A cloth pilling tester

A tester and cloth technology, applied in the field of cloth pilling tester, can solve the problems of waste of manpower, easy displacement of cloth, and difficulty in maintaining consistent grinding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

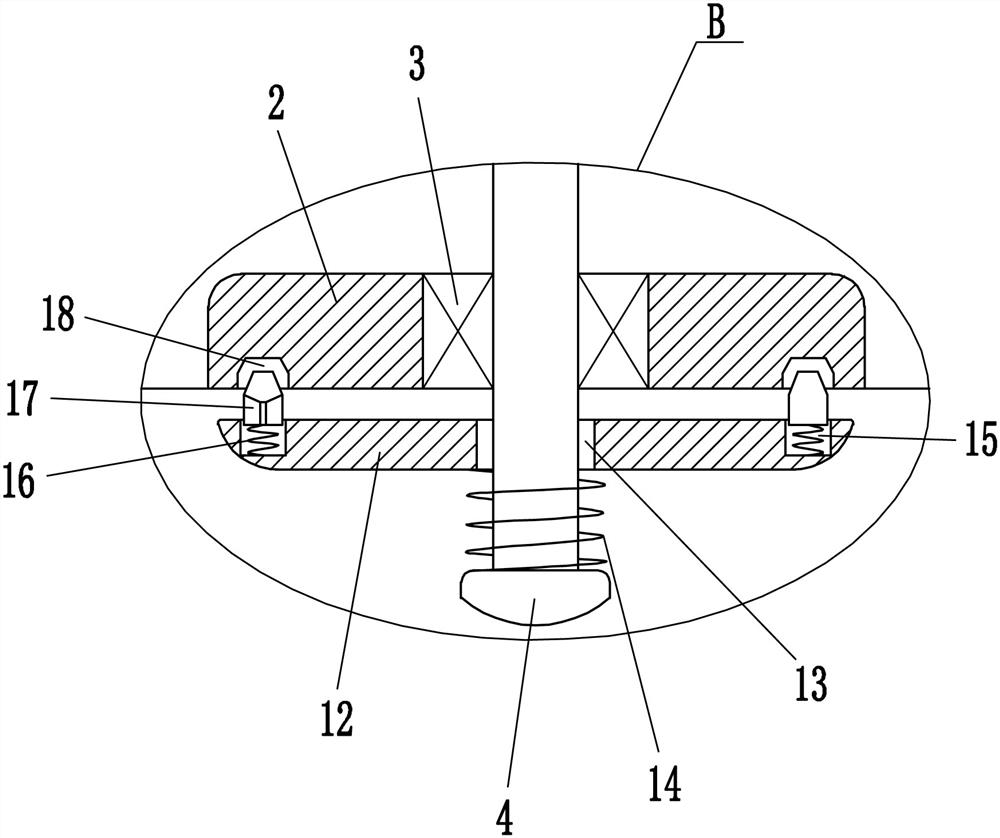

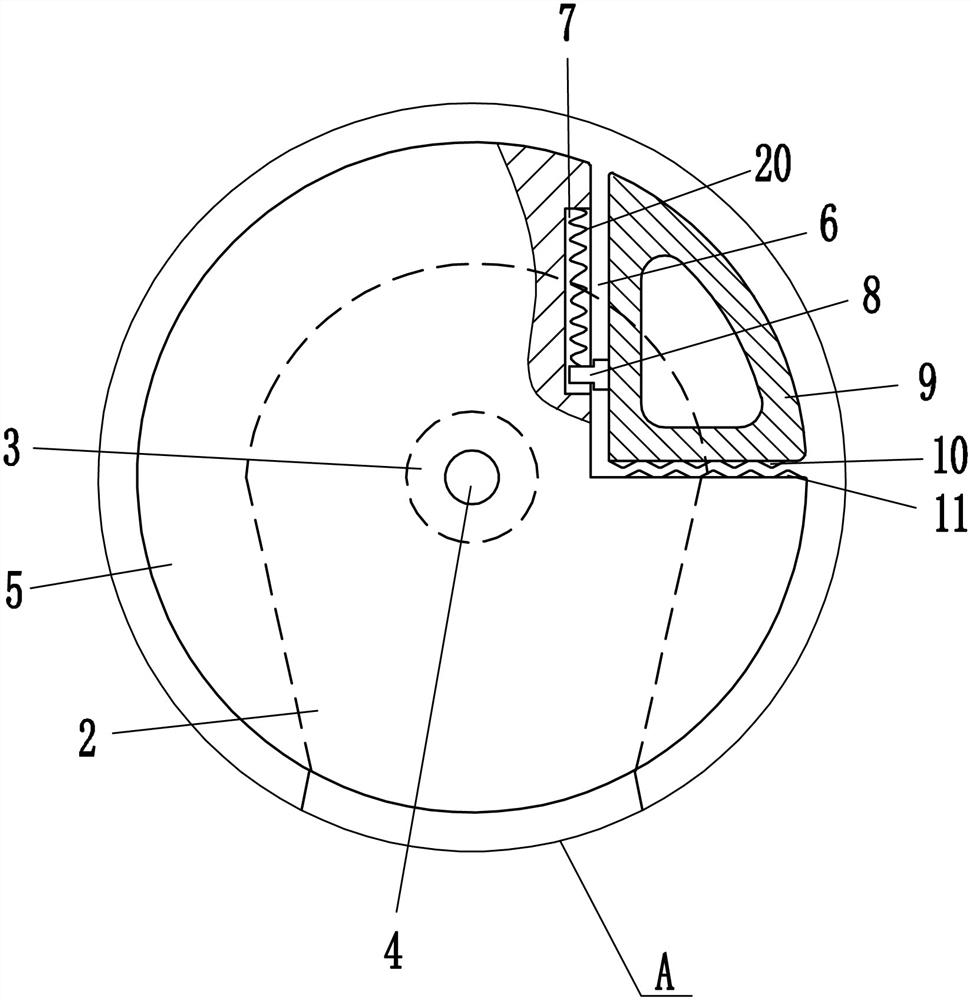

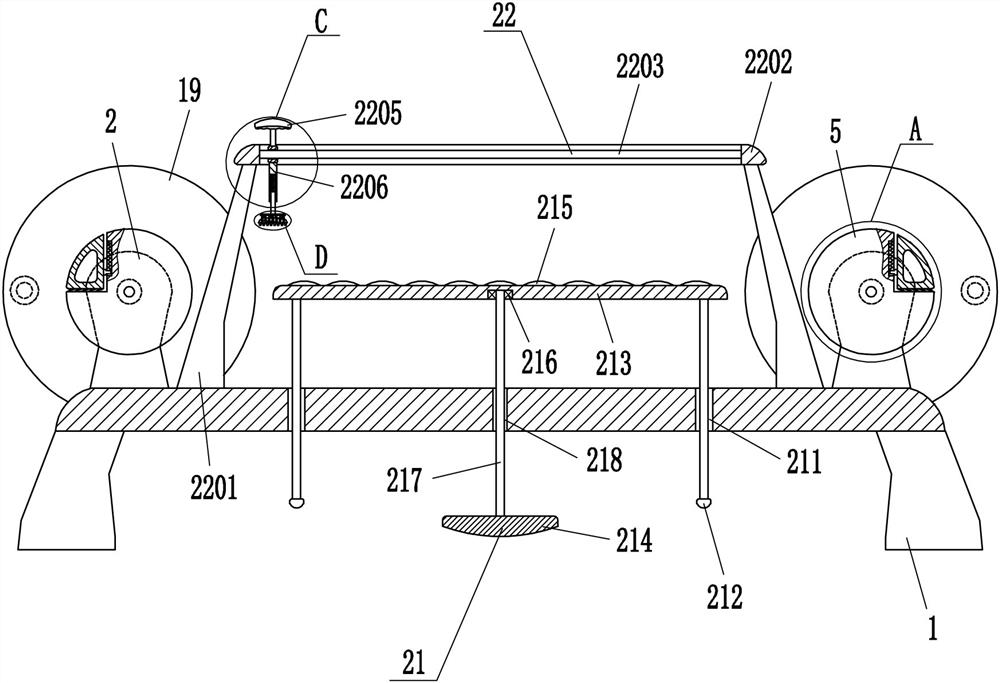

[0022] A fabric pilling tester such as Figure 1-6As shown, it includes a base 1, a mounting plate 2, a first bearing seat 3, a rotating shaft 4, a roller 5, a slider 8, a pressure plate 9, an upper tooth block 10, a lower tooth block 11, a disc 12, a first spring 14, The second spring 16, the ratchet 17, the rotating disk 19 and the third spring 20, the left and right sides of the top of the base 1 are symmetrically fixed with two mounting plates 2, and the mounting plate 2 tops on the left and right sides are embedded with the first A bearing seat 3, a T-shaped rotating shaft 4 is fixedly connected between the two first bearing seats 3 on the left side, and a T-shaped rotating shaft is also fixedly connected between the two first bearing seats 3 on the right side 4. The rollers 5 are fixedly fitted on the two rotating shafts 4, the left upper part of the left roller 5 and the right upper part of the right roller 5 are provided with installation grooves 6, and the right and r...

Embodiment 2

[0024] A fabric pilling tester such as Figure 1-6 As shown, it includes a base 1, a mounting plate 2, a first bearing seat 3, a rotating shaft 4, a roller 5, a slider 8, a pressure plate 9, an upper tooth block 10, a lower tooth block 11, a disc 12, a first spring 14, The second spring 16, the ratchet 17, the rotating