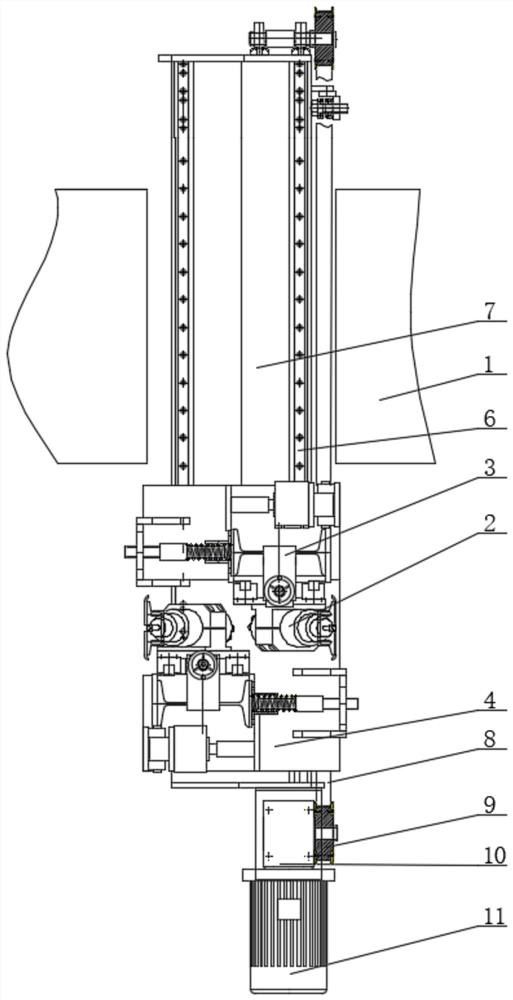

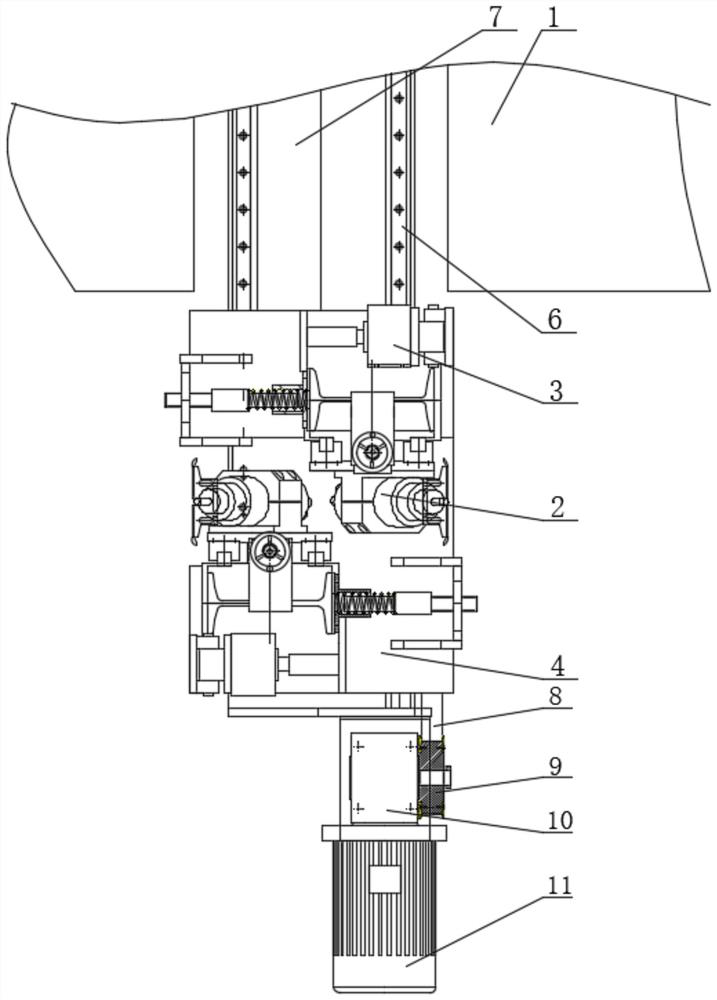

Multi-cutter progressive turning machine tool of slender shafts

PendingCN113579265AUniform cutReduce the amount of cuttingAuxillary equipmentTurning machinesReciprocating motionCentrifugal force

The invention discloses a multi-cutter progressive turning machine tool of slender shafts, belongs to the technical field of precision machining, counteracts one-way force of cutters on workpieces during machining, eliminates the deformation condition of slender shaft workpieces caused by centrifugal force generated during centering and machining of the traditional lathe and solves the technical problem that the machining size of the workpieces is limited at the same time. The machine tool comprises a machine tool body unit, a multi-tool machining unit, a left pre-tightening force unit and a right pre-tightening force unit, wherein the left pre-tightening force unit and the right pre-tightening force unit are distributed at the two ends of the machine tool body unit and drive the multi-tool machining unit to reciprocate in the axial direction; and the multi-cutter machining unit is arranged on the machine tool body unit and does reciprocating motion on the machine tool body unit to machine the slender shafts. The main motion of the traditional lathe is workpiece rotation; weak-rigidity tiny slender shafts can generate centrifugal force during rotation to cause workpiece deformation; the main motion of the lathe is improved from traditional workpiece rotation to cutter set rotation by the device; workpiece deformation is avoided; and the machining precision is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

