Patents

Literature

38results about How to "Constant contact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

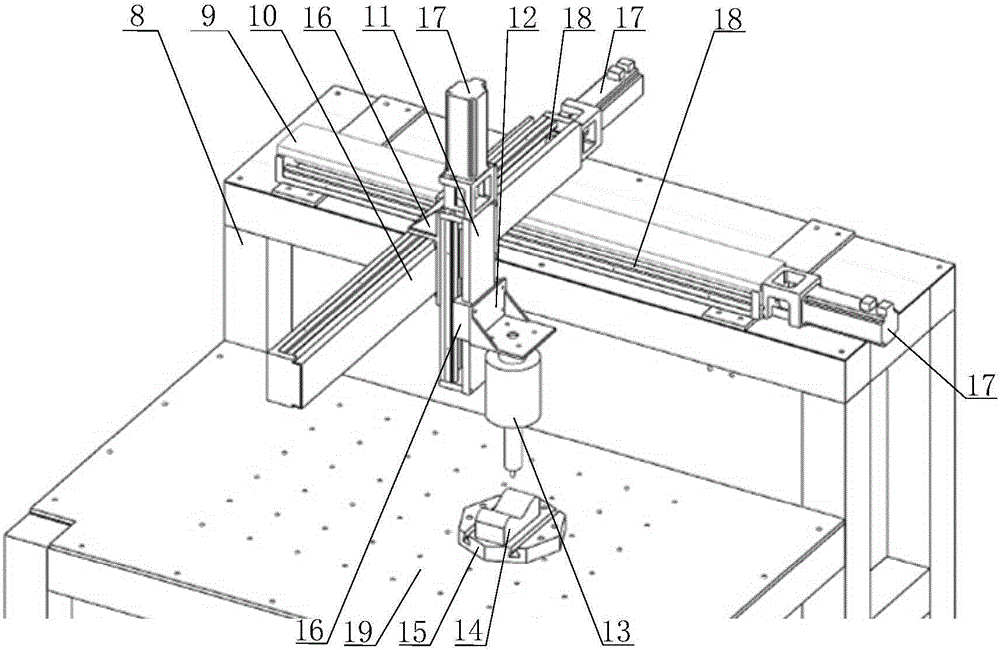

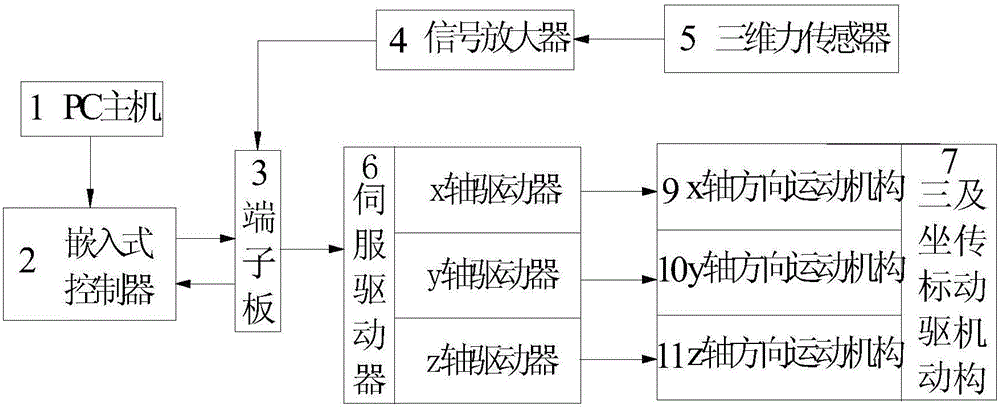

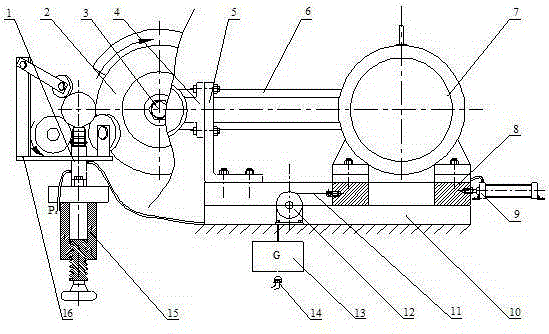

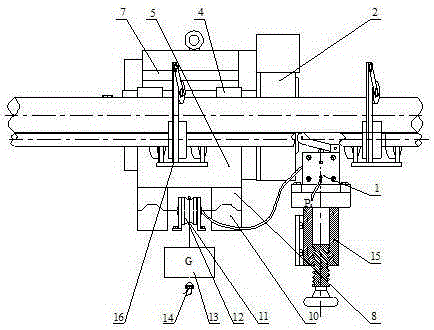

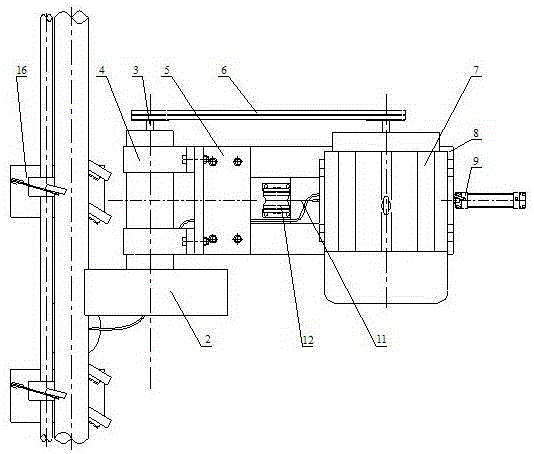

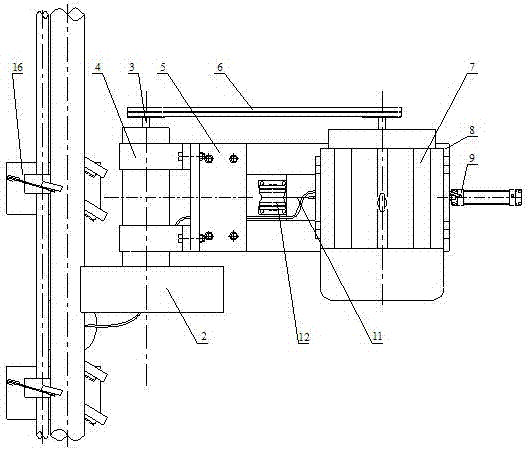

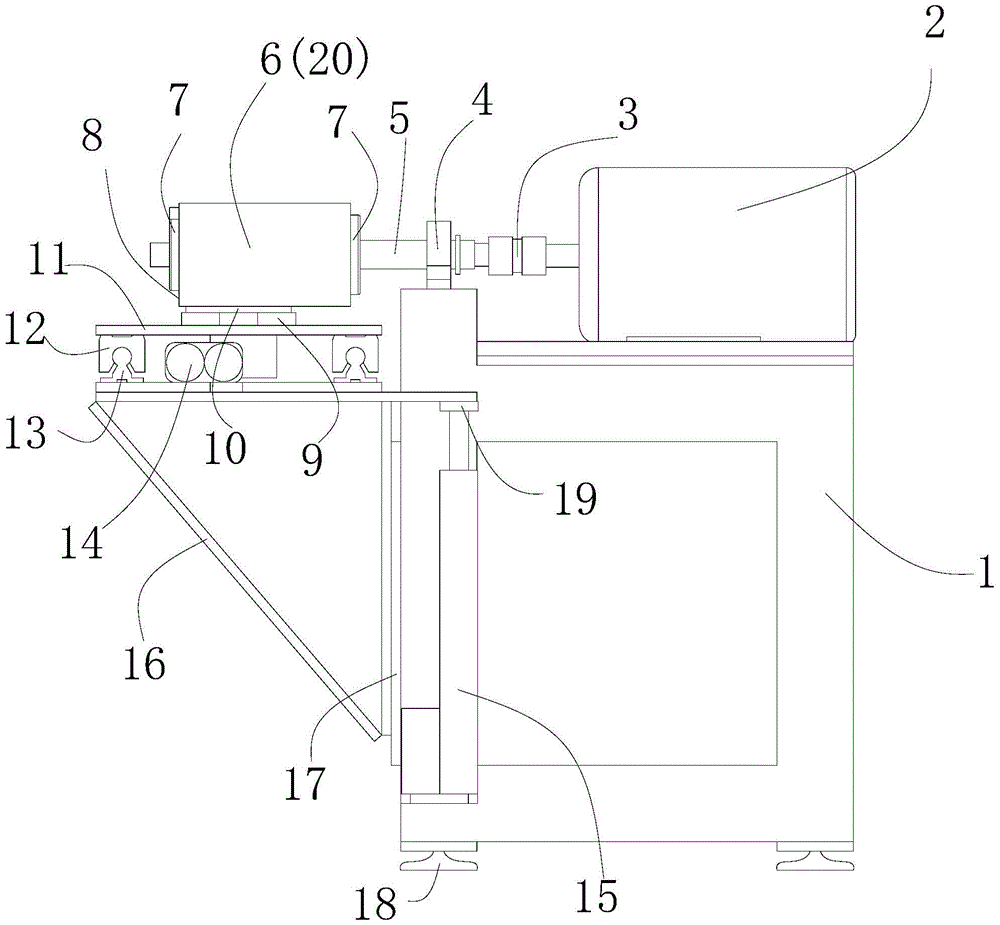

Force position coupling micro-motion precise polishing device and online force detection and control method

ActiveCN105729305AWith three-dimensional movementConstant contact forceGrinding carriagesGrinding feed controlMicro motionMachining process

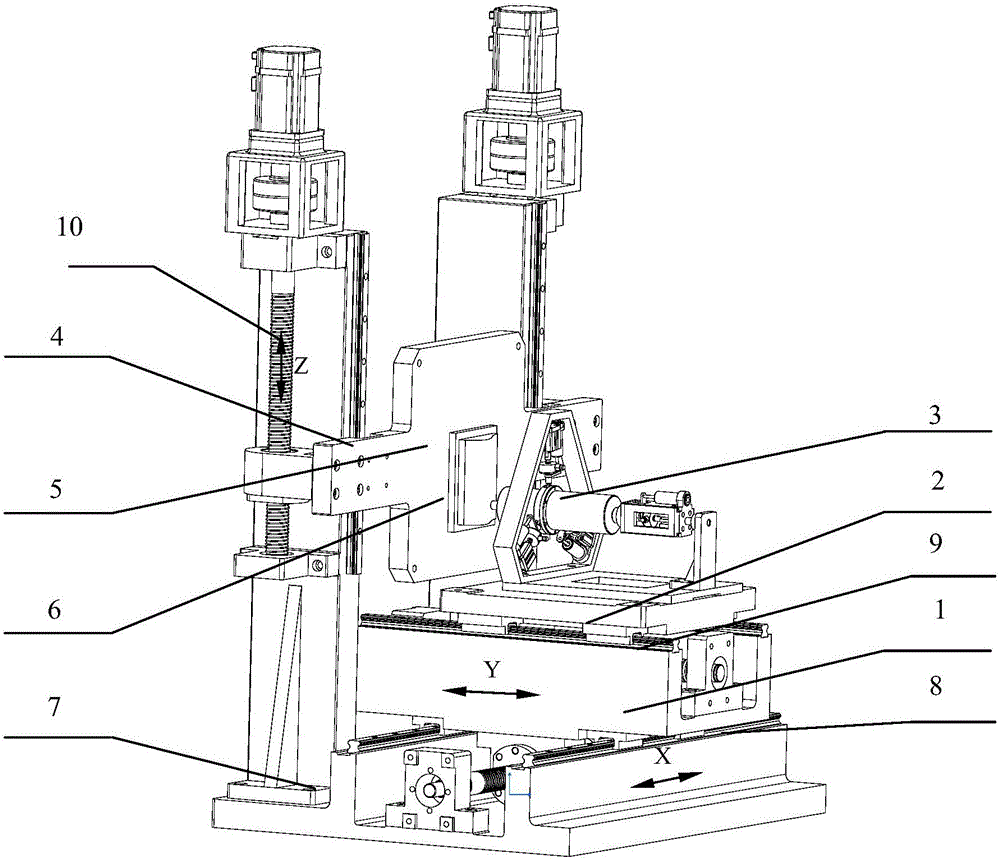

The invention relates to a force position coupling micro-motion precise polishing device and an online force detection and control method, and belongs to the field of machine manufacturing. An X-axis guide rail is fixedly installed on a machine body, and a Y-axis guide rail is installed on a slide carriage of the X-axis guide rail. A slide carriage of the Y-axis guide rail is slidably connected with the Y-axis guide rail. A micro-motion polishing tool system is installed on the slide carriage of the Y-axis guide rail. A Z-axis guide rail is fixedly installed on the machine body. A slide carriage of the Z-axis guide rail is slidably connected with the Z-axis guide rail. A workpiece clamp is fixed to the slide carriage of the Z-axis guide rail. According to the force position coupling micro-motion precise polishing device and the online force detection and control method, three-dimensional movement is provided by a machine, axial and radial micro-motion adjustment of the micro-motion polishing tool system can be achieved, and therefore machining of surfaces of complex workpieces can be achieved; the initial position of a spindle keeps unchanged in the machining process, and the magnitude of contact force of a cutter and the workpieces can be detected online, so that research of the relation of the contact force and the machining quality of the workpieces is facilitated; and meanwhile, control over the contact force of the cutter and the workpieces in the polishing process can be achieved through the micro-motion polishing tool system, and the purpose of improving the machining precision can be well achieved.

