Hydraulic driving system for driving electrode telescoping ram

A driving device and driving electrode technology, which is applied in fluid pressure actuating devices, electromechanical devices, electrical components, etc., can solve the problems of low work efficiency, low oil return pressure, and long measurement period, and achieve simple structure and low oil return pressure. The effect of increasing and shortening the measurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

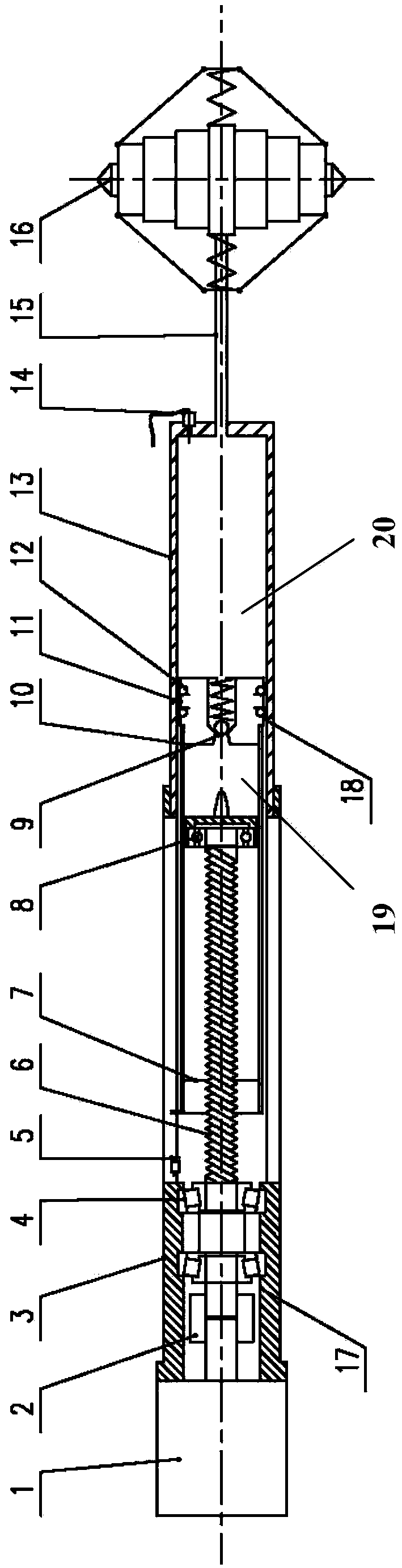

[0024] In order to overcome the problems of complex structure, poor stability and low work efficiency of the drive system of the existing electrode pusher, the present invention provides a simple structure, strong stability, high reliability and high work efficiency for driving the electrode pusher hydraulic drive unit.

[0025] Such as figure 1 Shown: The hydraulic drive device used to drive the electrode pusher, which is installed in the outer protective tube of the resistivity measuring instrument through the casing. The outer protection tube is filled with oil and communicates with a balance supply oil tank, which is sealed and separated from the outside world. The device includes a transmission component and a pressure transmission component;

[0026] Among them, the transmission assembly 17 includes a motor 1, a coupling 2, and a ball screw 6; the coupling 2 connects the output end of the motor 1 with the input end of the ball screw 6, so that the motor can drive the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com