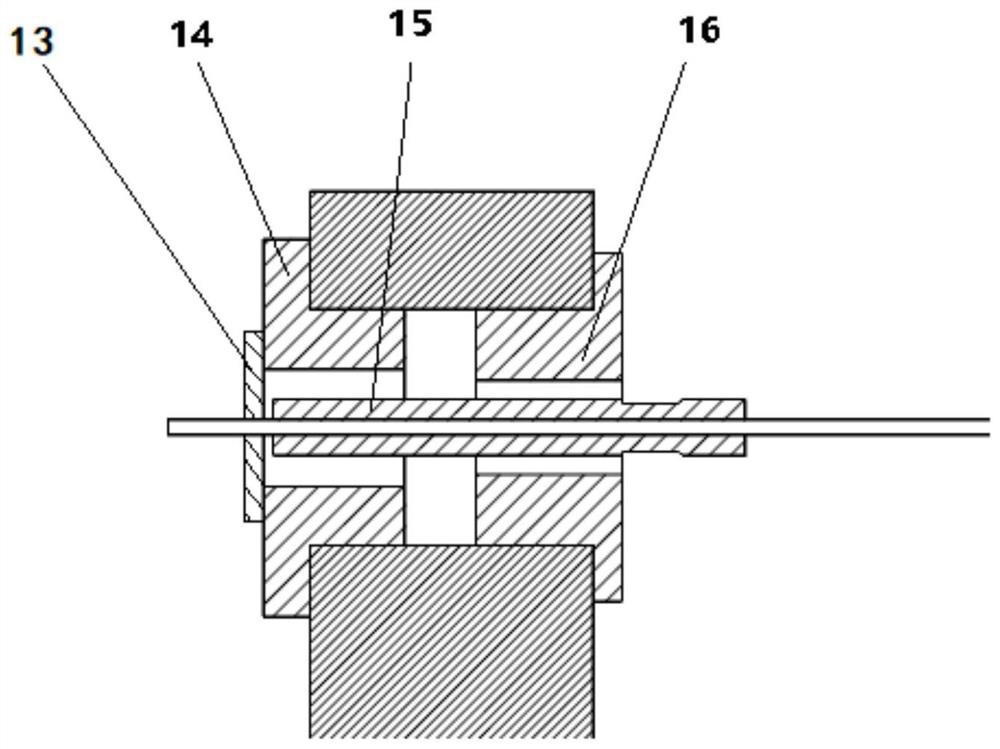

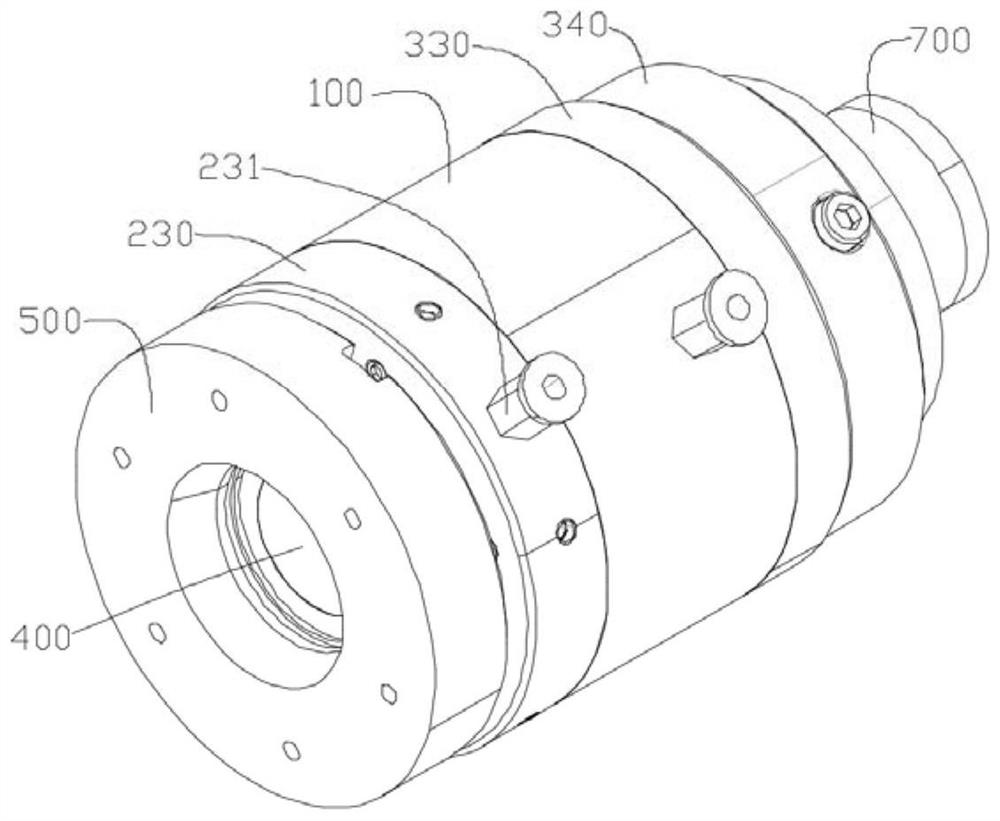

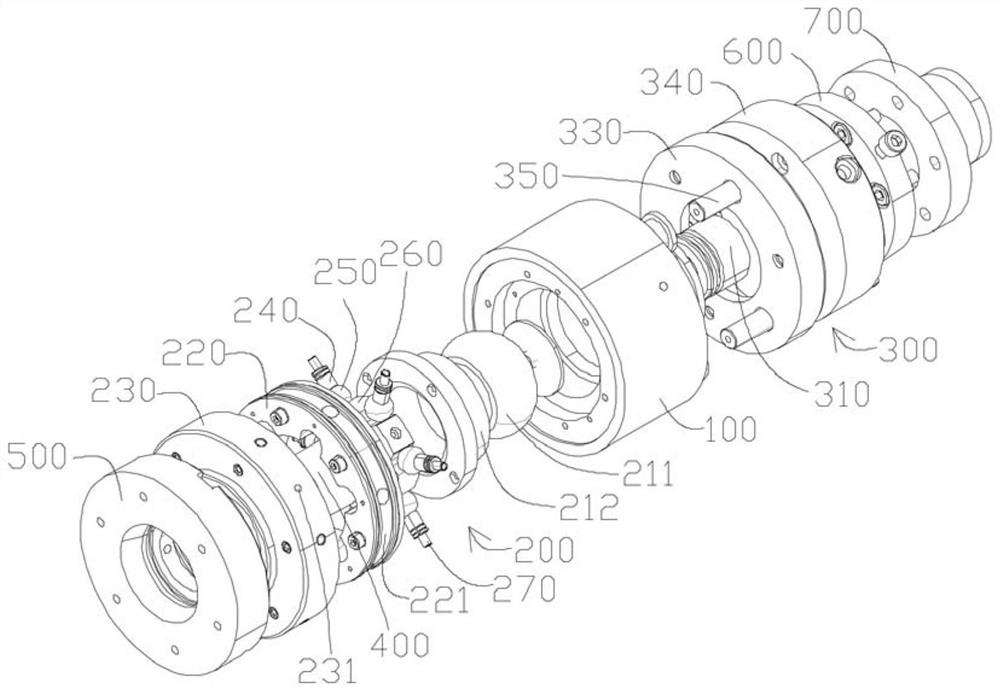

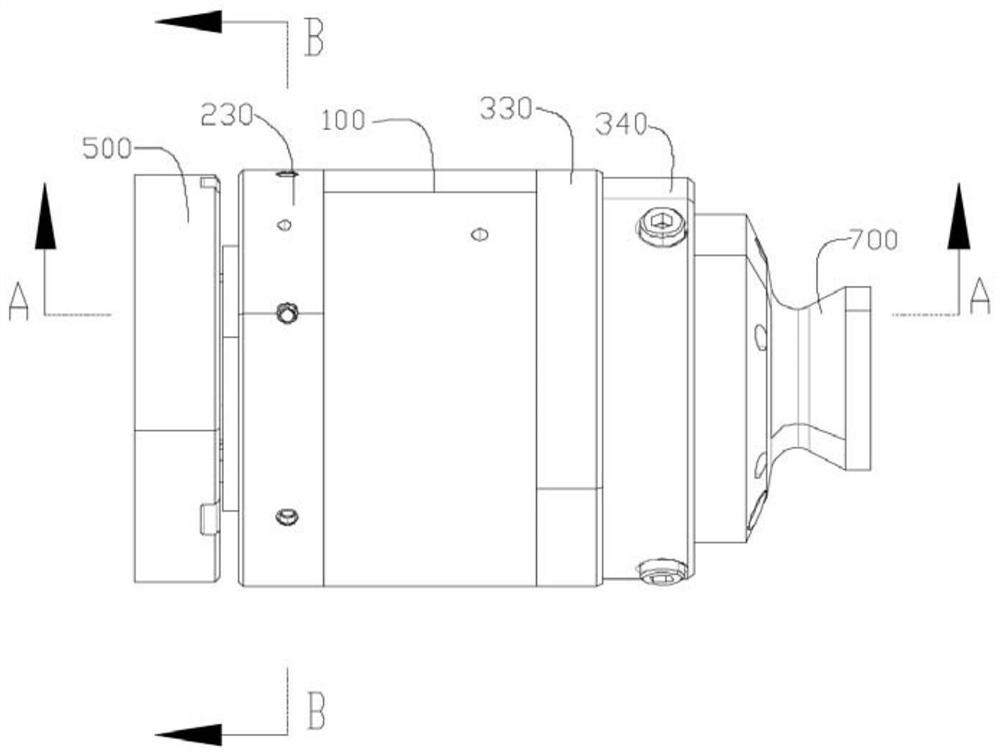

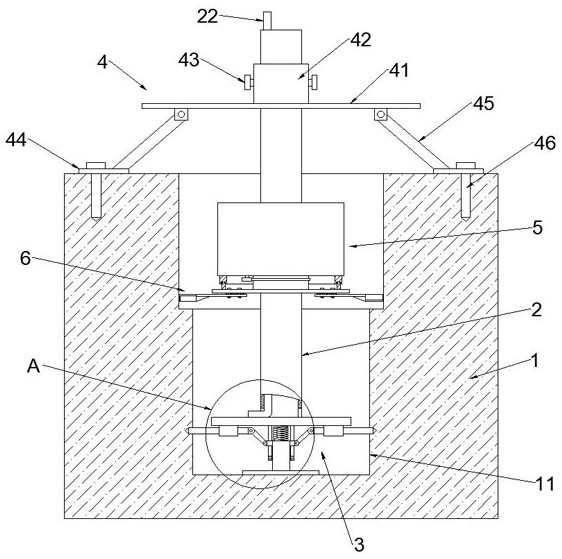

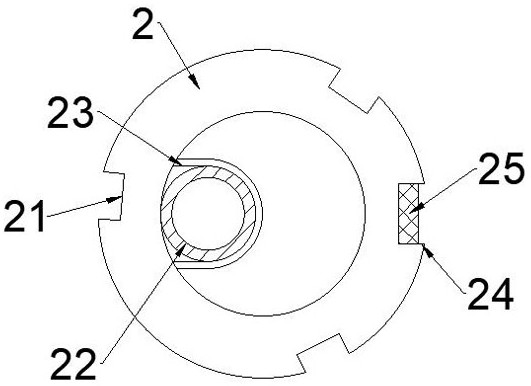

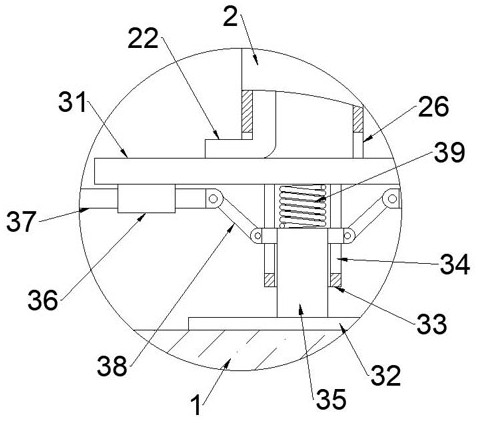

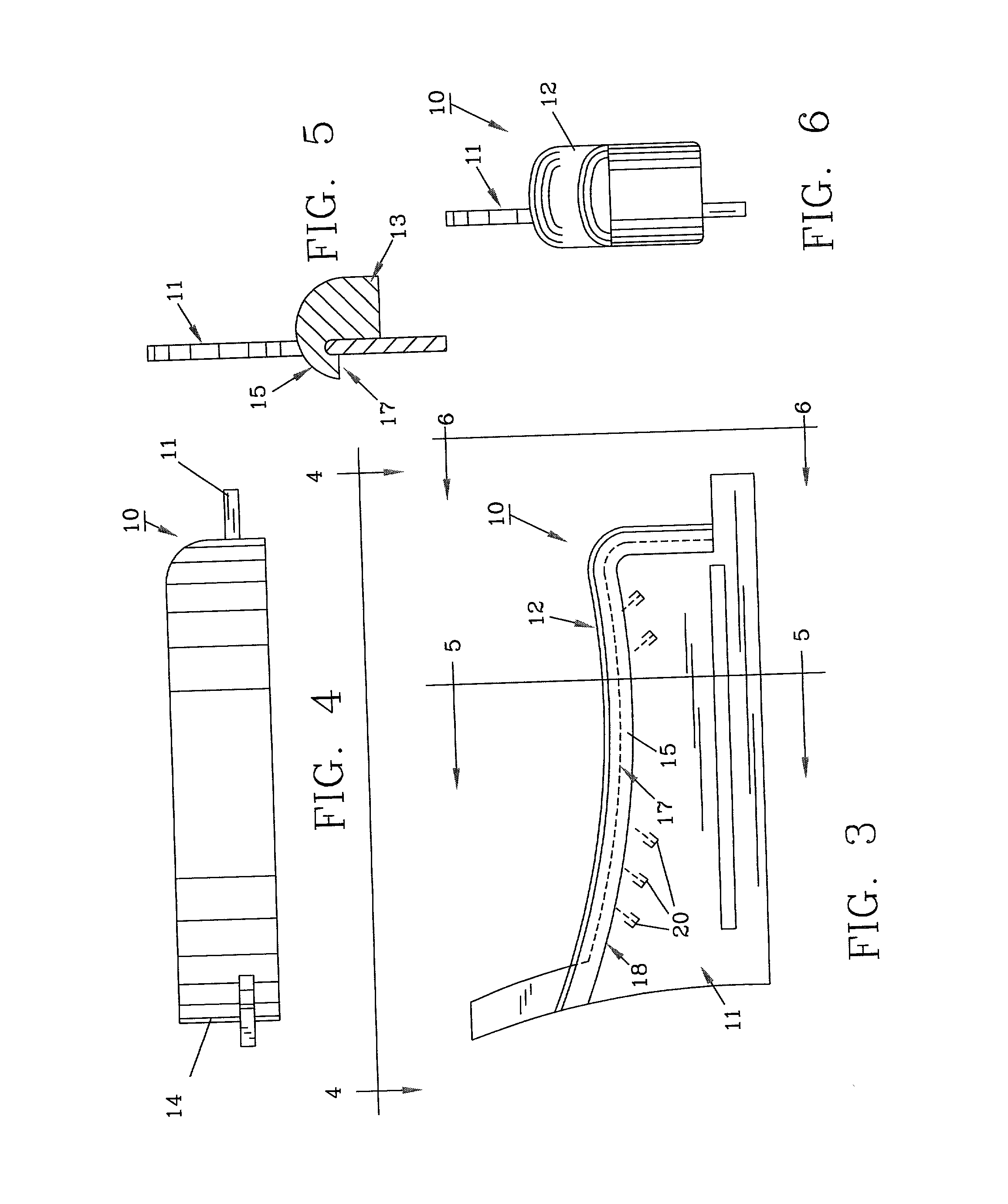

Floating device and electric spindle

PendingCN111633506AConstant contact forceUniform cutEdge grinding machinesGrinding machine componentsEngineeringElectrical and Electronics engineering

The invention provides a floating device and an electric spindle, and relates to the technical field of electric spindle floating. The floating device comprises a mounting base, a radial floating assembly, an axial floating assembly and a floating shaft, wherein one end of the mounting base is connected with a robot through the axial floating assembly; the radial floating assembly is arranged at the other end of the mounting base; the floating shaft is inserted into the radial floating assembly; and the end, away from the mounting base, of the floating shaft is connected with a spindle floating connecting disc. The electric spindle comprises the floating device. The technical effect of the good using effect is achieved.

Owner:苏州速科德电机科技有限公司

Foundation pile hole diameter expanding device

ActiveCN113445922AUniform cutAvoid secondary punchingConstructionsDerricks/mastsPunchingArchitectural engineering

The invention discloses a foundation pile hole diameter expanding device which comprises hollow stand columns, positioning assemblies, lifting assemblies and hole expanding assemblies. The positioning assemblies are installed on a foundation, the hollow stand columns are arranged in the positioning assemblies in a penetrating manner, a plurality of sets of pile holes are perpendicularly formed in the foundation, and supporting assemblies are installed at the bottoms of the hollow stand columns; the supporting assemblies are installed at the bottoms of the pile holes, the lifting assemblies are arranged on the hollow stand columns, the hole expanding assemblies are installed below the lifting assemblies through transmission assemblies, the rotating hole expanding assemblies driven by the lifting assemblies, and soil on the inner walls of the pile holes can be evenly cut off while the hole expanding assemblies ascend and descend in the pile holes; and the hole diameters of the pile holes are expanded while the shapes of the inner walls of the pile holes are not affected, and the hole diameter can be expanded without secondary punching.