Owner:JILIN UNIV

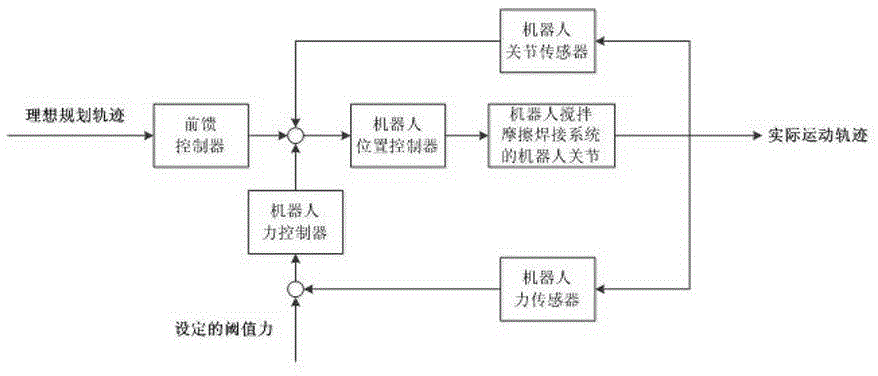

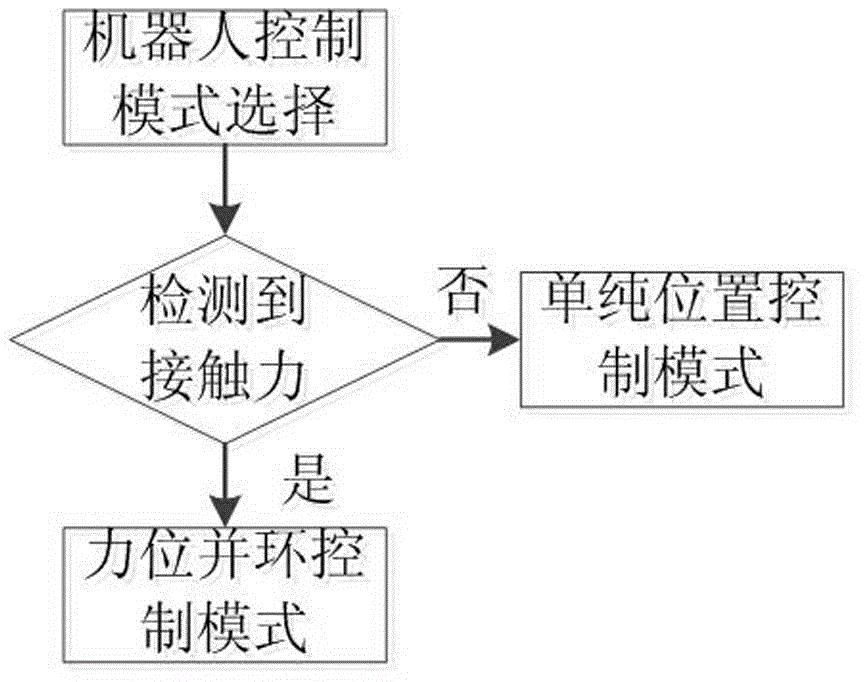

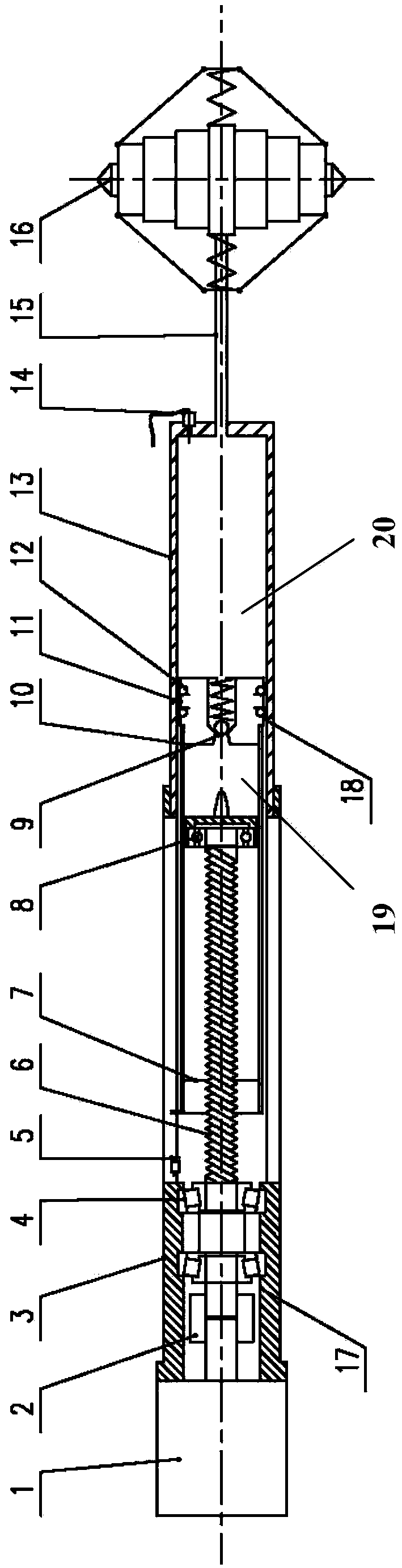

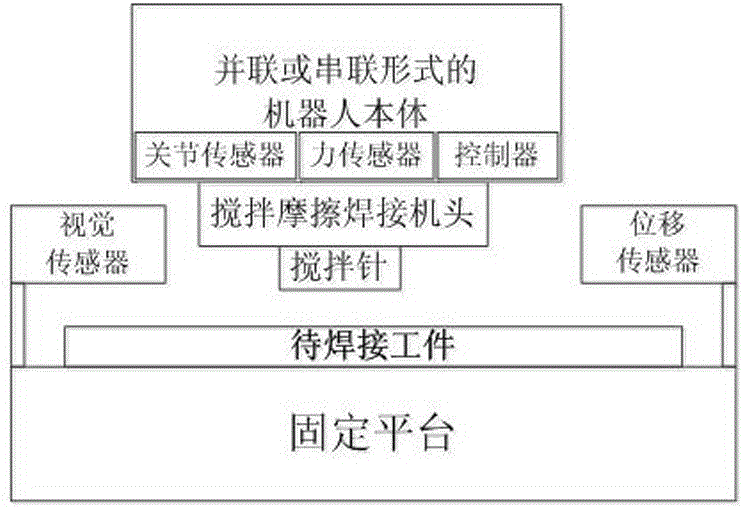

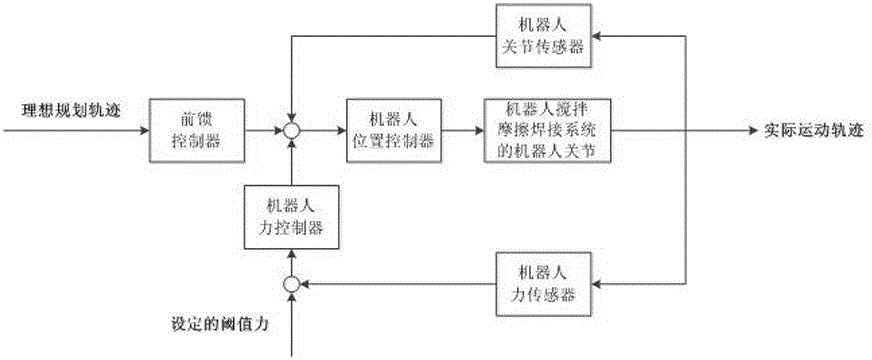

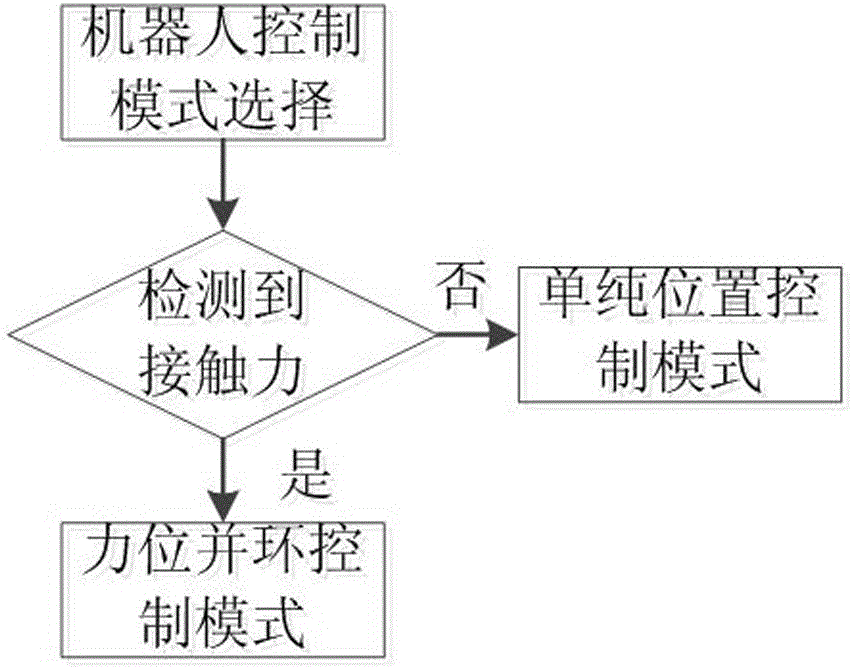

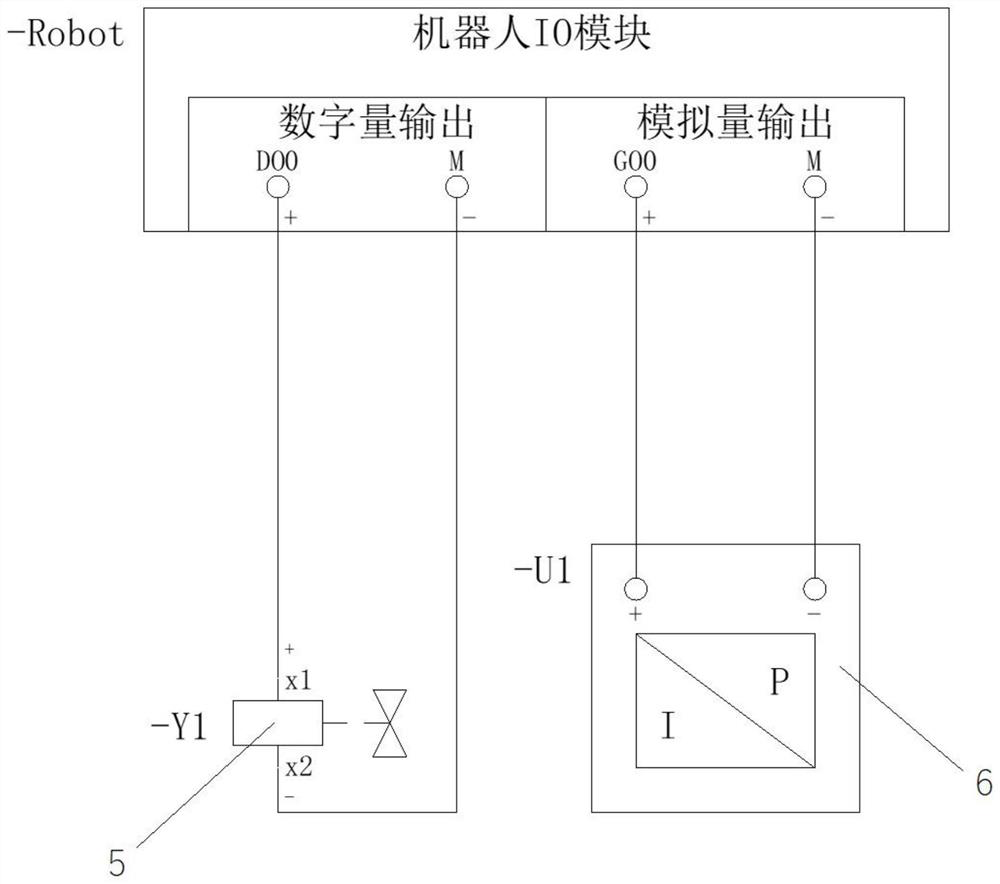

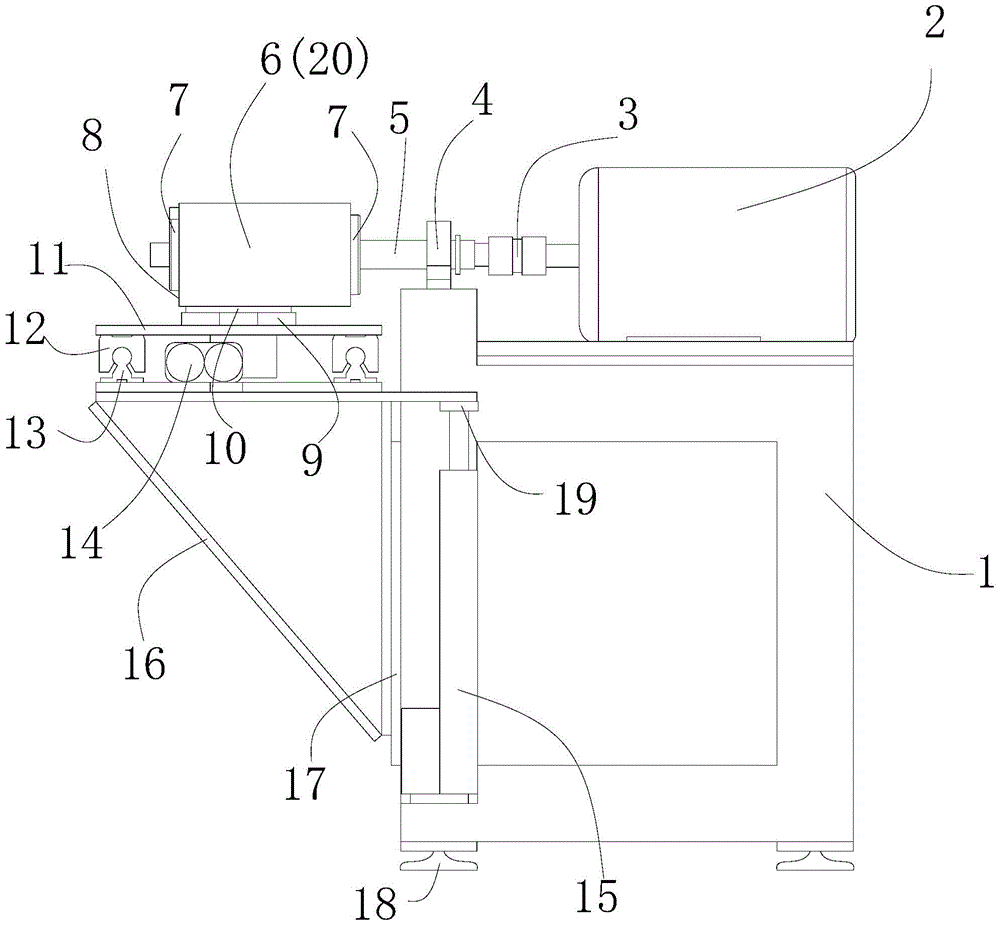

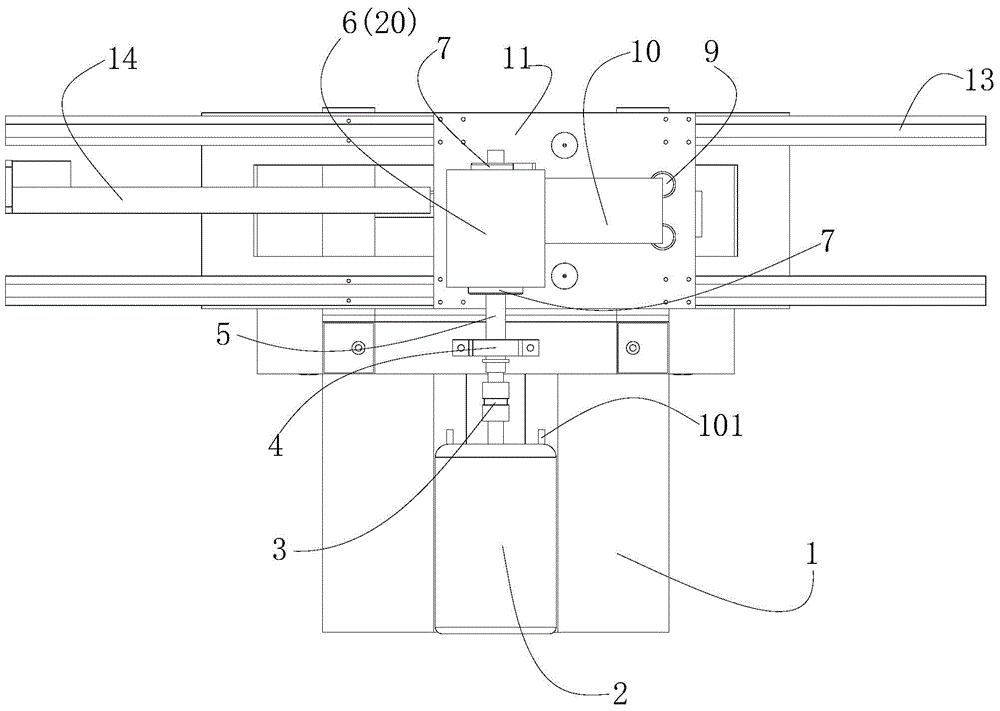

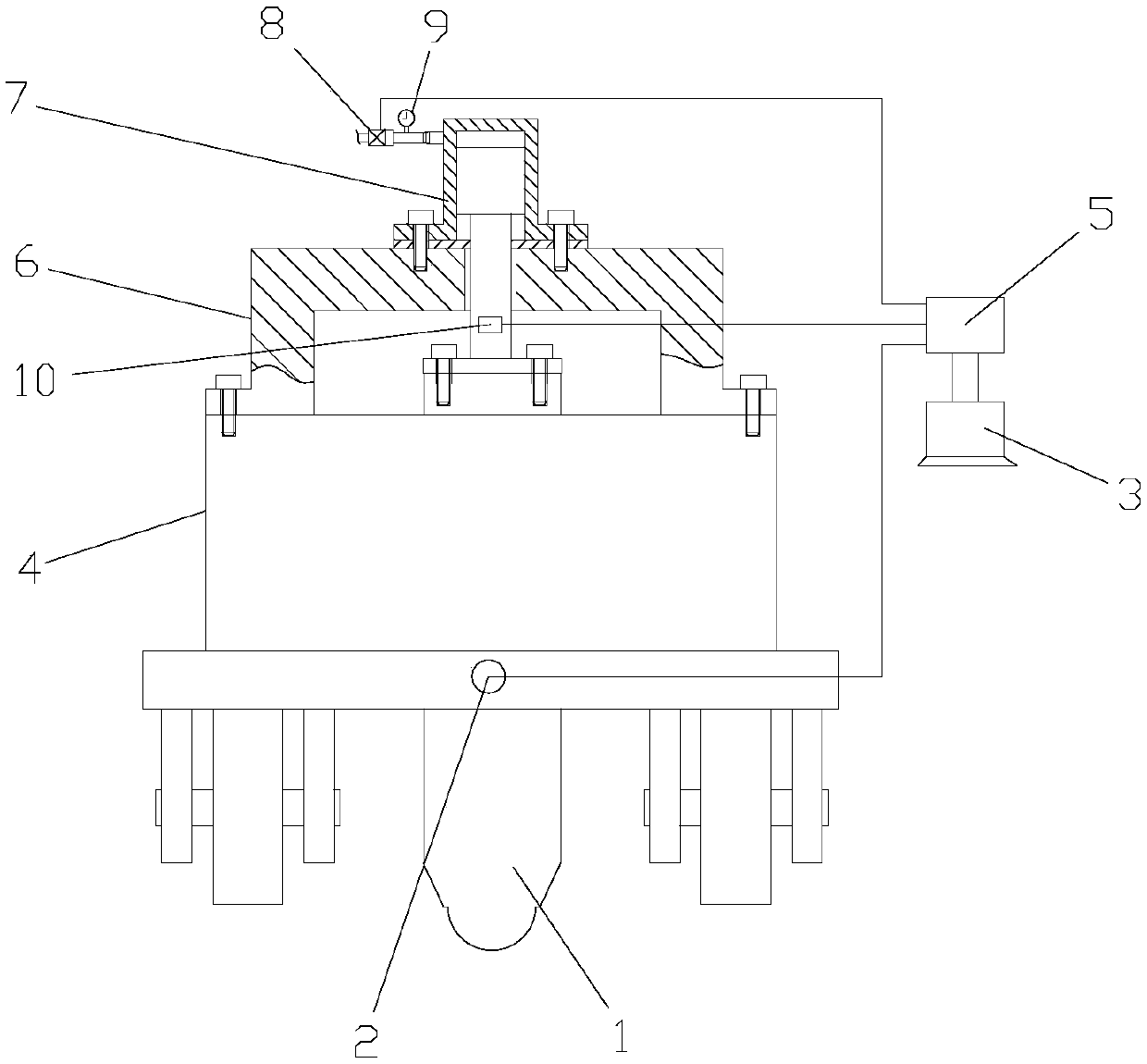

Robot stirring friction welding system and force position parallel loop hybrid control method thereof

ActiveCN104607795AConstant contact forceReal-time control of high-precision motionNon-electric welding apparatusFriction weldingContact force

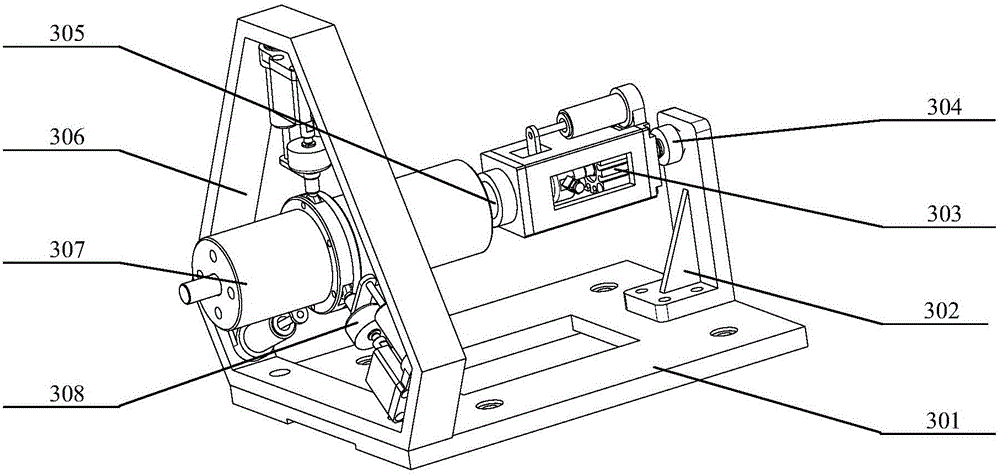

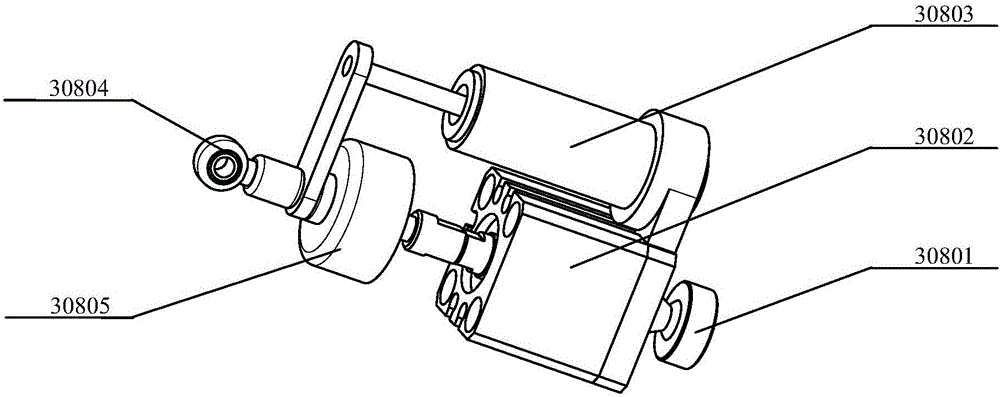

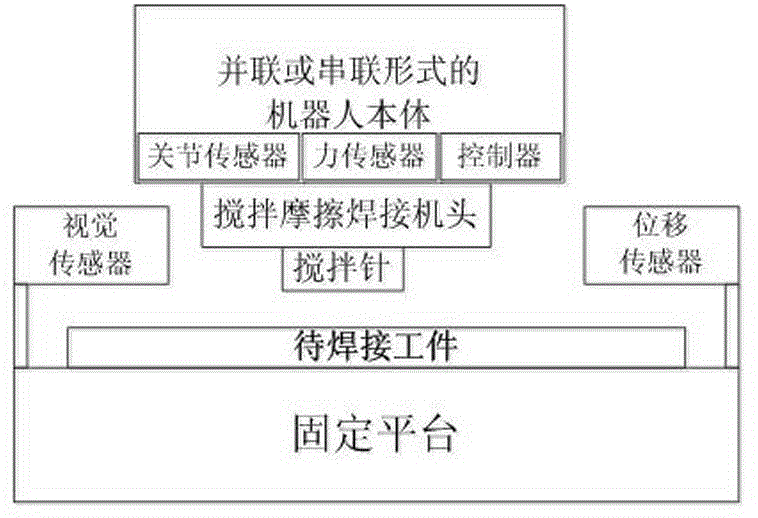

The invention discloses a robot stirring friction welding system which comprises a robot body, a stirring friction welding machine head, a stirring needle, a fixing platform, a displacement sensor and a visual sensor. The stirring friction welding machine head is arranged below the robot body and fixedly connected with a mechanical arm of the robot body, the robot body controls the stirring friction welding machine head to move, and the stirring needle is arranged below the stirring friction welding machine head and moves along with the stirring friction welding machine head. The displacement sensor and the visual sensor are arranged on the fixing platform, and the fixing platform is used for carrying a workpiece to be welded. The contact force of the stirring needle of the stirring friction welding machine head and the workpiece to be welded is constant, the stirring needle moves along an ideal welding track, welding is uniform, the welding depth is consistent, the welding track is obtained through a control algorithm of an inverse kinematics or kinetic model, the welding track is accurate, convenience and practicability are achieved, and a robot can be controlled in real time to complete the high-precision movement for stirring friction welding.