disk 19 and the third spring 20, the left and right sides of the top of the base 1 are symmetrically fixed with two mounting plates 2, and the mounting plate 2 tops on the left and right sides are embedded with the first A bearing seat 3, a T-shaped rotating shaft 4 is fixedly connected between the two first bearing seats 3 on the left side, and a T-shaped rotating shaft is also fixedly connected between the two first bearing seats 3 on the right side 4. The rollers 5 are fixedly fitted on the two rotating shafts 4, the left upper part of the left roller 5 and the right upper part of the right roller 5 are provided with installation grooves 6, and the right and ...

Embodiment 3

[0027] A fabric pilling tester such as Figure 1-6 As shown, it includes a base 1, a mounting plate 2, a first bearing seat 3, a rotating shaft 4, a roller 5, a slider 8, a pressure plate 9, an upper tooth block 10, a lower tooth block 11, a disc 12, a first spring 14, The second spring 16, the ratchet 17, the rotating disk 19 and the third spring 20, the left and right sides of the top of the base 1 are symmetrically fixed with two mounting plates 2, and the mounting plate 2 tops on the left and right sides are embedded with the first A bearing seat 3, a T-shaped rotating shaft 4 is fixedly connected between the two first bearing seats 3 on the left side, and a T-shaped rotating shaft is also fixedly connected between the two first bearing seats 3 on the right side 4. The rollers 5 are fixedly fitted on the two rotating shafts 4, the left upper part of the left roller 5 and the right upper part of the right roller 5 are provided with installation grooves 6, and the right and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com