Owner:江苏旌翔建材科技有限公司

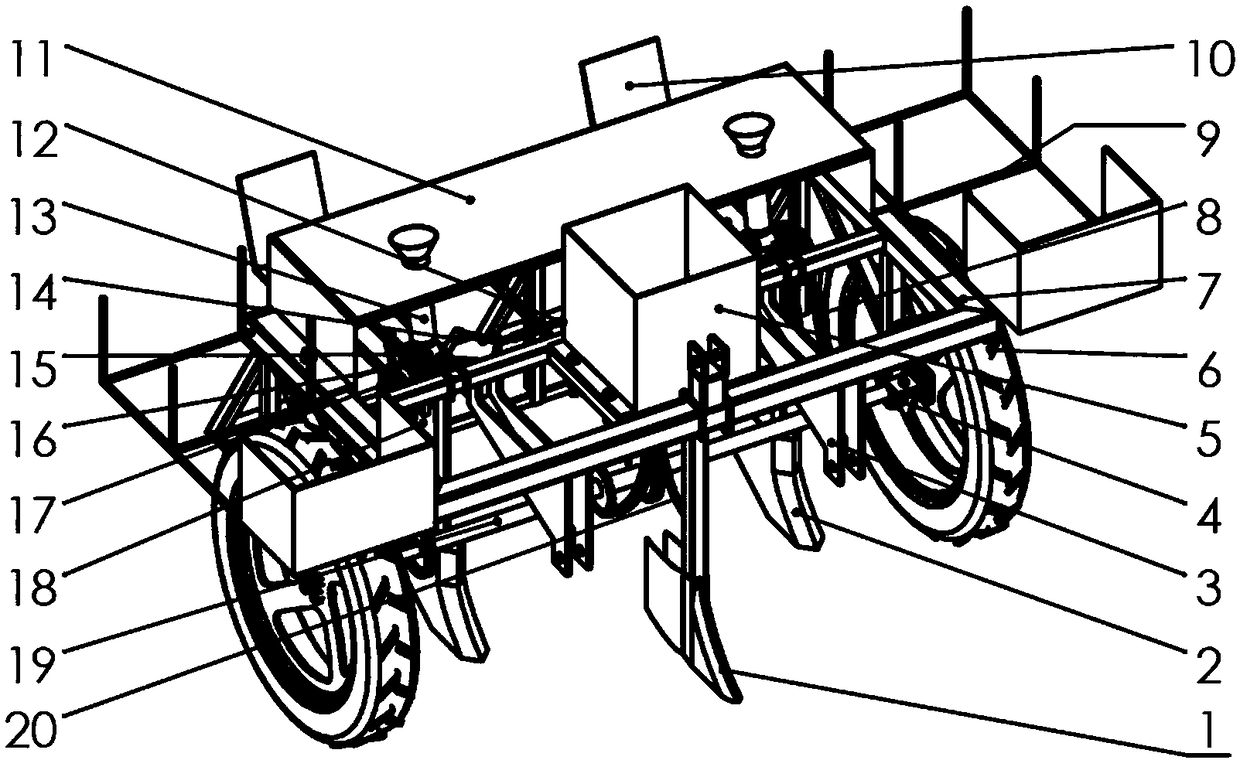

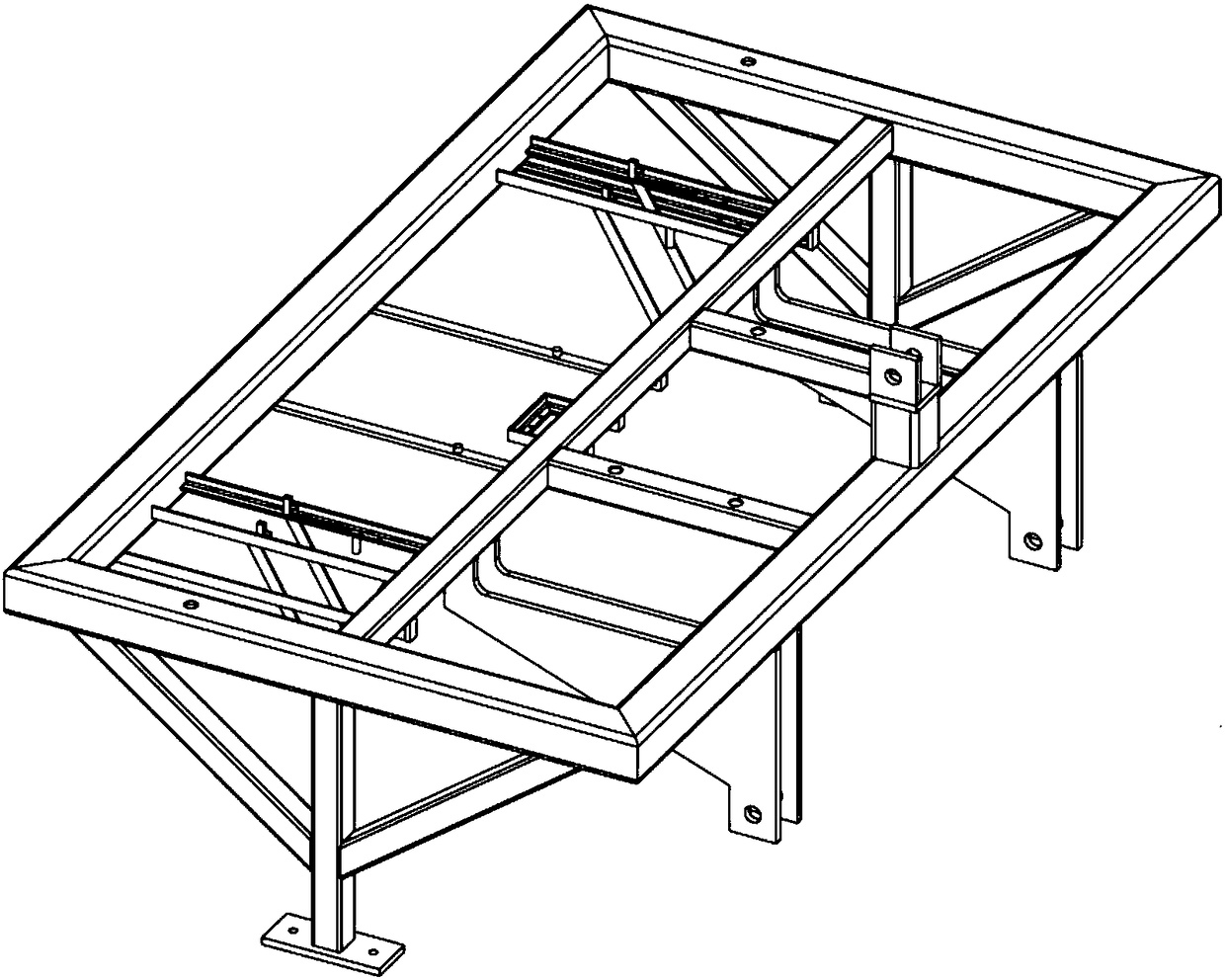

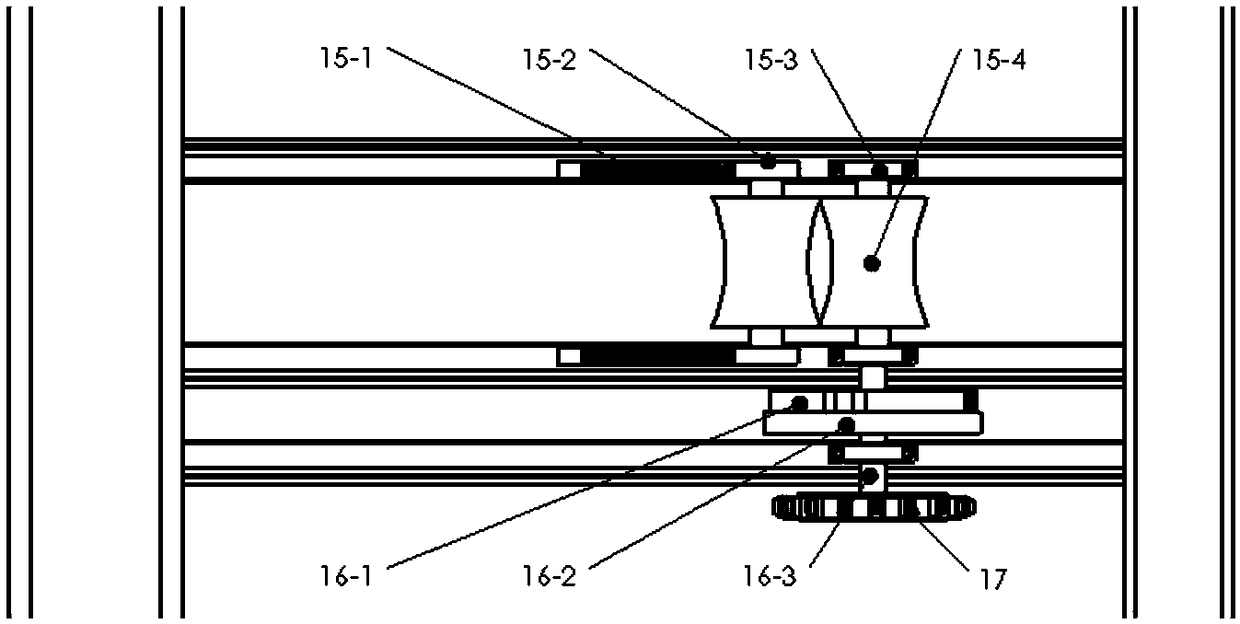

Inclined transplanting type cassava planting machine

PendingCN108419493AOblique transplantingFully absorbedFertiliser distributersPotato plantersAgricultural engineeringAgricultural machinery

The invention relates to an inclined transplanting type cassava planting machine and belongs to the field of agricultural machinery. The inclined transplanting type cassava planting machine works in an inclined transplanting mode, sufficient nutrients can be absorbed by cassava, and the machine is applicable to growth and later efficient harvesting of the cassava. Cassava seedlings are transplanted in two rows of a ridge in an inclined manner, and are planted at intervals in a shape of a Chinese character 'Pin', and thus good photosynthesis can be achieved. A fertilizer is deeply applied for one time between two rows of the cassava by using a fertilization furrower, then fertilizer requirements of the two rows of the cassava can be met, and a high fertilizer utilization rate can be achieved. A clamping conveying mechanism is designed in an elastic manner through concave nylon rollers and springs, so that cassava stems are not pressed, and the machine is low in cassava stem damage rate.The cassava stems are cut by using a scissor mechanism, the cut surfaces of the cassava stems are flat, and a low splitting damage rate can be achieved. With the combination of a maltese mechanism and a 'heart'-shaped track disc, uniform cutting and planting can be carried out. The planting machine is capable of carrying out multiple operation items such as fertilization, furrowing, seed stem sowing and automatic soil covering at one time, and is very high in adaptability, simple in structure and easy to popularize.