Owner:宁波中创焊接技术有限公司

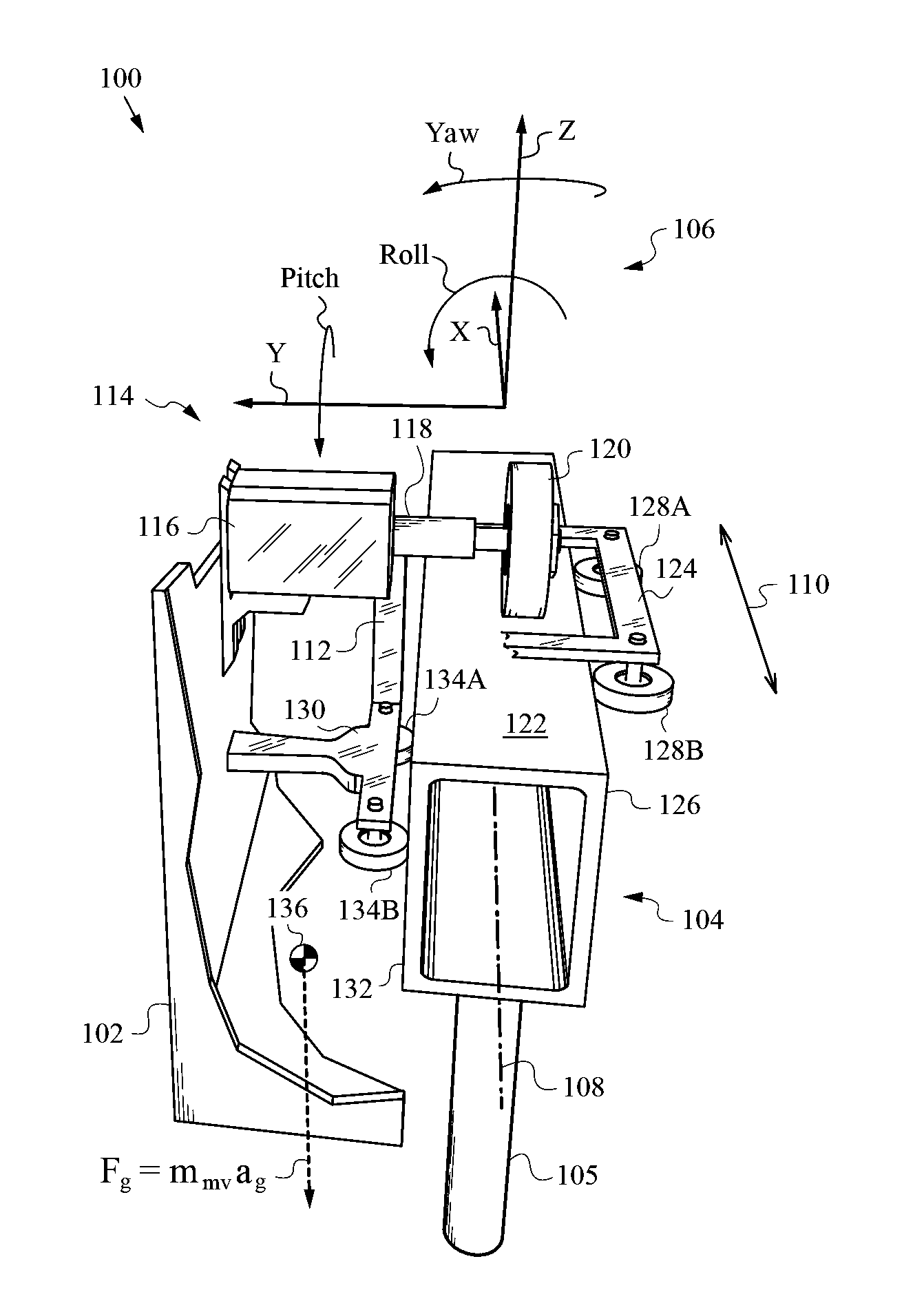

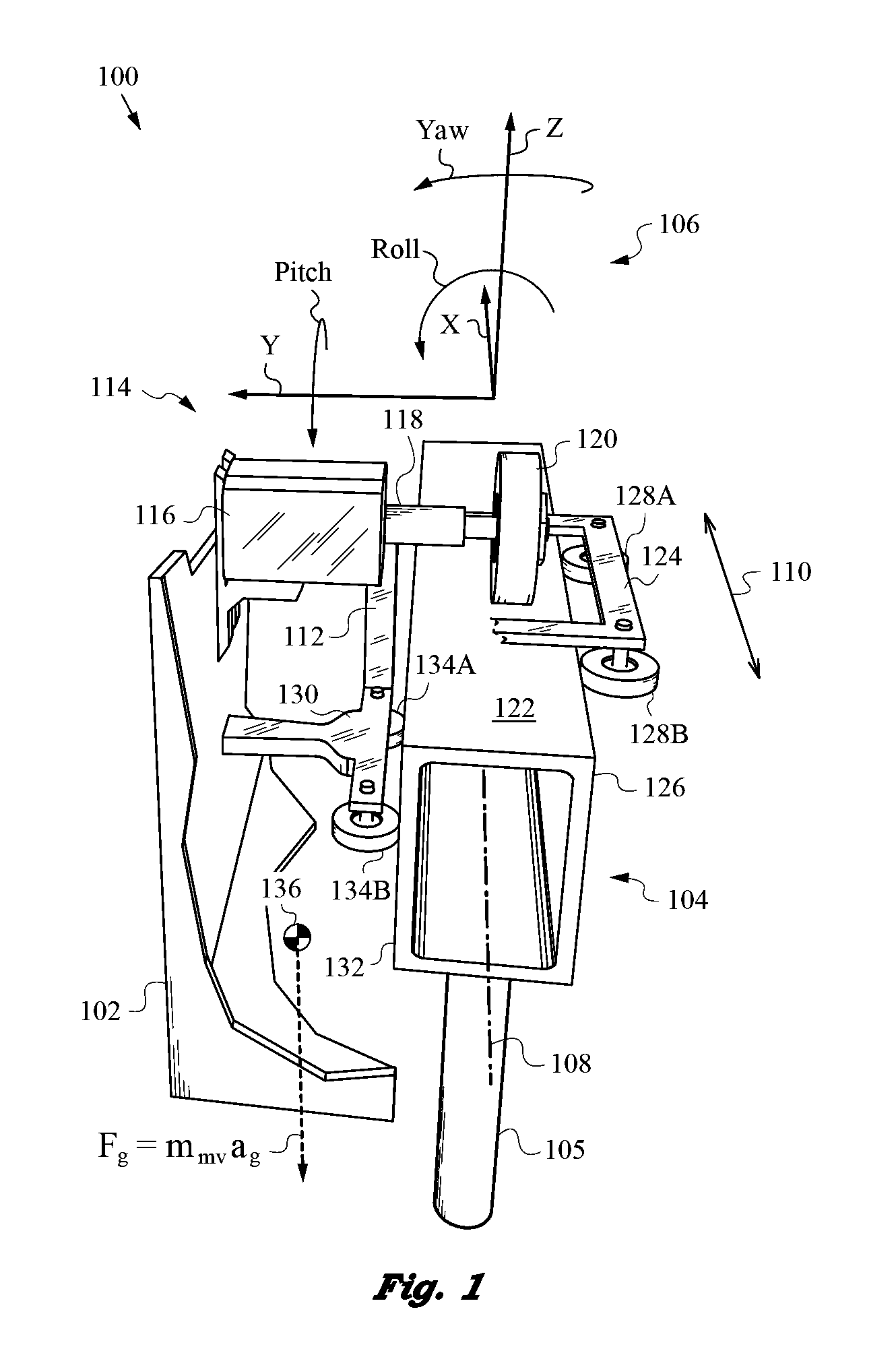

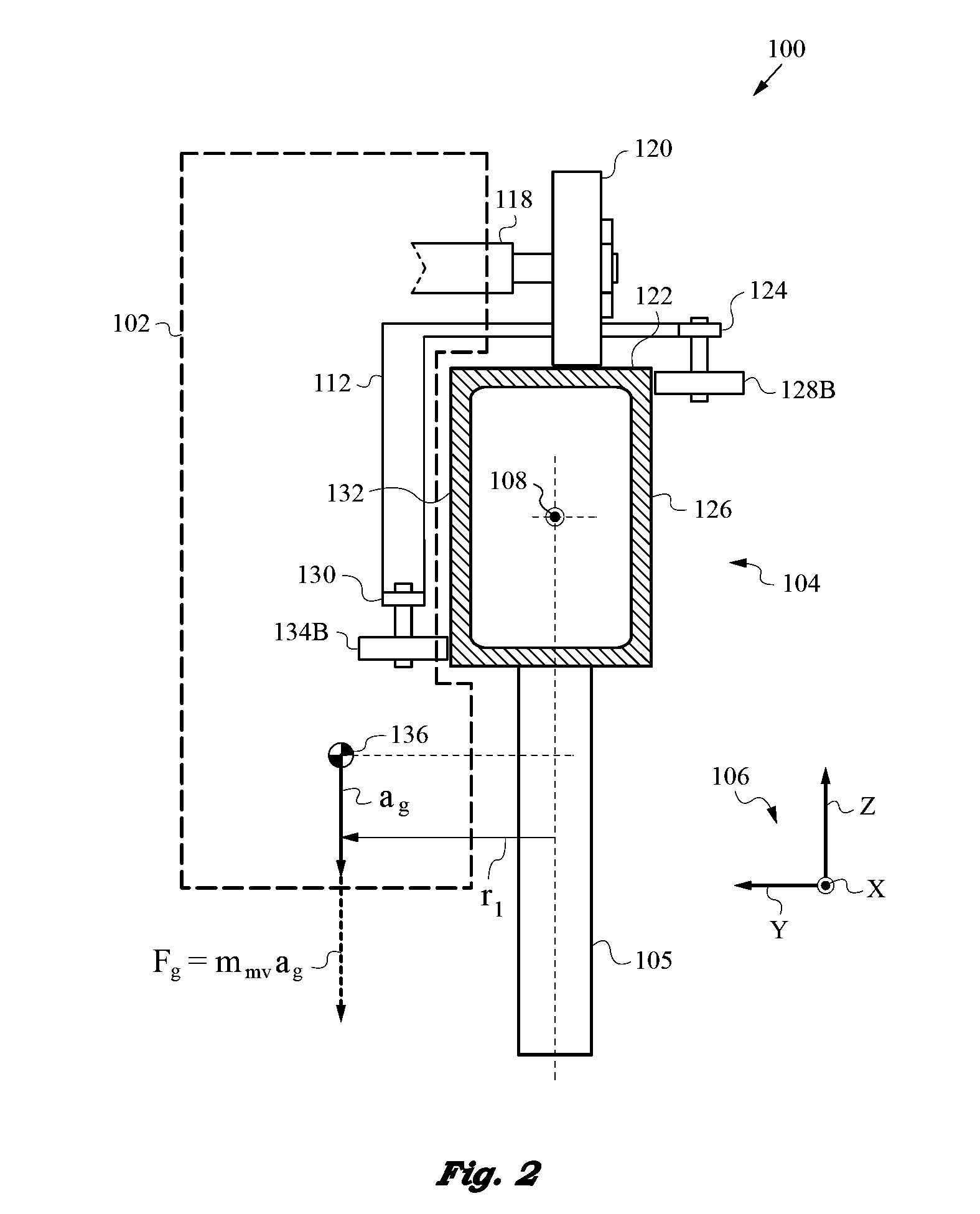

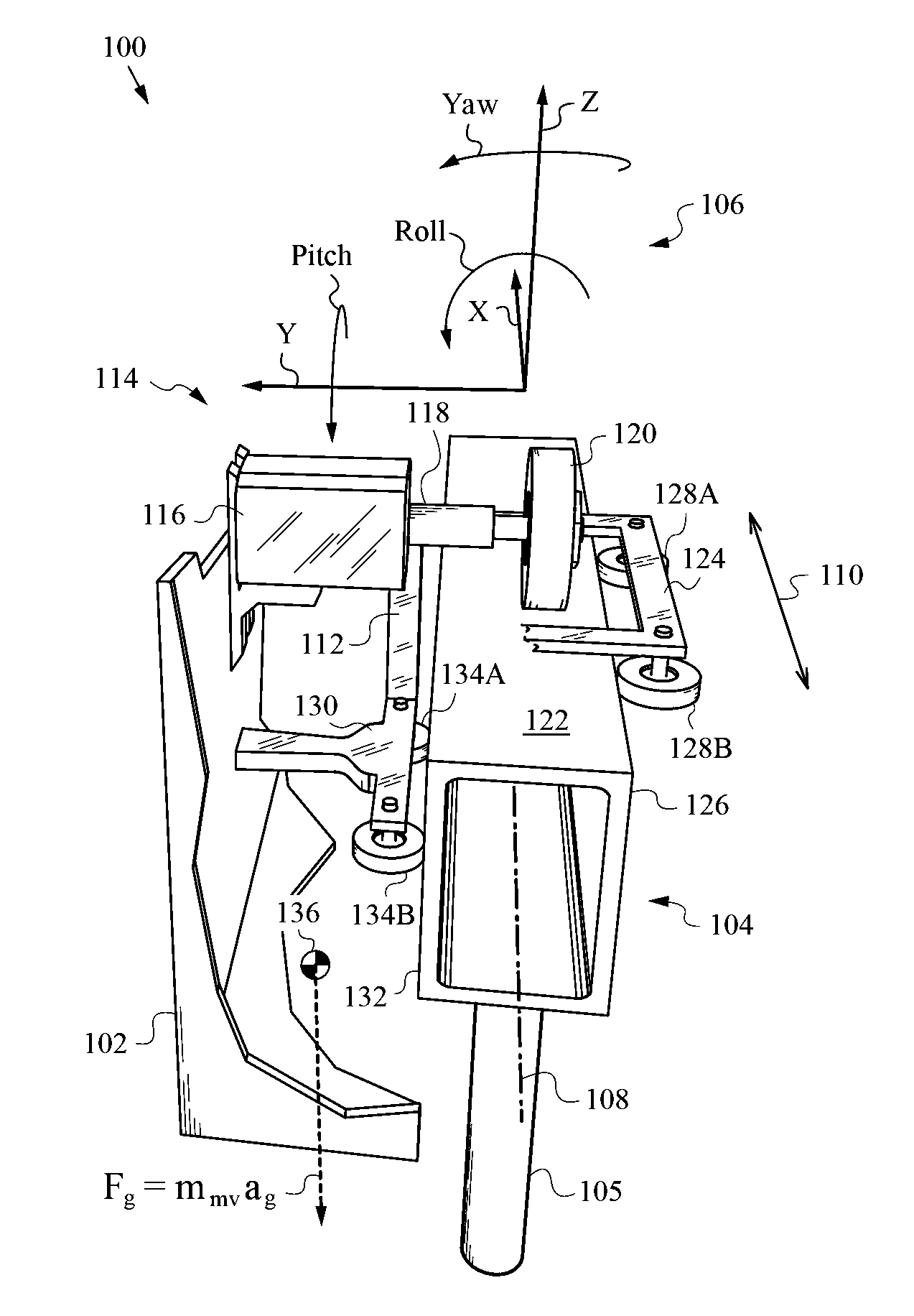

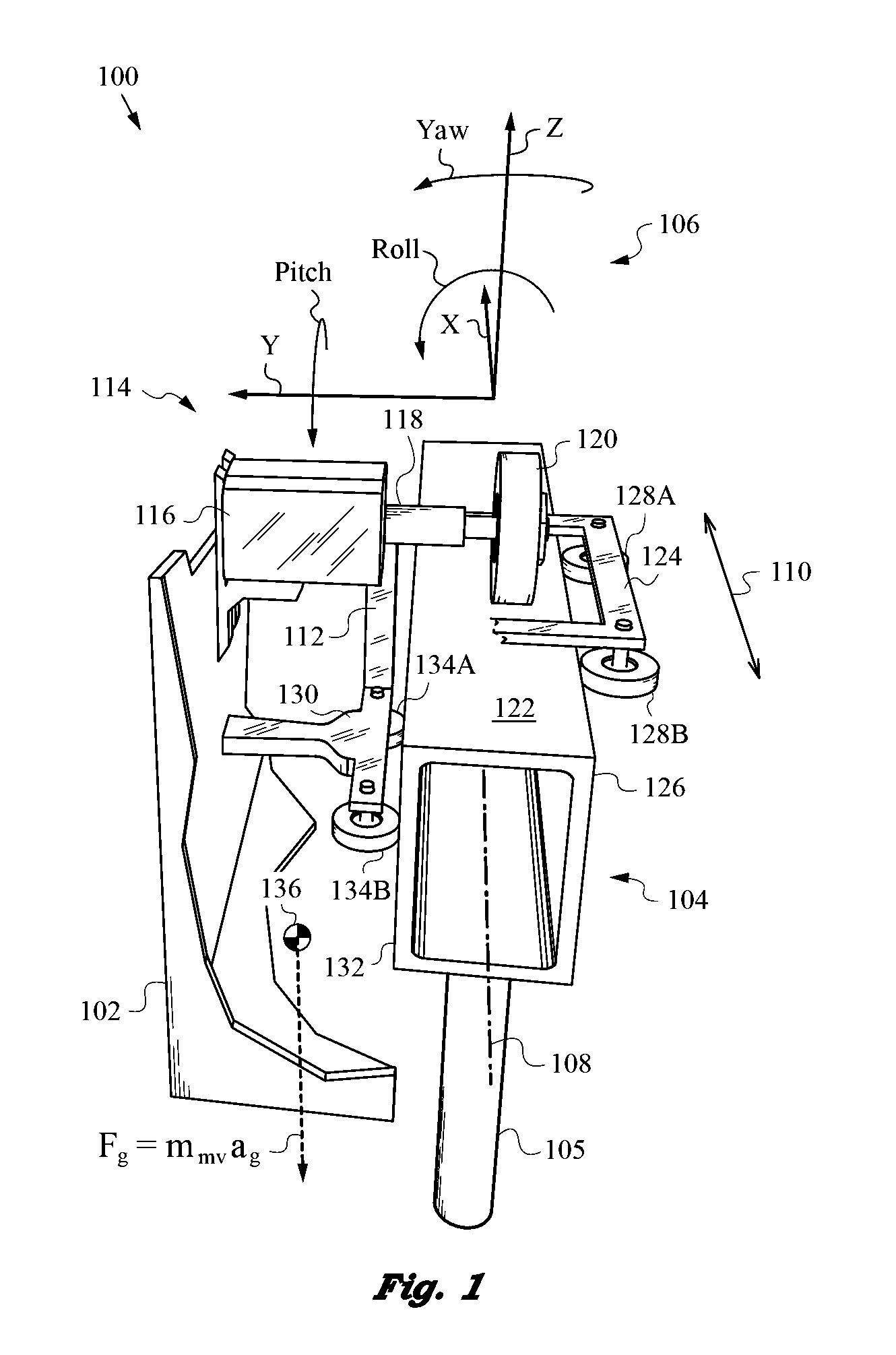

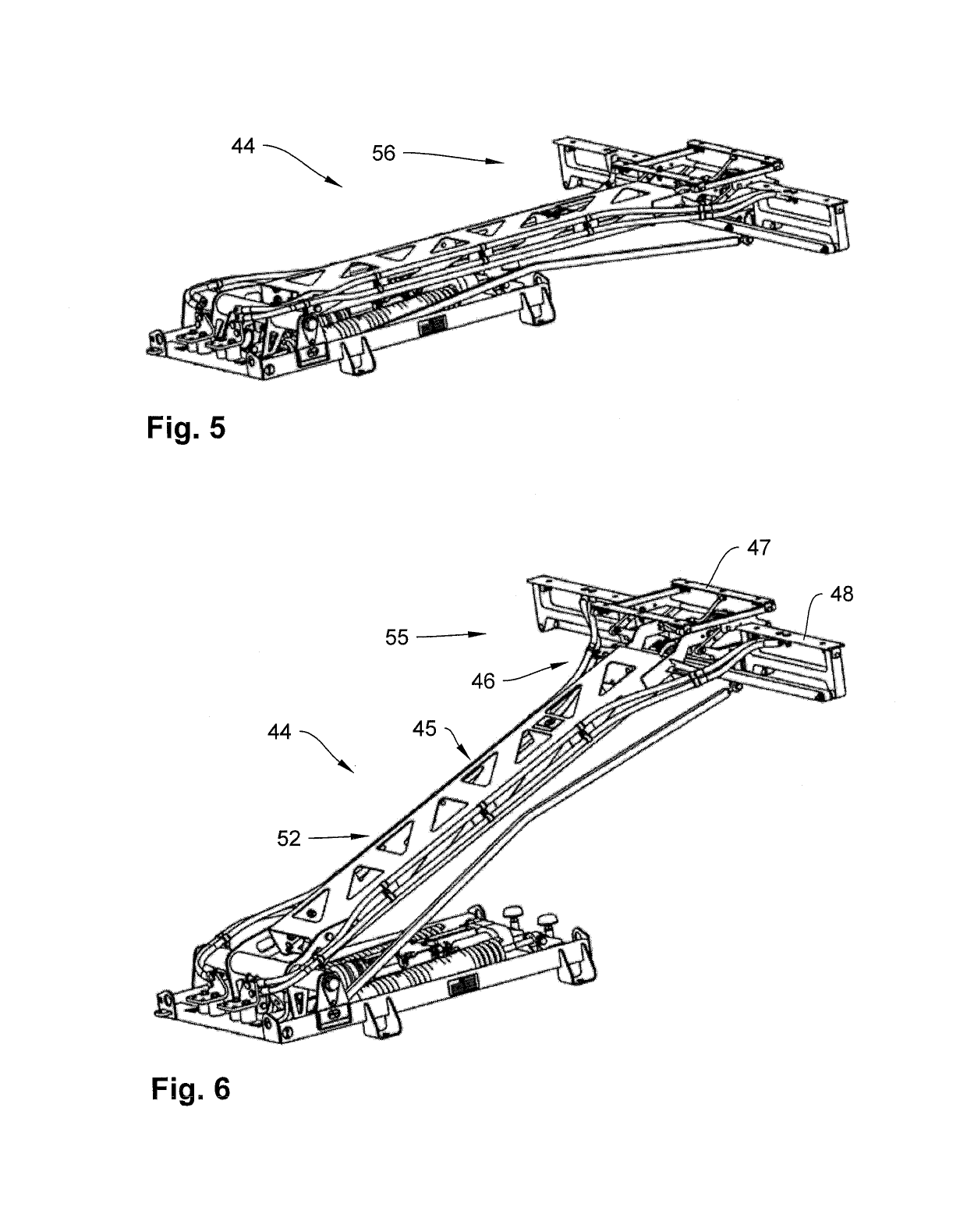

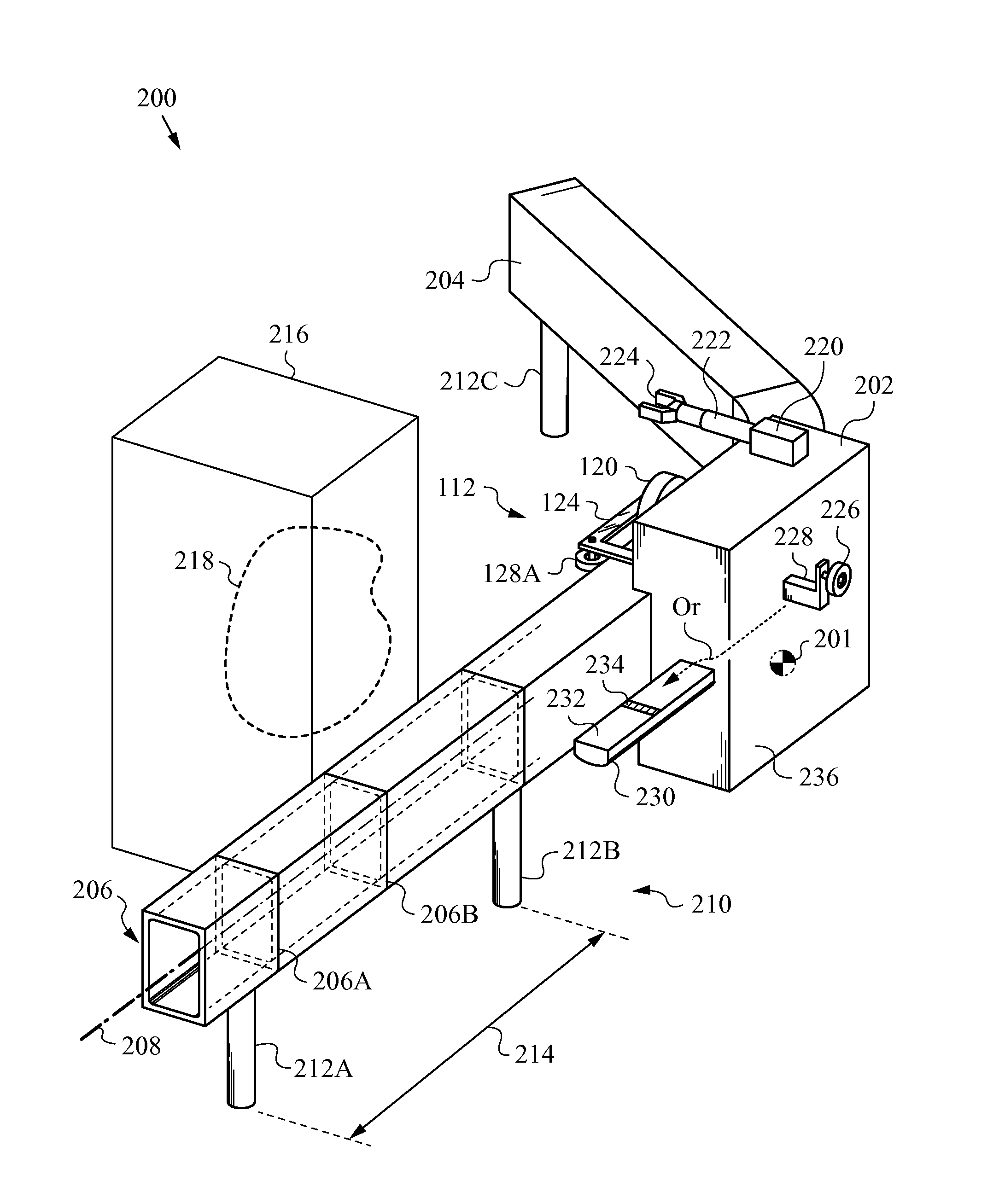

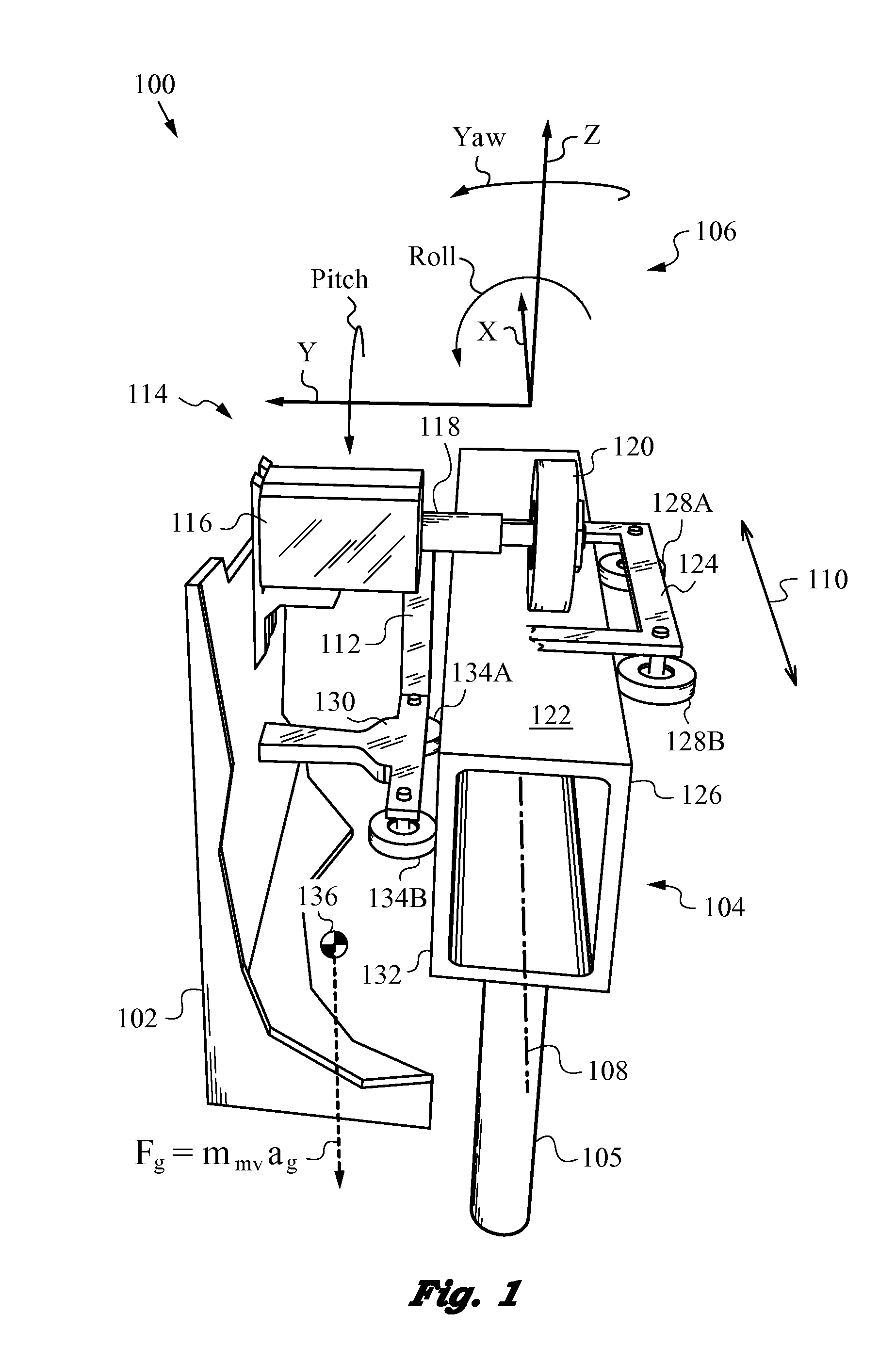

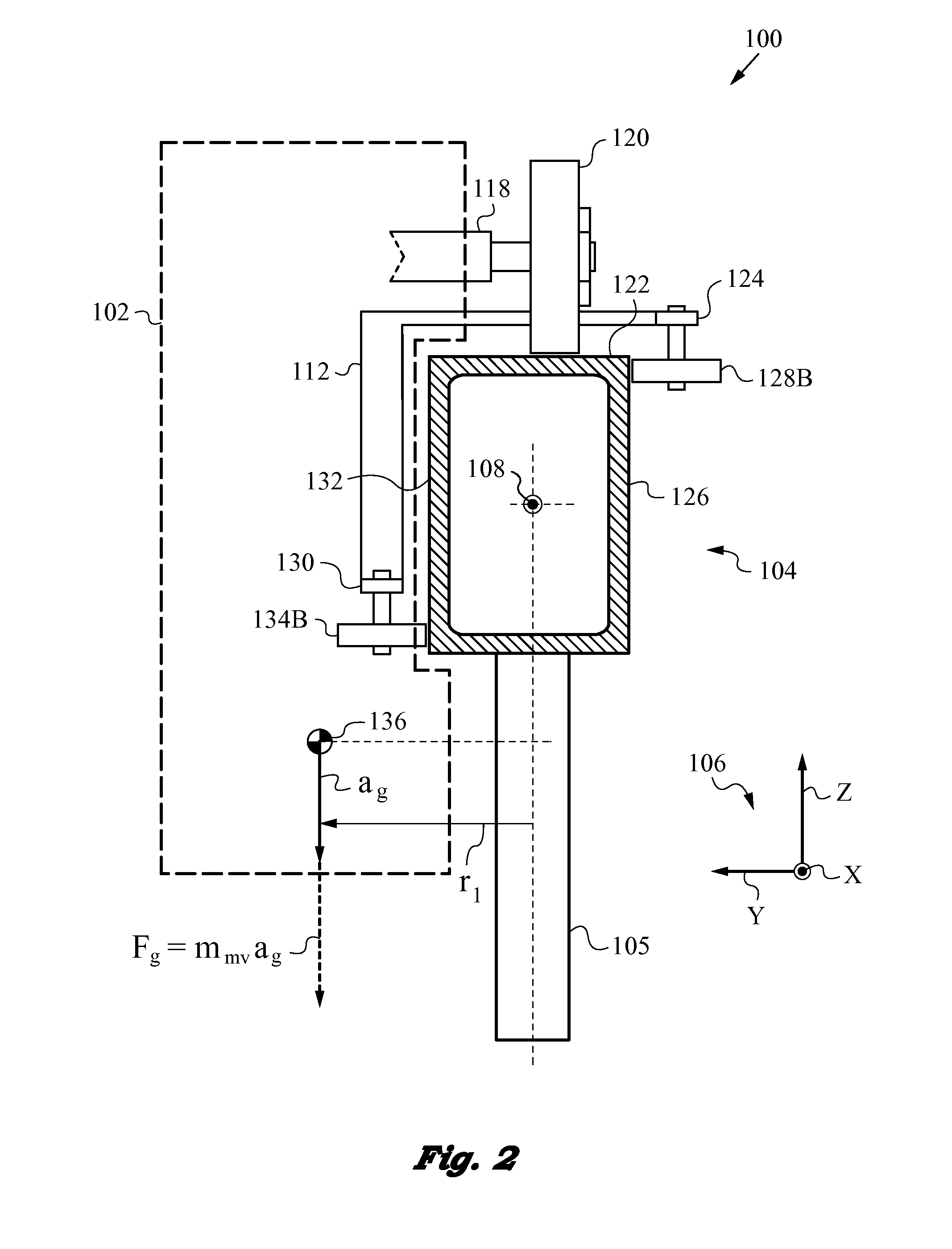

Monorail Vehicle Apparatus with Gravity-Controlled Roll Attitude and Loading

InactiveUS20140174315A1Significant changeConstant contact forceMonorailsRailway componentsBogieRolling moment

Monorail vehicle that travels on a non-featured rail with substantial profile variation and controls roll attitude, lateral location, and loading through judicious placement of the vehicle's center of gravity without using springs or suspensions. The vehicle has a bogie for engaging the non-featured rail so the center of gravity has a lateral offset r1 from the rail centerline to produce a roll moment Nr determined by vehicle's mass and value of r1. The center of gravity also has a vertical offset r2. The bogie uses first and second assemblies for engaging the rail to produce a pair of surface normal reaction forces to thus control roll attitude and loading by the placement of the center of gravity, thereby enabling accurate alignment of the monorail vehicle.

