Inclined transplanting type cassava planting machine

A technology for planting machines and cassava, applied in potato planting machines, planting methods, fertilizer distributors, etc., can solve the problems of increasing the lifting torque of three-point suspension, the soil cannot be reflowed and covered in time, and the cassava seed stems will be burned, etc., to achieve Simple structure, low cleavage damage, strong photosynthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

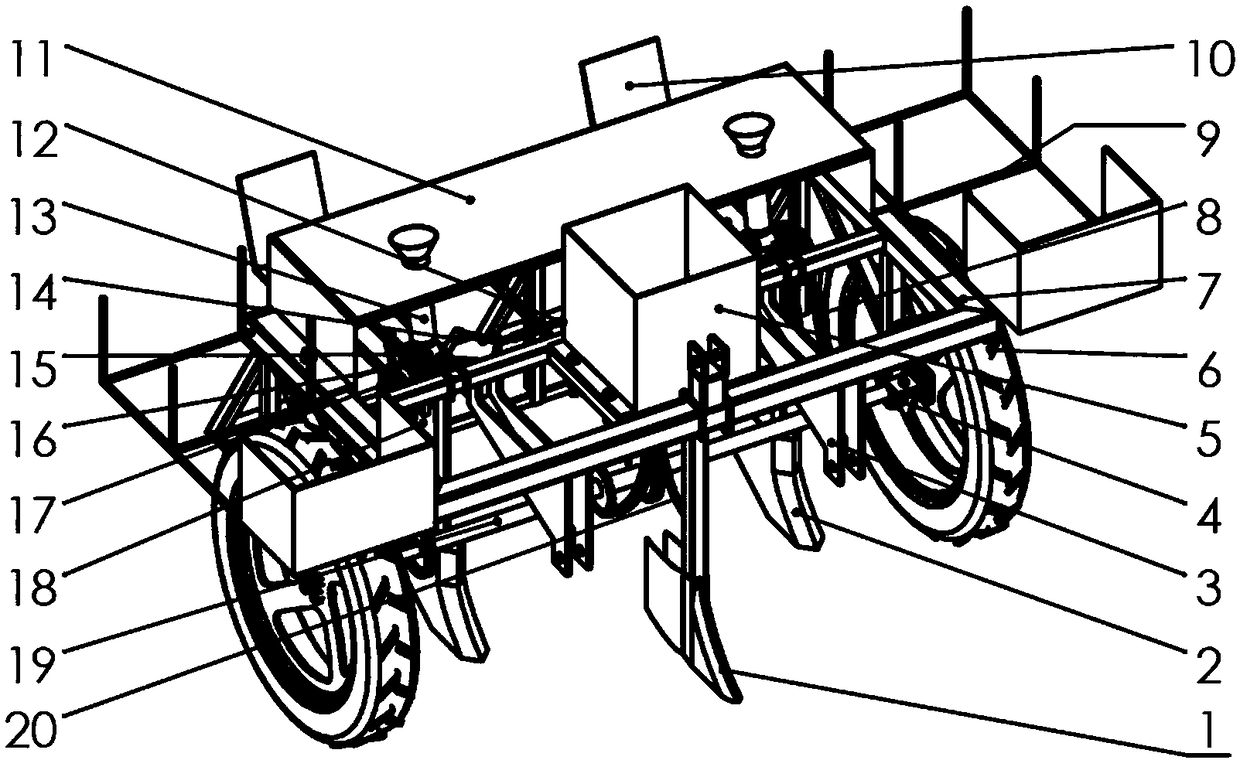

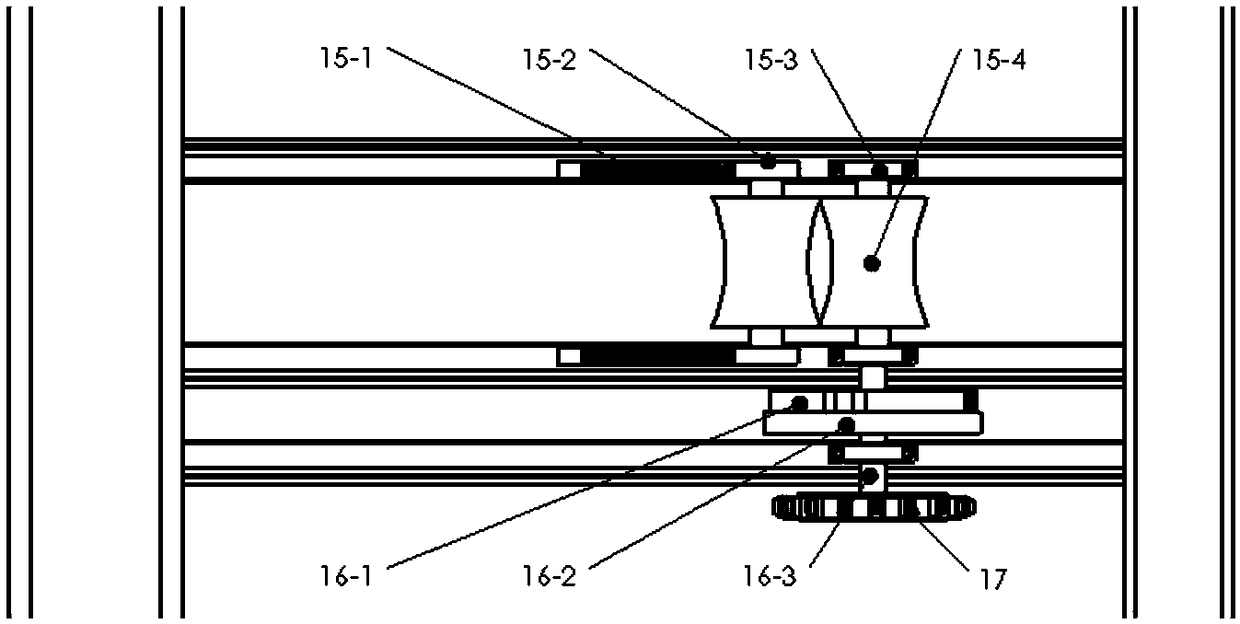

[0035] like Figure 1-10 As shown, the inclined transplanting type cassava planter of the present invention includes a frame 7, a three-point suspension device 3, two sowing conveying sprockets 