Patents

Literature

35results about How to "Even sanding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight environment-friendly type pumice for ceramic ware and its production method and usage

InactiveCN1762910AStrong wear resistanceReduce cleanup workloadDry-cleaning apparatus for textilesCeramicwareSewage treatmentMetallurgy

The present invention relates to light environment friendly ceramic pumice and its manufacture and usage. The ceramic pumice is used widely in fading, fluffing, softening, ageing and other processing of clothing, fabric, cloth, etc. The ceramic pumice of the present invention contains no harmful matter, and results in simplified fabric cleaning post-treatment and no environmental pollution. Treating fabric with the ceramic pumice makes fabric soft, good look, personalized, permeable and comfortable.

Owner:何晓洪

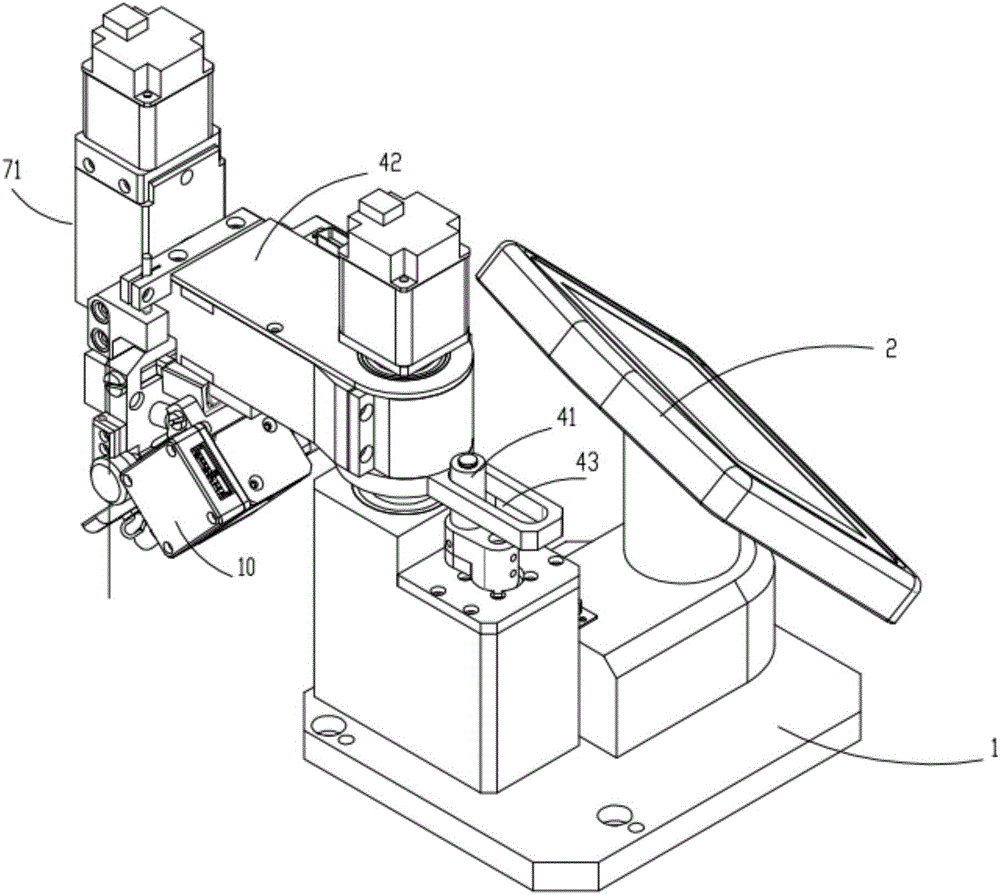

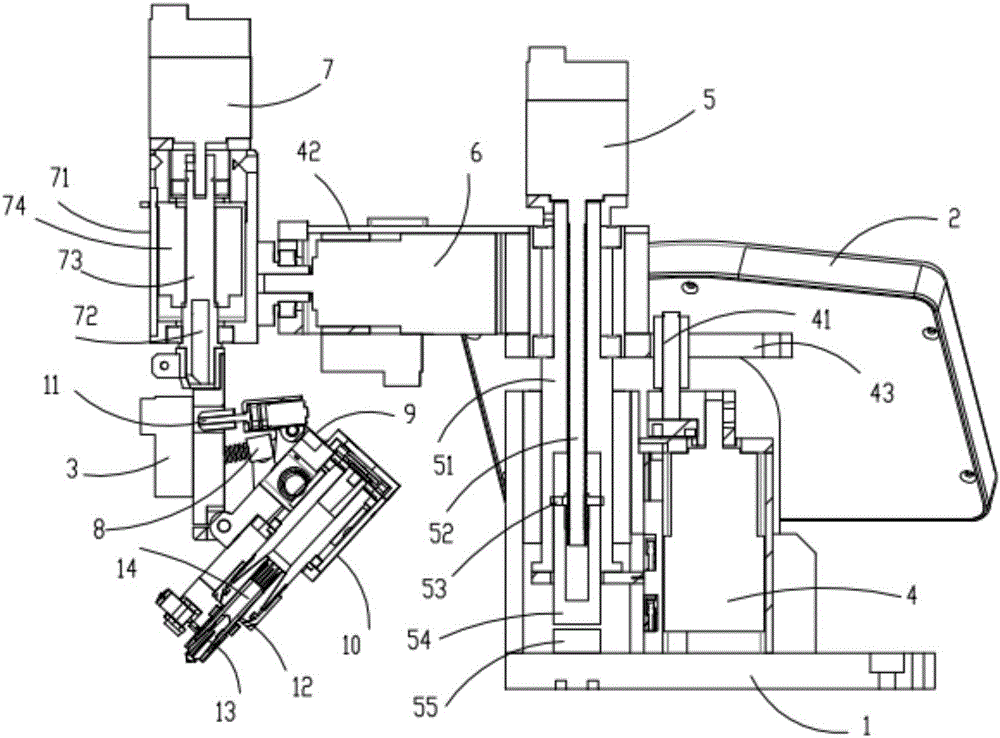

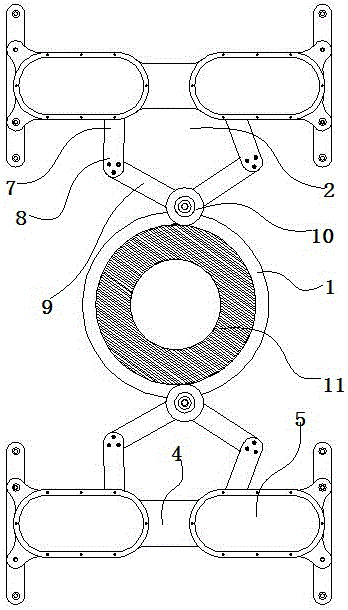

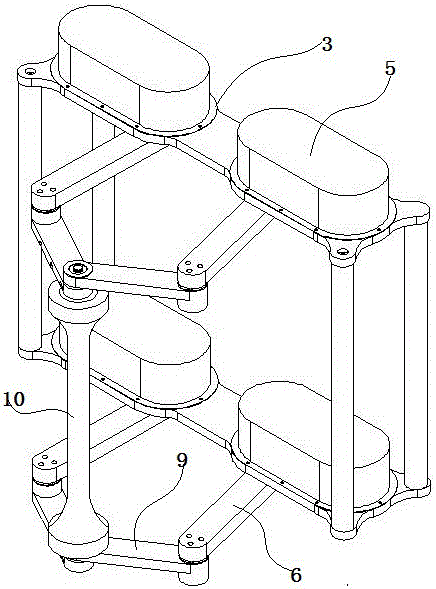

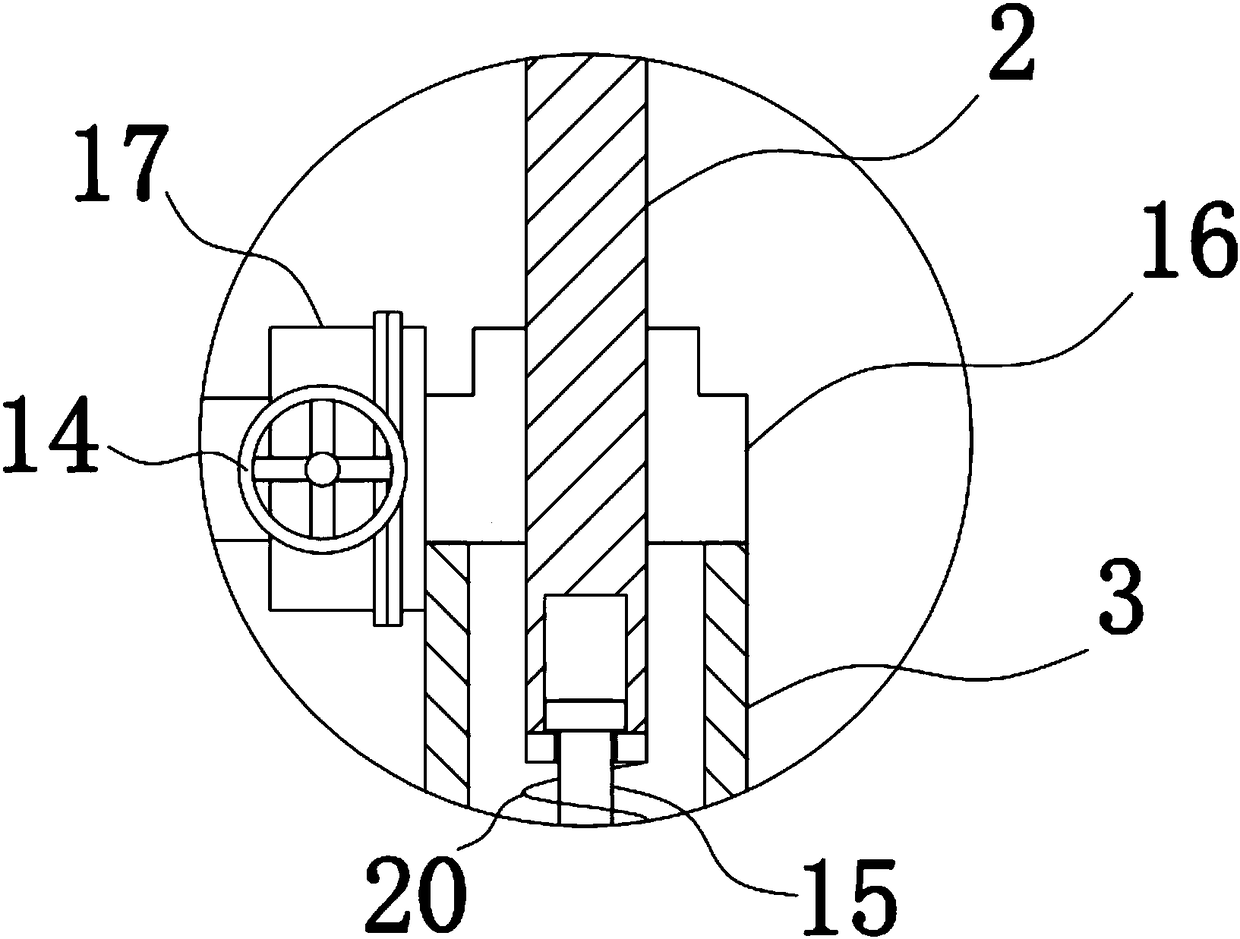

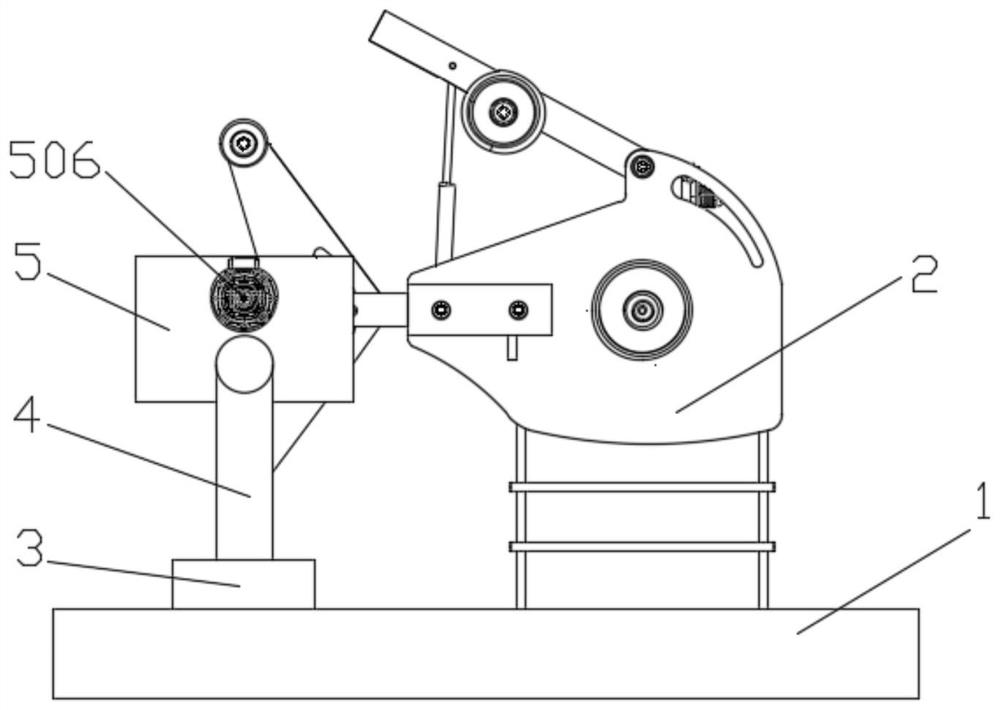