Owner:SOLARCITY

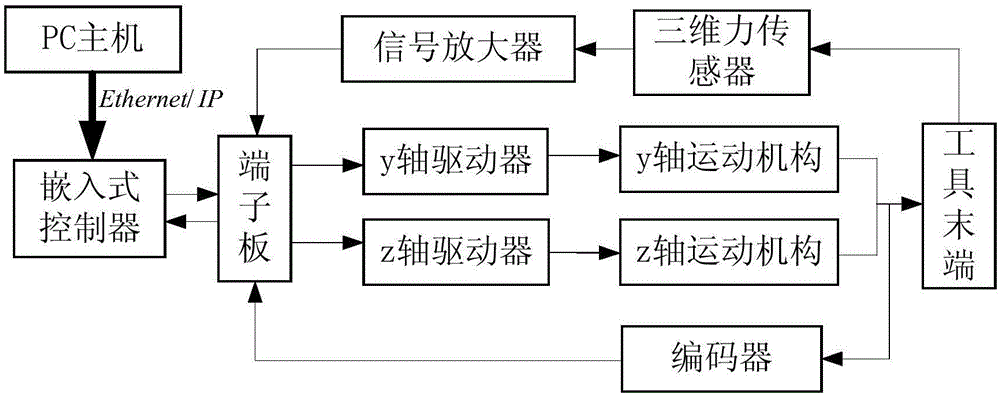

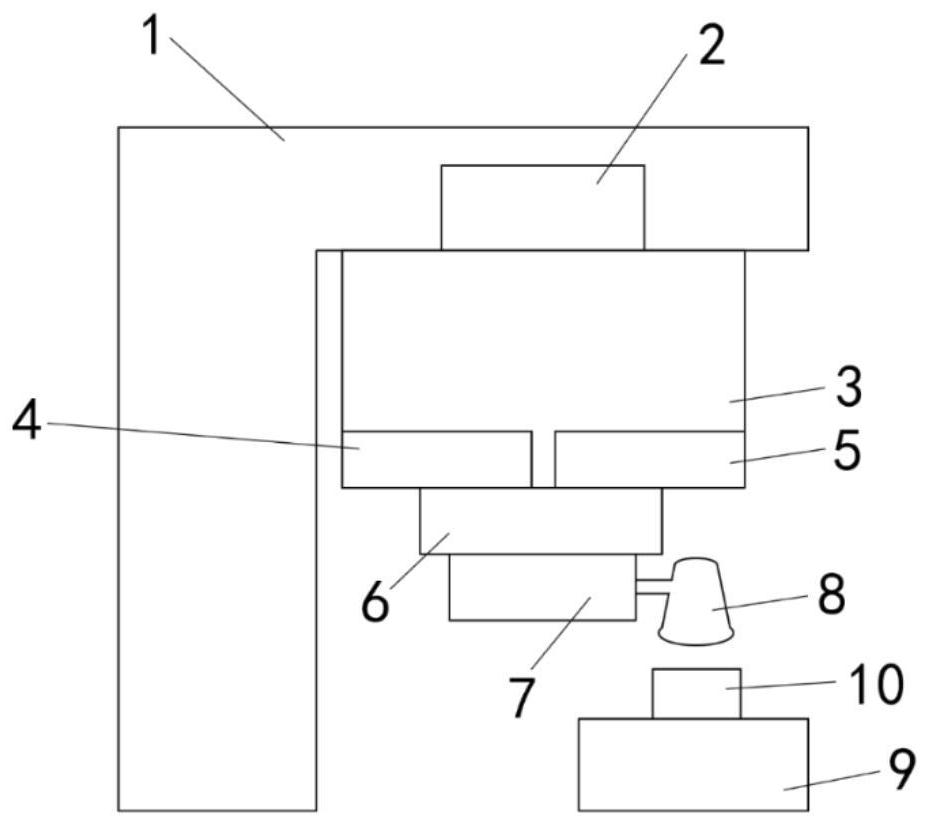

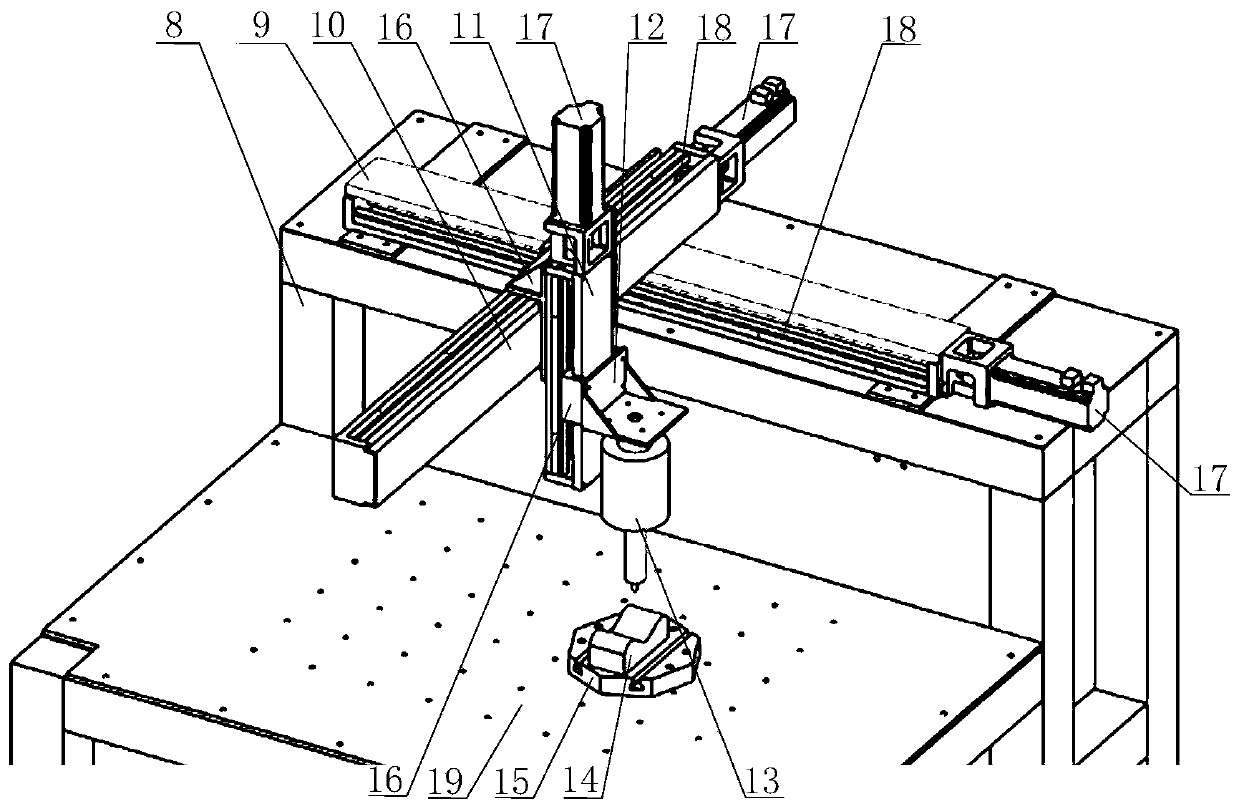

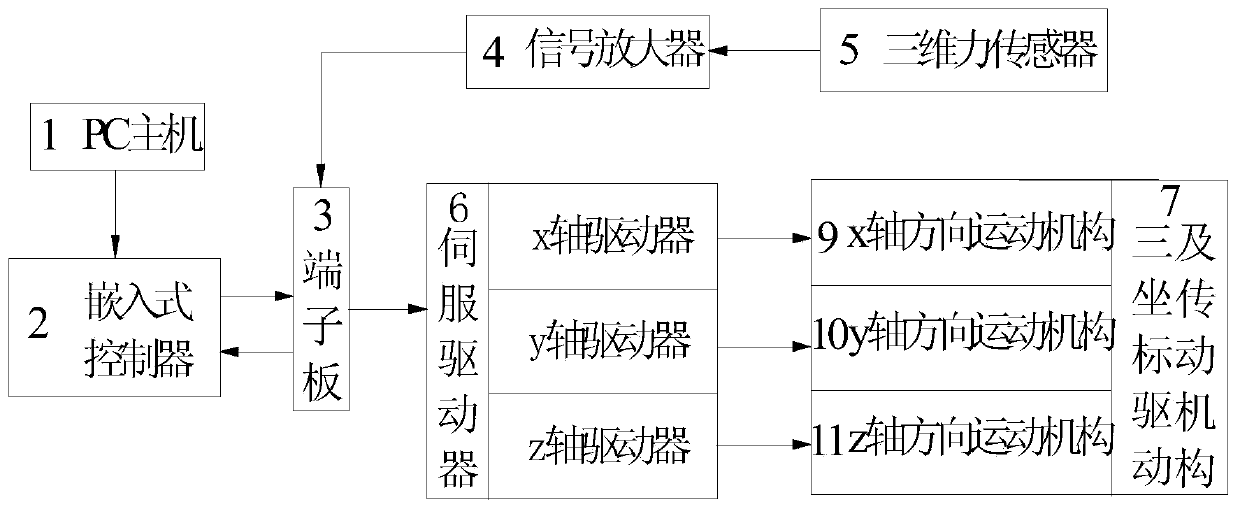

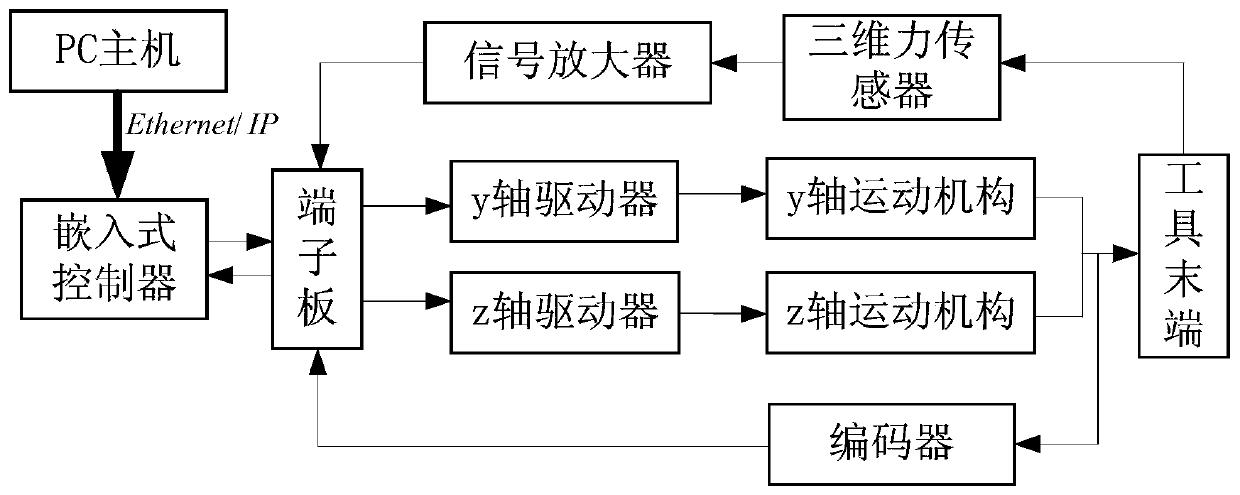

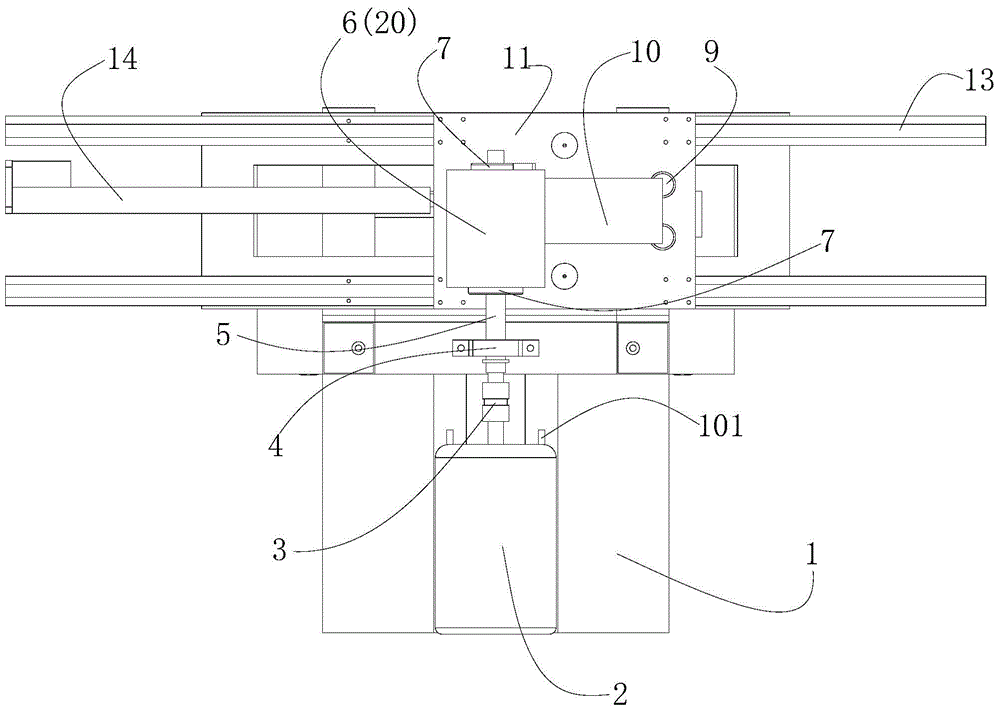

Curved surface profile constant force tracking method and application based on non-linear double closed loop control

ActiveCN106383495AStable contact forceConstant contact forceProgramme controlComputer controlKinematic controllerConstant force

The invention discloses a curved surface profile constant force tracking method based on non-linear double closed loop control, and the method comprises the steps: according to a curved surface profile tracking motion model, force analysis is performed on a model of the contact force between a tool end and a work piece, a relation between an actual motion inclination angle and a normal contact force error and a double closed loop force control method can be obtained through the force analysis and a motion coordinate transformation formula; according to the double closed loop force control method, a control flow of a non-linear PID force controller and a non-linear PID control formula can be obtained, a motion controller can be adopted to control motion of three motion mechanisms in three coordinate directions, so that the tool end can track unknown curve surface profile motion with constant normal contact force. The invention also provides an application device for realizing the method, the device comprises a control part and a mechanical part, the control part comprises a PC host, an embedded motion controller, a terminal board, a signal amplifier, a three-dimensional force sensor, a server driver and a three-coordinate drive and transmission mechanism, and the mechanical part comprises a work rack, movement mechanisms in x, y and z axis directions arranged on the work rack, a sensor clamping rack, a processing tool and a work piece holder for clamping a curved surface part.