Owner:CHINA AGRI UNIV

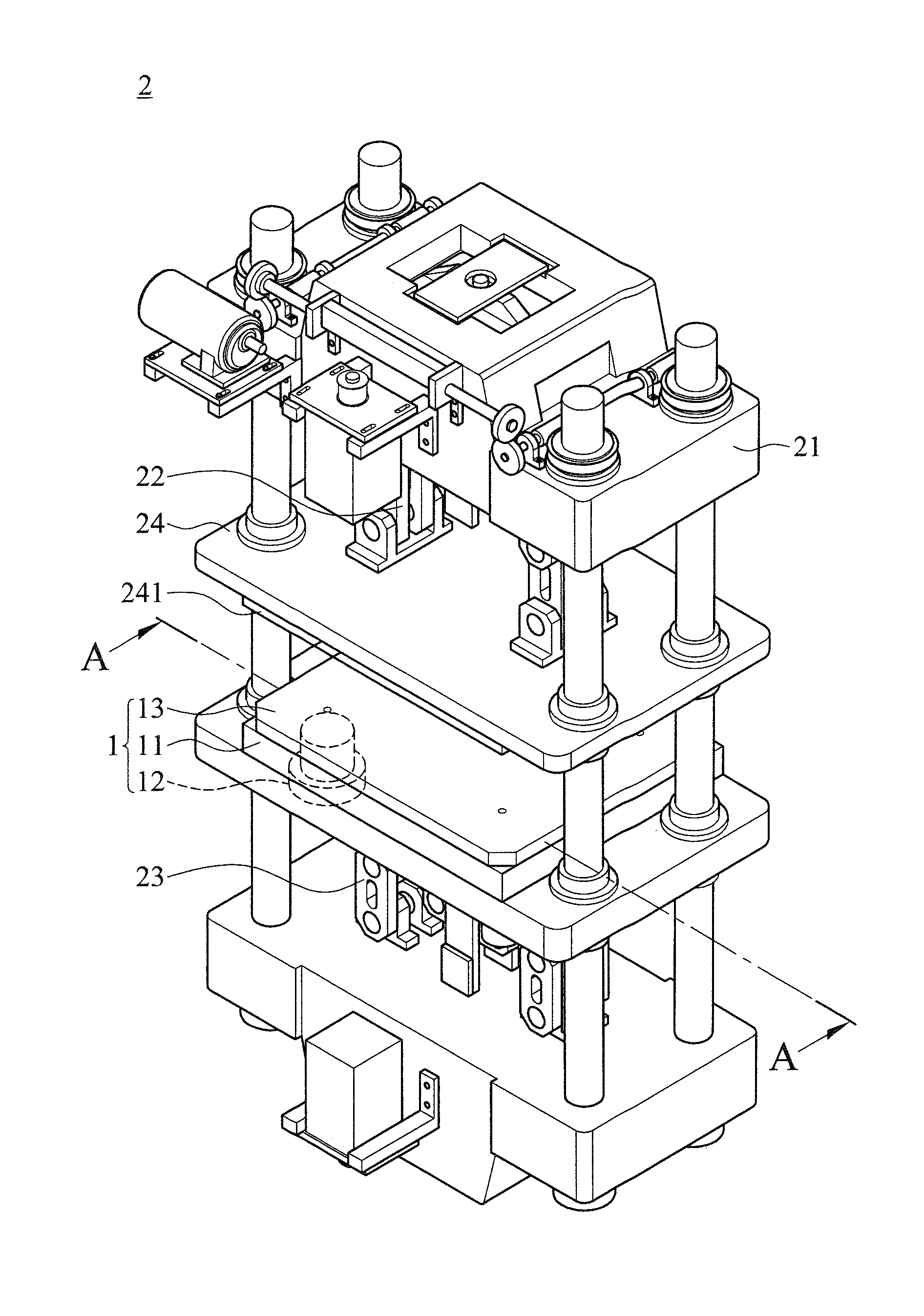

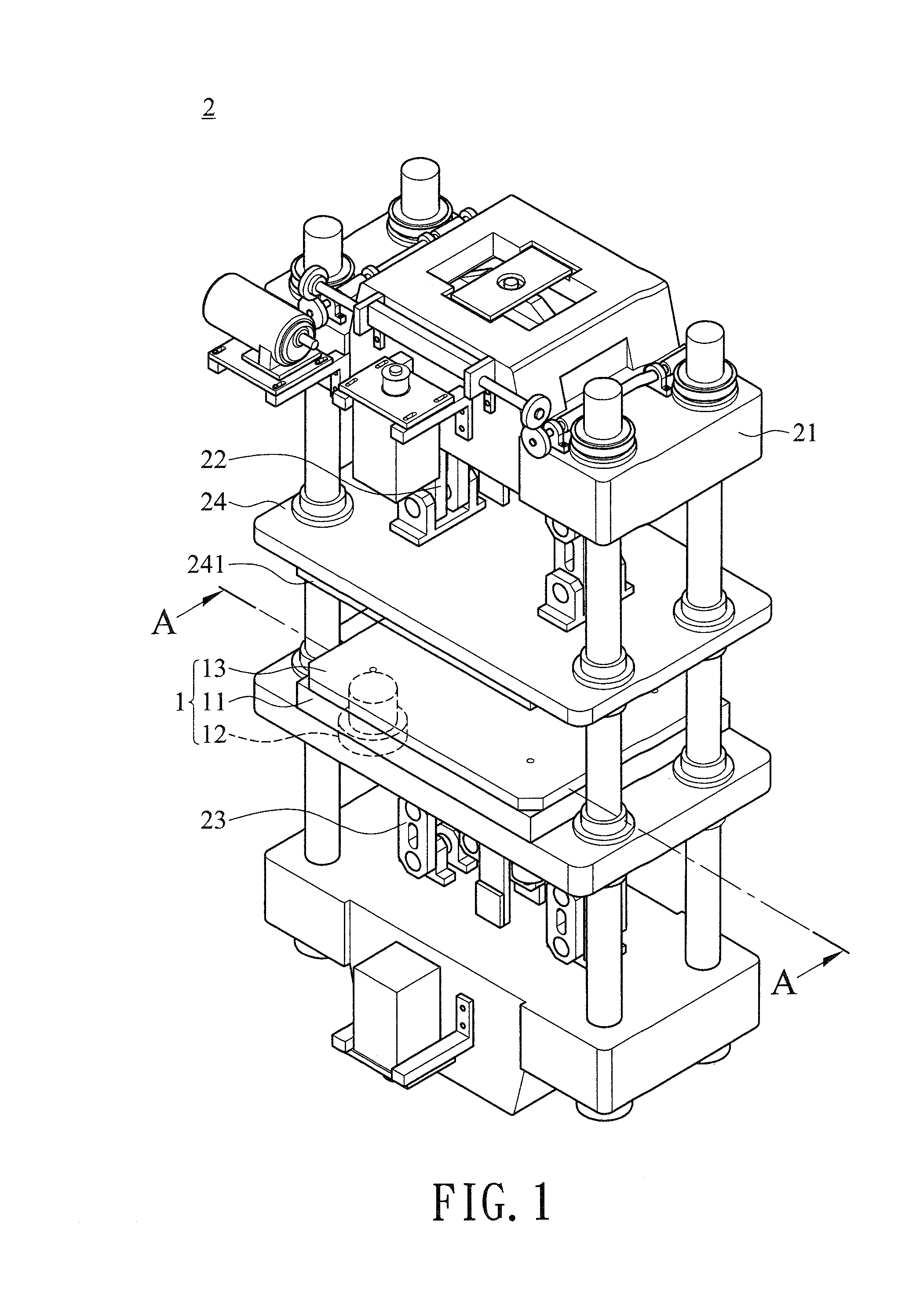

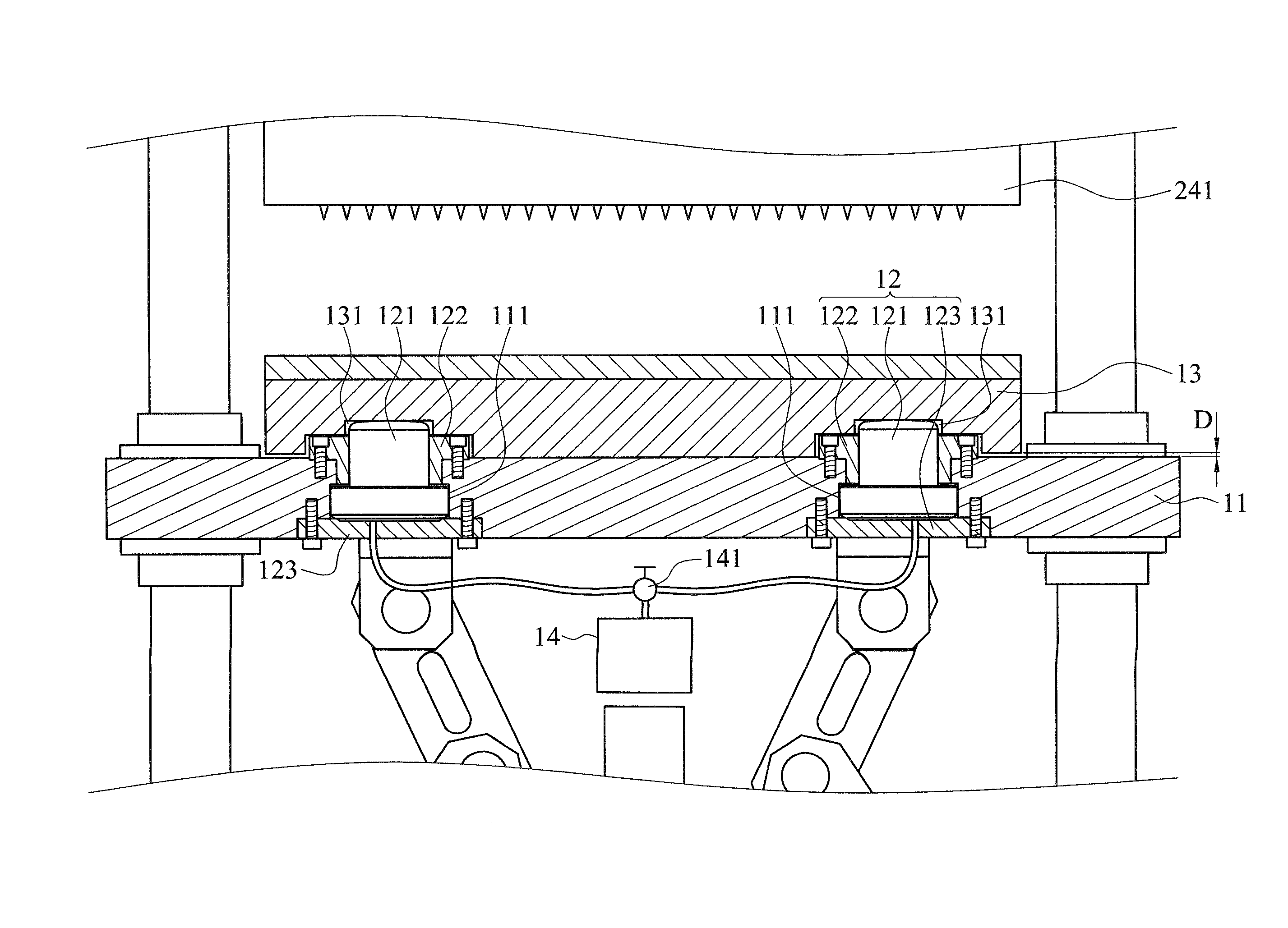

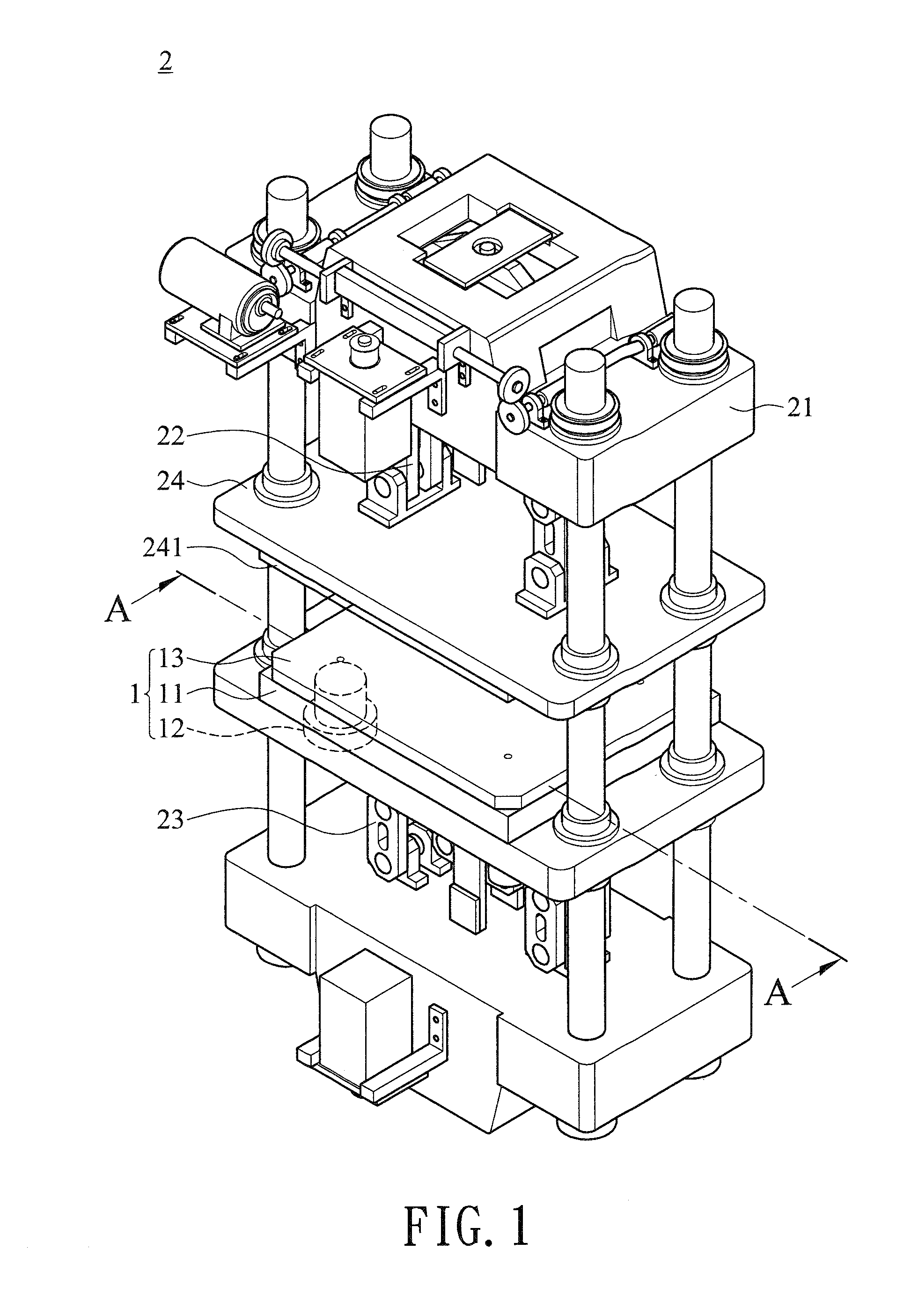

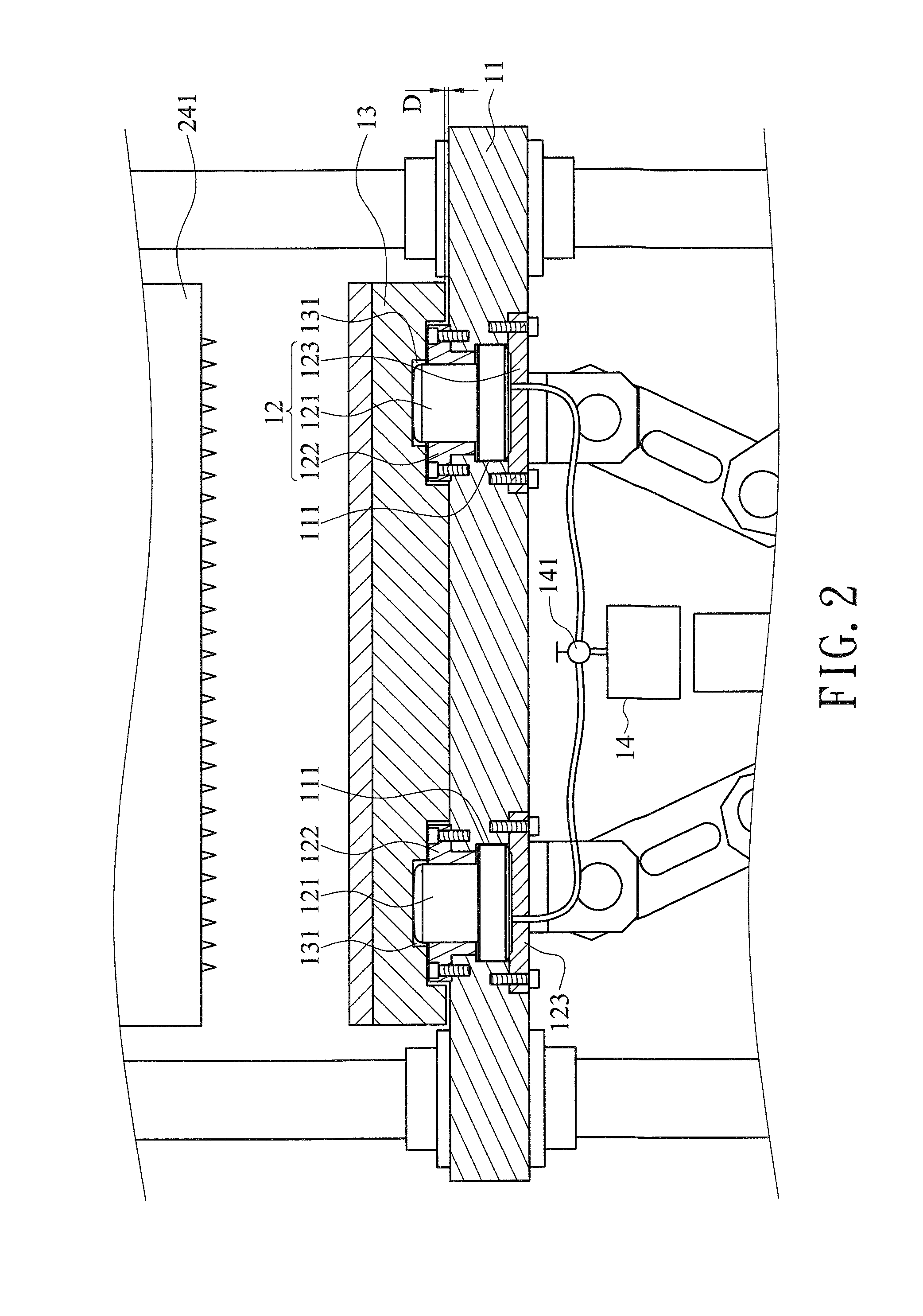

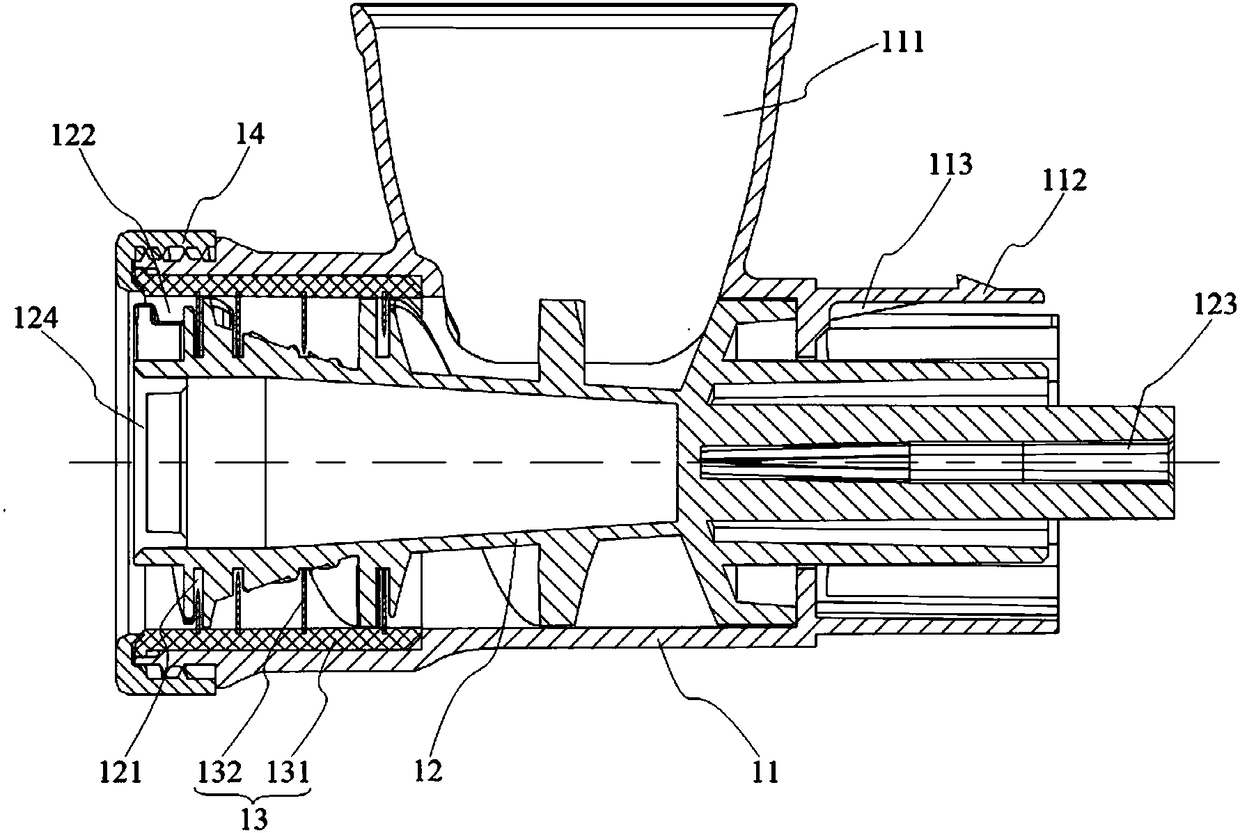

Buffer assembly of vacuum molding and cutting machine

ActiveUS20140144738A1Improve cutting effectImprove cut qualitySpringsMetal working apparatusEngineeringMachine

Disclosed is a buffer assembly of a vacuum molding and cutting machine, and the buffer assembly includes a lower mold base, at least four hydraulic elements and a movable plate. The lower mold base has at least four installing holes for installing the hydraulic elements respectively, and each hydraulic element includes a piston plunger for propping the movable plate to a predetermined distance. When the cutting thickness is 0.1 mm-0.5 mm of a sheet, the impact force can be absorbed effectively to maintain the parallelism for the cutting, so as to improve the cutting quality and extend the service life of a die cutting tool.