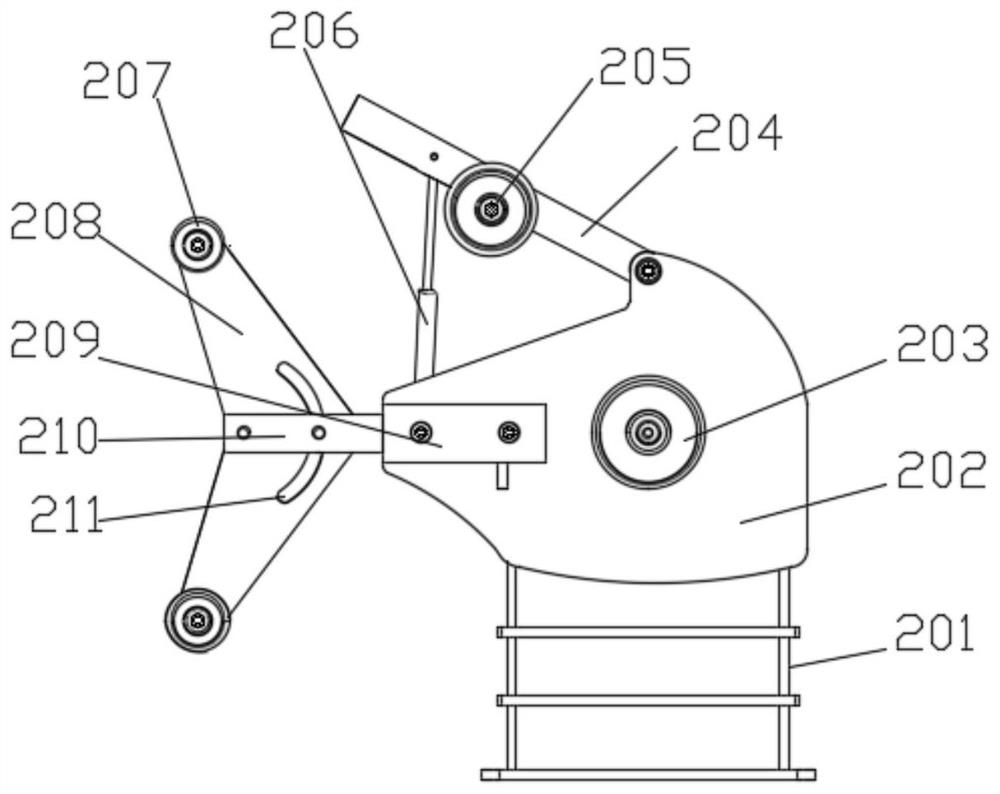

Automatic polisher capable of rotating diamonds at all-dimensional angles

The invention discloses an automatic polisher capable of rotating diamonds at all-dimensional angles. The automatic polisher comprises a base, a control center arranged on the base, a motor driver connected to the control center, a swing control motor connected to the motor driver, a lift control motor, a grinding head automatic lift control motor, a direction control motor, a grinding head dip angle control motor, a worm drive motor, a swing arm rod, a lift arm connected to the swing arm rod, a swing control rod in pin connection with the swing arm rod, a direction adjusting arm and a grinding head; the grinding head is provided with a diamond angle worm, the motor driver connected to the control center drives the motors to correspondingly act on the swing arm rod, the lift arm, the direction adjusting arm and the diamond angle worm through setting of the control center, and therefore the grinding head clamping the diamonds can rotate at all-dimensional angles, and the uniform grinding effect can be realized.