Owner:SOUTH CHINA UNIV OF TECH

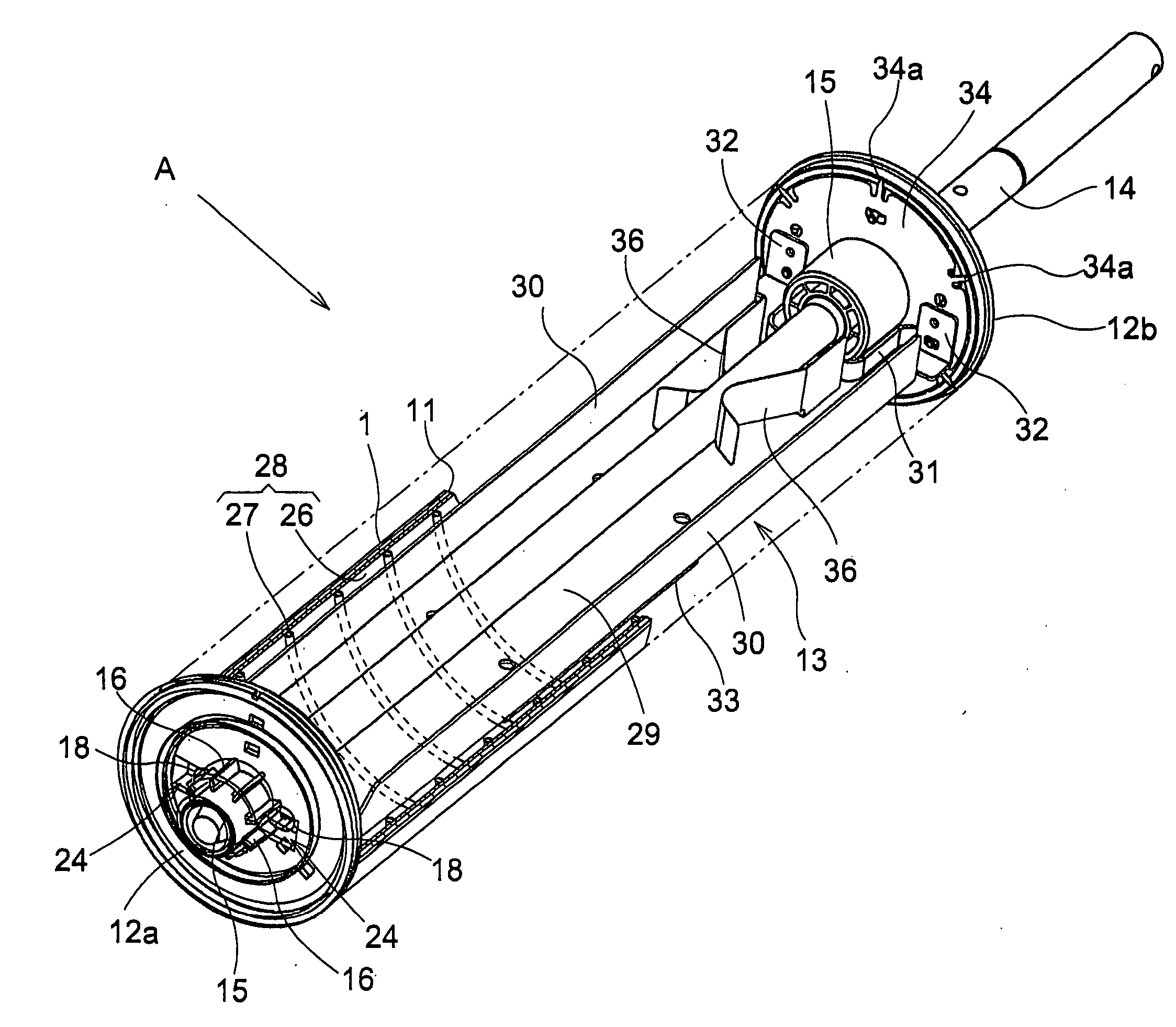

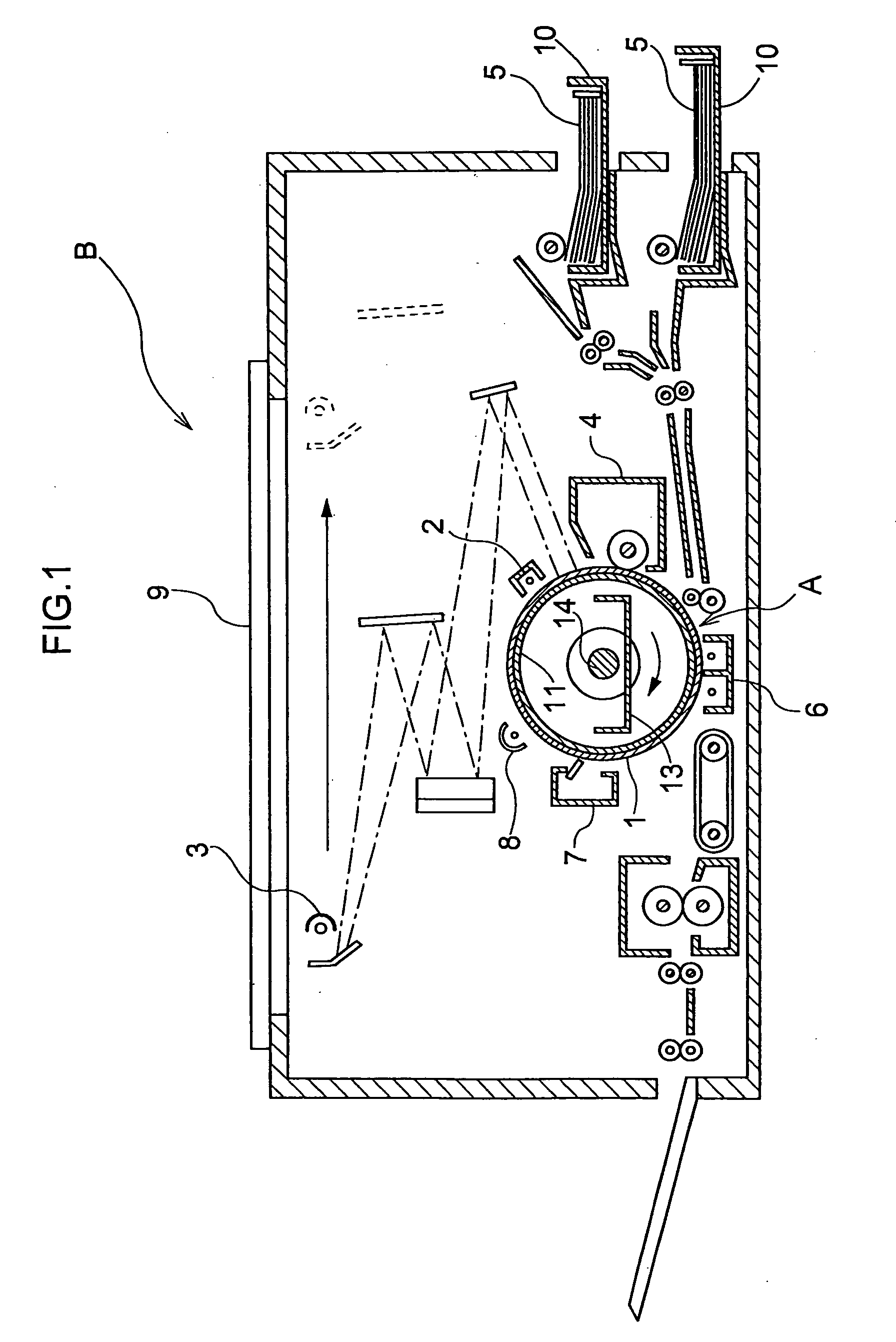

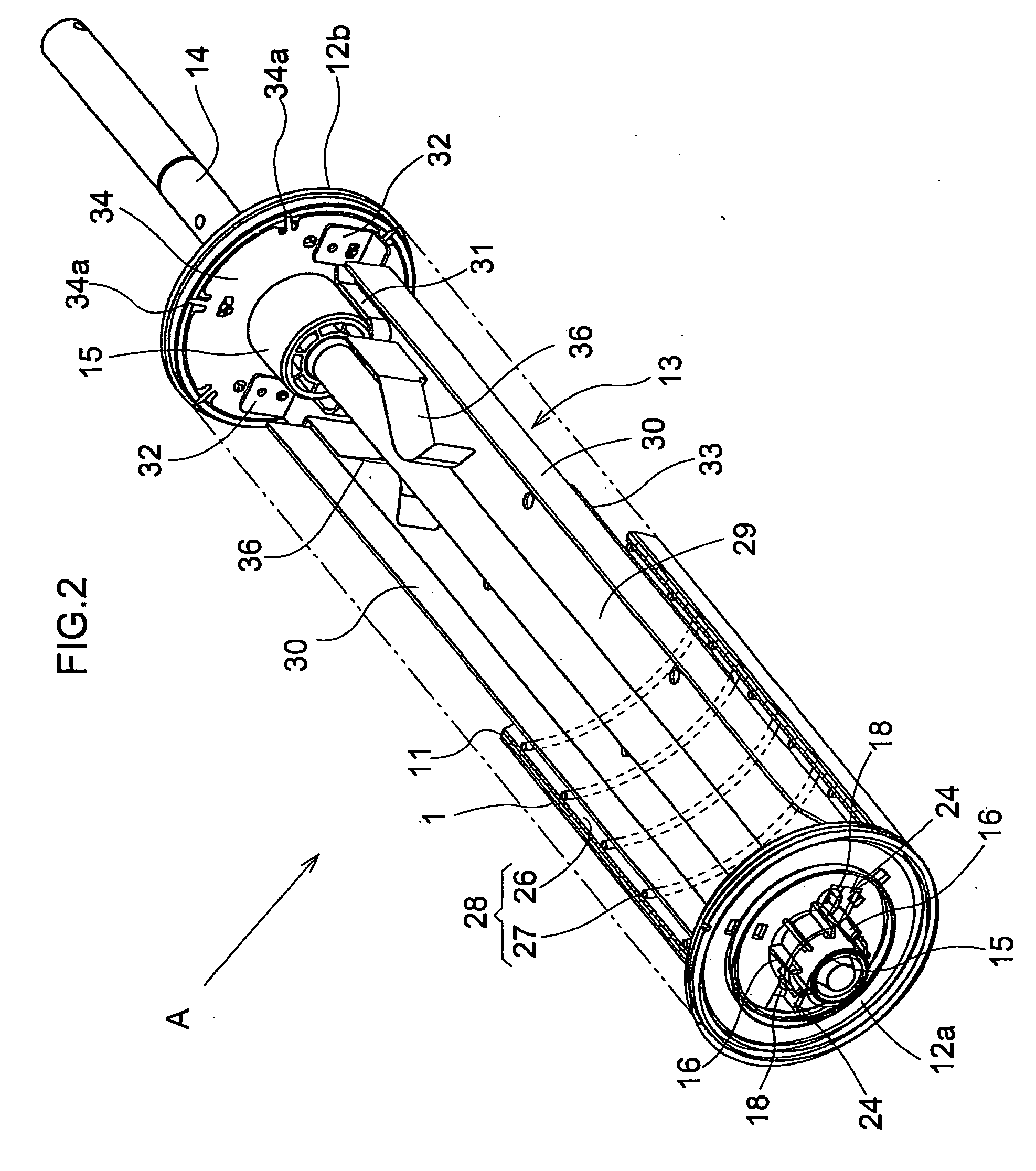

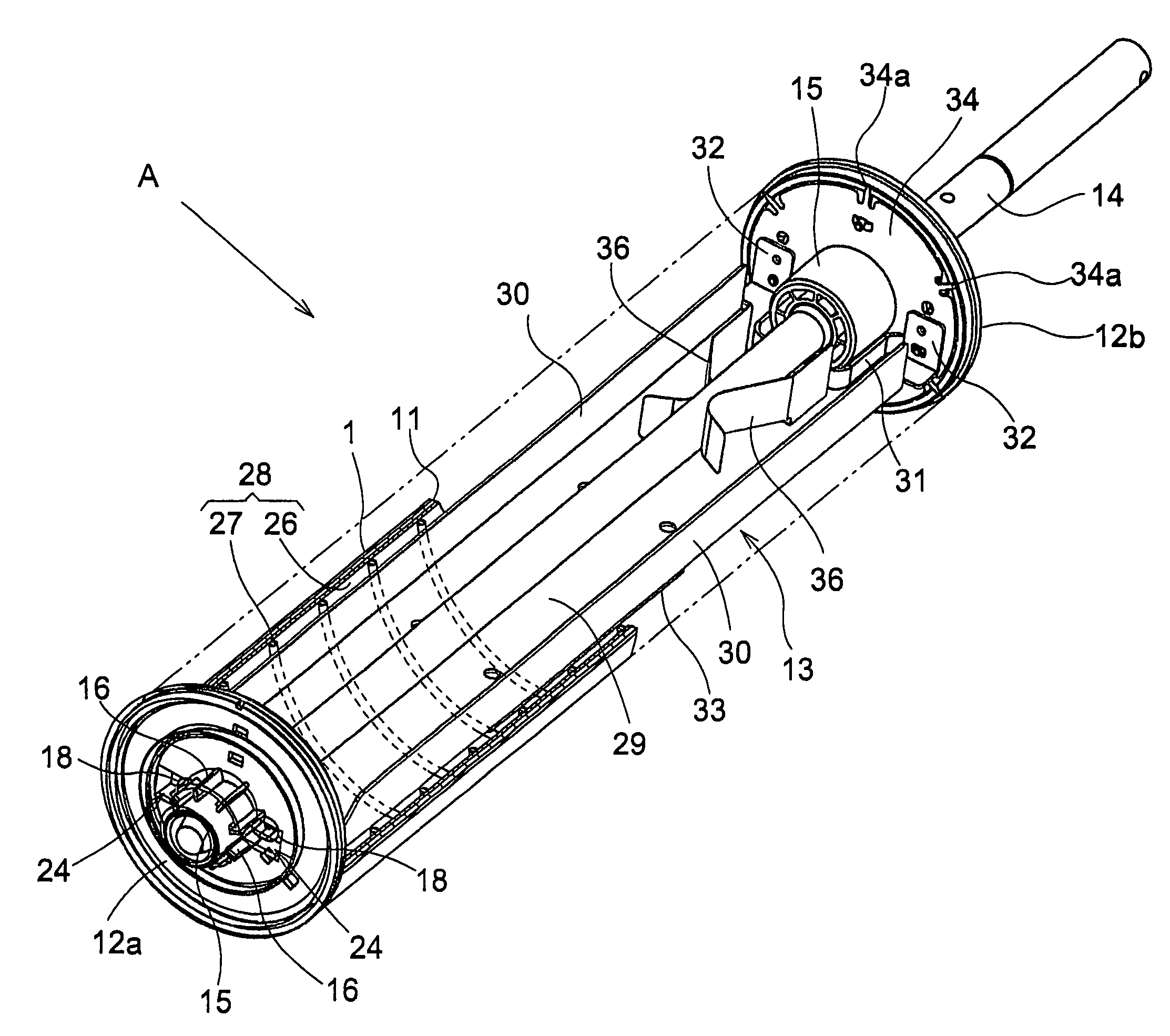

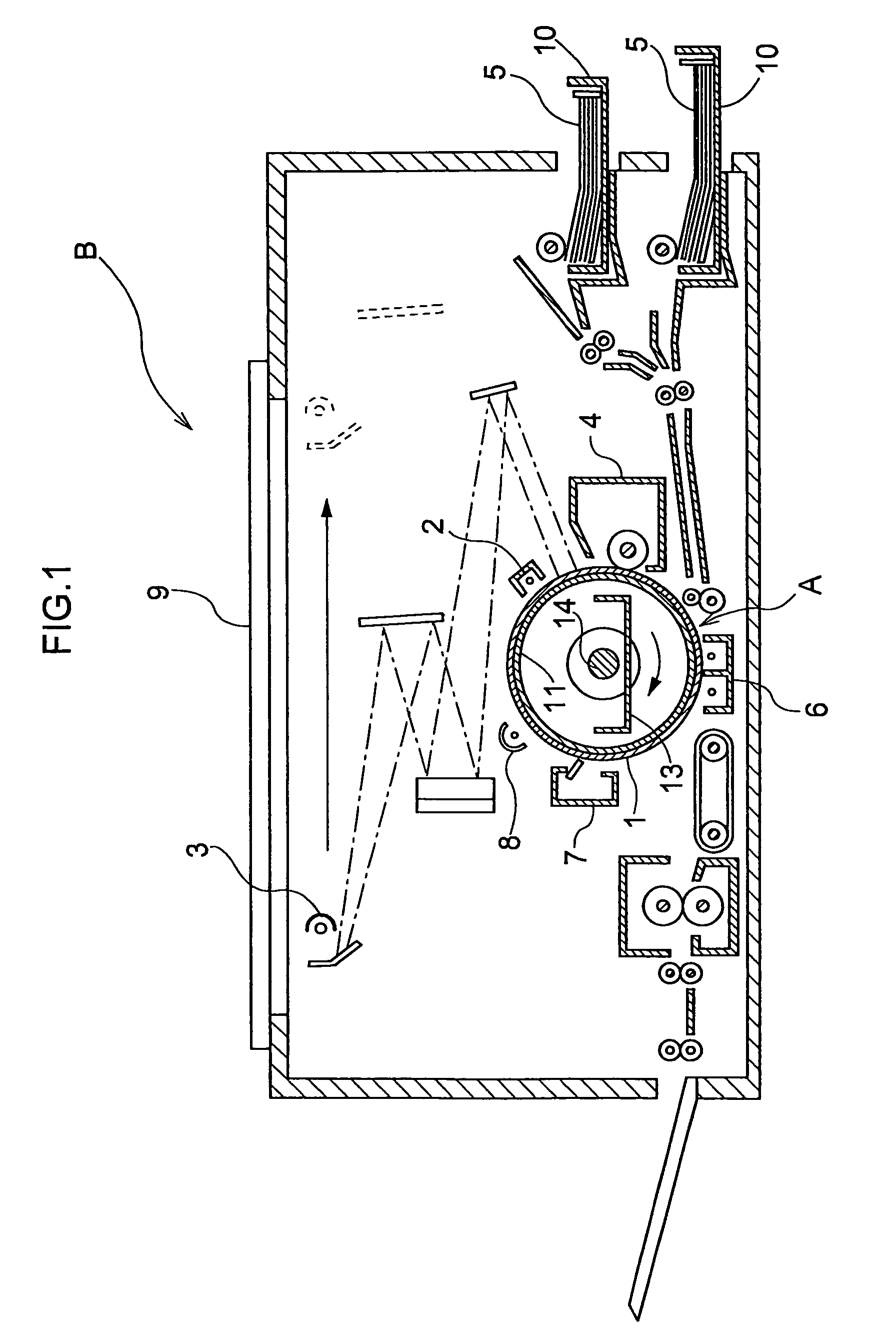

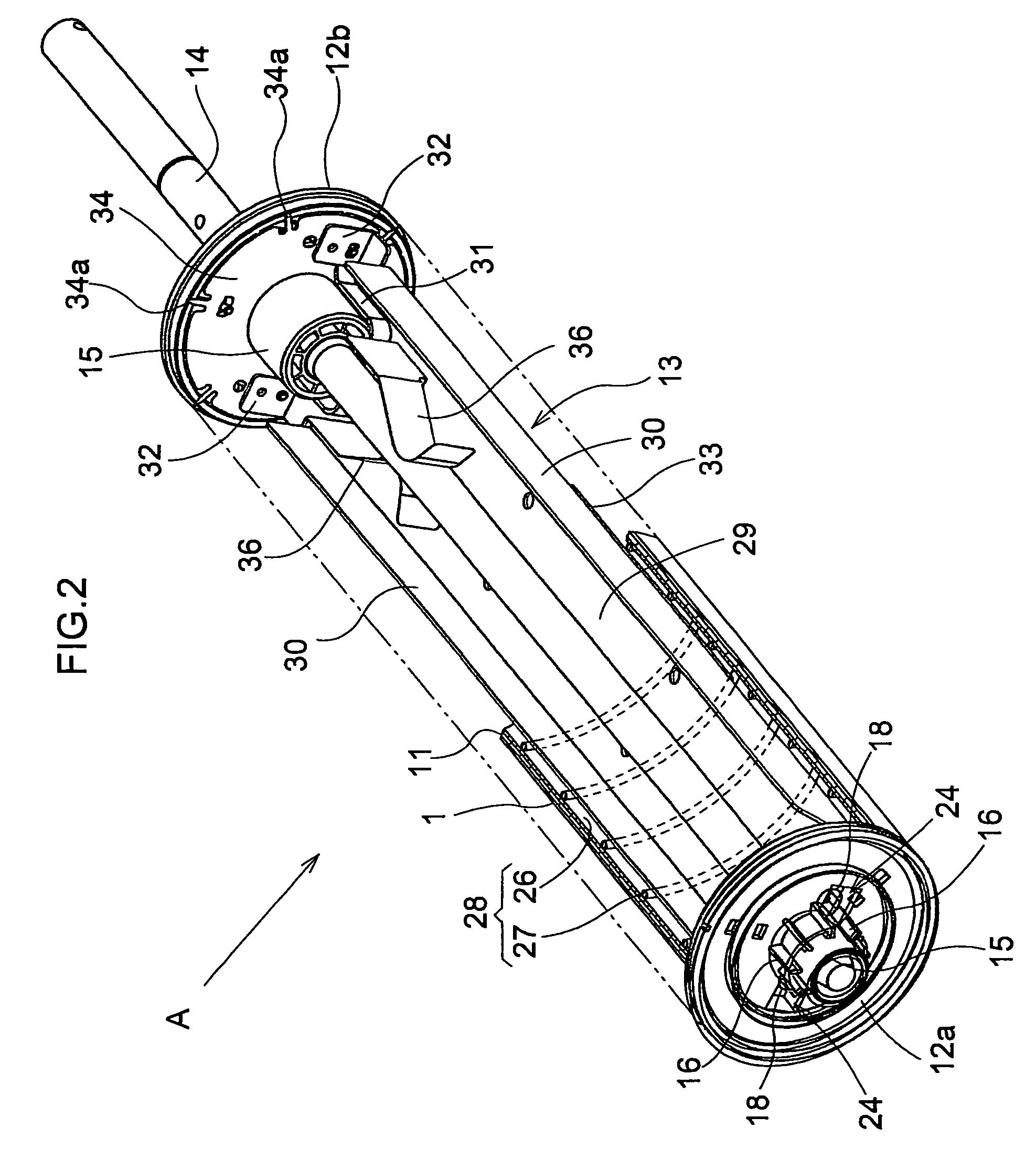

Photosensitive drum

InactiveUS20060165436A1Reduce manufacturing costReduce in quantityElectrographic process apparatusEngineeringContact force

To realize easier assembly of the photosensitive drum with appropriate contact force to the end face of the drum body, while restricting manufacture cost increase and avoiding need for high skill and / or experience for the factory worker who assembles the drum. A photosensitive drum for use in an electrophotographic image forming apparatus. The drum includes a cylindrical drum body 11 having a photosensitive layer, a pair of flanges 12a, 12b attached to opposed end faces of the drum body, a reinforcing stay 13 provided inside the drum body, a drum shaft 14 for rotatably supporting the drum body via the flanges. The flanges are fixed to the reinforcing stay in such a manner that outer peripheries of the flanges are elastically contacted against the end faces of the drum body. Each flange includes, as a cantilever-like extension thereof, a fixing arm 18 for the reinforcing stay, a leading end of the fixing arm being fixed to the reinforcing stay with the fixing arm being elastically deformed toward the inside of the drum body, such that the fixing arm provides an elastic resilience for causing the outer periphery of the flange to be elastically contacted against the corresponding end face of the drum body.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Monorail vehicle apparatus with gravity-controlled roll attitude and loading

InactiveUS8950336B2Accurate constraintAccurate translationMonorailsRailway componentsBogieEngineering

Monorail vehicle that travels on a non-featured rail with substantial profile variation and controls roll attitude, lateral location, and loading through judicious placement of the vehicle's center of gravity without using springs or suspensions. The vehicle has a bogie for engaging the non-featured rail so the center of gravity has a lateral offset r1 from the rail centerline to produce a roll moment Nr determined by vehicle's mass and value of r1. The center of gravity also has a vertical offset r2. The bogie uses first and second assemblies for engaging the rail to produce a pair of surface normal reaction forces to thus control roll attitude and loading by the placement of the center of gravity, thereby enabling accurate alignment of the monorail vehicle.

Owner:SOLARCITY

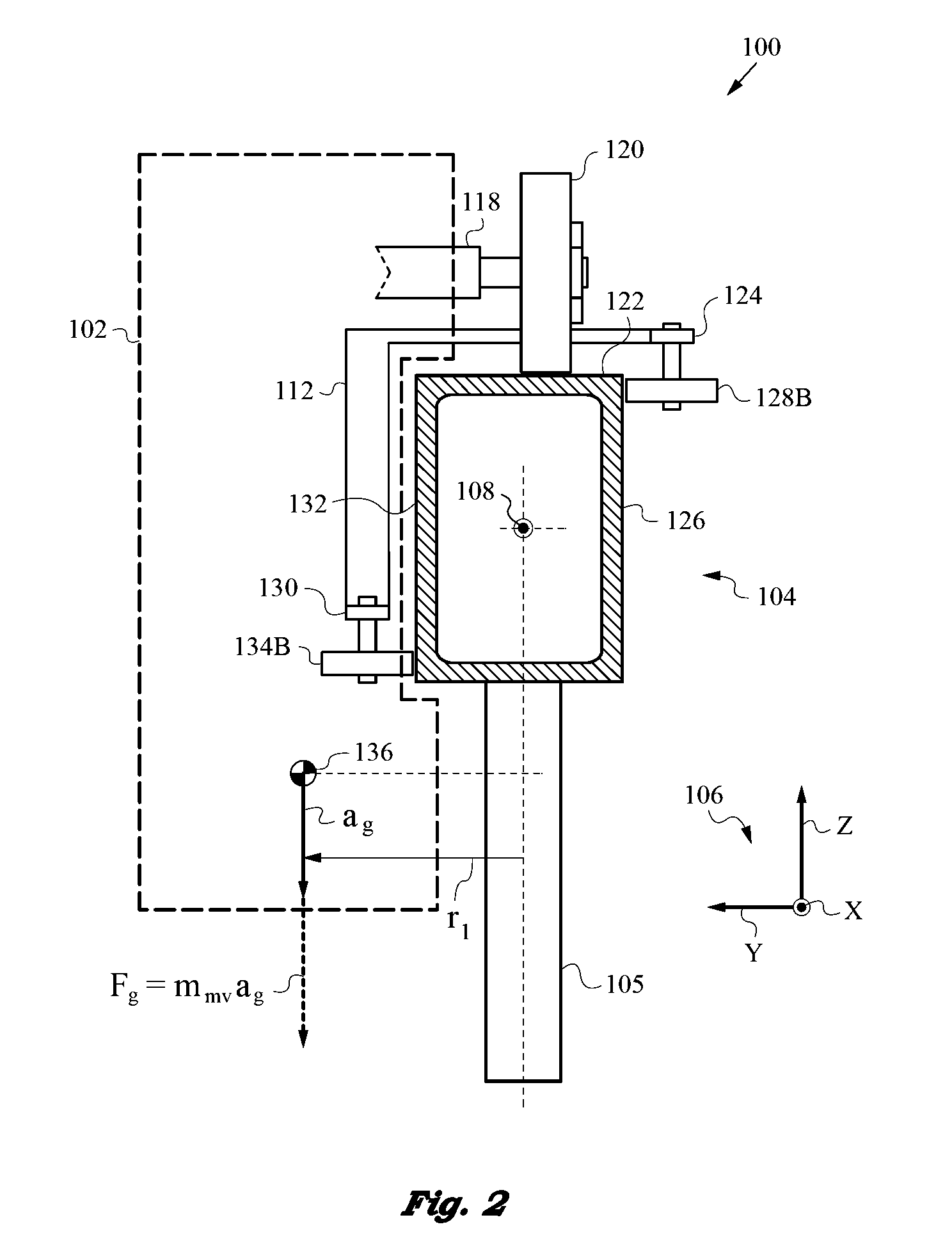

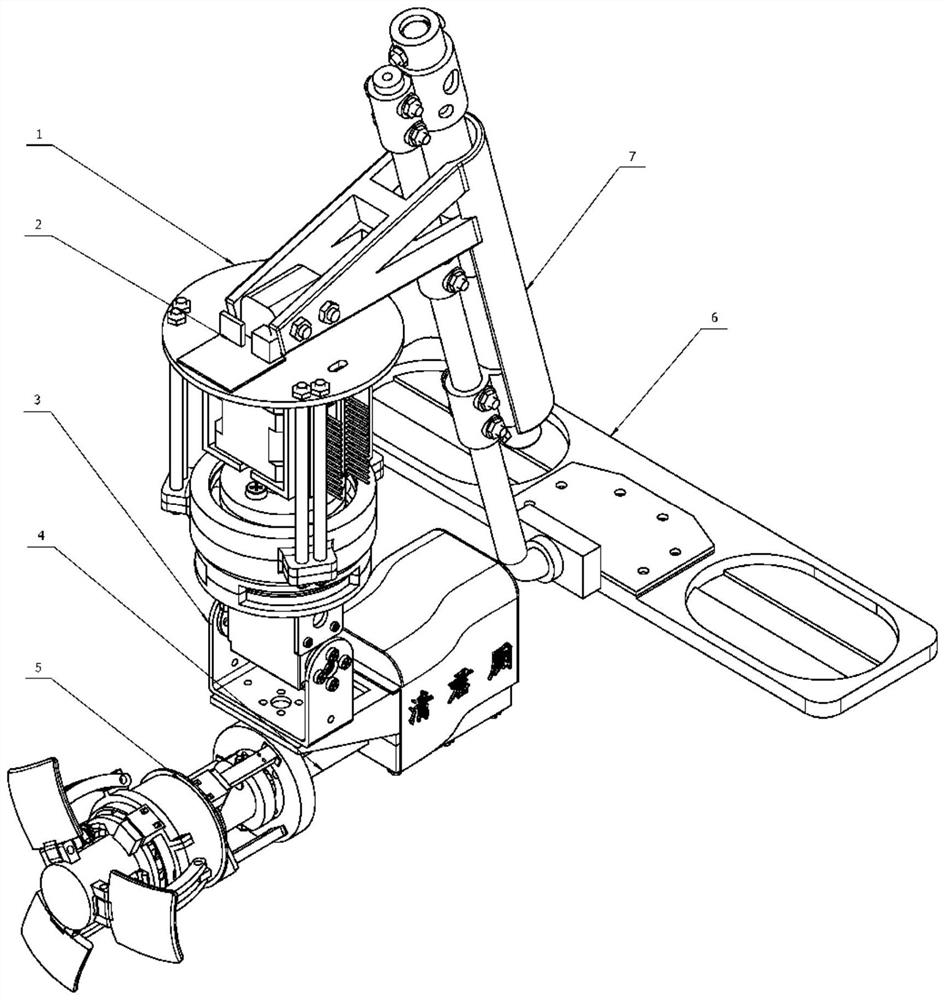

Positioning unit and contacting method

ActiveUS20190105989A1Constant contact forceWell formedElectric vehicle charging technologyPower current collectorsContact methodContact force

A positioning unit and method for forming an electrically conductive connection between a stationary charging station and a vehicle, wherein an electrical charging contact of a positioning unit is movable relative to a charging contact surface and contacted by the positioning unit having an articulated arm device and a corresponding drive device, wherein the charging contact includes a contact position for power transmission and a retracted position for power interruption, the drive device having an adjustment drive acting on the articulated arm device and a spring device wherein a contact force acting on the charging contact surface can be formed by the adjustment drive having a control device and an electric motor actuated by the control device, wherein the adjustment drive is designed such that a torque of the electric motor is detected by the control device, and the contact force controlled by the control device based on the torque.

Owner:SCHUNK TRANSIT SYST GMBH

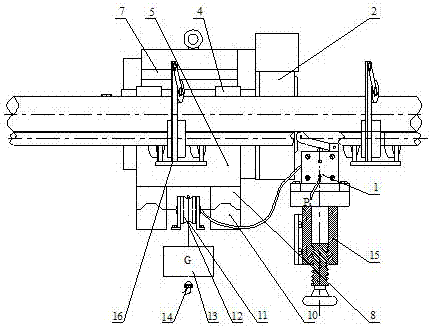

Metal surface uniform film-removing device based on self-compensation

InactiveCN105234787ANo manual adjustment requiredSimple structureGrinding drivesGrinding machinesConstant forceSelf compensation

The invention relates to a metal surface uniform film-removing device based on self-compensation. According to the technical scheme, a motor (7) drives a steel wire brush (2) to rotate through a belt (6); and a heavy object block (13) is connected with a guide rail pair (8) through a fixed pulley (12) by virtue of a steel wire rope. An air cylinder (9) is hinged with the right end surface of the guide rail pair (8); height of a stroke valve (1) is regulated by virtue of a height regulator (15), so that a rod to be subjected to film removal can press down a roller wheel of the stroke valve (1), and a valve element of the stroke valve (1) reverses. During the film removal, the steel wire brush (2) is in constant-force contact with the rod to be subjected to film removal under the gravity action of the heavy object block (13), so that self-compensation uniform film removal is realized. When the film removal is completed, the air cylinder (9) pulls the guide rail pair (8) to move rightwards to wait for a rod to be subjected to film removal. When the steel wire brush (2) reaches use limit, the heavy object block (13) is descended to a maximum position for triggering an alarm switch (14), so that an indicator lamp (18) is turned on to remind a worker to replace the steel wire brush (2). The metal surface uniform film-removing device based on self-compensation has the characteristics of low cost, a simple structure, uniform film removal, automatic abrasion gap compensation and high production efficiency.

Owner:WUHAN UNIV OF SCI & TECH

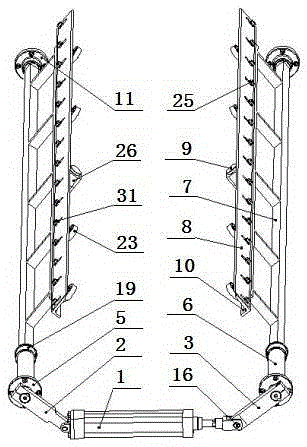

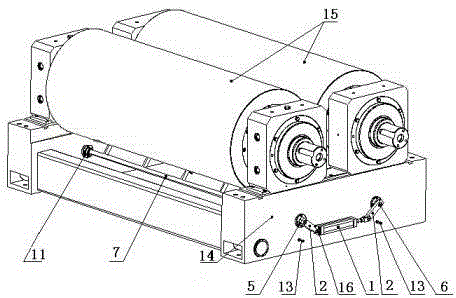

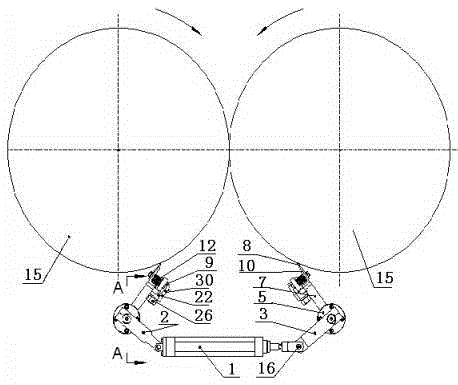

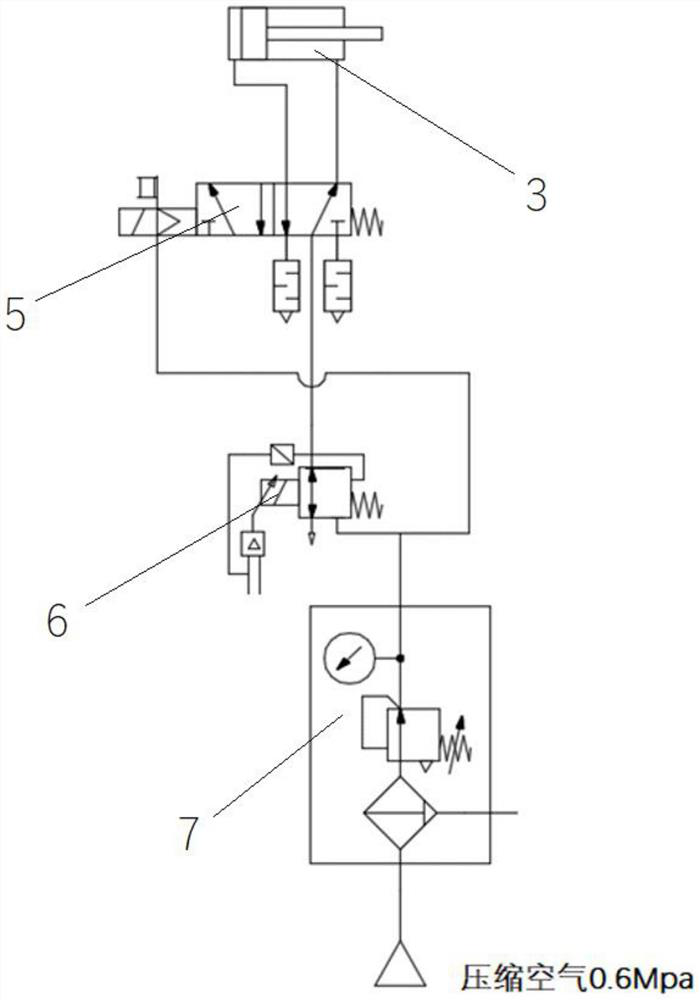

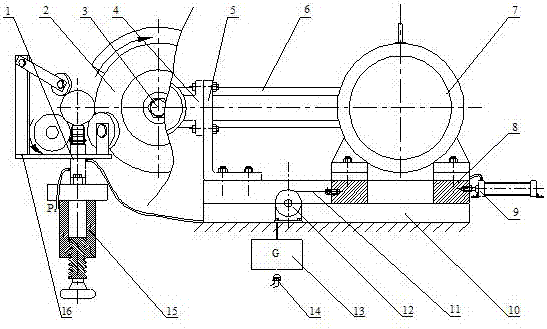

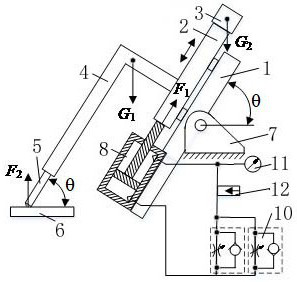

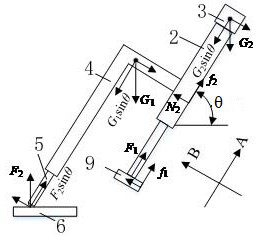

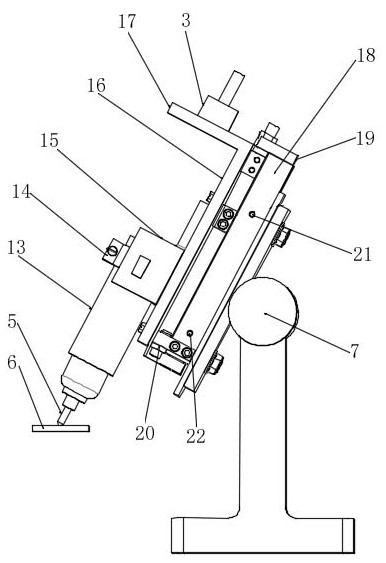

Pneumatic scraper mechanism capable of automatically regulating degree of parallelism between milling roll bus and scraper blade surface

InactiveCN105268668AAutomatically adjust parallelismImprove fitCleaning using toolsPressesSlider bearingDrive shaft

The invention relates to a pneumatic scraper mechanism capable of automatically regulating degree of parallelism between a milling roll bus and a scraper blade surface. The pneumatic scraper mechanism is characterized by being provided with a double-acting air cylinder (1), wherein a front rocker arm (2) and a rear rocker arm (3) are arranged at the two sides of the air cylinder (1); a scraper device is mounted by arranging pressure covers (5), pressure cover bolts (17), supporting bases (11), supporting shaft slide bearings (28), supporting base bolts (29), a transmission shaft (6) and a transmission shaft slide bearing 19; and meanwhile, a scraper guide mechanism is mounted on a scraper base (10) of the scraper device. The pneumatic scraper mechanism reasonably provides contact force between the scraper and a milling roll by virtue of the air cylinder, and is constant in contact force; a scraper automatically follows up after being worn, and scheduled maintenance is not required. The pneumatic scraper mechanism has the characteristics of automatically regulating the degree of parallelism between the milling roll bus and the scraper blade surface, and improving fitness between the scraper and the roll surface and the like.

