A kind of cylindrical grinding process of wafer dicing blade

A technology for cutting blades and wafers, which is applied in the direction of grinding workpiece holders, manufacturing tools, grinding drive devices, etc., can solve problems such as edge fracture and edge stress damage of annular blades, and achieve improved sharpness, accuracy, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

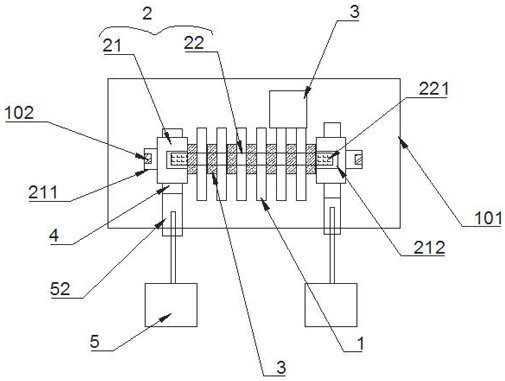

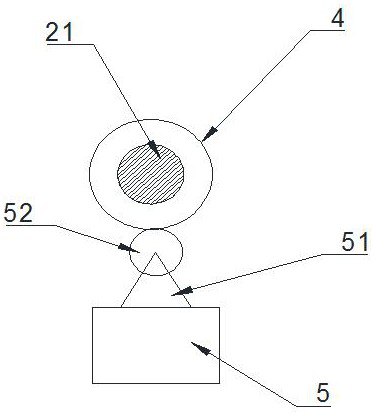

[0022] like Figure 1 to Figure 2 A specific embodiment of the present invention specifically includes the following steps:

[0023] S1. Install several annular blades 1 concentrically on the grinding tool 2, and a protective block 3 is separated between two adjacent annular blades 1;

[0024] S2, rotating and installing the grinding tool 2 on the machine tool 101, during installation, the machining center line of the machine tool 101 coincides with the center line of the grinding tool 2;

[0025] S3, the rotating grinding tool 2 is approached to the rotating emery wheel 6, the rotation direction of the grinding wheel 6 is opposite to that of the grinding tool 2, and the grinding wheel 6 grinds the edge of the annular blade 1;

[0026] In the step S3, an industrial camera is used to find defects on the end face of the annular blade 1 at any time, and the feed rate and grinding position of the grinding wheel 6 are controlled according to the defects of the annular blade 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com