Owner:周生生钻石(广东)有限公司

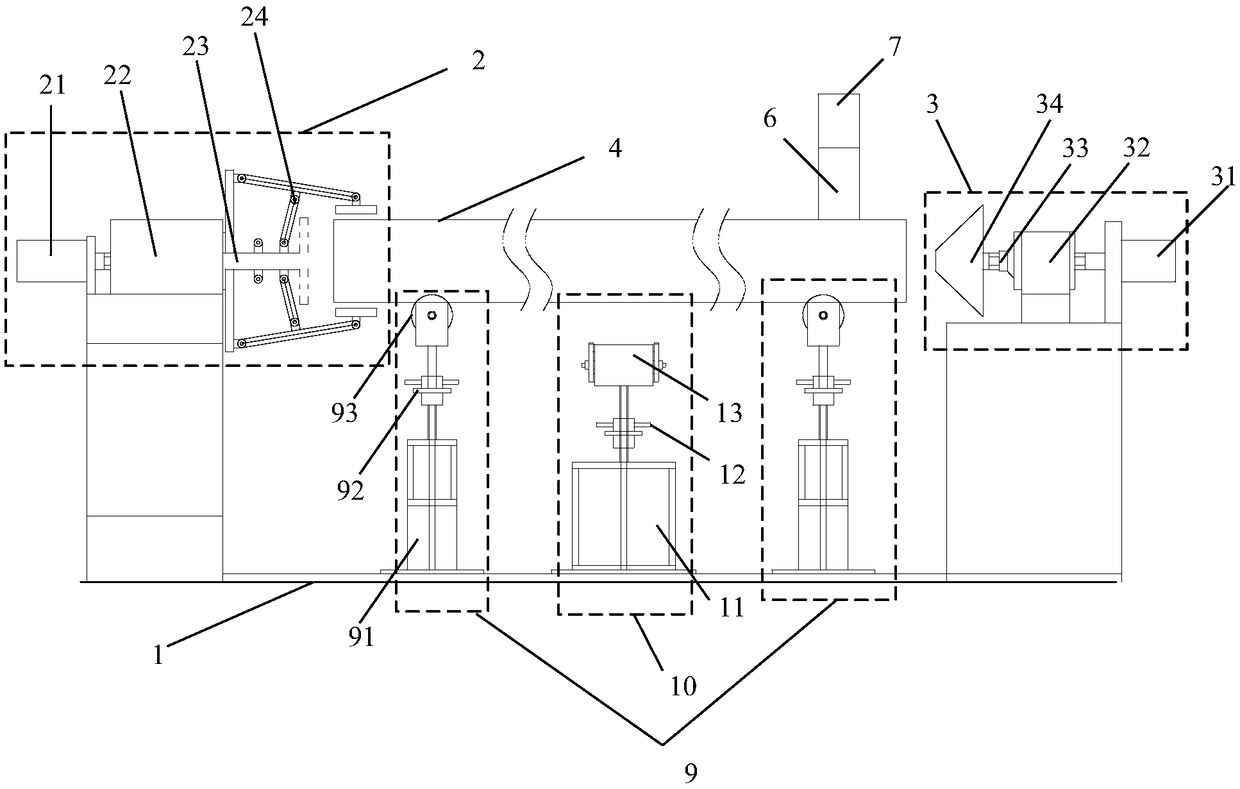

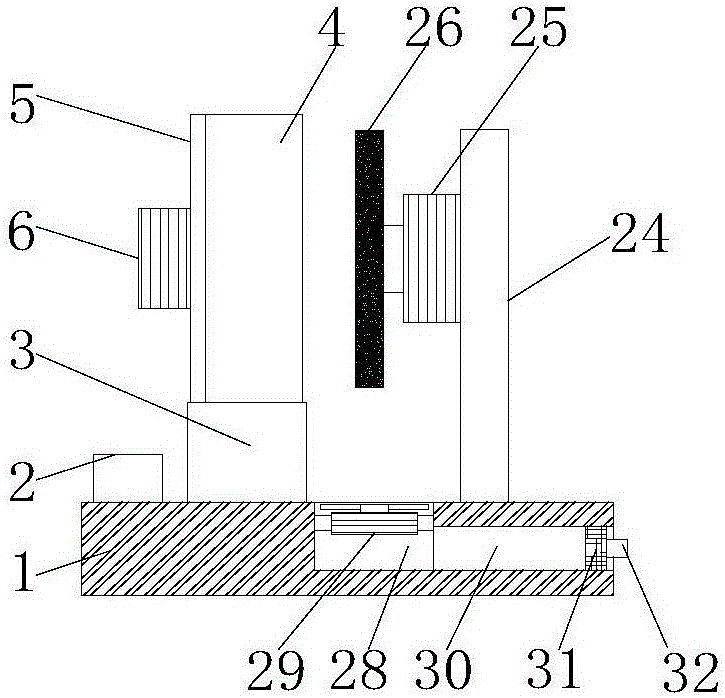

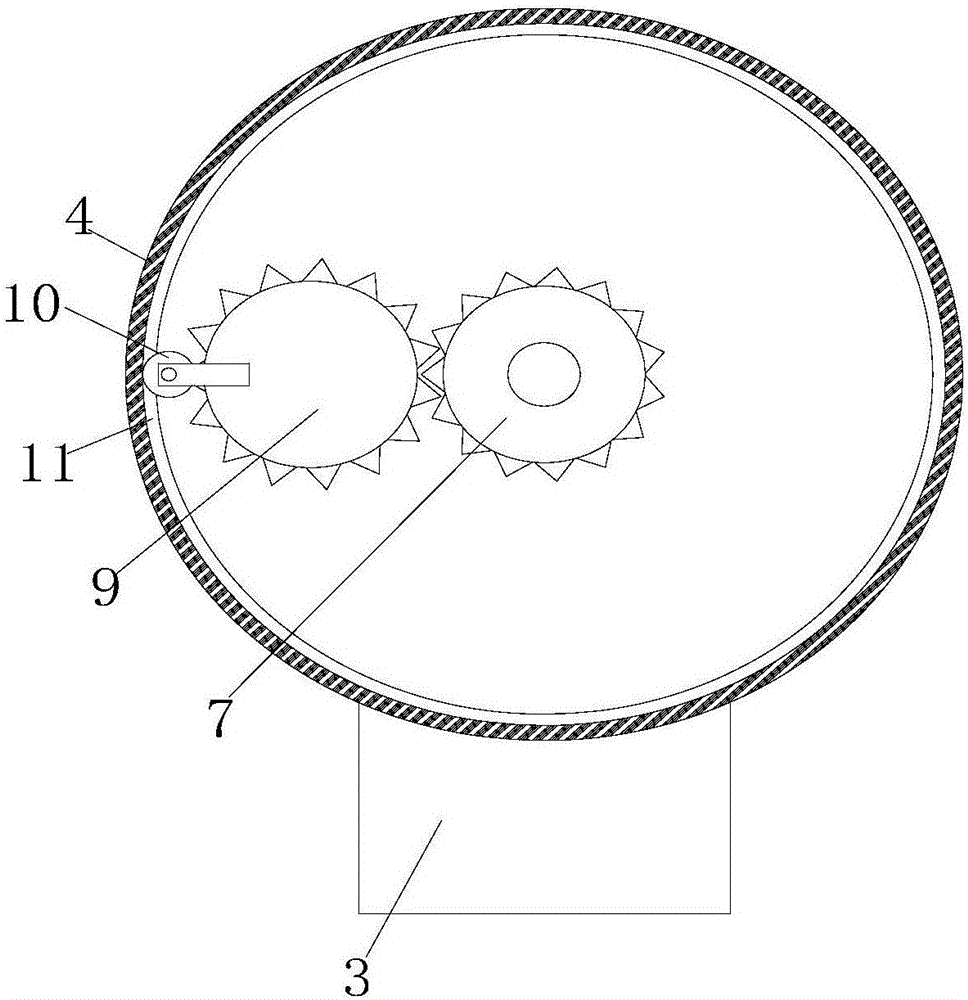

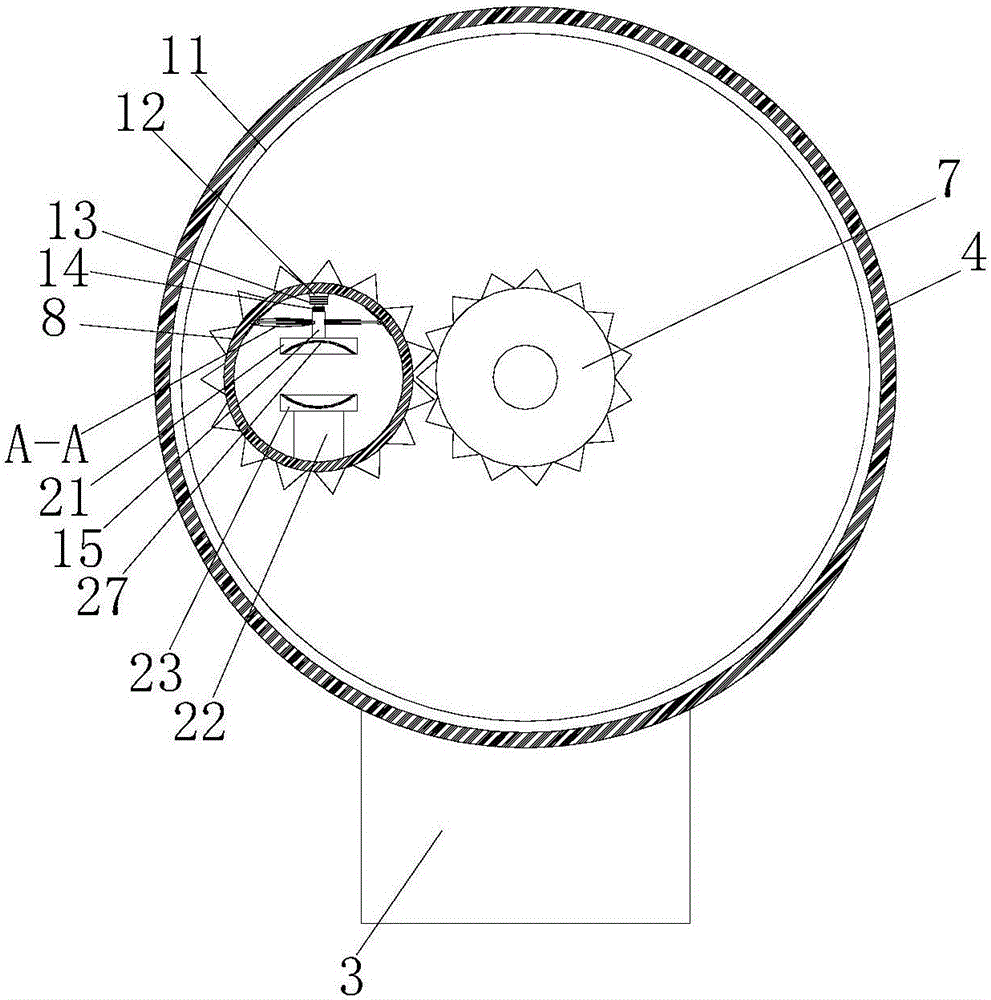

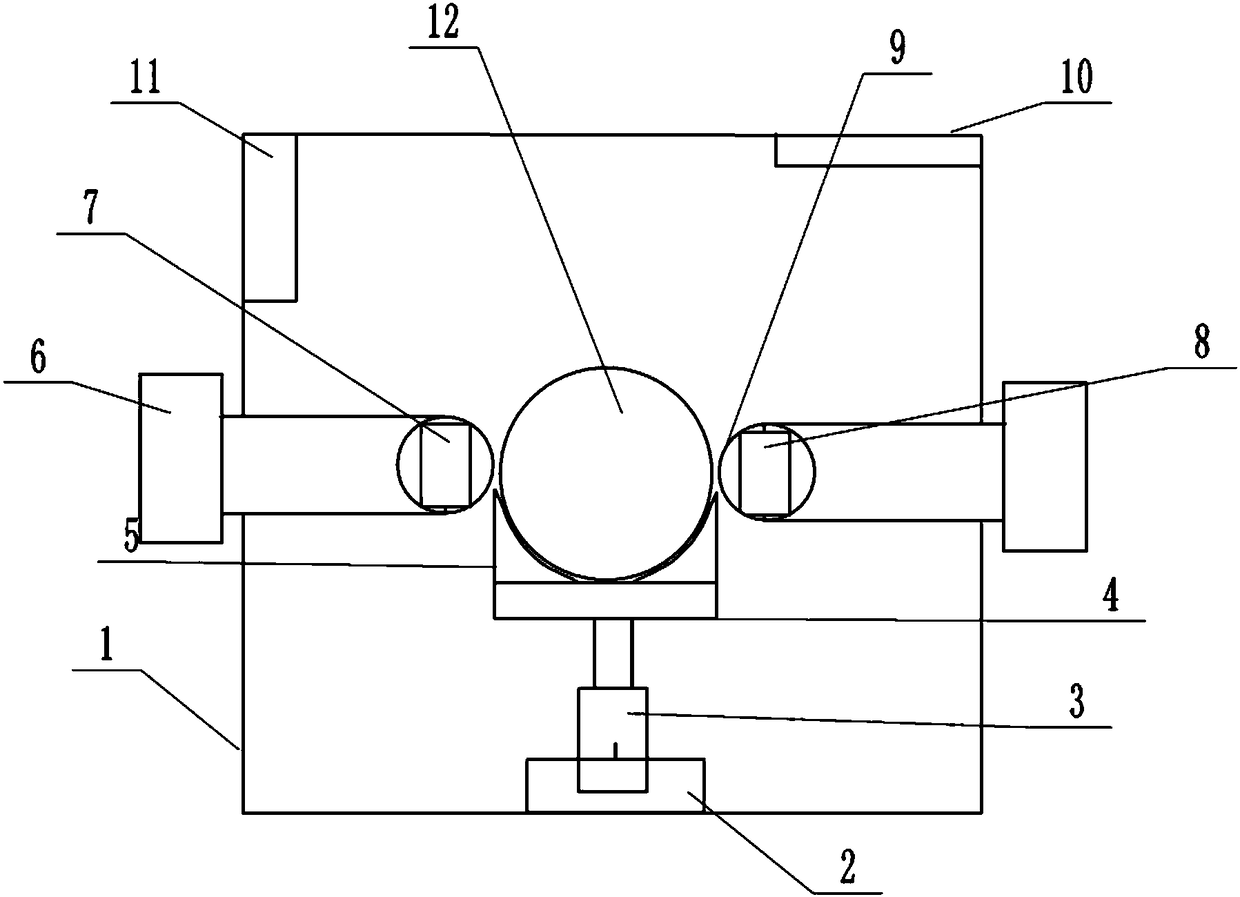

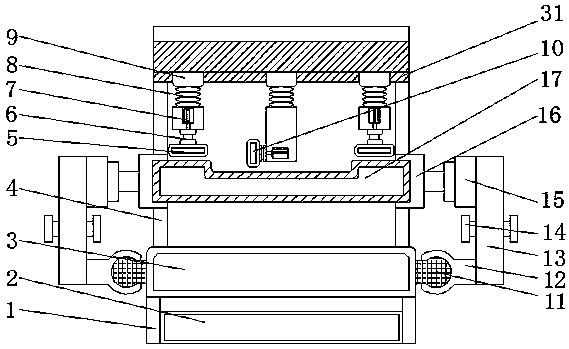

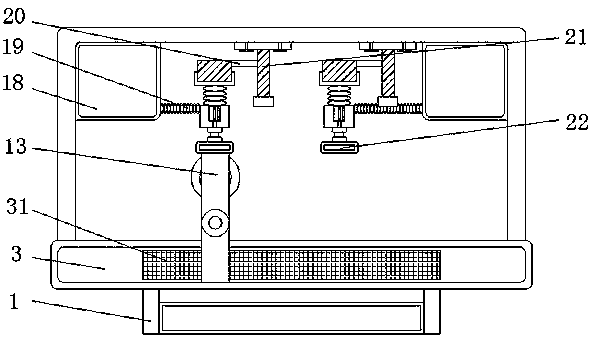

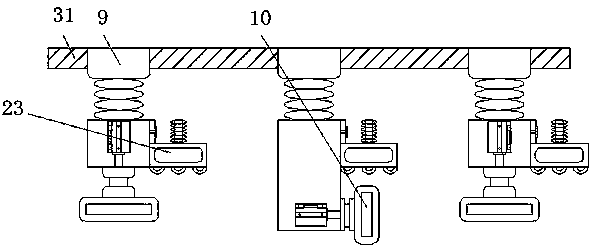

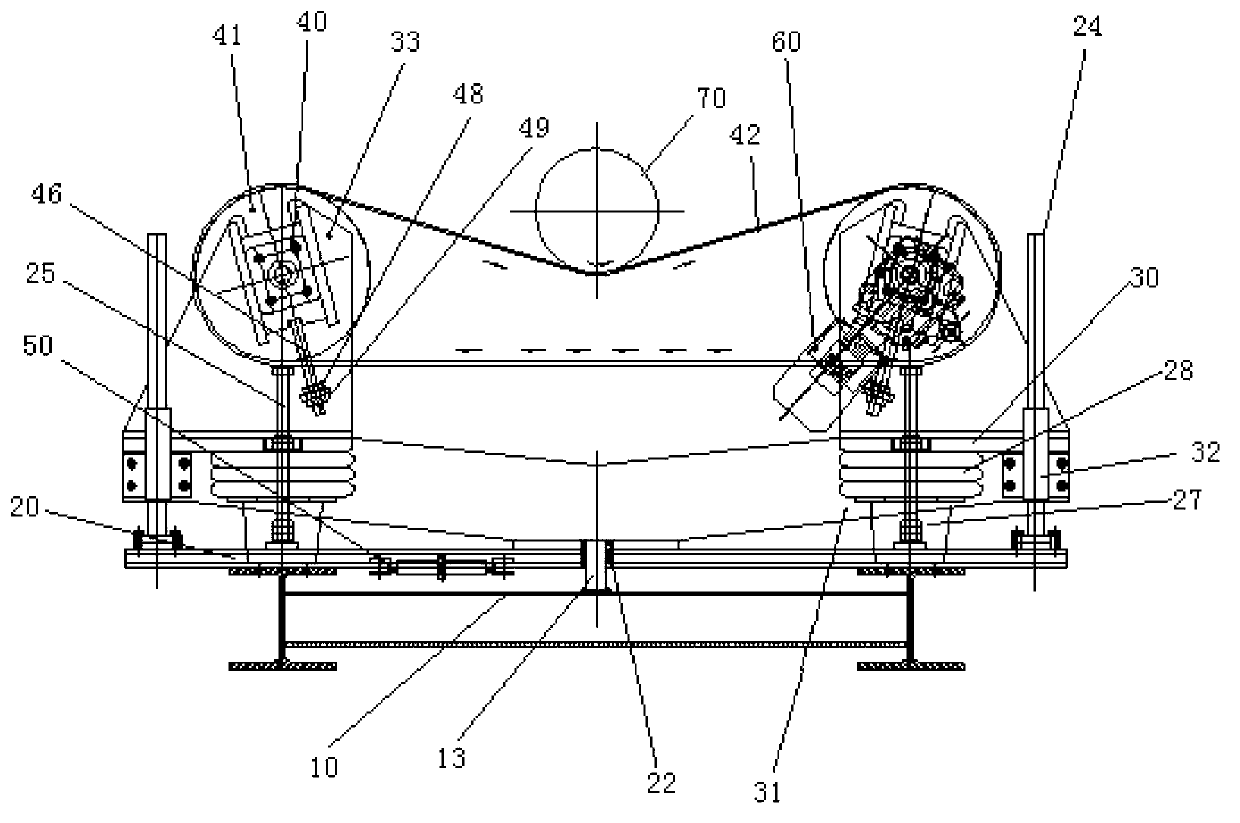

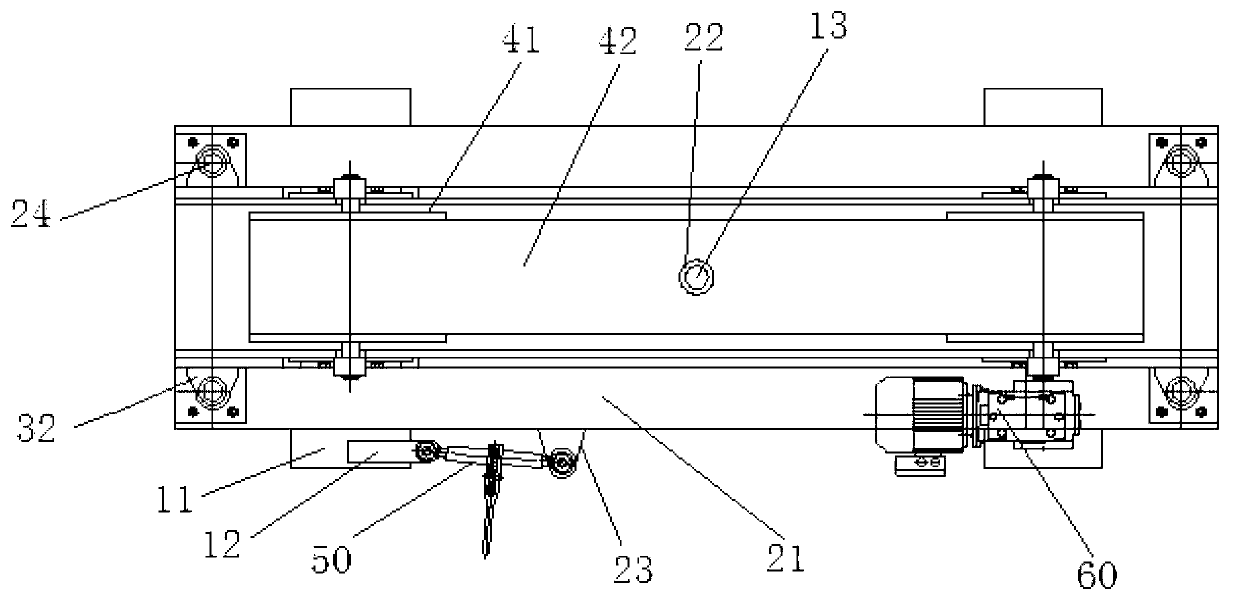

