A contact force control device for EDM with damping function

A technology of EDM deposition and control devices, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve serious, complex, vibration and other problems, and achieve the effects of ensuring stable contact, ensuring control accuracy, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

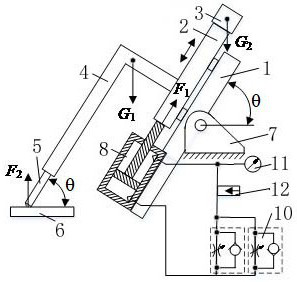

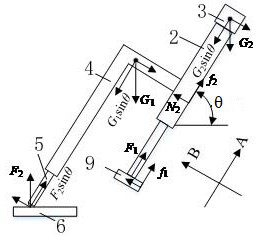

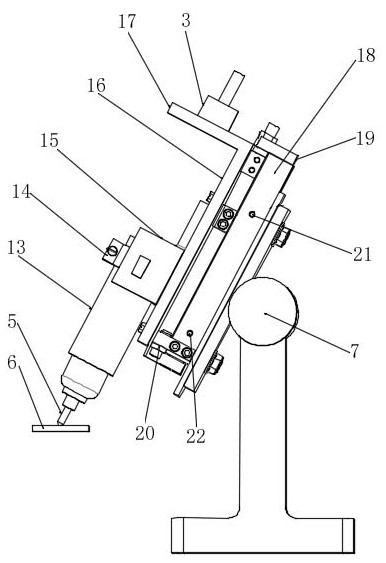

[0056] The technical scheme of the present invention will be further described in conjunction with specific embodiments below. In this embodiment, the SMC type MXS25*100 pneumatic slide table is selected. The pneumatic slide table 18 adopts double pistons and double cylinders, and the cylinder 8 and the linear guide rail slide table 2 are designed as One body, with advantages of compact structure, high guiding precision, stable transmission, etc.; each cylinder 8 of the pneumatic slide table 2 has a cylinder diameter of 25mm, a stroke of 100mm, a piston rod diameter of 12mm, and an operating pressure range of 0.15-0.7MPa.

[0057] Such as Figure 3-4 As shown, the control device of this embodiment includes a workpiece 6, an electrode 5, a welding torch 13, a clamping snap ring 14, a mounting plate 15, a fixing plate 16, a counterweight plate 17, a weight 3, a pneumatic sliding table 18, and a front end limiter. Device 19, exhaust hole 21, air intake hole 22, rear end limiter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com