17, two clamping conveying mechanisms 15, two scissor mechanisms 14, two A sheave mechanism 16, a stem guide tube, two background seats 10, two stem placement racks 9, a shield 11, two sowing openers 2, a fertilizer discharge system 5, a ground wheel system and a power transmission system 12;

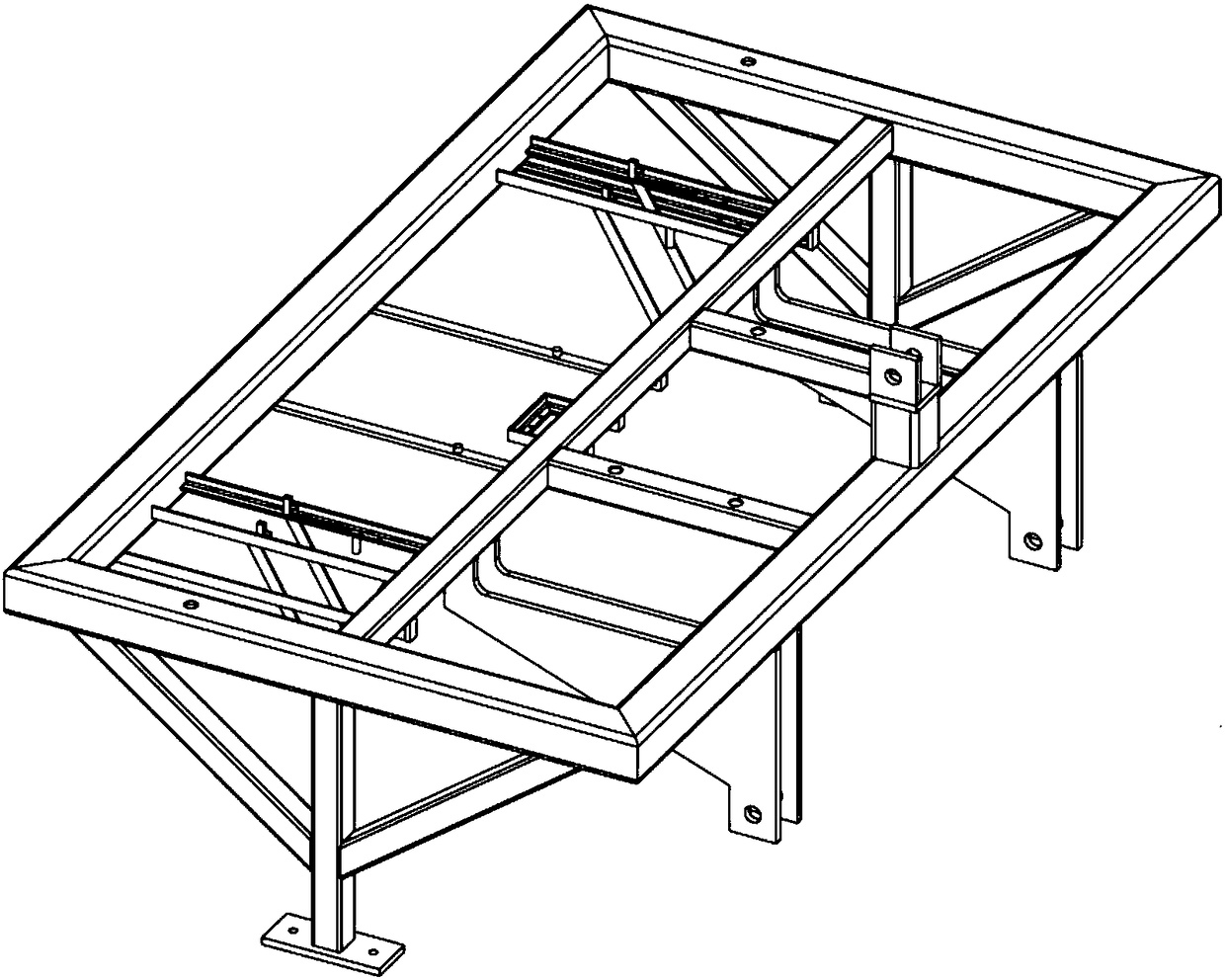

[0036] The frame 7 is welded by a hollow rectangular steel pipe and an equilateral angle steel, and the equilateral angle steel is symmetrically welded on the middle beam and the rear beam of the frame 7, and two background seats 10 are symmetrically welded on the rear beam of the frame 7 , two seed stem placement frames 9 are symmetrically welded on the side beams at the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com