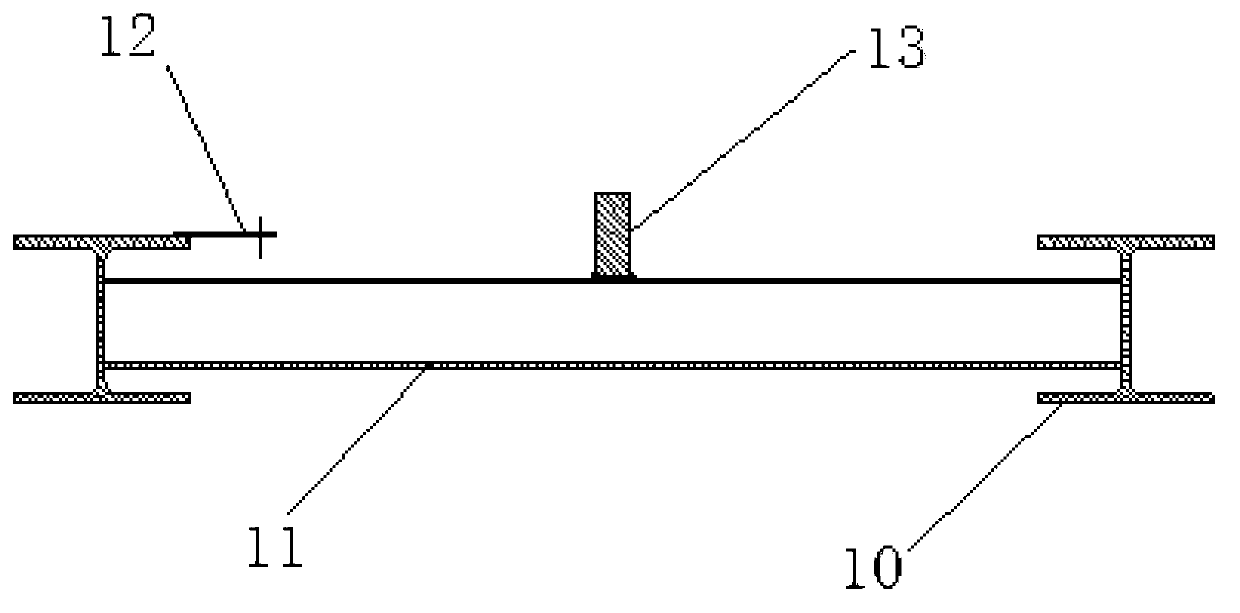

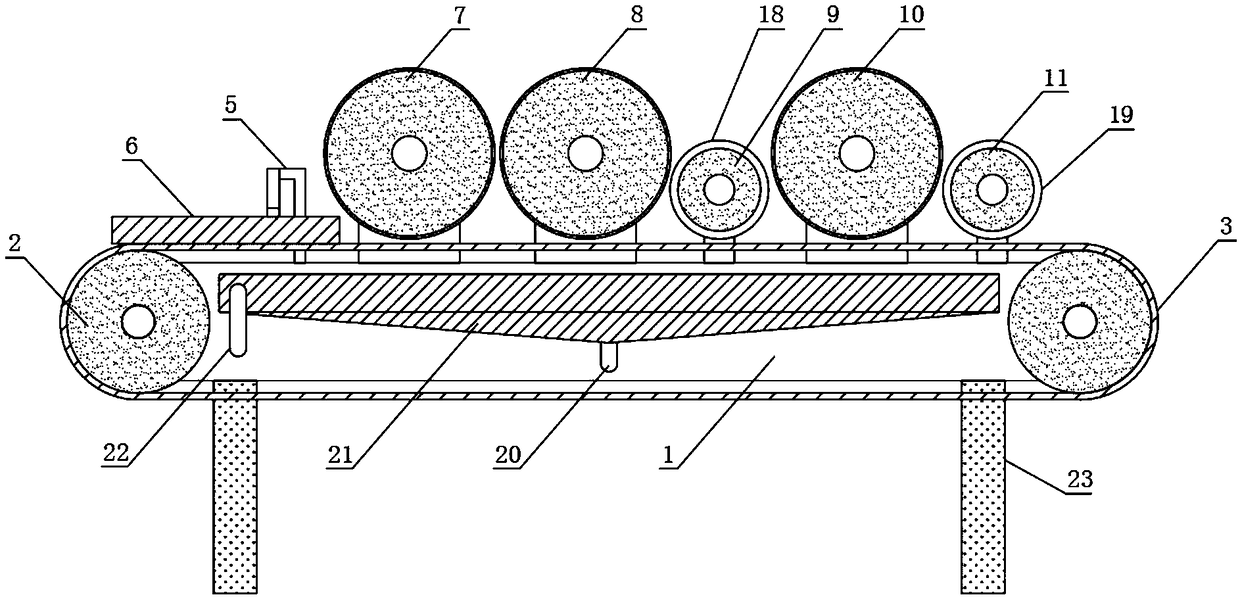

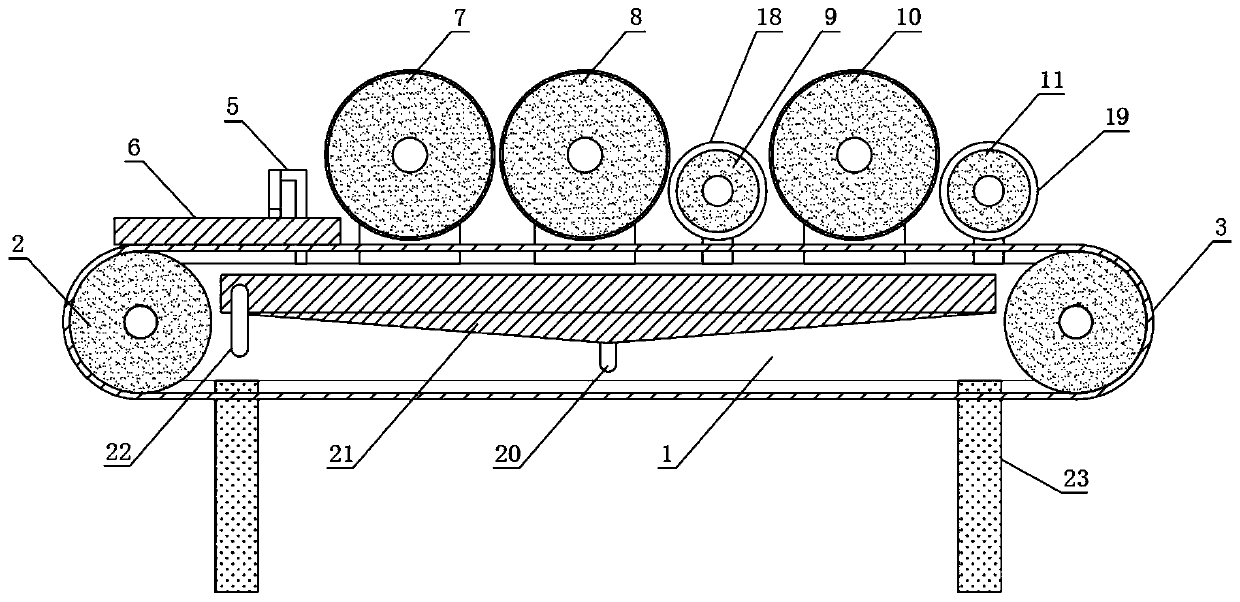

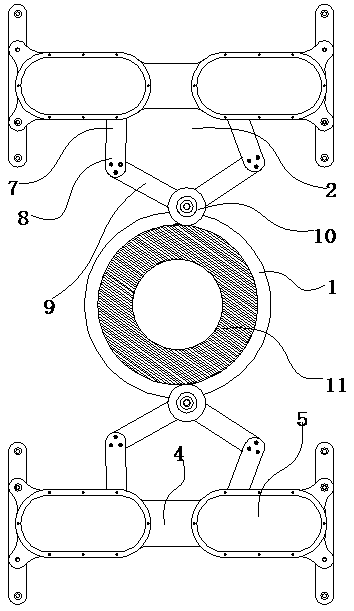

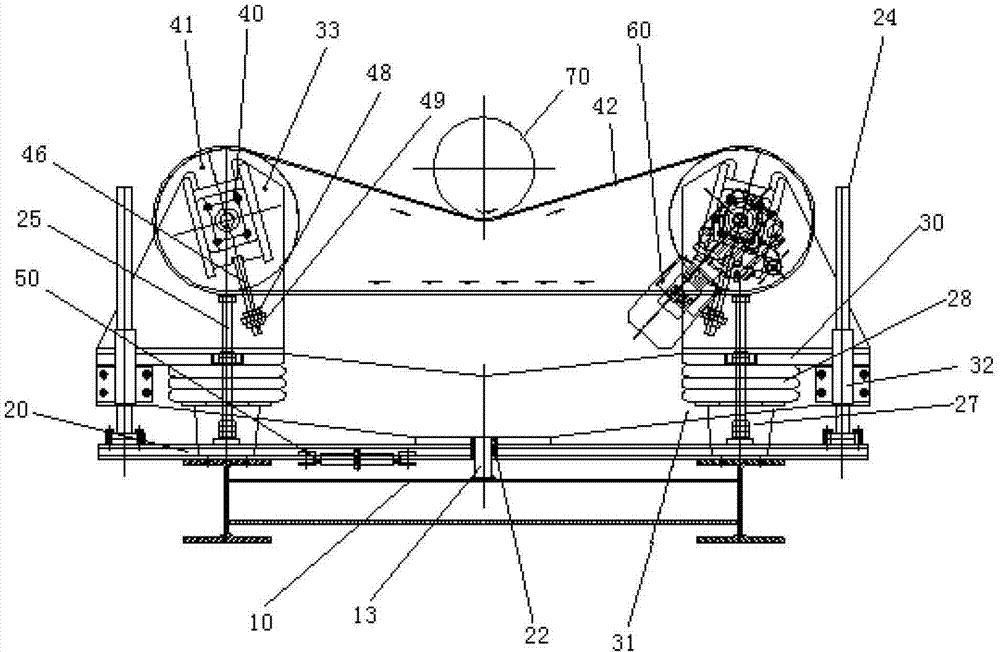

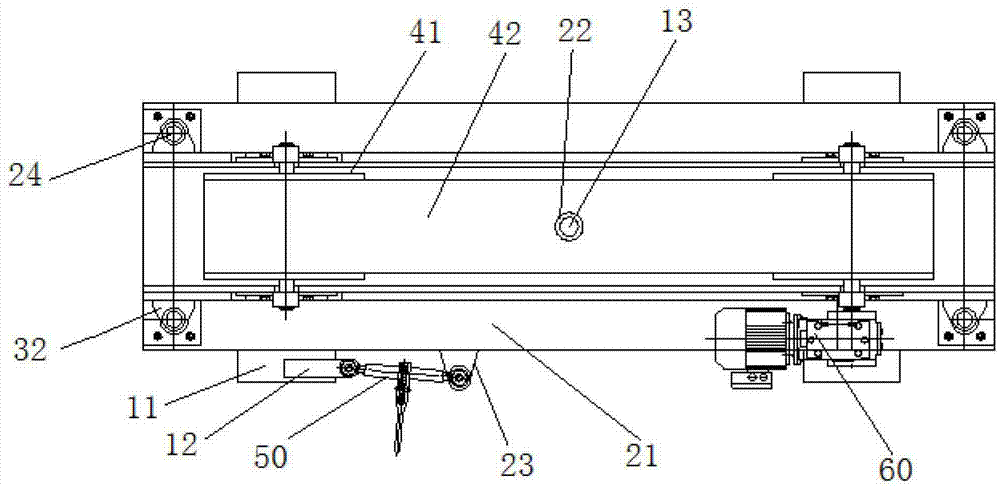

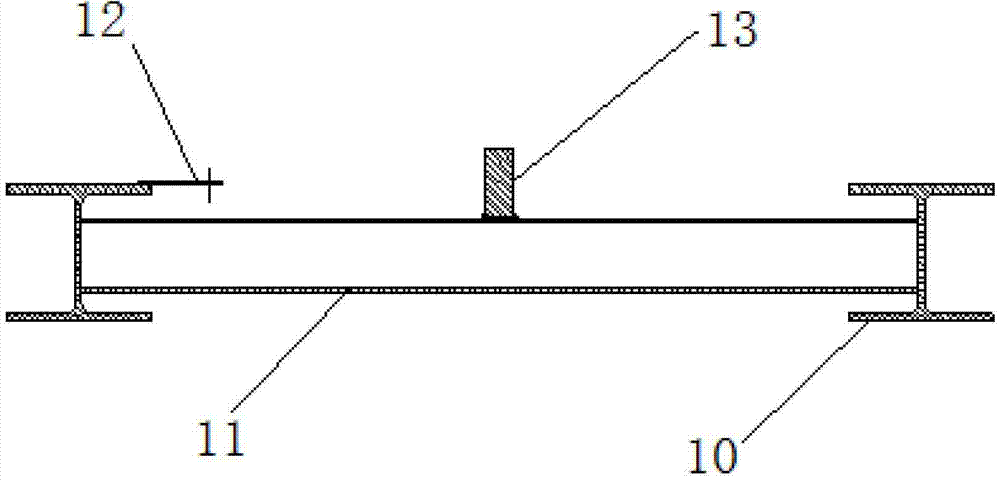

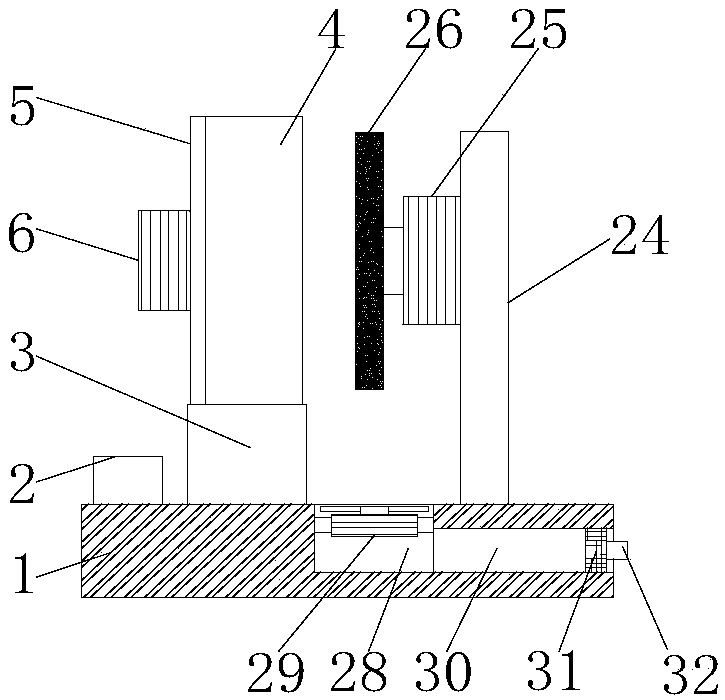

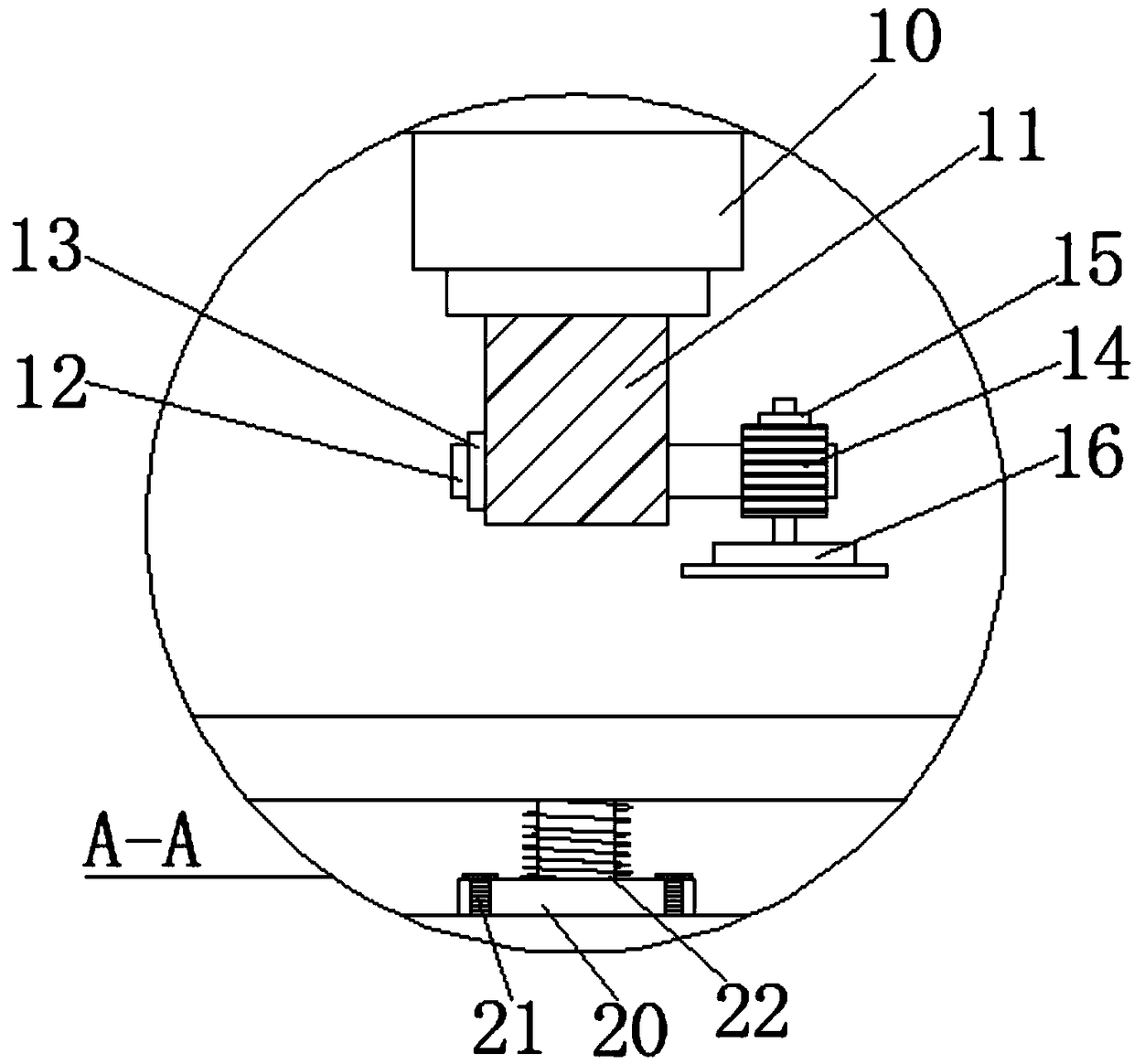

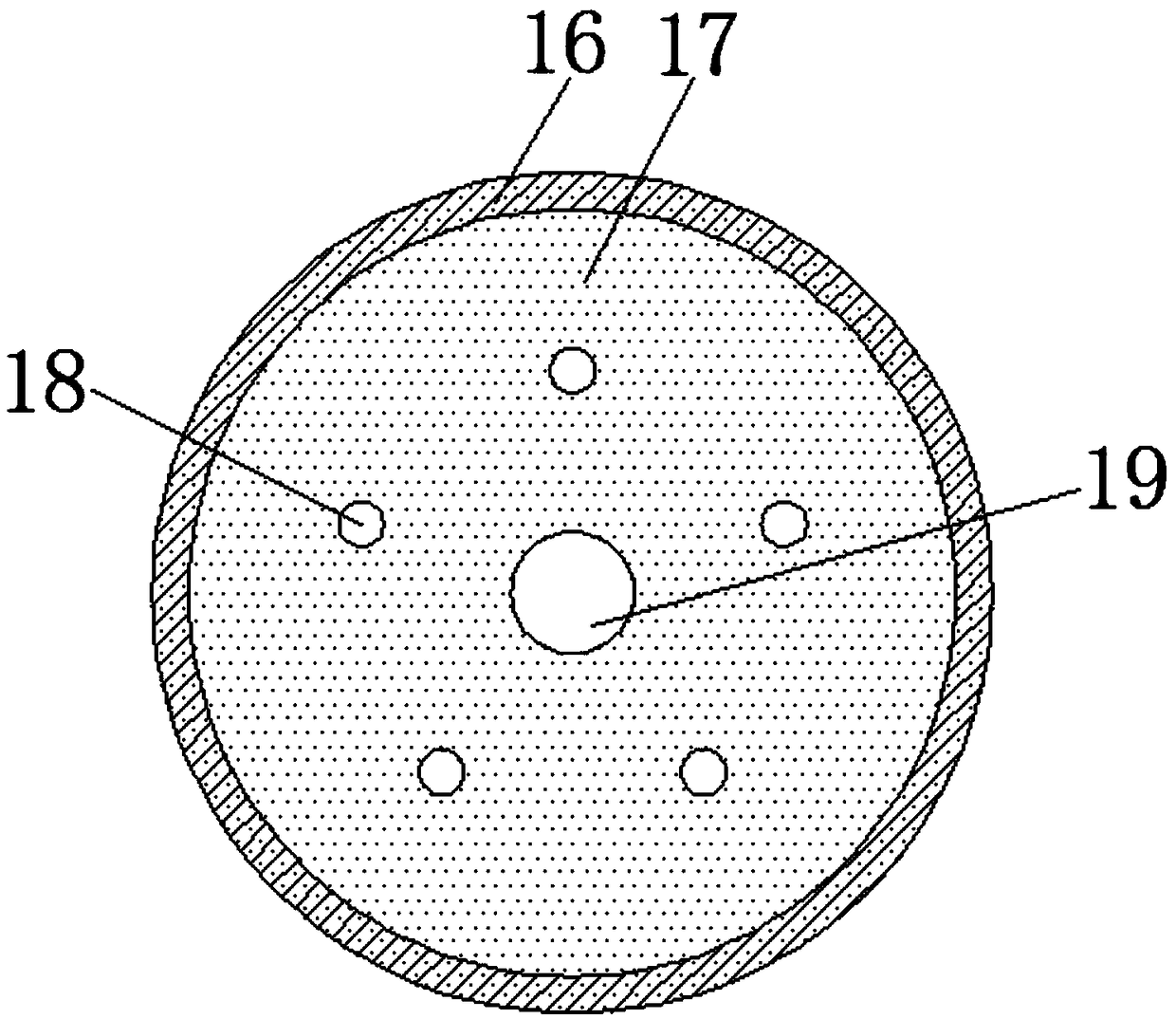

Abrasive belt grinding machine