Owner:CHENG MEI MACHINE

Scissors

The present invention relates to rounded blade scissors. The rounded blade scissors according to one embodiment of the present invention comprise: a first cutting portion including a first cutting blade bent in one direction to cut a target; a second cutting portion including a second cutting blade having a closed annular or polygonal shape to surround the surface of the first cutting portion; a first frame portion supporting the first cutting portion on one side of the first cutting portion; a second frame portion supporting the second cutting portion on one side of the second cutting portion; and a coupling portion that hingedly couples the first frame portion with the second frame portion so that the first cutting portion comes into contact with the second frame portion through rotation. Therefore, the cutting can be performed in a safe and effective manner. According to the present invention, the cutting target can be cut in an easy, convenient, and safe manner.

Owner:KIM JEONG PYO

Furniture construction and method

InactiveUS20020063462A1Easy to installRapid and efficient mannerVehicle seatsStuffed mattressesEngineeringUpholstered furniture

A method of constructing upholstered furniture is provided using unitary ends which are covered with molded polymeric foam cushions. The construction method saves time and reduces the cost of the finished furniture while allowing relatively unskilled workers to produce top quality furniture in an efficient manner.

Owner:CLEARY BOBBY D

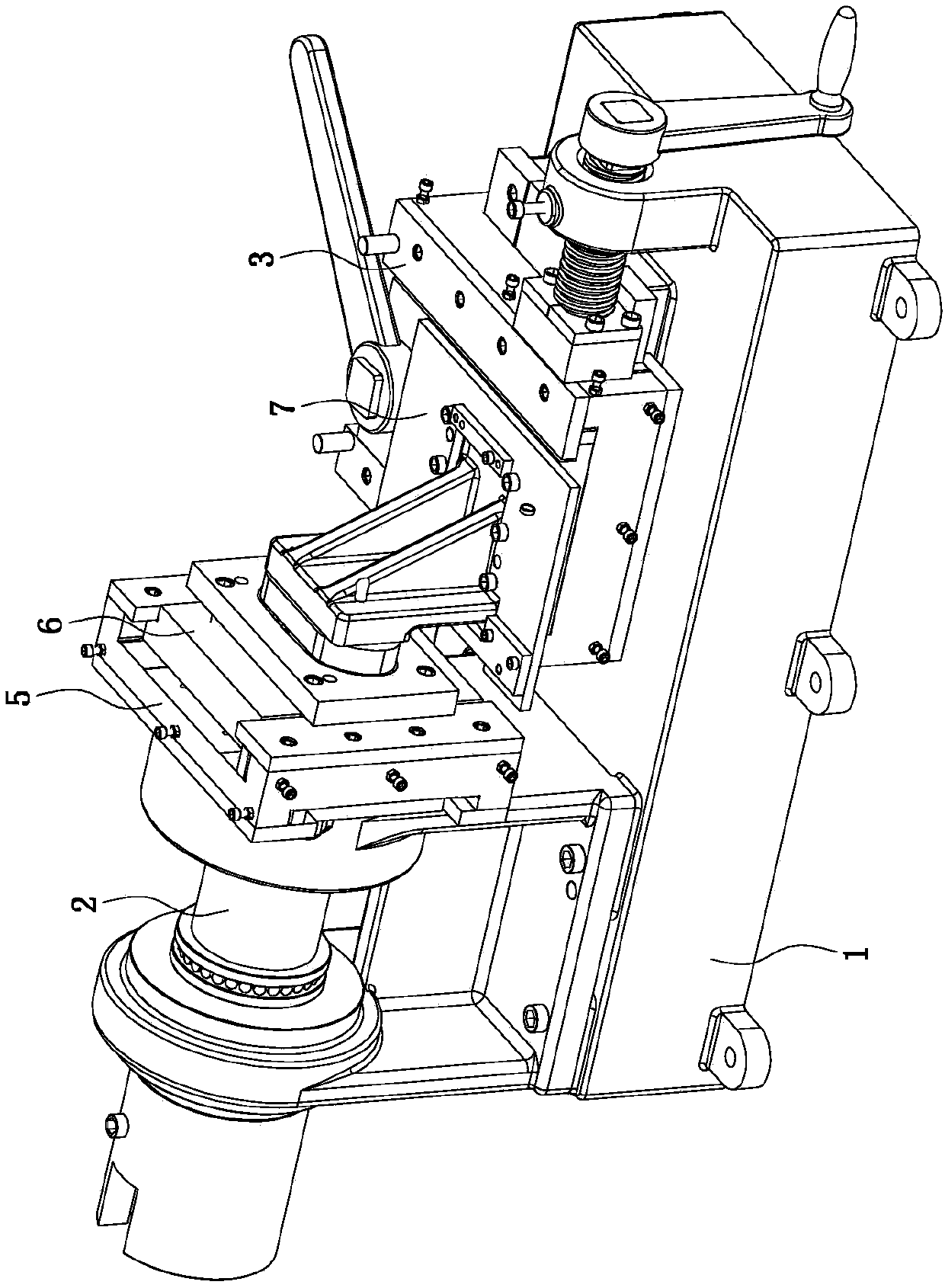

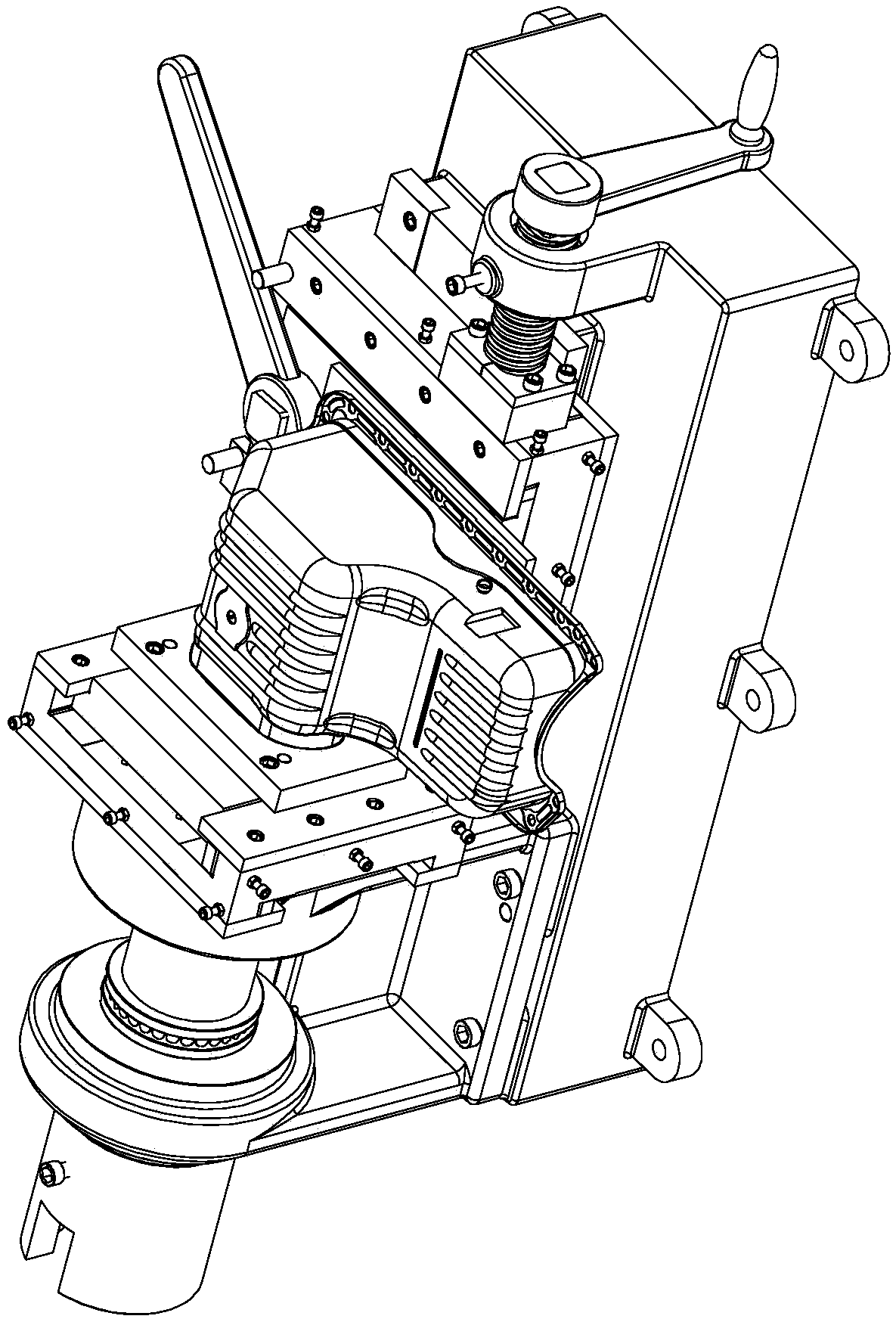

Edge Trimming Machine for Side Surface of Oil Pan

The invention relates to a hooked side face edge trimming machine of an oil pan. The machine comprises a machine base, a rotating shaft rotatably arranged on the machine base and a drive device for driving the rotating shaft; a convex die base is arranged on the machine base, the output end of the rotating shaft is eccentrically arranged, the output end of the rotating shaft is sleeved with a bearing, a concave die base is arranged on the machine base in a front-and-back sliding manner, the outer side of the circumference of the bearing is sleeved with the concave die base, and the concave die base is provided with an edge cutting concave die in a vertical sliding manner; the convex die base can slide in a left-and-right manner along the machine base, and a mounting base used for containing of the oil pan is arranged on the convex die base in a front-and-back sliding manner.

Owner:泉州市双塔汽车零件有限公司

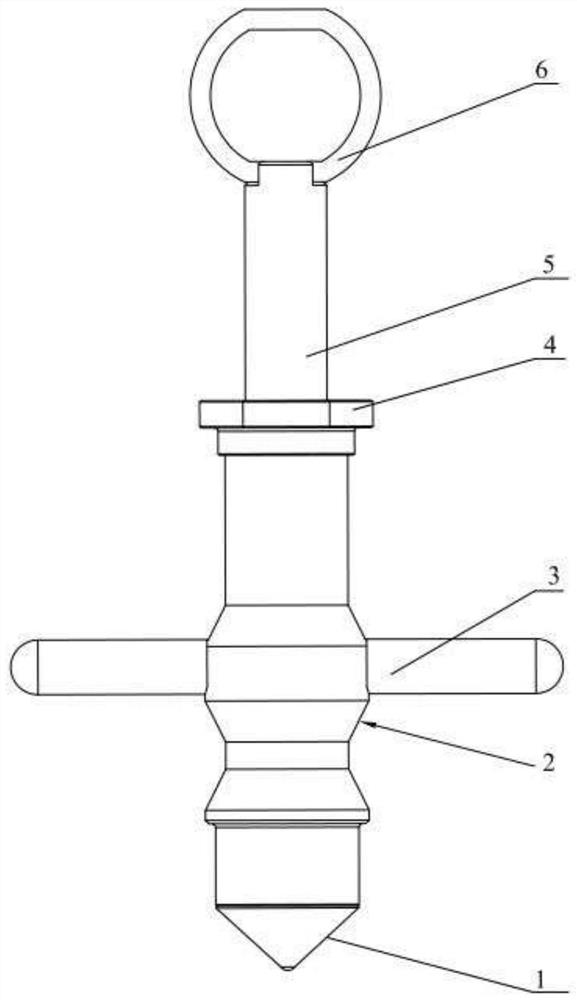

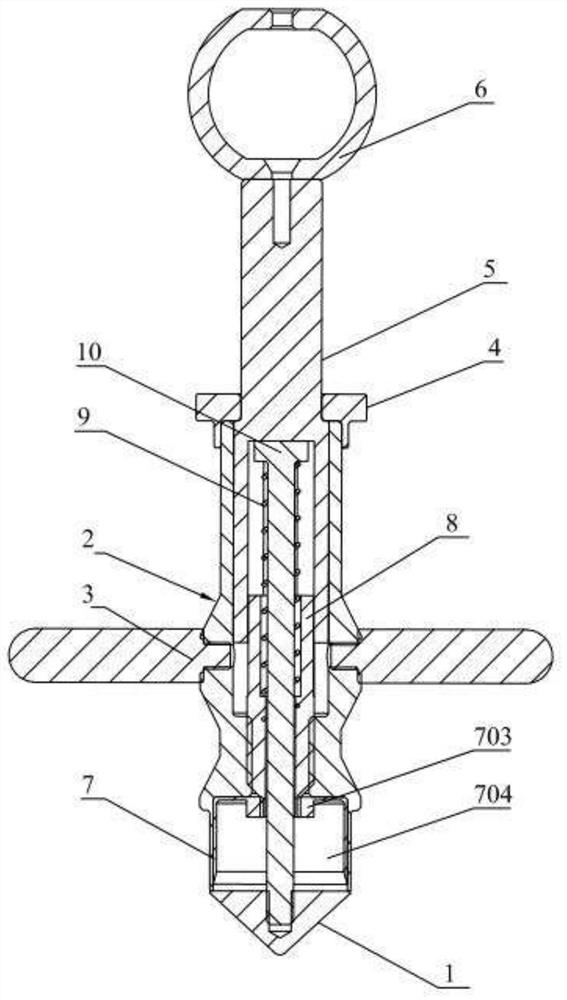

Puncher and operation method thereof

PendingCN114668456AFor the purpose of tighteningUniform cutExcision instrumentsStructural engineeringIndustrial engineering

The invention relates to a puncher and an operation method thereof, the puncher comprises a knife rest, a driving part, a cutting assembly and a pressing assembly, the driving part is provided with a through part which is at least partially and movably arranged on the knife rest, the near end of the pressing assembly is movably arranged on the cutting assembly, and the far end of the pressing assembly is arranged on the outer side of the knife rest; and when the driving piece moves, the pressing assembly is driven to axially move relative to the tool rest. The elastic piece is arranged on the outer side of the second shaft, so that the tool apron can automatically rebound under the deformation action of the elastic piece after penetrating through cut tissue, and the cut tissue is pressed. The first limiting part and the second limiting part abut against each other to limit the axial movement of the first shaft but not limit the axial movement of the first shaft along with the rotation of the driving part, so that the pressed human tissue is uniformly cut off, the shape of an incision is guaranteed, and a doctor does not need to carry out secondary trimming.