Owner:ZHAODONG DONG LONG SAVING ENERGY NEW TECH

Photosensitive drum

InactiveUS7463846B2Easy to assembleAvoiding need for high skill and experienceElectrographic process apparatusElastomerContact force

To realize easier assembly of the photosensitive drum with appropriate contact force to the end face of the drum body, while restricting manufacture cost increase and avoiding need for high skill and / or experience for the factory worker who assembles the drum. A photosensitive drum for use in an electrophotographic image forming apparatus. The drum includes a cylindrical drum body 11 having a photosensitive layer, a pair of flanges 12a, 12b attached to opposed end faces of the drum body, a reinforcing stay 13 provided inside the drum body, a drum shaft 14 for rotatably supporting the drum body via the flanges. The flanges are fixed to the reinforcing stay in such a manner that outer peripheries of the flanges are elastically contacted against the end faces of the drum body. Each flange includes, as a cantilever-like extension thereof, a fixing arm 18 for the reinforcing stay, a leading end of the fixing arm being fixed to the reinforcing stay with the fixing arm being elastically deformed toward the inside of the drum body, such that the fixing arm provides an elastic resilience for causing the outer periphery of the flange to be elastically contacted against the corresponding end face of the drum body.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

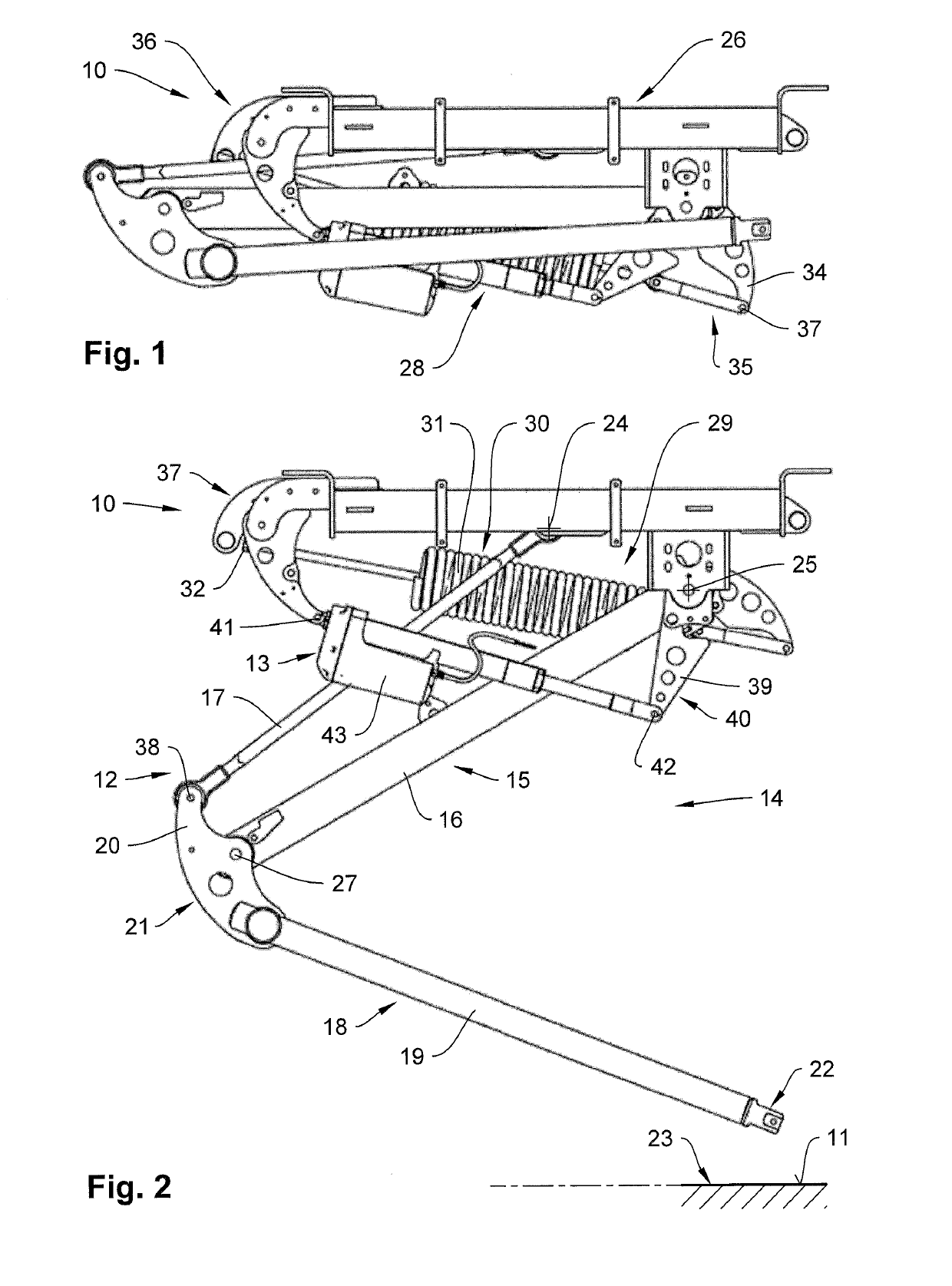

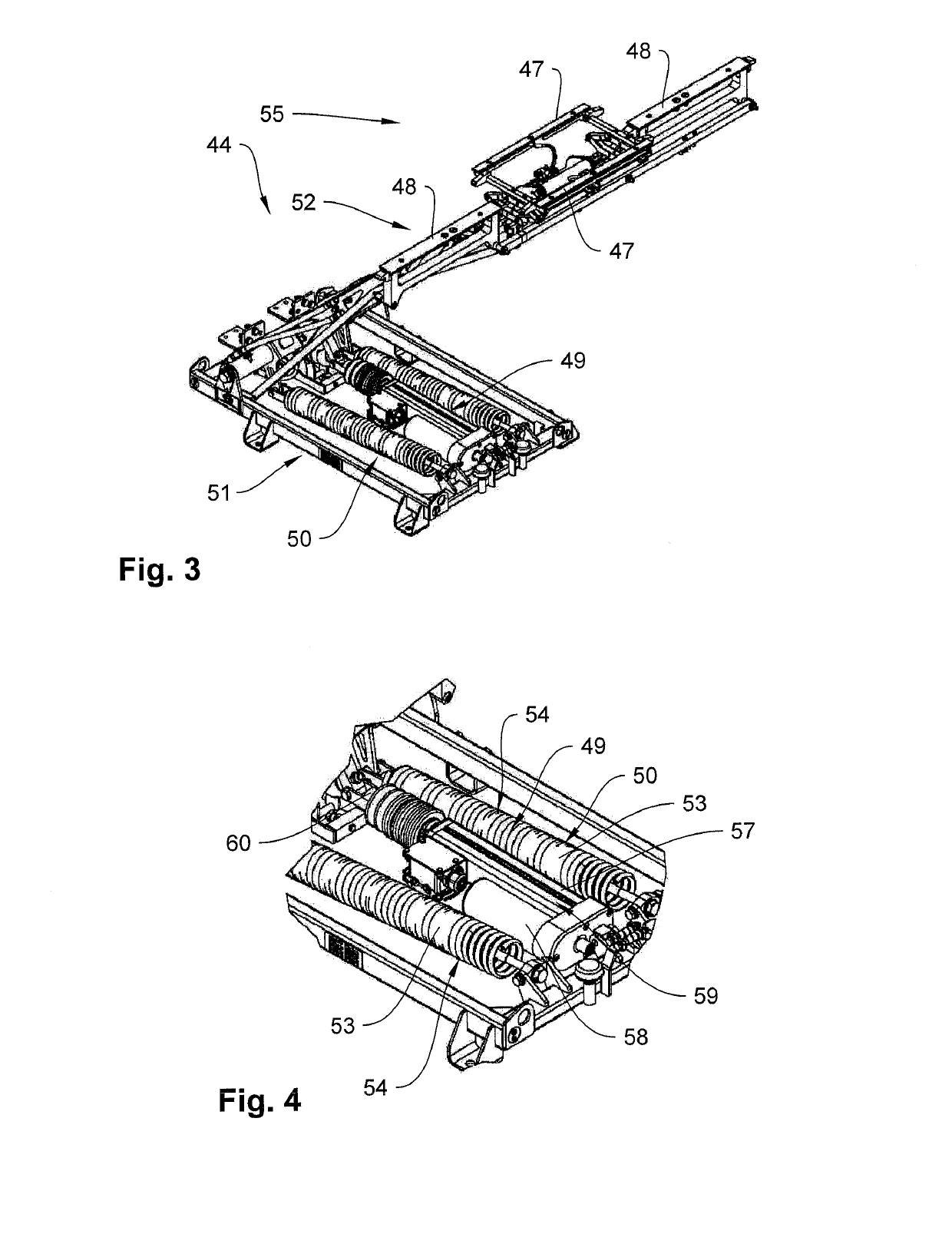

Monorail vehicle apparatus with trucks designed to accommodate movement along curved rail sections

The present invention teaches a monorail vehicle apparatus and method for controlling roll attitude, lateral location, and loading of a monorail vehicle traveling on a non-featured rail exhibiting substantial profile variation by the placement of the vehicle's center of gravity and without the use of additional mechanisms such as springs or suspensions. The design is especially well adapted for travelling along curves by using at least two trucks connected by a linkage mechanism.

Owner:SOLARCITY

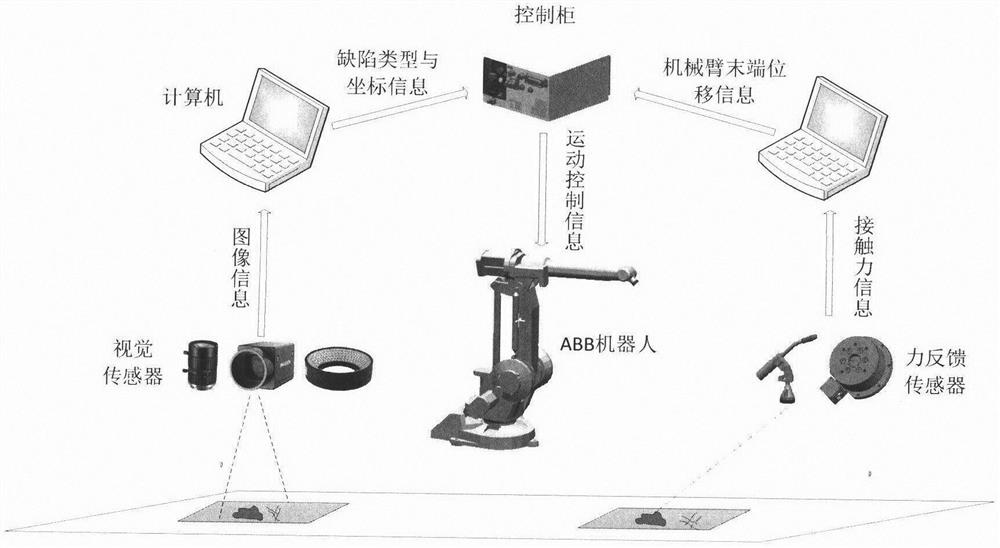

Robot polishing method based on multiple sensors

PendingCN111823221ASolve the problem that the grinding quality is difficult to guaranteeConstant contact forceProgramme-controlled manipulatorImage analysisMedical equipmentData set

The invention discloses a robot polishing method based on multiple sensors. The robot polishing method based on the multiple sensors comprises the steps that (1) type selection is conducted on hardware of a robot polishing system, and the composition of hardware of the visual sensor is calibrated; (2) the surfaces of automobile punching parts are subjected to defect collection through the visual sensor, collected image data are manually marked, true value images are obtained, and a defect data set is established; (3) the partition of workpiece surface defects is accomplished by a PixelNet convolutional neural network; (4) signals collected by the torque sensor are preprocessed in three aspects of static calibration, filtering and gravity compensation; and (5) the robot defect polishing system which carries the torque sensor conducts the polishing operation on the defects by utilizing known defect information and a force / position mixed control algorithm and adopting an orthogonal path polishing scheme. The robot polishing method based on the multiple sensors can be widely applied to lots of production and manufacturing fields including the science and technology fields requiring industrial robots such as the aerospace field, the rail transit field, the medical equipment field and the furniture making field.

Owner:TIANJIN POLYTECHNIC UNIV

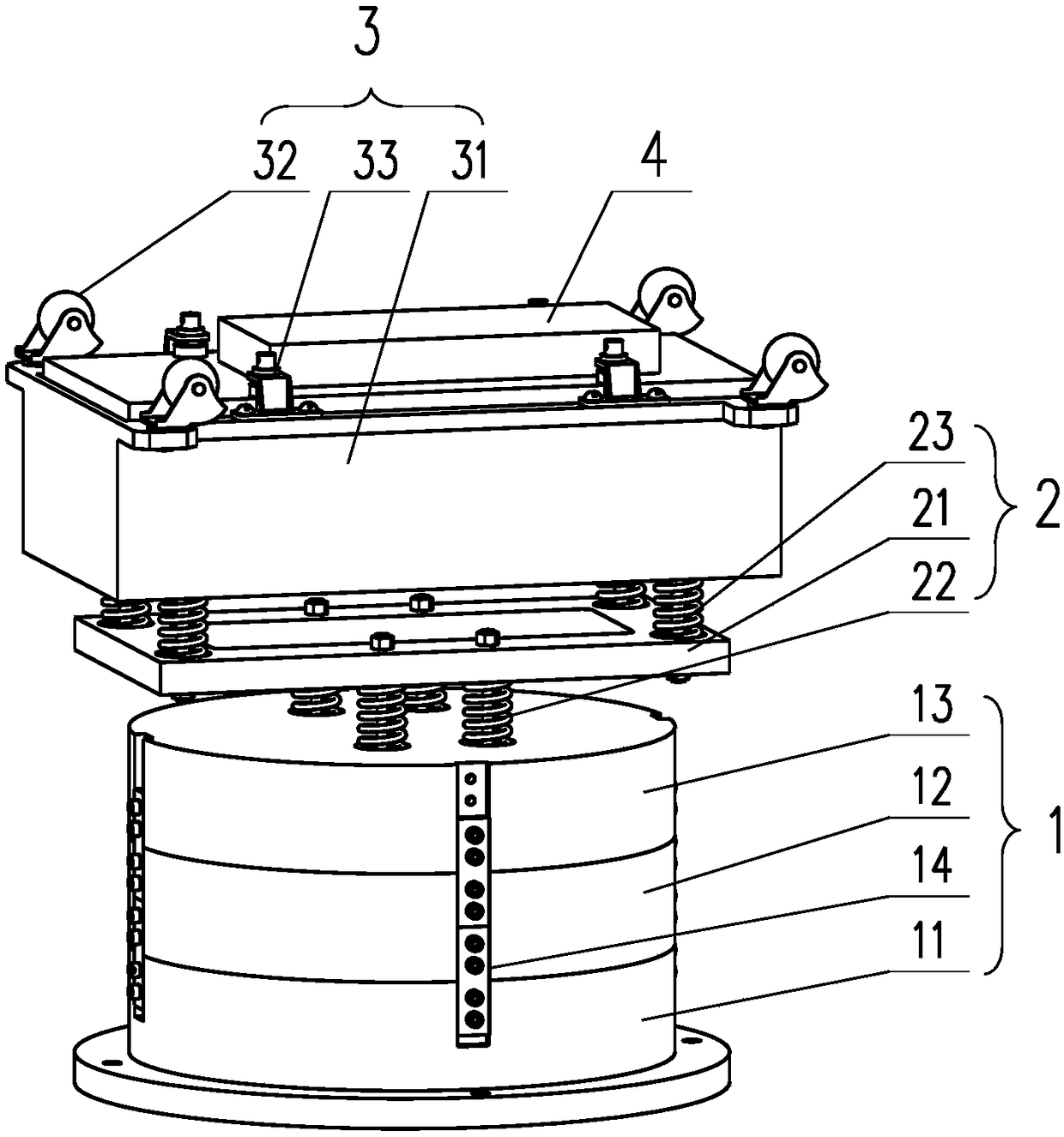

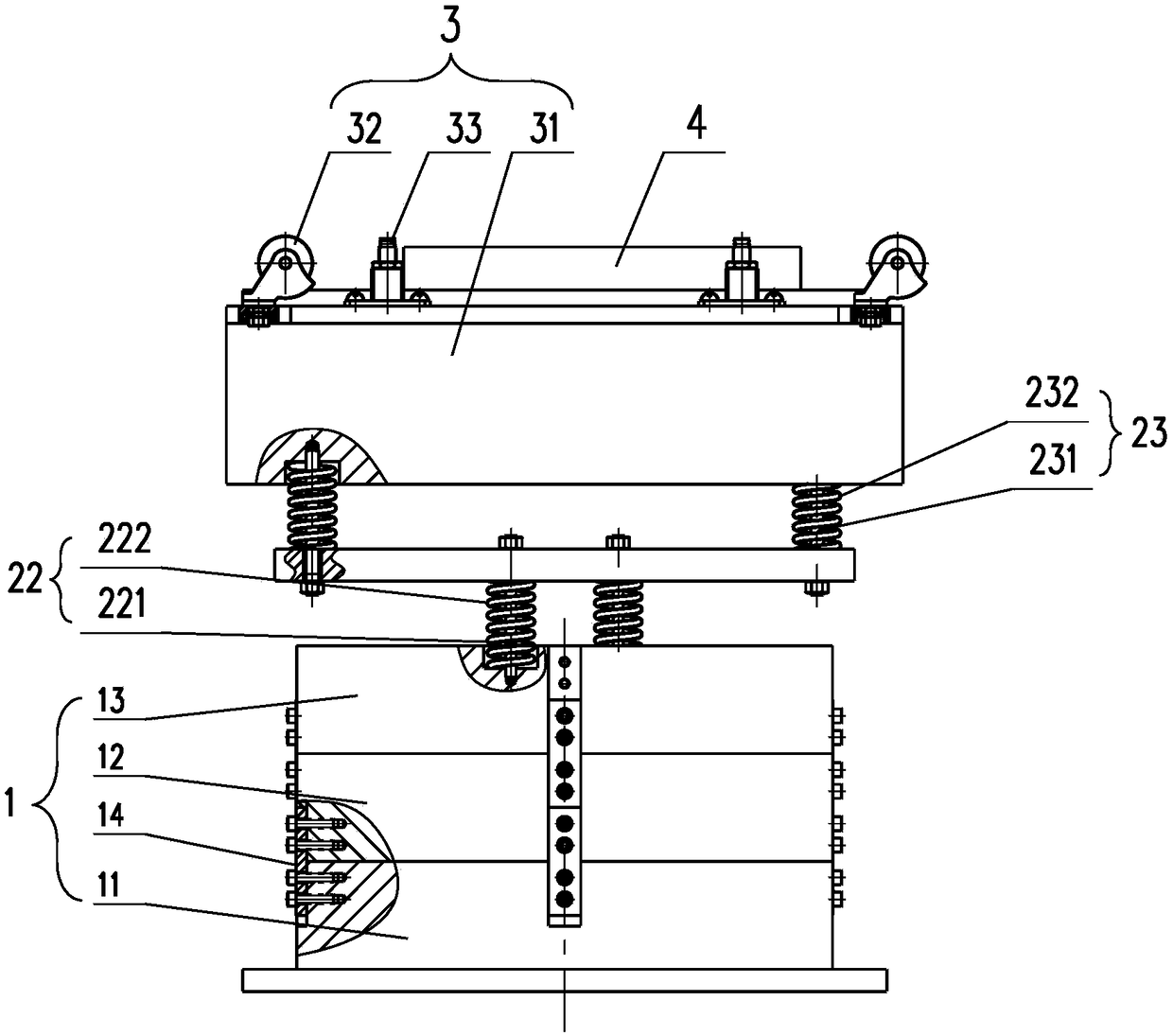

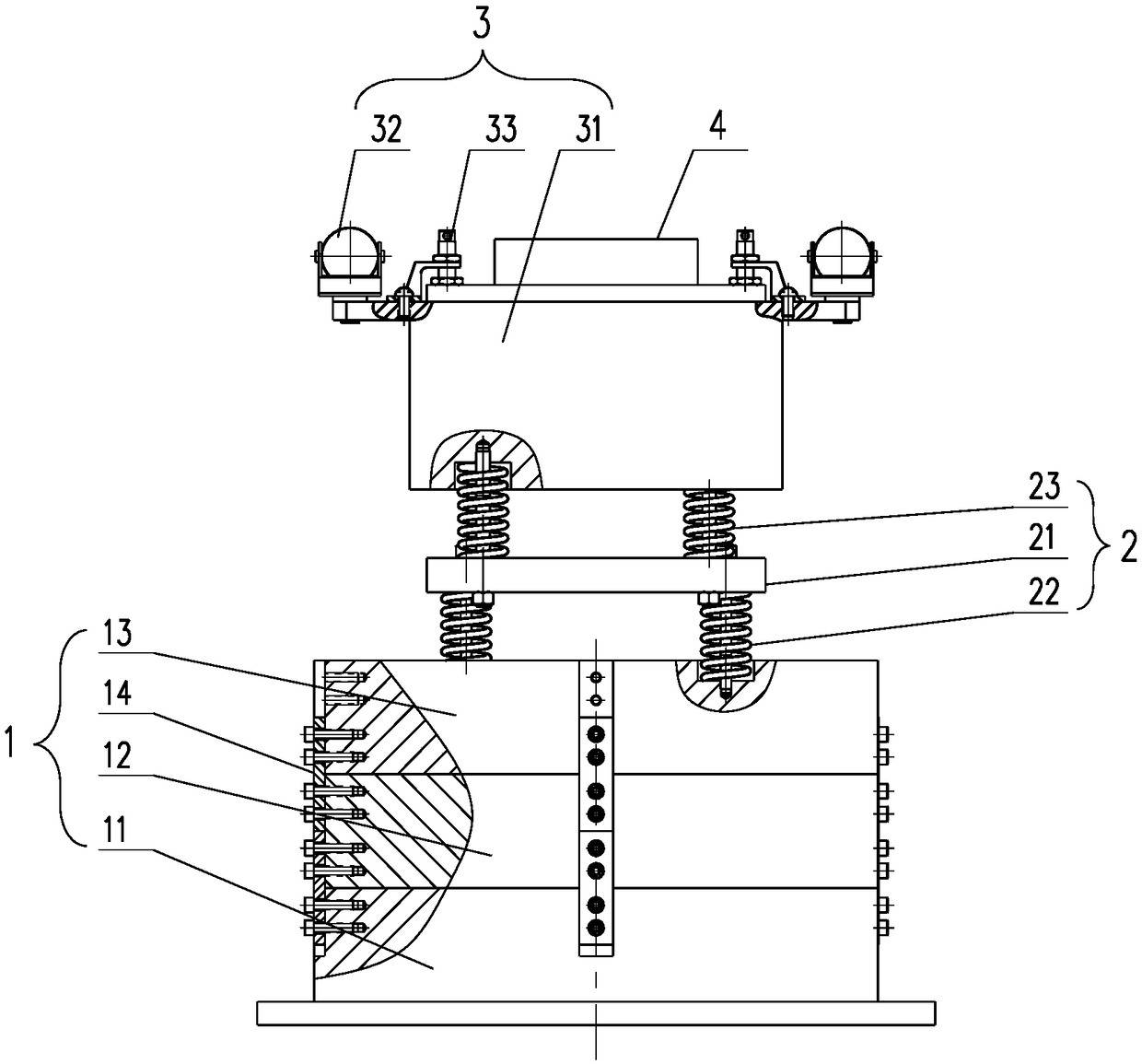

Two-stage spring type tunnel detecting radar tray device

The invention discloses a two-stage spring type tunnel detecting radar tray device which comprises a bottom part height adjusting support, an elastic self-adaptive mechanism, a load receiving mechanism and a detecting radar; the elastic self-adaptive mechanism comprises a spring transition support rack, a number of hard spring assemblies and a plurality of soft spring assemblies; the spring transition support rack is positioned between the hard spring assembly and the soft spring assembly. The device disclosed in the invention is advantaged by compact structure, simple operation, convenient installation, strong applicability, and particular suitability for installation and fixation of the detecting radar during detection of a surface of a tunnel top lining; the elastic self-adaptive mechanism is arranged to ensure that the load receiving mechanism can be in contact with the surface of the top lining all along and constant contact force can be kept during a tunnel detecting process whenthe surface of the tunnel top lining is not flat, a road surface is uneven, and a detection car bumps along or slither; distance between the detection radar and the surface of the top lining can be kept from being changed or the detection radar and the surface of the top lining can be prevented from being crushed by the hard top, and that the detection process can be carried out smoothly and thatthe detection data is accurate and stable can be ensured.

Owner:EAST CHINA JIAOTONG UNIVERSITY

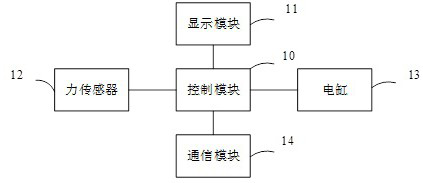

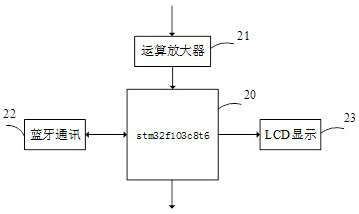

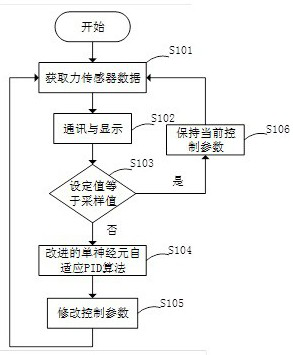

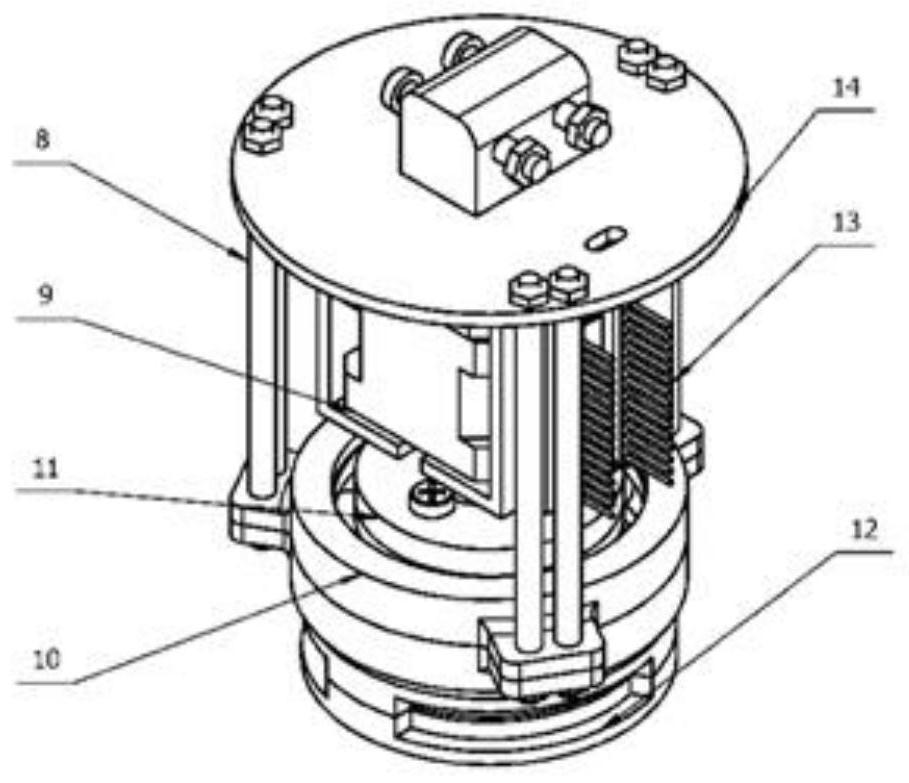

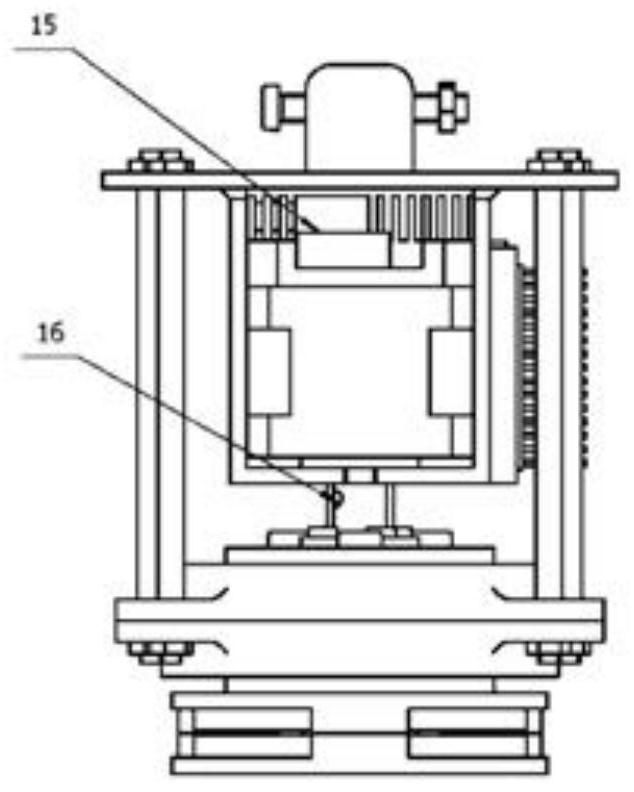

Active self-adaptive force control device for mechanical arm and control method thereof

PendingCN112605997AConstant contact forceSimple structureProgramme-controlled manipulatorData packInformation transmission

The invention relates to the technical field of robot grinding or polishing constant force control, in particular to an active self-adaptive force control device for a mechanical arm and a control method of the active self-adaptive force control device. The active self-adaptive force control device is characterized by comprising a control module, a force sensor, the mechanical arm, a communication module, a display module and an electric cylinder, the mechanical arm is connected with the electric cylinder, the force sensor is arranged on the mechanical arm, the control module is connected with the force sensor, the electric cylinder, the display module and the communication module, the control module can output control signals and conduct signal transmission with other modules, and the force sensor can detect the contact force between the electric cylinder and the surface of a workpiece in real time and transmit the contact force to the control module; the display module can display a force signal transmitted to the control module by the force sensor in real time; and the communication module can achieve transparent information transmission between the control module and a PC terminal, various parameters of the control device are sent to the PC terminal through data packets, and the active self-adaptive force control device has the advantages of being simple in structure, good in control effect, sensitive in force control, stable in work and the like.

