A laboratory-specific metal composite material surface pretreatment grinding machine and grinding method

A metal composite material and surface pretreatment technology, which is applied to machine tools, metal processing equipment, grinders, etc., which are suitable for grinding workpiece planes, can solve the problems of difficult quality assurance of metal composite materials, uneven grinding of metal material surfaces, and grinding intensity. Difficult to control and other problems, to achieve the effect of benefiting scientific research, polishing evenly, and ensuring diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

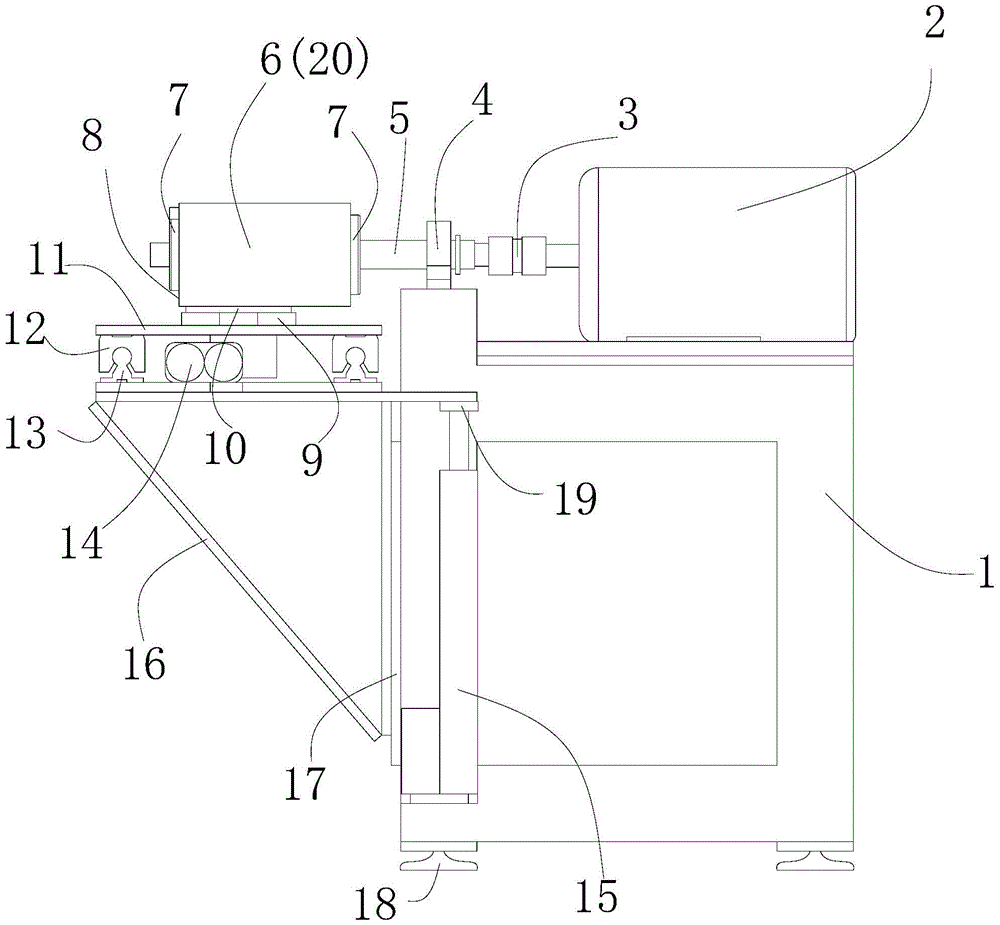

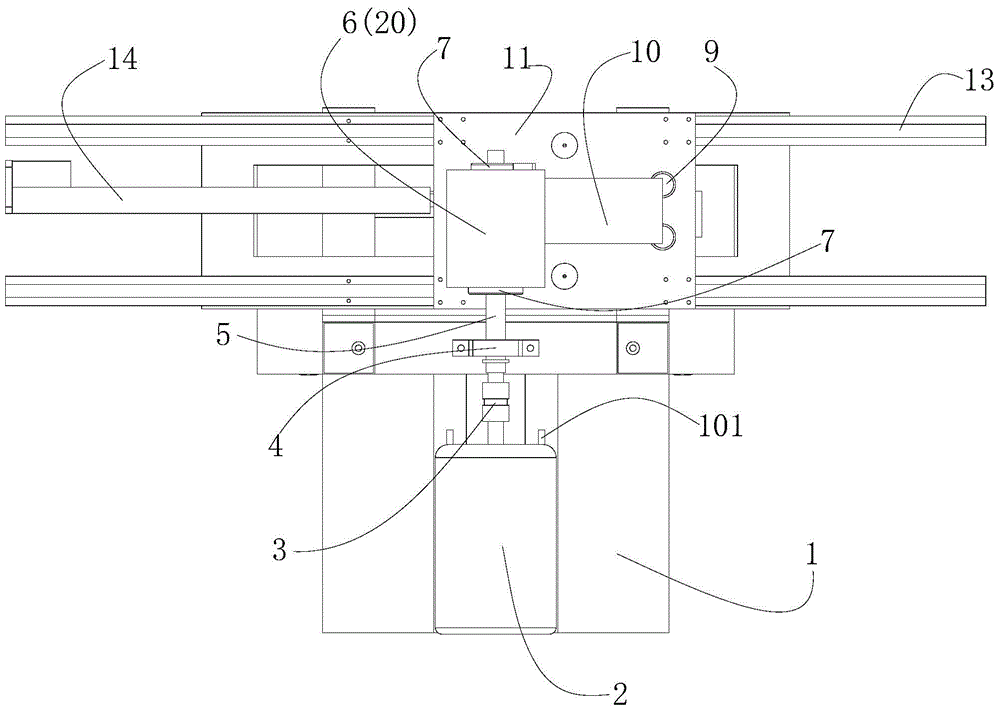

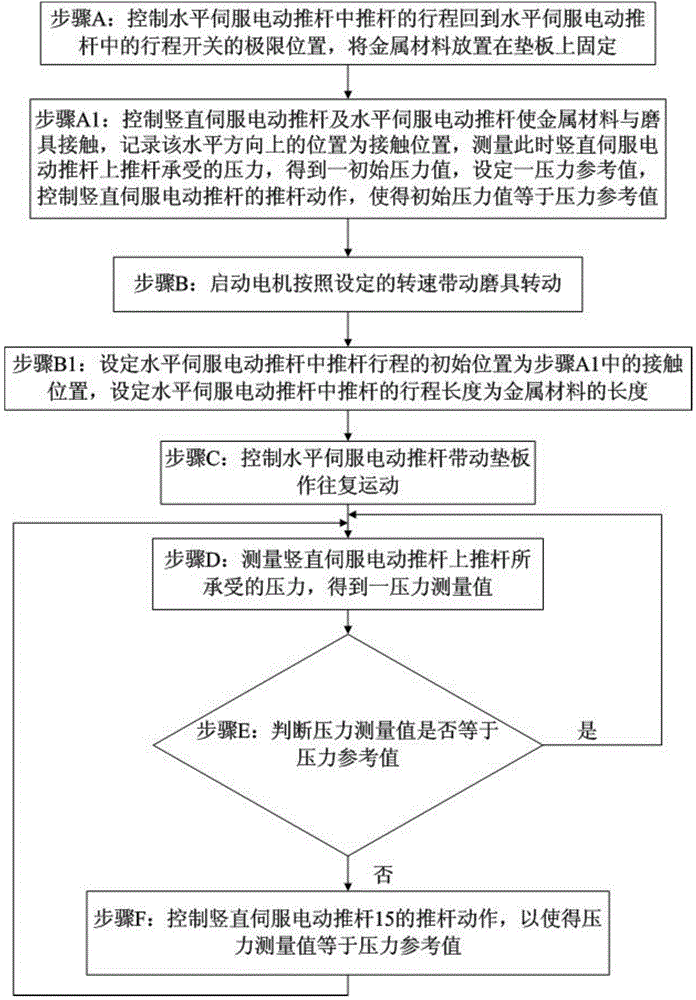

[0026] Such as Figure 1-2 As shown, a kind of laboratory-specific metal composite material surface pretreatment grinding machine of the present invention includes frame 1, motor 2, grinding tool 6 and support 16, and the upper surface of frame 1 offers a chute 101, and motor 2 The base of the motor is fixedly installed on the chute 101, so the installation position of the motor 2 on the chute 101 can be adjusted according to the needs, which is more convenient and flexible to use. The output shaft of the motor 2 is connected with a main shaft 5 through a coupling 3, and the main shaft 5 Installed on the frame 1 through the bearing 4 with a seat, the sleeve 20 is set on the main shaft 5, the two ends of the sleeve 20 are installed on the main shaft through the flange 7 and set on the main shaft 5, and the grinding tool 6 is set on the sleeve 20 Outside, thus can change different grinding tools 6 on sleeve 20 according to needs, can put the grinding tools of different sizes acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com