Owner:CARDIOPOWER MEDTECH SHANGHAI CO LTD

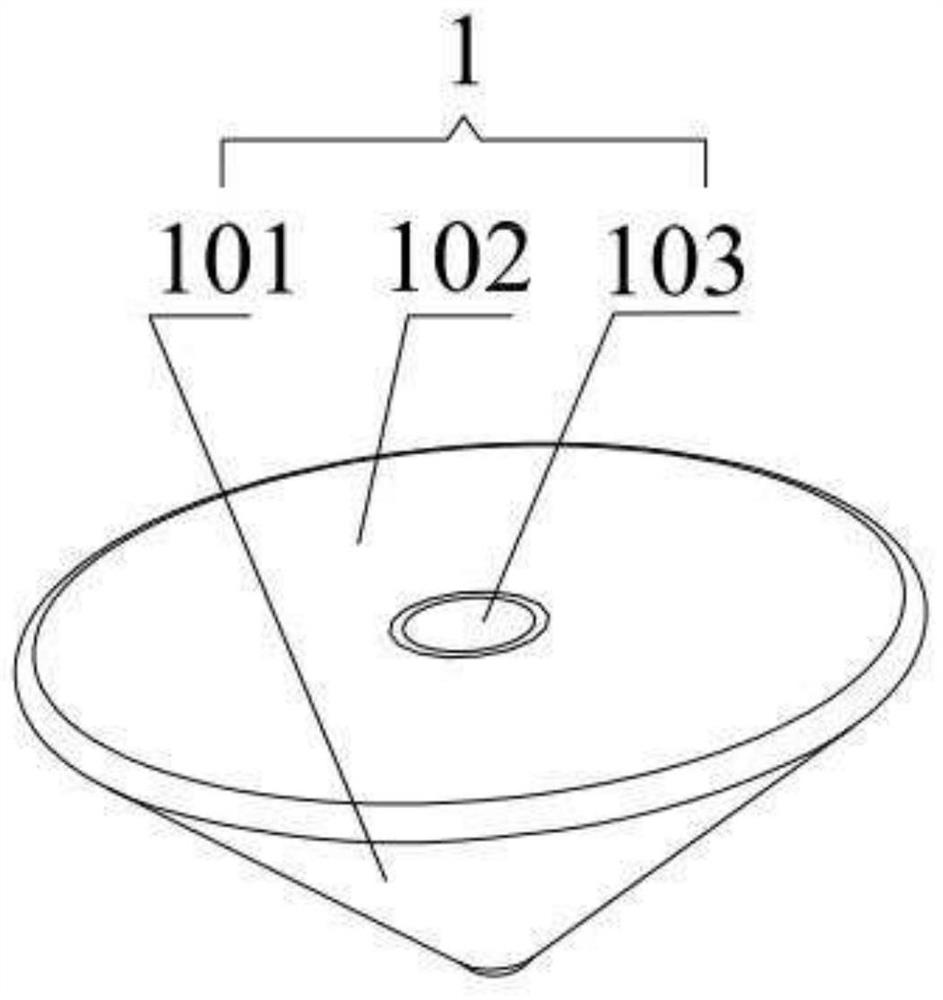

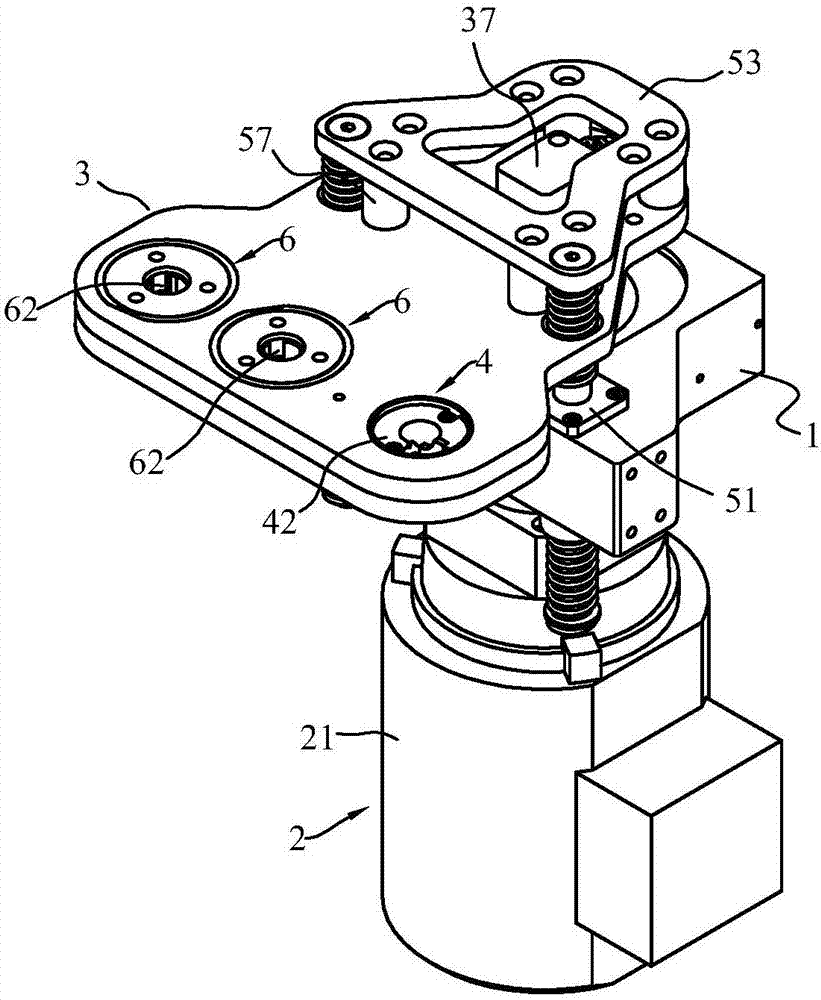

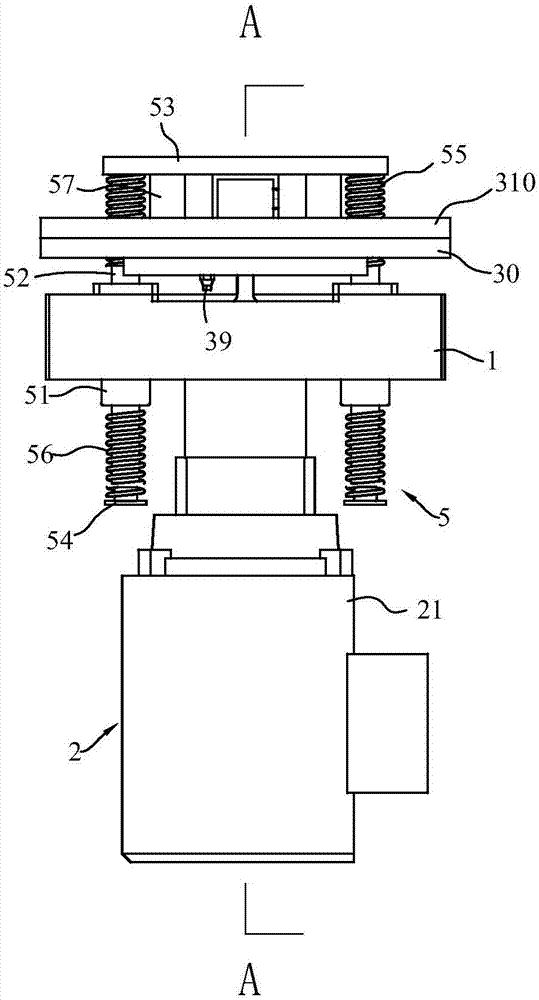

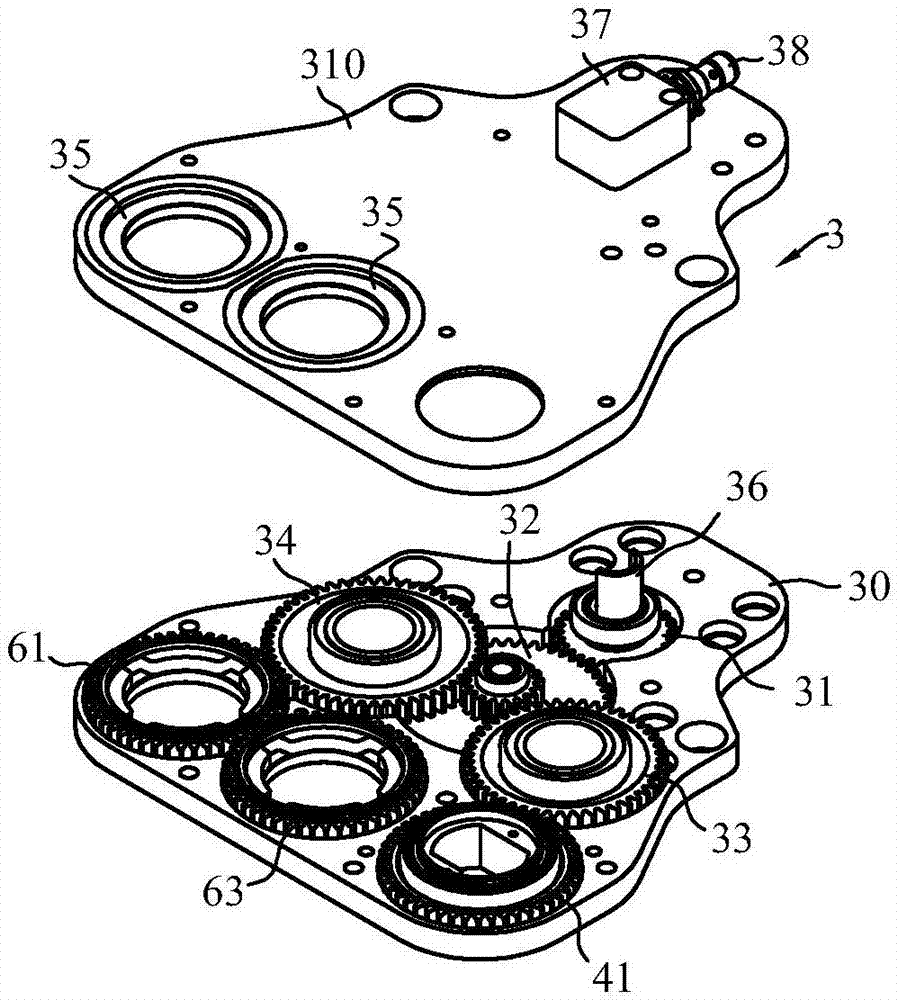

Self-adapting rotation machining device

ActiveCN107088671AReduce weightRealize the cutting operationMilling equipment detailsEngineeringMachining

The invention discloses a self-adapting rotation machining device used for the field of automatic machining equipment. The self-adapting rotation machining device comprises a machine base, a power device and a transmission device; the transmission device is provided with a cap repairing unit and a transmission component in direct or indirect transmission connection with the cap repairing unit, and the transmission device is installed on the machine base through a flexible floating mechanism; and the power device is fixedly installed on the machine base and achieves power transmitting with the transmission component through a flexible transmission mechanism. By means of the above scheme, the power device and the transmission device are separated, the weight of the transmission device is reduced, and finally the floating milling machining cutting amount is more even.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

Buffer assembly of vacuum molding and cutting machine

ActiveUS9314958B2Improve cutting effectImprove cut qualityMetal working apparatusVibration suppression adjustmentsEngineeringPiston

Disclosed is a buffer assembly of a vacuum molding and cutting machine, and the buffer assembly includes a lower mold base, at least four hydraulic elements and a movable plate. The lower mold base has at least four installing holes for installing the hydraulic elements respectively, and each hydraulic element includes a piston plunger for propping the movable plate to a predetermined distance. When the cutting thickness is 0.1 mm-0.5 mm of a sheet, the impact force can be absorbed effectively to maintain the parallelism for the cutting, so as to improve the cutting quality and extend the service life of a die cutting tool.

