Novel-structured vertical hook of jacquard machine and novel-structured vertical hook component with same

A new structure, technology of jacquard machine, applied in jacquard machine, weaving, textile and paper making, etc., can solve problems such as time delay, inability to release quickly, fabric defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

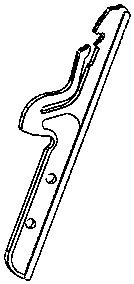

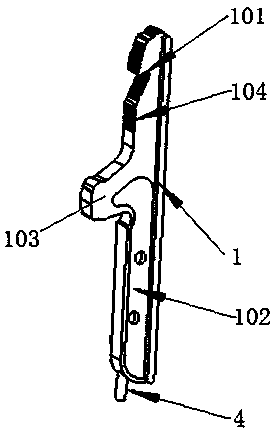

[0025] What this embodiment provides is a kind of carabiner of new structure of jacquard machine, comprises carabiner body 1, the hook body part 101 that is positioned on the carabiner body, through wire connection part 102 and girdle fitting part 103, and traditional carabiner structure The difference is that this embodiment cancels the reed structure in the traditional vertical hook, and replaces it with an auxiliary suction boss 104 formed protrudingly along one side of the vertical hook body 1, and the auxiliary suction boss 104 is transitionally connected Between the hook body part 101 of the carabiner body 1 and the lifting knife matching part 103, the auxiliary suction boss 104 is a rigid structure. An oil groove is arranged on the surface of the auxiliary suction boss 104, and the oil grooves are arranged on the surface of the auxiliary suction boss 104 in close-toothed manner to attach lubricating fluid to reduce the gap between the auxiliary suction boss 104 and the m...

Embodiment 2

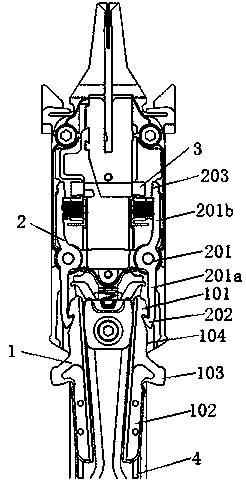

[0027]This embodiment provides a jacquard new structure jacquard hook assembly, including a number of movement channels formed by overlapping and arranging panels 5, bottom plates 6 and splints 7. In each movement channel, according to the positional relationship from top to bottom, It includes an electromagnet 3, a moving iron 2, a new vertical hook 10, a pulley combination 8 and a quick joint 9 in sequence, and the new vertical hook 10 includes a vertical hook body 1, a hook body part 101 located on the vertical hook body 1, and a through-wire connection part 102 and the lifting knife matching part 103, the upper part of the vertical hook is hooked and matched with the moving iron 2 through the hook body part 101, and the lower part of the vertical hook is connected with the common wire 4 and the quick joint 9 through the common wire connecting part 103; The new vertical hook 10 uses an auxiliary suction boss 104 to replace the tongue spring of the traditional vertical hook s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com