Owner:HARBIN INST OF TECH AT WEIHAI +1

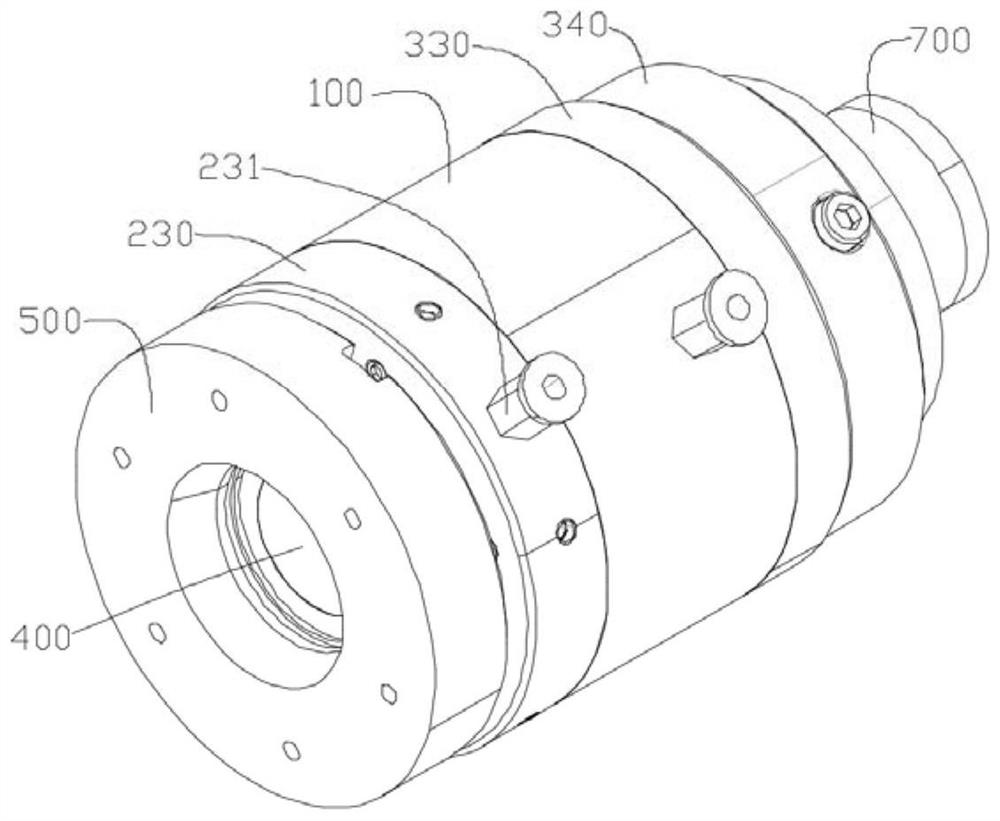

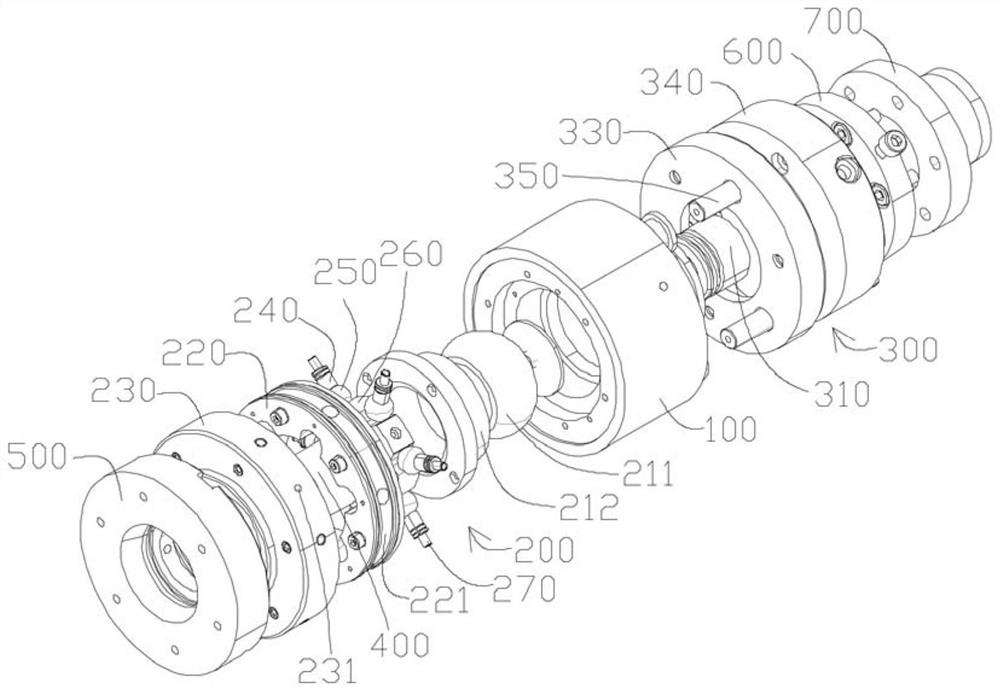

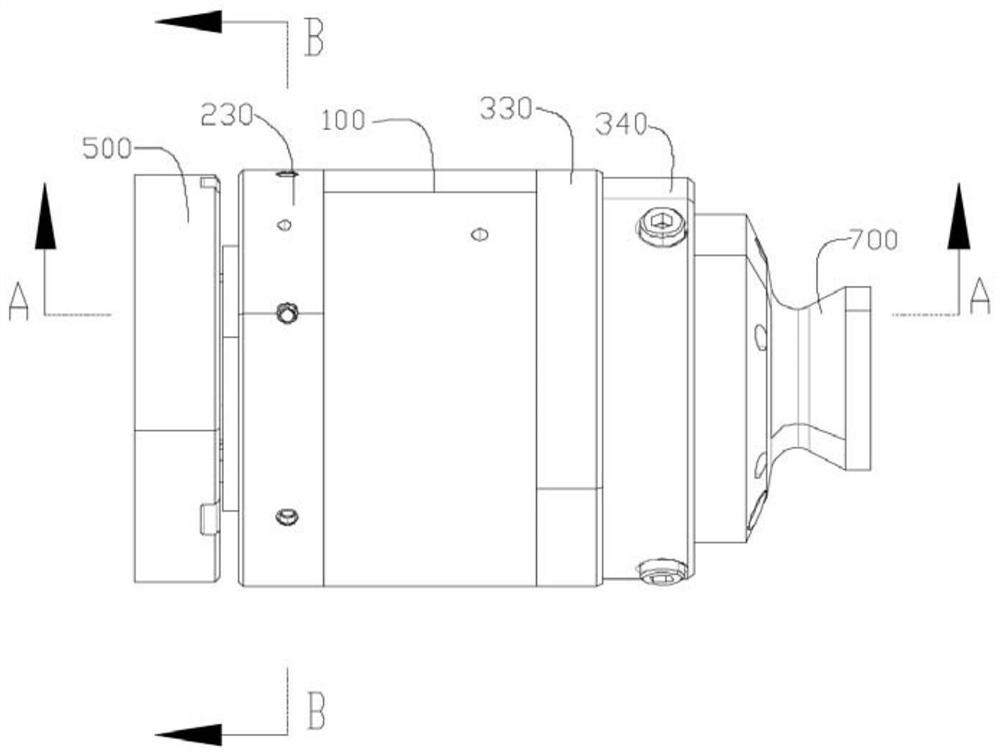

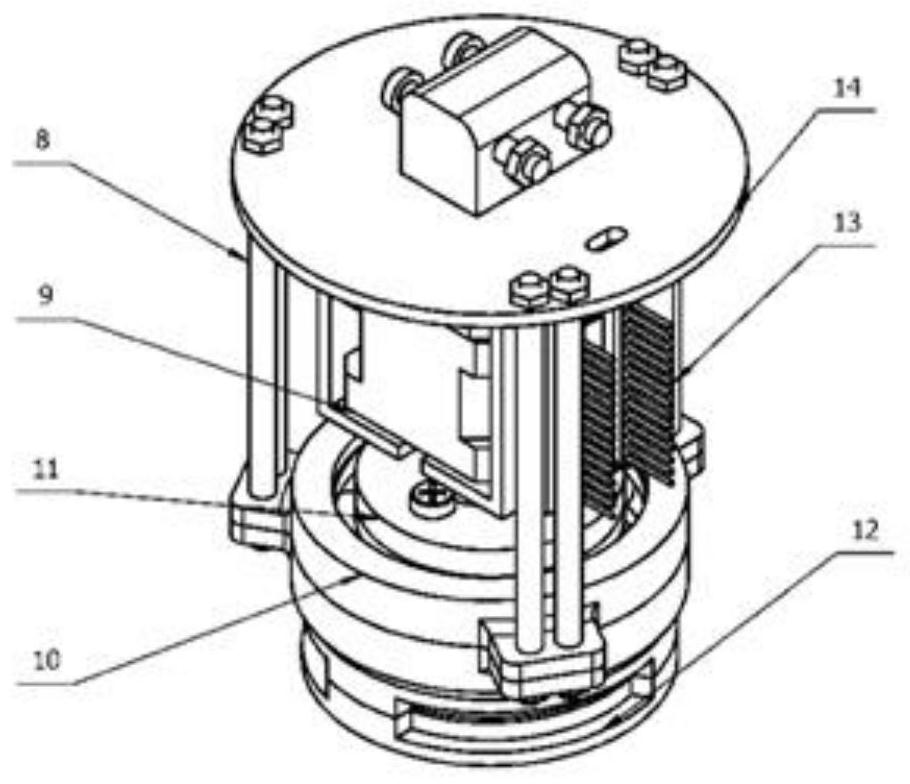

Floating device and electric spindle

PendingCN111633506AConstant contact forceUniform cutEdge grinding machinesGrinding machine componentsEngineeringElectrical and Electronics engineering

The invention provides a floating device and an electric spindle, and relates to the technical field of electric spindle floating. The floating device comprises a mounting base, a radial floating assembly, an axial floating assembly and a floating shaft, wherein one end of the mounting base is connected with a robot through the axial floating assembly; the radial floating assembly is arranged at the other end of the mounting base; the floating shaft is inserted into the radial floating assembly; and the end, away from the mounting base, of the floating shaft is connected with a spindle floating connecting disc. The electric spindle comprises the floating device. The technical effect of the good using effect is achieved.

Owner:苏州速科德电机科技有限公司

Hydraulic driving system for driving electrode telescoping ram

InactiveCN104389838AConstant contact forceSimple structureSurveyFluid-pressure actuatorsPressure transmissionWell logging

The invention, which belongs to the technical field of well logging in petroleum exploration, relates to a hydraulic driving device for driving an electrode telescoping ram. The hydraulic driving device comprises a drive assembly and a pressure transmission assembly; the drive assembly comprises a motor, a coupling and a ballscrew; the coupling connects the output end of the motor with the input end of the ballscrew; the pressure transmission assembly comprises a nut, a connecting barrel, a piston, a check valve and a pump barrel; the nut is mounted on the ballscrew, one end of the connecting barrel fixedly sleeves the nut, and the other end of the connecting barrel is fixedly connected with the piston; the piston is mounted in the pump barrel and divides the pump barrel into a front chamber and a rear chamber; the check valve is mounted in the piston; the rear chamber of the pump barrel communicates with an electrode telescoping ram through a tubing. The hydraulic driving device has a simple structure and high reliability, and moreover, the working efficiency of the hydraulic driving device is greatly increased in comparison with the working efficiency of the prior art.

Owner:XIAN SITAN INSTR

Robotic Friction Stir Welding System and Its Force-Position Combined Ring Hybrid Control Method

ActiveCN104607795BConstant contact forceReal-time control of high-precision motionNon-electric welding apparatusFriction weldingRobot hand

Owner:宁波中创焊接技术有限公司

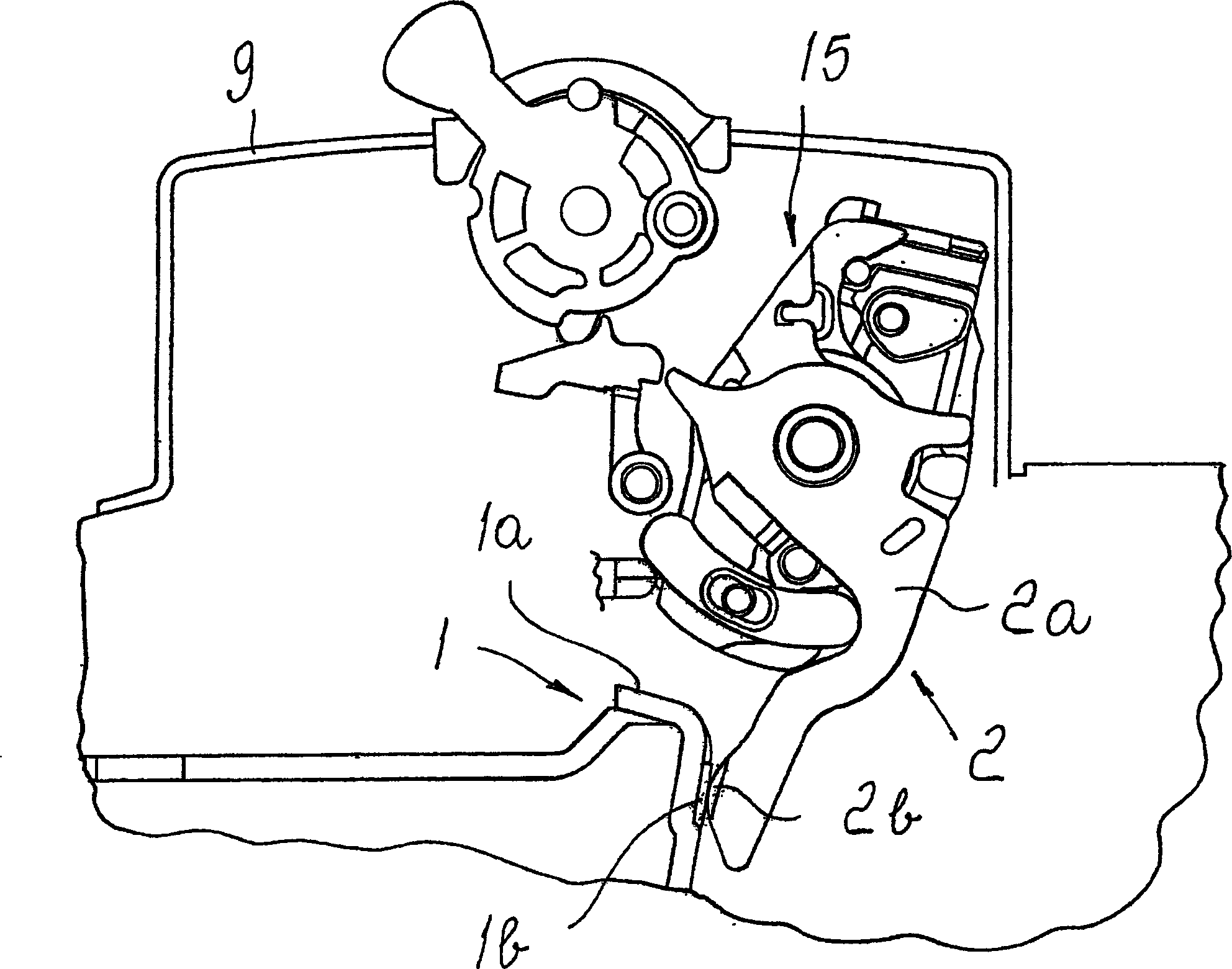

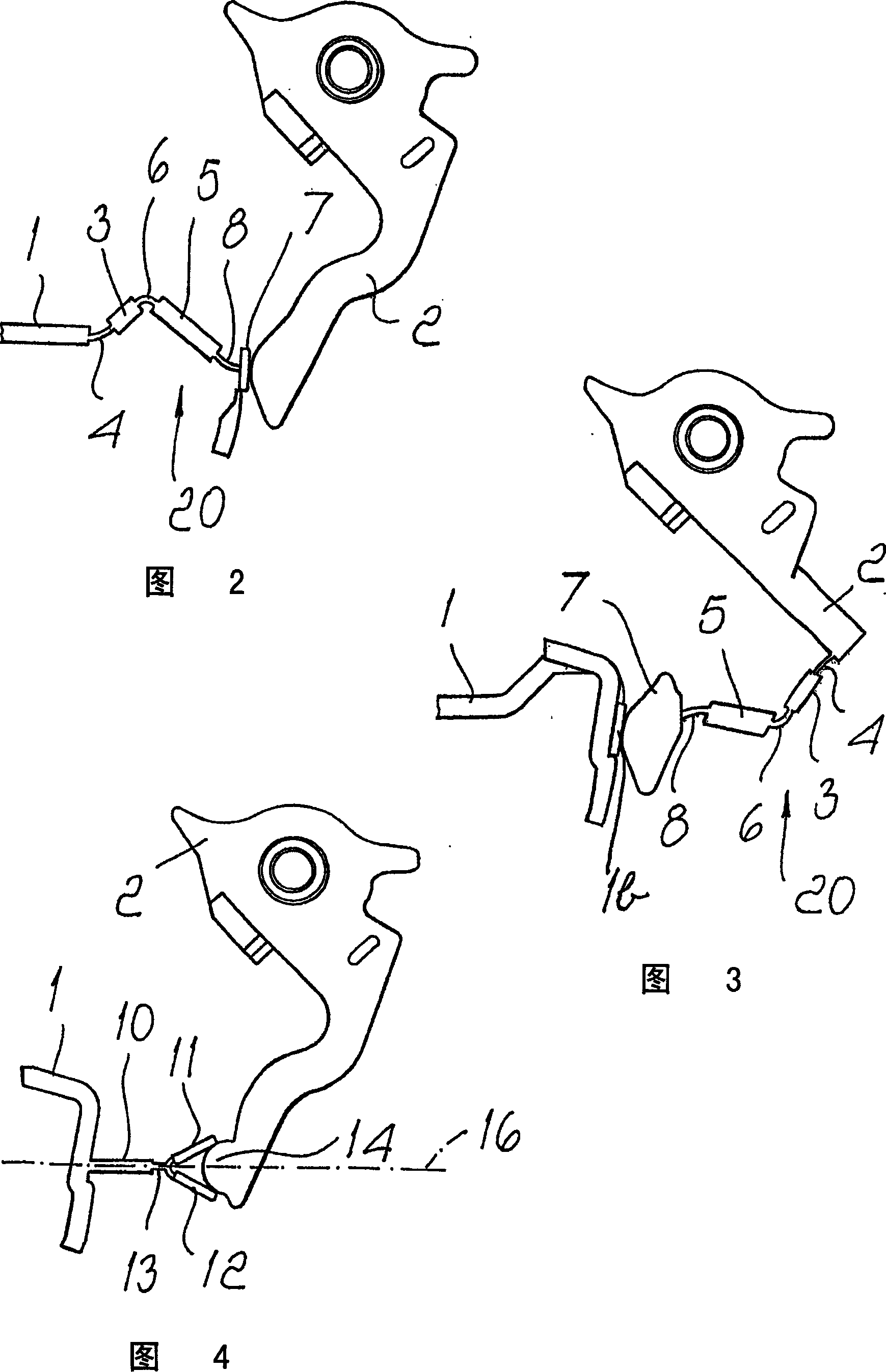

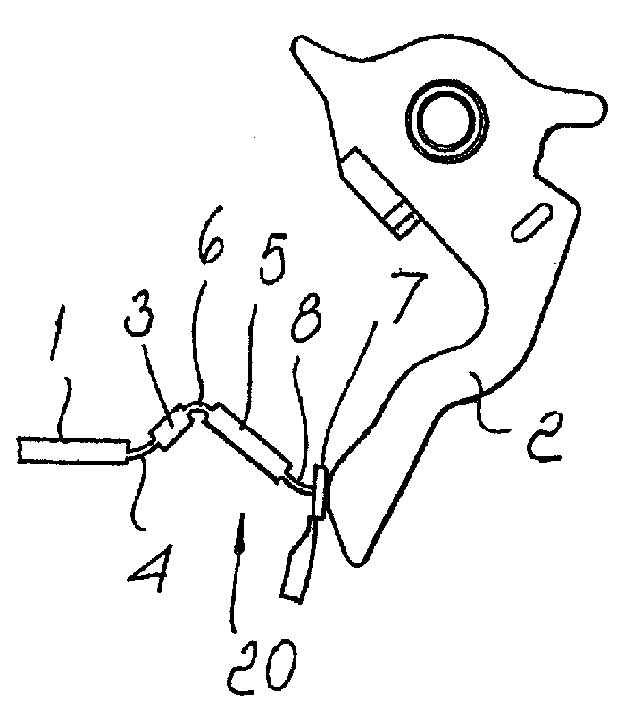

Circuit breaker for low-voltage currents

InactiveCN1465080AConstant contact forceSolid electrolytic capacitorsContact engagementsLow voltageConstant force

A circuit breaker for low-voltage currents, comprising an enclosure that contains moving contact means and fixed contact means, the moving contact means comprising at least one moving contact, the fixed contact means comprising at least one fixed contact, a kinematic chain that comprises a plurality of levers that move the moving contact between an open position, in which the contacts are separated, and a closed position, in which they are coupled, and a mechanism that ensures a substantially constant force between the contacts in the closed position, its particularity consisting of the fact that the mechanism comprises a single body that has a first rigid element, which is associated with at least one of the fixed and moving contacts, and a second rigid element, which is arranged adjacent to the first rigid element and is connected thereto by virtue of a flexible hinge constituted by a first elastic and resilient element.

Owner:ABB (SCHWEIZ) AG

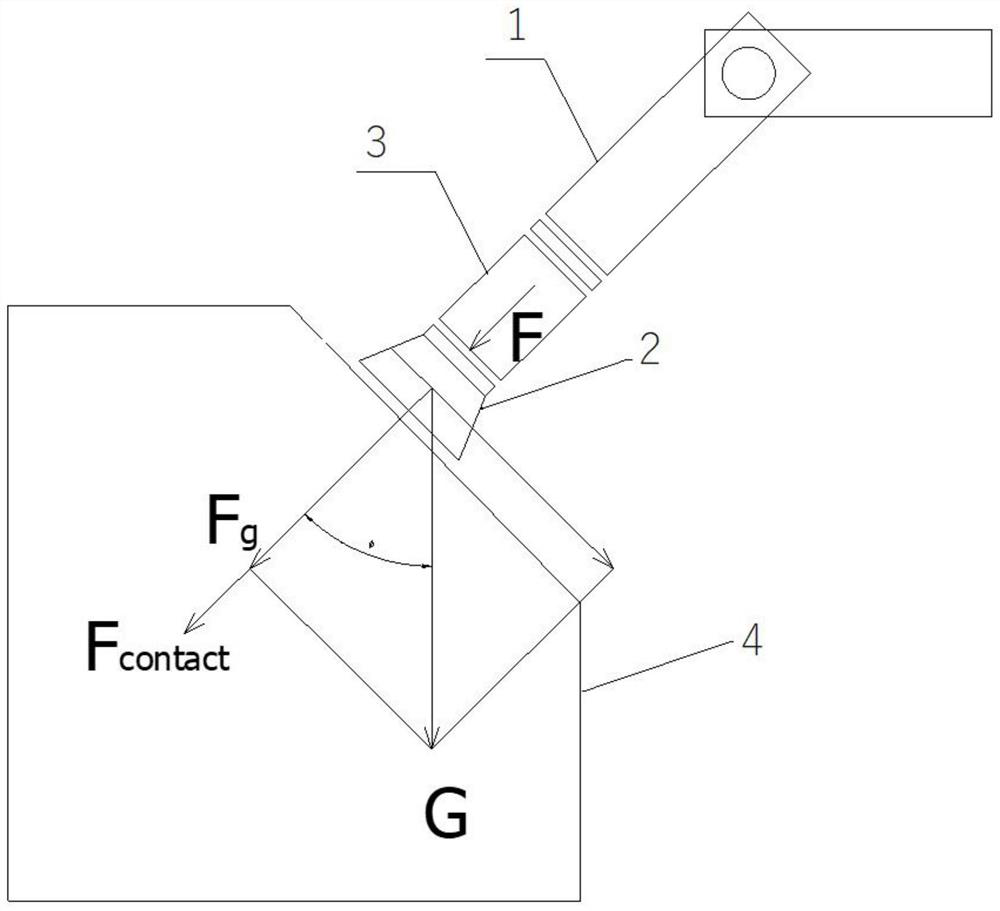

Tool inclination angle gravity compensation method

PendingCN112720466AConstant contact forceHigh measurement accuracyProgramme-controlled manipulatorGrinding feed controlAnti jammingEngineering

The invention provides a tool inclination angle gravity compensation method. A tool is grabbed through driving equipment. The method comprises the steps that the axial direction of the tool is obtained, and an included angle between the axial direction of the tool and the gravity direction is calculated; the gravity of the tool is calculated according to the mass of the tool, and the component force of the gravity of the tool in the axial direction of the tool is calculated based on the included angle; and the tool has a contact force preset value, the output force which should be given to the tool by the driving equipment is calculated according to the contact force preset value and the component force of the gravity of the tool in the axial direction of the tool, and constant control over the contact force when the tool is subjected to polishing and grinding operation is achieved. According to the method, the inclination angle of the tool is calculated through a robot, influence of tool gravity and tool space posture on the contact force is corrected in real time, constant contact force in the machining process is guaranteed, and the method has the characteristics of being high in measurement precision, short in response time and high in anti-jamming capability. Control over the non-axial force can also be subjected to extension calculation by this method.

