Cloth cutting device for garment processing

A cutting device, cloth technology, applied in the cutting of textile materials, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

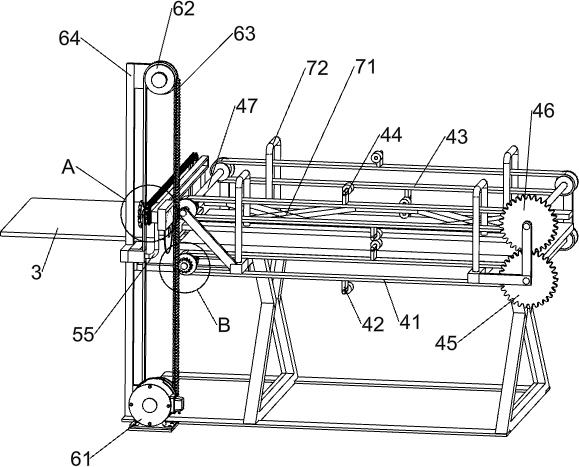

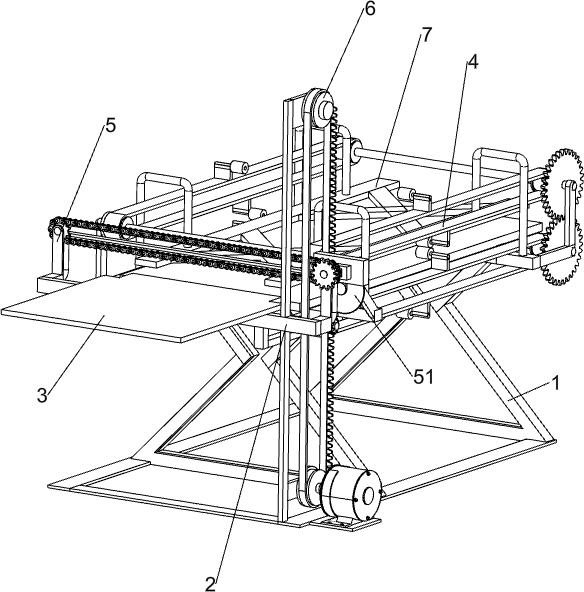

[0022] A cloth cutting device for garment processing, such as Figure 1-5 As shown, it includes a base 1, a mounting frame 2, a material placing plate 3, a material shifting mechanism 4 and a cutting mechanism 5, the upper left side of the base 1 is connected with a mounting frame 2, and the top of the mounting frame 2 is connected with a material setting plate 3 in the middle A cutting mechanism 5 is installed on the right side of the mounting frame 2, and a material shifting mechanism 4 is installed between the inner surfaces of the base 1 top.

[0023] The material shifting mechanism 4 includes a first conveyor belt 41, a first clamping rod 42, a second conveyor belt 43, a second clamping rod 44, a first gear 45, a second gear 46, a transmission shaft 47 and a third gear 48, and the base 1. Two drive shafts 47 are rotatably connected between the inner surface of the upper left side, and the two drive shafts 47 on the left are symmetrical up and down. Two drive shafts 47 are...

Embodiment 2

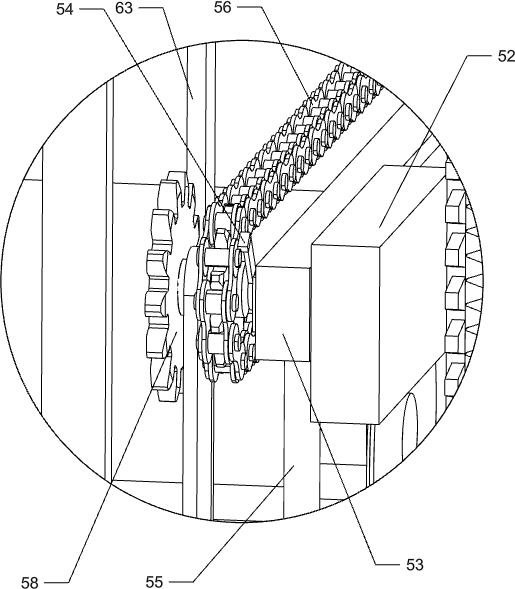

[0027] On the basis of Example 1, such as Figure 1-5 As shown, a linkage mechanism 6 is also included, and the linkage mechanism 6 includes a servo motor 61, a pulley 62, a rack belt 63 and a fixed frame 64, the bottom left side of the base 1 is equipped with a servo motor 61, and the output shaft of the servo motor 61 passes through The shaft coupling is connected with a pulley 62, and the top of the mounting frame 2 on the front side of the material plate 3 is connected with a fixed mount 64, and the fixed mount 64 is also connected with a pulley 62 in a rotating manner, and a rack belt 63 is connected between the two pulleys 62. The rack belt 63 meshes with the third gear 48 , and the rack belt 63 also meshes with the fourth gear 58 .

[0028] Initially, the rack belt 63 meshes with the third gear 48, and the servo motor 61 is manually activated to make the pulley 62 on it rotate counterclockwise. The counterclockwise rotation of the pulley 62 drives the rack belt 63 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com