Owner:CHENG MEI MACHINE

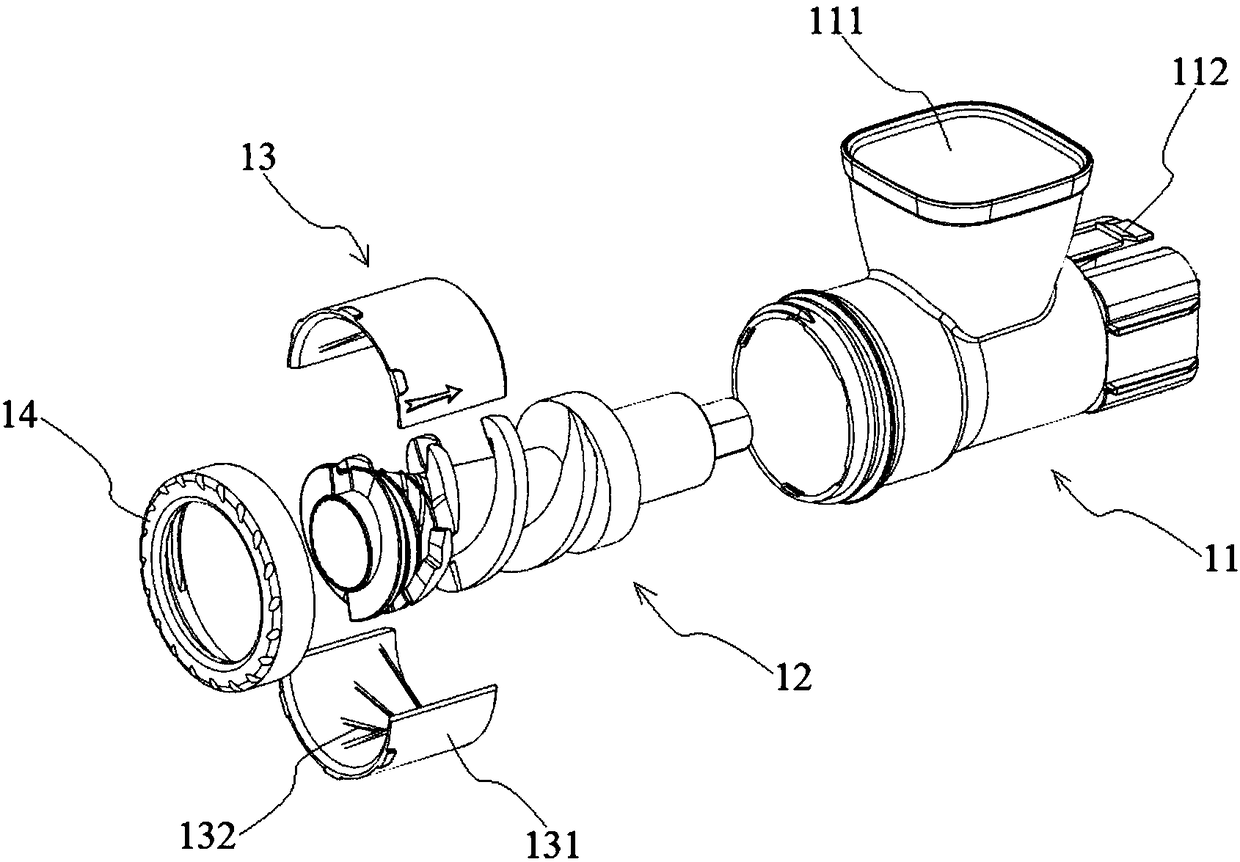

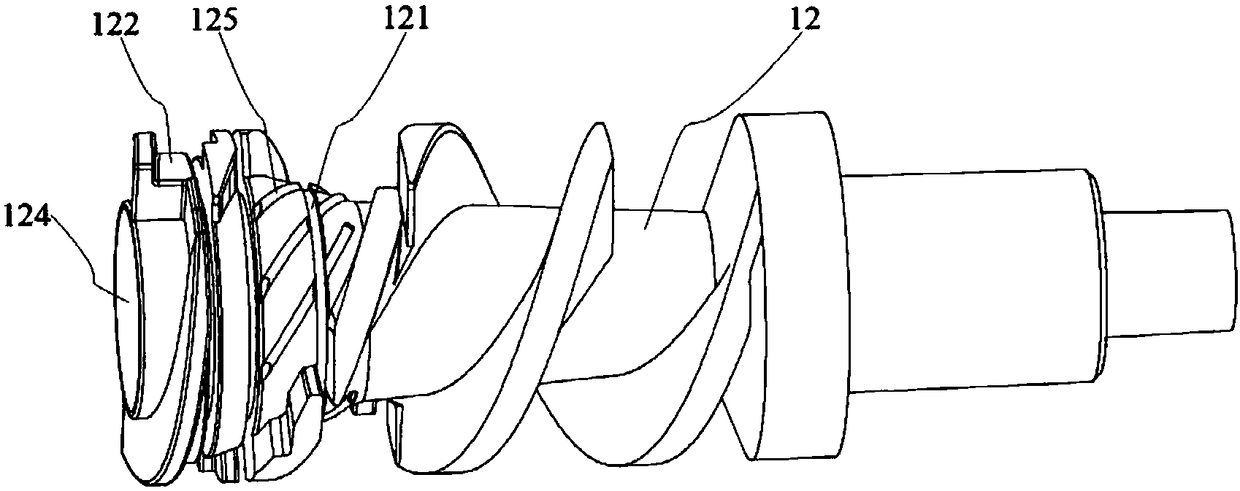

A labor-saving grinding mechanism and a meat grinder using it

ActiveCN106076516BUniform cutTwisting labor-saving and easyGrain treatmentsPulp and paper industryKnife blades

The invention discloses a labor-saving grinding mechanism and a meat grinding machine with the mechanism, and belongs to the technical field of grinding machines. The labor-saving grinding mechanism comprises a cylinder and a screw rod arranged in the cylinder and further comprises two blade sets clamped on the screw rod; the blade sets are positioned in the cylinder, and therefore rotation of the blade sets is limited; each blade set comprises a blade holder and a plurality of blades fixed to the blade holder at intervals; each blade is perpendicular to the axial direction of the screw rod and is matched with a cutter groove in the screw rod; the invention further discloses the meat grinding machine with the labor-saving grinding mechanism. The two sets of blades clamped on the screw rod are utilized for achieving uniform grinding of meat, grinding is more labor-saving and easy, and the grinding efficiency is high; the possibility that a consumer makes contact with the blades does not exist, use safety of the meat grinding machine is improved, the grinding mechanism and the meat grinding machine are convenient to dismount and mount, and use is convenient and rapid.