Owner:廊坊市亿创科技有限公司

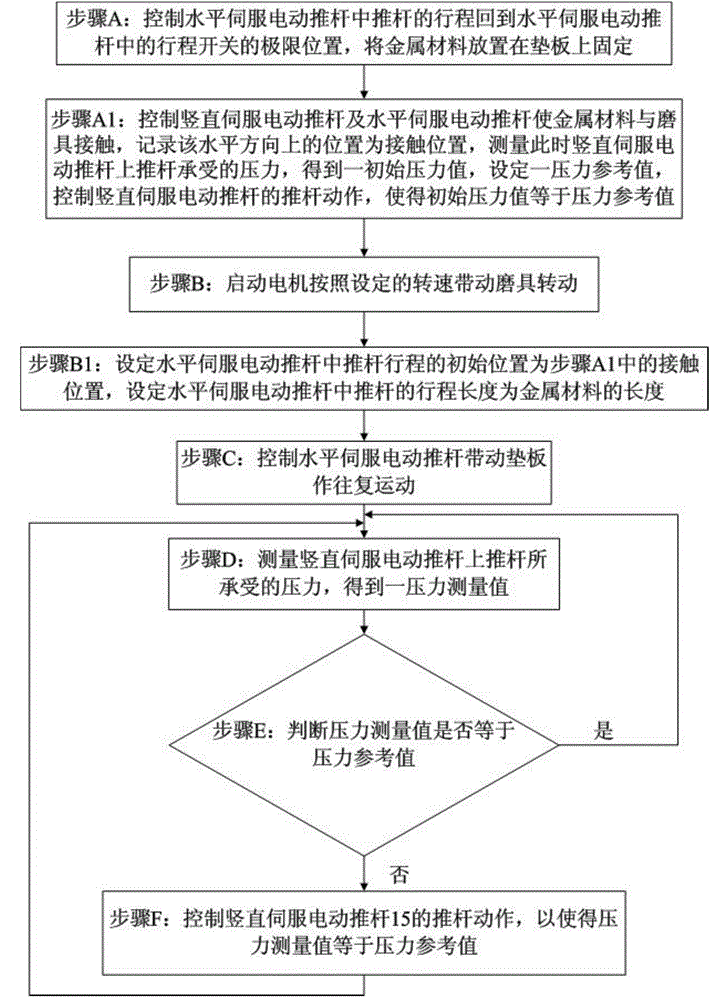

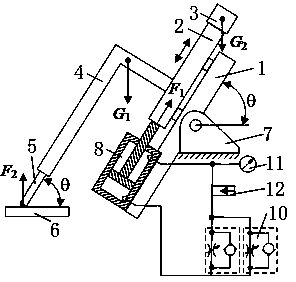

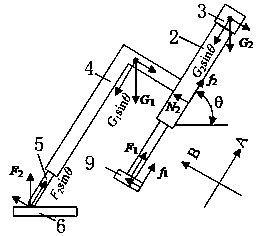

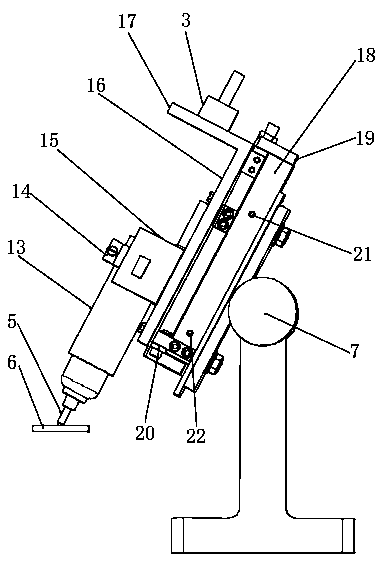

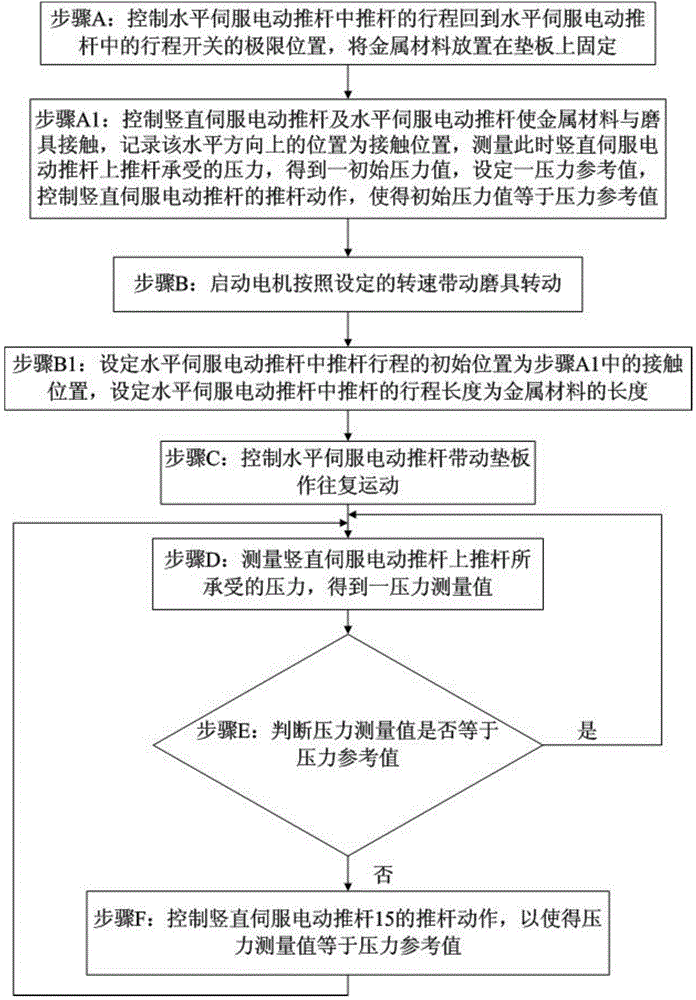

Grinding machine and method for surface pre-processing of special metallic composite materials for laboratory

ActiveCN104148999AConsistent sandingPolished evenlyGrinding drivesAutomatic grinding controlReciprocating motionControl system

Disclosed are a grinding machine and method for surface pre-processing of special metallic composite materials for a laboratory. The grinding machine comprises a machine frame, a motor, a spindle, a grinding tool, a base plate, a support and a control system, wherein the motor and the spindle are arranged on the machine frame, the base plate is provided with a horizontal servo electric push rod, and the support is provided with a vertical servo electric push rod and a pressure sensor. An output shaft of the motor is connected with the spindle, the grinding tool is arranged on the spindle in a sleeved mode, the base plate is arranged below the grinding tool, the support is arranged at the bottom of the base plate and can slide upwards and downwards along the machine frame, a plurality of sucking disks used for fixing the metallic composite materials are arranged on the base plate, the control system is in signal connection with the motor, the horizontal servo electric push rod, the pressure sensor and the vertical servo electric push rod, and therefore the control system can control the rotation speed of the motor and reciprocating movement of the horizontal servo electric push rod, and can further adjust movement of the vertical servo electric push rod according to pressure signals received by the pressure sensor. The grinding machine and method can conduct even and reciprocating grinding on the surfaces of the metallic materials to enable the surfaces of the metallic materials to be ground more evenly.

Owner:银邦(安徽)新能源材料科技有限公司

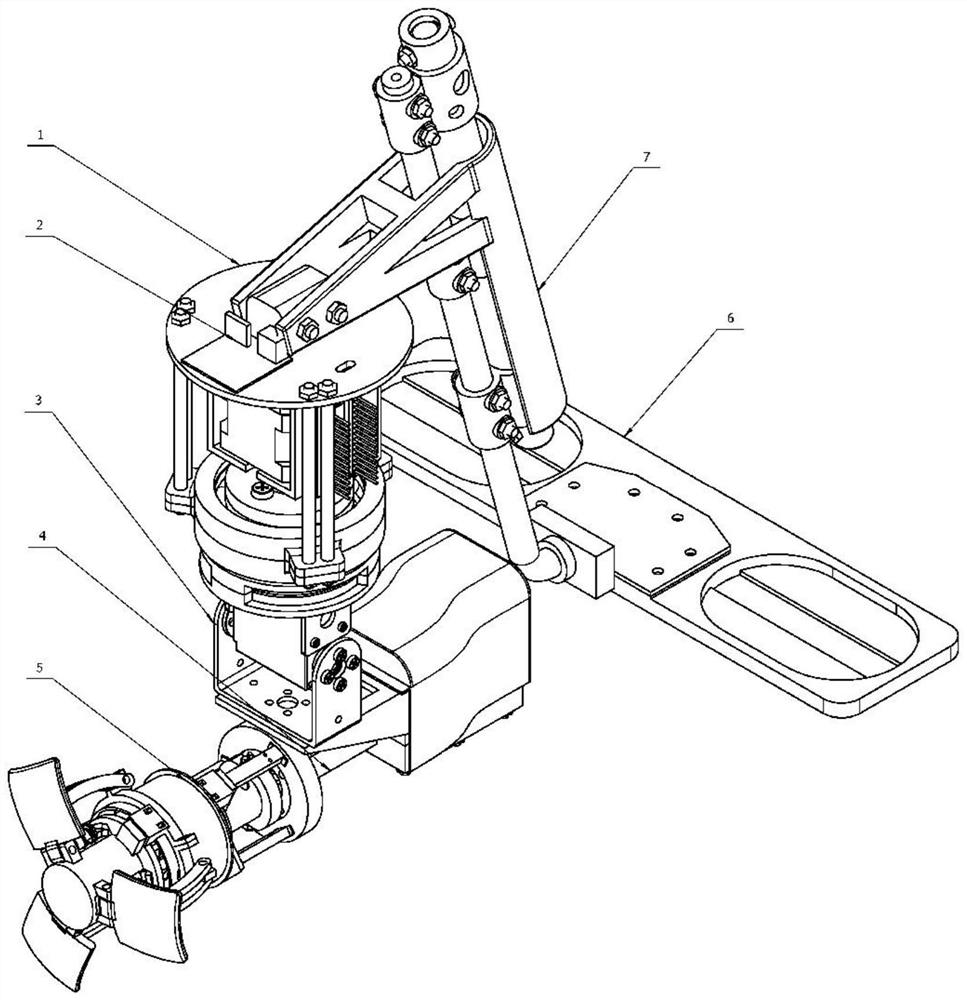

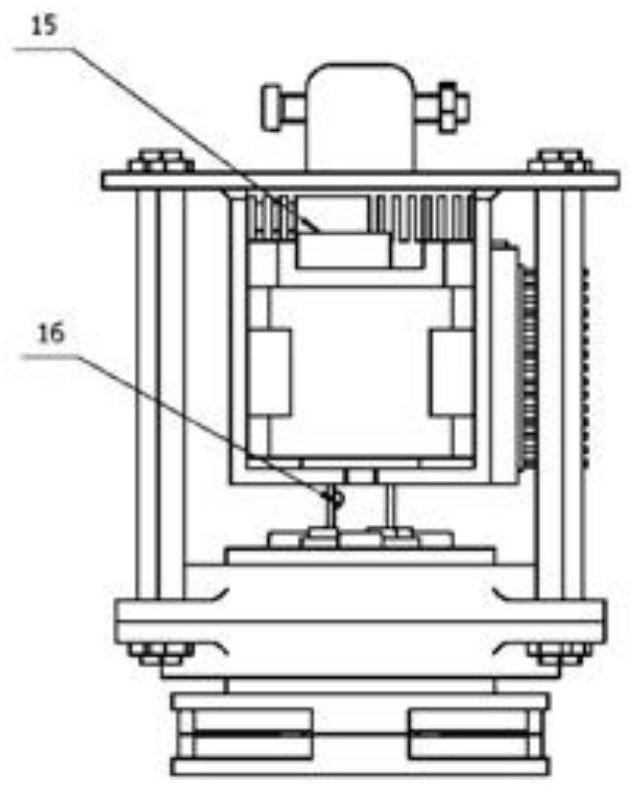

Electric spark deposition contact force controlling device with damping function

ActiveCN111168268AThe contact position does not changeConstant contact forceWelding/cutting auxillary devicesAuxillary welding devicesDamping functionValve stem

The invention relates to an electric spark deposition contact force controlling device with a damping function. The electric spark deposition contact force controlling device with the damping functionmainly comprises an air cylinder, a sliding table, a base, a weight, a clamping mechanism, an angle adjusting device, a throttle valve, a pressure gauge, an inflating valve and the like, wherein themoving direction of a piston of the air cylinder is consistent with the moving direction of the sliding table, and the sliding table moves when the piston moves, so that an electrode is driven to moveup and down, and when the electrode moves downwards, the electrode makes contact with a workpiece. The gravity of a sliding part is counteracted by using thrust generated by the air cylinder in an airtight pneumatic system, the sliding part is pushed by the gravity of the weight to move downwards to form contact force between the electrode and the workpiece, the throttle valve in the airtight pneumatic system generates damping on movement of the piston, electrode vibration caused by recoil force generated in a moving process of the electrode and the workpiece is restrained, in an electric spark deposition surfacing process, stable contact between the electrode and the workpiece and constant contact force can be ensured along with electrode loss and movement of the sliding table, work is reliable, and adjustment is convenient.

Owner:HENAN UNIV OF SCI & TECH

A device based on self-compensation for uniform film removal on metal surfaces

InactiveCN105234787BNo manual adjustment requiredSimple structureGrinding drivesGrinding machinesConstant forceSelf compensation

The invention relates to a metal surface uniform film-removing device based on self-compensation. According to the technical scheme, a motor (7) drives a steel wire brush (2) to rotate through a belt (6); and a heavy object block (13) is connected with a guide rail pair (8) through a fixed pulley (12) by virtue of a steel wire rope. An air cylinder (9) is hinged with the right end surface of the guide rail pair (8); height of a stroke valve (1) is regulated by virtue of a height regulator (15), so that a rod to be subjected to film removal can press down a roller wheel of the stroke valve (1), and a valve element of the stroke valve (1) reverses. During the film removal, the steel wire brush (2) is in constant-force contact with the rod to be subjected to film removal under the gravity action of the heavy object block (13), so that self-compensation uniform film removal is realized. When the film removal is completed, the air cylinder (9) pulls the guide rail pair (8) to move rightwards to wait for a rod to be subjected to film removal. When the steel wire brush (2) reaches use limit, the heavy object block (13) is descended to a maximum position for triggering an alarm switch (14), so that an indicator lamp (18) is turned on to remind a worker to replace the steel wire brush (2). The metal surface uniform film-removing device based on self-compensation has the characteristics of low cost, a simple structure, uniform film removal, automatic abrasion gap compensation and high production efficiency.

Owner:WUHAN UNIV OF SCI & TECH

Constant-force self-adaptive closestool cleaning robot

The invention discloses a constant-force self-adaptive closestool cleaning robot. The robot comprises a rotating mechanism, a swing rod mechanism, a constant-force brush head, a telescopic mechanism, a driving mechanism, a lifting mechanism, a control mechanism and an electric slip ring assembly. The brush head part is designed to be constant in force, so that the brush head and the inner wall of the closestool can keep constant contact force, and a good cleaning effect is guaranteed; and due to the foldable design of the brush head part, the brush head can clean any position of the inner wall of the closestool, and the cleaning range is large. In an unfolded state, a brush plate is stressed to deform when making contact with different positions of the inner wall of the closestool so as to fit the shape of the inner wall and attach to the inner wall of the closestool, and when a drainage port is brushed, the brush plate can be completely put away due to stress, so that the occupied area of the robot is reduced, and the robot stretches into the drainage port for cleaning.

Owner:XI AN JIAOTONG UNIV

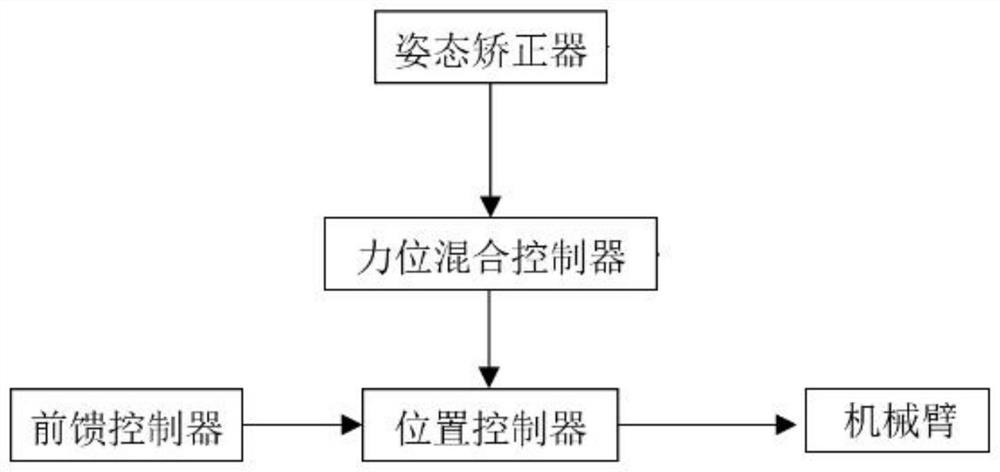

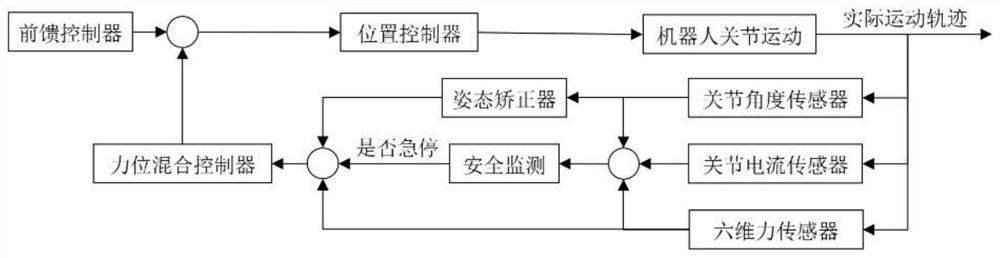

A human body automatic ultrasonic scanning robot, controller and control method

ActiveCN110488745BConstant contact forceRelieve painNumerical controlHuman bodyPhysical medicine and rehabilitation

The invention provides a human body automatic ultrasonic scanning robot and a control method thereof, and a controller. The controller comprises a feed-forward controller, a position controller, a force-position hybrid controller and a posture corrector, an ultrasonic detection probe held by a user is controlled to keep constant contact force, a certain friction force and a posture to adapt to skin outer contour movement, and the feed-forward controller controls the ultrasonic detection probe to move in the preset direction; the position controller controls a mechanical arm of the robot body to move; the force-position hybrid controller controls the contact force between the ultrasonic detection probe and the human skin surface to be constant and the friction force to be within a certain range; the posture corrector corrects the posture of the ultrasonic detection probe to enable the ultrasonic detection probe to better conform to the skin outline. Pressure and friction feedback is adopted, it is guaranteed that the contact force between the ultrasonic detection probe and the skin of a patient is basically constant, and the pain, caused by scanning force, of the patient is relieved; friction force feedback and historical scanning tracks correct the posture of the ultrasonic detection probe at the same time to adapt to skin surfaces with different contours.

Owner:SHANGHAI JIAO TONG UNIV

A constant pressure contact sensor

ActiveCN106949924BConstant contact forceGuaranteed accuracyMeasurement devicesTime informationControl system

The invention discloses a constant-pressure contact type sensor, belonging to the field of measurement technologies. The constant-pressure contact type sensor comprises a contact type sensor, an imaging device, a pressure applying device, a moving device and a constant-pressure control system, wherein the pressure applying device comprises a supporting frame and a lifting mechanism fixed on the supporting frame, the moving device is a motor vehicle, the supporting frame is detachably fixed on the motor vehicle by means of fasteners, the contact type sensor is fixed on the lifting mechanism, the lifting mechanism is an oil cylinder, and the imaging device comprises a scanner which is arranged on the motor vehicle and used for forming an image of a detected surface. The constant-pressure contact type sensor can realize detection of the sensor through the lifting function of the pressure applying device, and provides accurate ground information by means of the imaging device, so that the constant-pressure control system can provide more precise real-time information for the pressure applying device, thereby ensuring that a contact force between the sensor and the detected surface is constant, and finally guaranteeing the accuracy of detection results.

Owner:东营新瑞石油科技有限责任公司

Curved surface contour constant force tracking method and application device based on nonlinear double closed-loop control

ActiveCN106383495BStable contact forceConstant contact forceProgramme controlComputer controlControl flowConstant force

The invention discloses a curved surface profile constant force tracking method based on non-linear double closed loop control, and the method comprises the steps: according to a curved surface profile tracking motion model, force analysis is performed on a model of the contact force between a tool end and a work piece, a relation between an actual motion inclination angle and a normal contact force error and a double closed loop force control method can be obtained through the force analysis and a motion coordinate transformation formula; according to the double closed loop force control method, a control flow of a non-linear PID force controller and a non-linear PID control formula can be obtained, a motion controller can be adopted to control motion of three motion mechanisms in three coordinate directions, so that the tool end can track unknown curve surface profile motion with constant normal contact force. The invention also provides an application device for realizing the method, the device comprises a control part and a mechanical part, the control part comprises a PC host, an embedded motion controller, a terminal board, a signal amplifier, a three-dimensional force sensor, a server driver and a three-coordinate drive and transmission mechanism, and the mechanical part comprises a work rack, movement mechanisms in x, y and z axis directions arranged on the work rack, a sensor clamping rack, a processing tool and a work piece holder for clamping a curved surface part.

Owner:SOUTH CHINA UNIV OF TECH

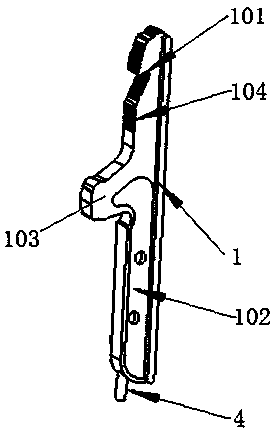

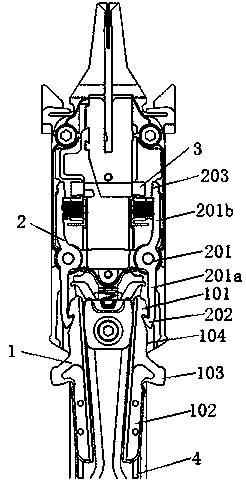

Novel-structured vertical hook of jacquard machine and novel-structured vertical hook component with same

ActiveCN110878437ASolve adverse effects such as fatigue wearConstant contact forceJacquardsTextile/flexible product manufactureEngineeringMachine

The invention relates to a novel-structured vertical hook of a jacquard machine; the novel-structured vertical hook comprises a vertical hook body, a hook part, a harness cord connecting part and a griffe fitting part, wherein the vertical hook body, the harness cord connecting part and the griffe fitting part are arranged on the vertical hook body; the novel-structured vertical hook is characterized in that a reed of the traditional vertical hook structure is replaced by an auxiliary suction terrace, and the auxiliary suction terrace is raised from one side of the vertical hook body and is ofrigid structure. A novel-structured vertical hook component of the jacquard machine sequentially comprises an electromagnet, a moving iron and a vertical hook according to a position relationship from top to bottom, the vertical hook comprises a vertical hook body, and a hook part, a harness cord connecting part and a griffe fitting part which are arranged on the vertical hook body, the upper part of the vertical hook is in hanging fit with the moving iron through the hook part, and the lower part of the vertical hook is connected with the harness cord through the harness cord connecting part; the novel-structured vertical hook component is characterized in that an auxiliary suction terrace is used to replace a reed of a traditional vertical hook structure, and the auxiliary suction terrace is raised on one side of the vertical hook body and is of rigid structure. The novel-structured vertical hook has excellent fatigue resistance, abrasion to a jacquard component is effectively reduced, the service life of the jacquard component is extended, and overall operation reliability of the jacquard machine is improved accordingly.

Owner:烟台宋和宋智能科技股份有限公司

A contact force control device for EDM with damping function

ActiveCN111168268BConstant contact forceWork reliablyWelding/cutting auxillary devicesAuxillary welding devicesDamping functionEngineering

The invention relates to an electric spark deposition contact force control device with a damping function. The device is mainly composed of a cylinder, a slide table, a base, a weight, a clamping mechanism, an angle adjustment device, a throttle valve, a pressure gauge and an air valve, etc. , the moving direction of the cylinder piston is consistent with the moving direction of the sliding table. When the piston moves, it drives the sliding table to move, thereby driving the electrode to move up and down. When moving down, the electrode is in contact with the workpiece, and the thrust generated by the cylinder in the closed pneumatic system is used to offset the sliding parts. The gravity of the weight pushes the sliding part down to form the contact force between the electrode and the workpiece. The throttle valve in the airtight pneumatic system damps the movement of the piston and suppresses the recoil force caused by the movement of the electrode and the workpiece. Electrode vibration; in the process of EDM deposition welding, with the electrode loss and the movement of the sliding table, it can ensure the stable contact between the electrode and the workpiece and the constant contact force, reliable operation and convenient adjustment.

Owner:HENAN UNIV OF SCI & TECH

A Constant Force Adaptive Toilet Cleaning Robot

ActiveCN112681469BConstant contact forceEasy to cleanLavatory sanitoryConstant forceClassical mechanics

Owner:XI AN JIAOTONG UNIV

A laboratory-specific metal composite material surface pretreatment grinding machine and grinding method

ActiveCN104148999BConsistent sandingPolished evenlyGrinding drivesAutomatic grinding controlControl systemReciprocating motion

Disclosed are a grinding machine and method for surface pre-processing of special metallic composite materials for a laboratory. The grinding machine comprises a machine frame, a motor, a spindle, a grinding tool, a base plate, a support and a control system, wherein the motor and the spindle are arranged on the machine frame, the base plate is provided with a horizontal servo electric push rod, and the support is provided with a vertical servo electric push rod and a pressure sensor. An output shaft of the motor is connected with the spindle, the grinding tool is arranged on the spindle in a sleeved mode, the base plate is arranged below the grinding tool, the support is arranged at the bottom of the base plate and can slide upwards and downwards along the machine frame, a plurality of sucking disks used for fixing the metallic composite materials are arranged on the base plate, the control system is in signal connection with the motor, the horizontal servo electric push rod, the pressure sensor and the vertical servo electric push rod, and therefore the control system can control the rotation speed of the motor and reciprocating movement of the horizontal servo electric push rod, and can further adjust movement of the vertical servo electric push rod according to pressure signals received by the pressure sensor. The grinding machine and method can conduct even and reciprocating grinding on the surfaces of the metallic materials to enable the surfaces of the metallic materials to be ground more evenly.

Owner:银邦(安徽)新能源材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com