Owner:常州麦鲜生电器有限公司

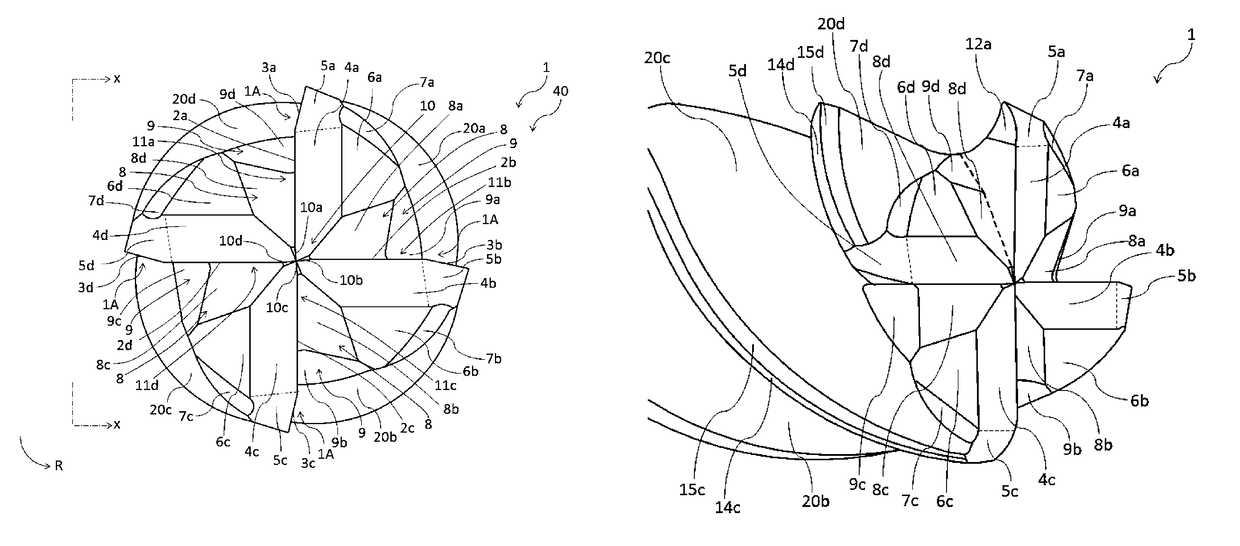

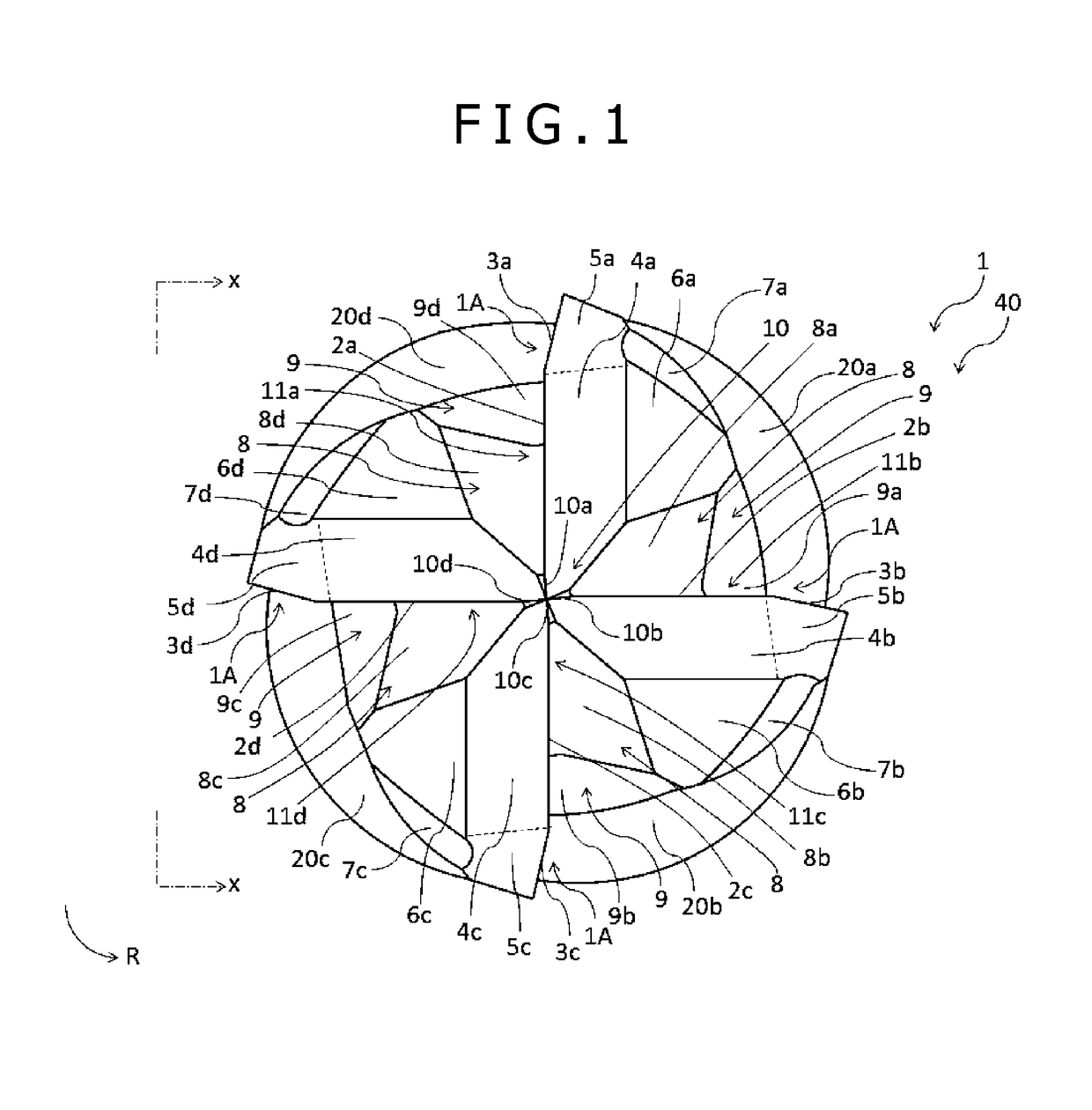

Ceramic end mill and method for cutting difficult-to-cut material using the same

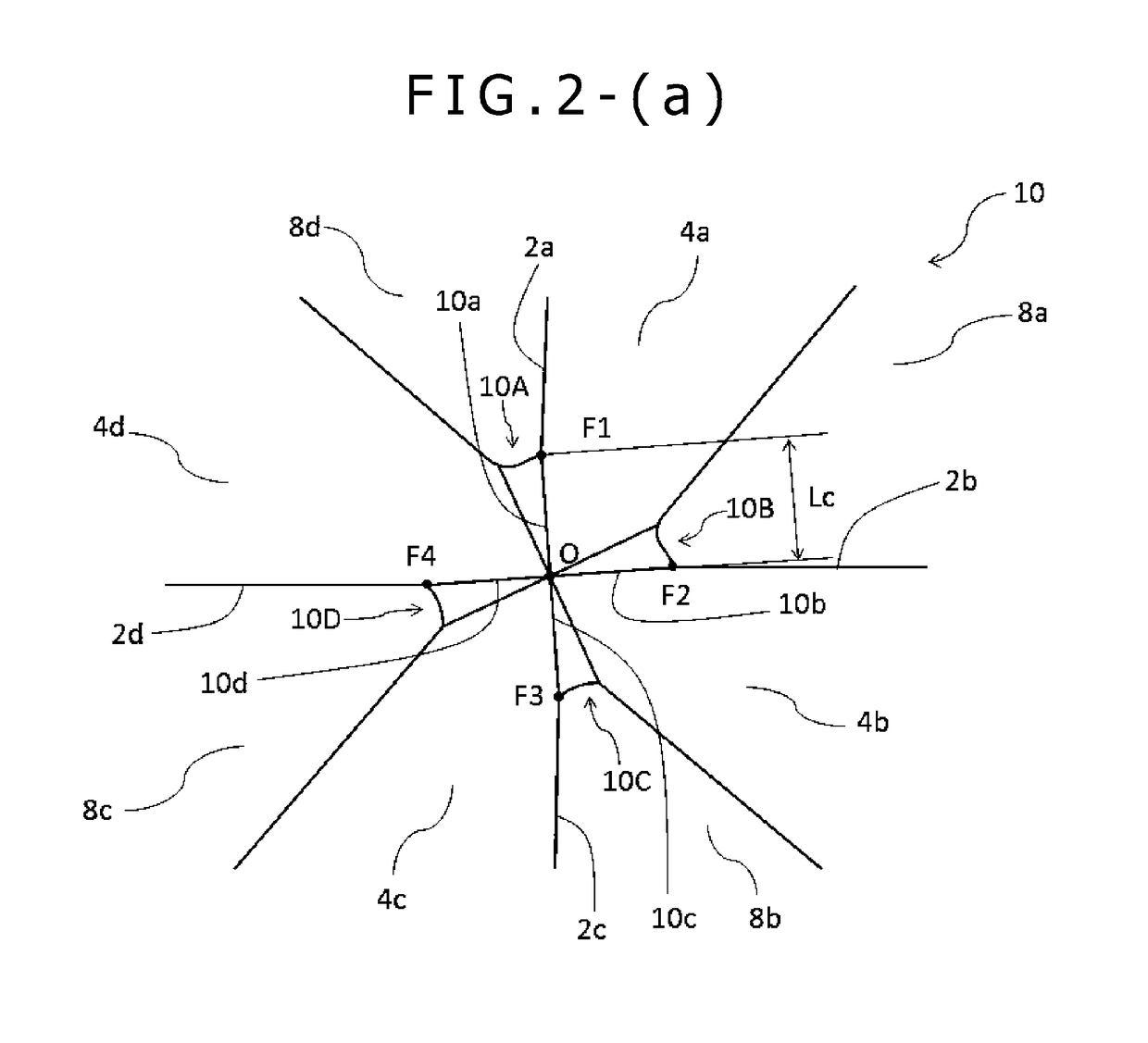

Ceramic end mill with cutting edge portion including gashes between cutting edges and adjacent in a rotation direction. Center cut edges are formed at end cutting edges close to and facing rotation axis O. Center grooves are formed on rear sides of center cut edges and end cutting edges in the rotation direction continuous with a radial direction. The center grooves are continuous with positions where end cutting edge second surfaces face or approach rotation axis O. End cutting edge second surfaces are laid between center cut edges and end cutting edges. Center grooves are formed between end cutting edge second surfaces and center cut edges positioned on a rear side of end cutting edge second surfaces in the rotation direction. The center grooves pass on rotation axis O. Center grooves double as rake faces of the respective center cut edges and are continuous with the gashes.

Owner:HITACHI TOOL ENG LTD

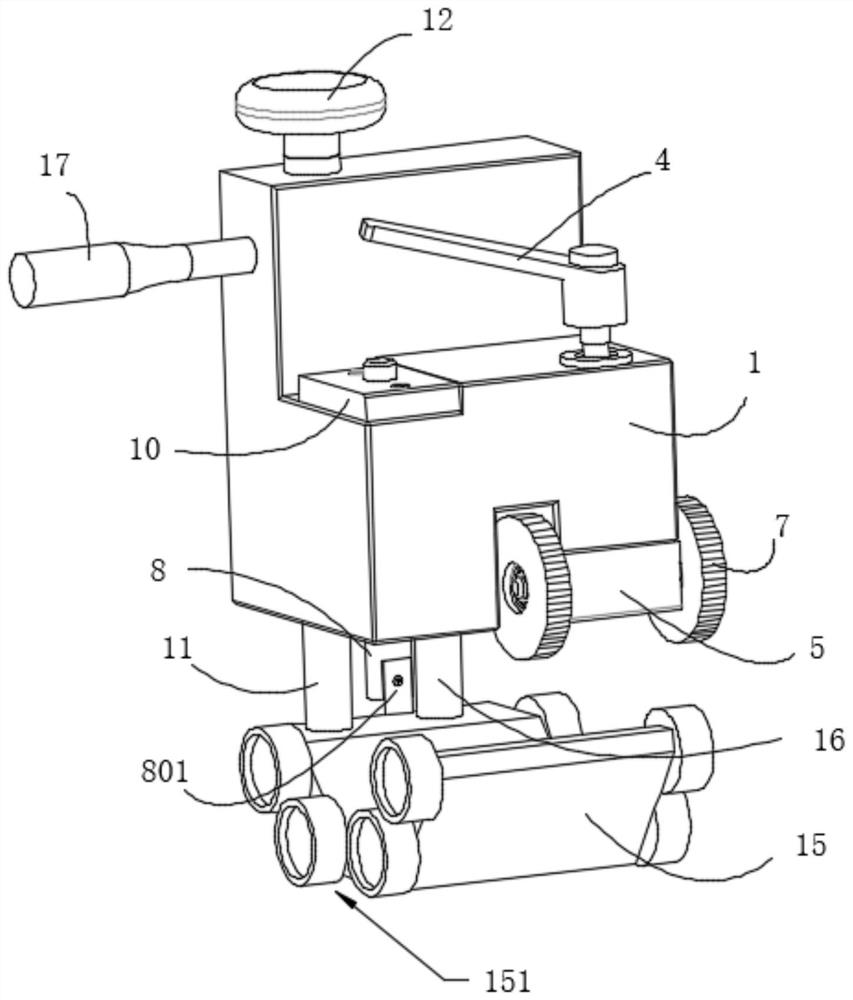

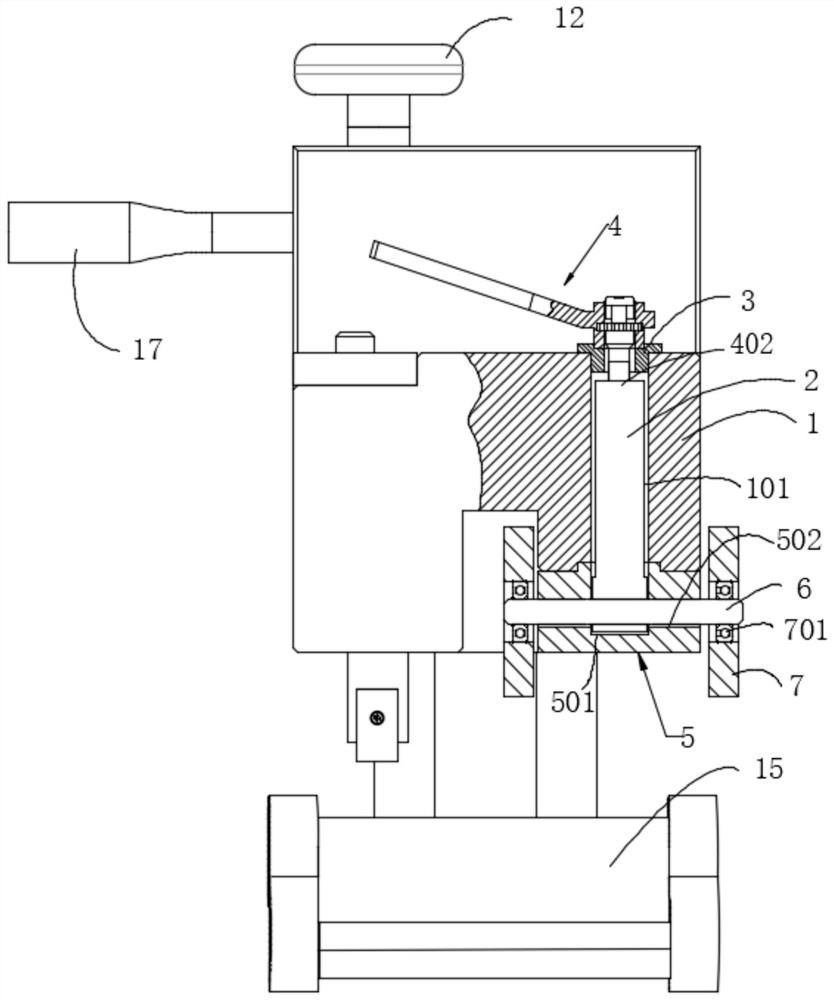

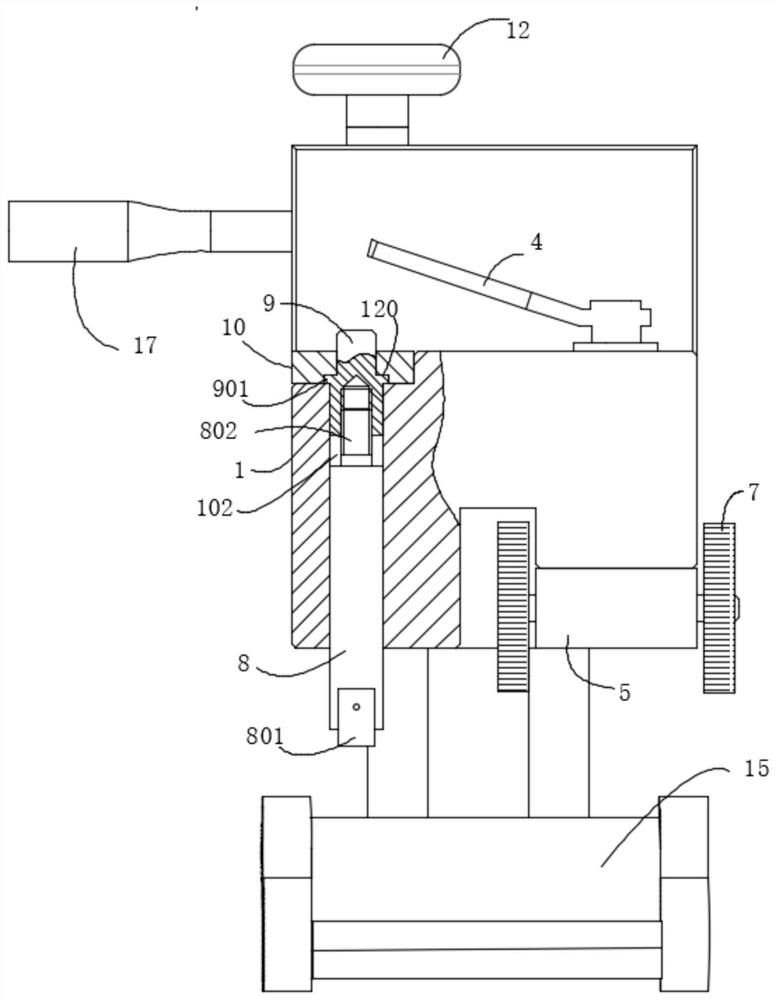

Rotary scraper

The invention discloses a rotary scraper machine, which comprises a machine body (1), one side of the body (1) is provided with a rotating handle (17), the upper part of the body (1) is provided with a first through hole (101), the first The through hole (101) is provided with a driving wheel locking pull rod (2), one side of the first through hole (101) is provided with a positioning ring (3), and the positioning ring (3) is provided with a ratchet directional locking handle (4 ), the bottom of the ratchet directional locking handle (4) is provided with an external threaded rod (402), and the external threaded rod (402) is connected with one end of the driving wheel locking pull bar (2). The invention can effectively scrape the circumferential surface of the plastic pipe, cut evenly, and have good processing quality; in addition, it is small in size and easy to carry.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composite board sawing on-line tracking deburring limiting control device and operation method thereof

PendingCN112658352AFacilitates deburring workCompact structureAutomatic control devicesFeeding apparatusTool bitProduction line

The invention discloses a composite board sawing on-line tracking deburring limiting control device and an operation method thereof. The device comprise a support, wherein a dragging plate is arranged on the support in a sliding mode, and limiting compensation assemblies are oppositely arranged on the upper surface of the dragging plate in the longitudinal direction; a rotary cutting tool assembly is further arranged on each limiting compensation assembly, and the two rotary cutting tool assemblies are arranged in the transverse direction of the dragging plate in a back-to-back mode; and limiting plates are arranged at tool bits at the output ends of the rotary cutting tool assemblies in a matched mode, the limiting plates and the tool bits correspond to workpieces, and the workpieces are located at the two outer ends of the dragging plate in the transverse direction. The deburring work of a composite board line in the continuous production process can be conveniently completed through cooperative use of the two symmetrically-arranged rotary cutting tool assemblies and the limiting compensation assemblies, operation of the device is easy and convenient, the device is combined in automatic production line equipment, action is sensitive, the machining requirement is met, the production efficiency and the finished product rate are greatly improved, and manual cleaning is not needed.

Owner:无锡市威华机械有限公司

Hooked side face edge trimming machine of oil pan

The invention relates to a hooked side face edge trimming machine of an oil pan. The machine comprises a machine base, a rotating shaft rotatably arranged on the machine base and a drive device for driving the rotating shaft; a convex die base is arranged on the machine base, the output end of the rotating shaft is eccentrically arranged, the output end of the rotating shaft is sleeved with a bearing, a concave die base is arranged on the machine base in a front-and-back sliding manner, the outer side of the circumference of the bearing is sleeved with the concave die base, and the concave die base is provided with an edge cutting concave die in a vertical sliding manner; the convex die base can slide in a left-and-right manner along the machine base, and a mounting base used for containing of the oil pan is arranged on the convex die base in a front-and-back sliding manner.

Owner:泉州市双塔汽车零件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com