InactiveCN108747737AEven sanding effectShorten the timeGrinding drivesBelt grinding machinesContact pressureEngineering

The invention discloses an abrasive belt grinding machine, relates to the field of workpiece polishing and aims to adjust the pressure between an abrasive belt and a to-be-ground workpiece during thepolishing process so as to enable grinding to be uniform, save the abrasive belt and improve the polishing efficiency. According to the main technical scheme, the abrasive belt grinding machine comprises a grinding machine body as well as a first clamping part and a second clamping part fixed on the grinding machine body and arranged oppositely, and further comprises a polishing part and a grinding head support mechanism; the first clamping part and the second clamping part are fixing the two ends of the to-be-ground workpiece separately; the first clamping part is connected with a rotary driving part; the rotary driving part is used for driving the first clamping part to drive the to-be-ground workpiece to rotate; the polishing part comprises the abrasive belt and a grinding head; the abrasive belt is wound on the outer side of the grinding head and is used for being driven by rotation of the grinding head to move relative to the to-be-ground workpiece; one end of the grinding head support mechanism is fixed on the grinding machine body; the other end of the grinding head support mechanism is used for supporting the grinding head; and the grinding head support mechanism is used for changing the contact pressure between the abrasive belt and the to-be-ground workpiece. The abrasive belt grinding machine is mainly used for polishing the workpiece.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

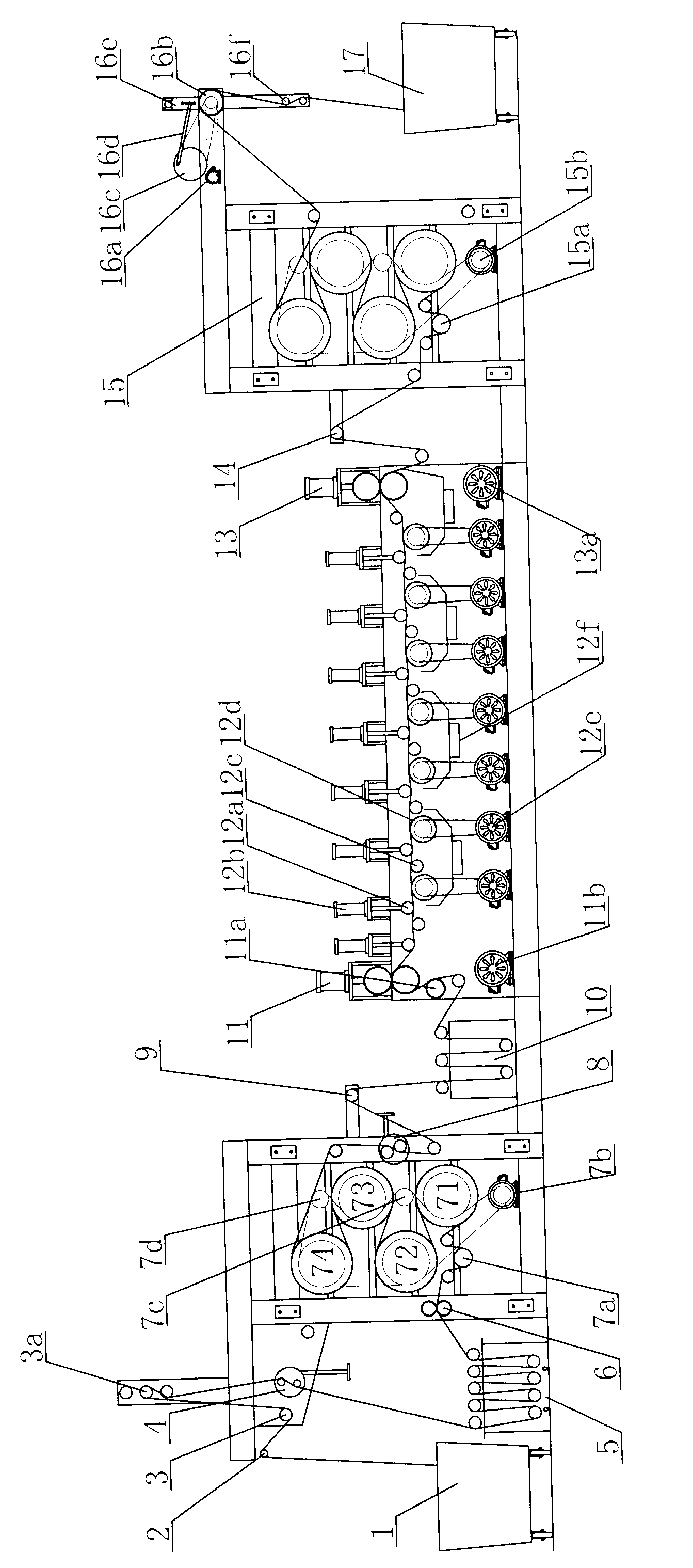

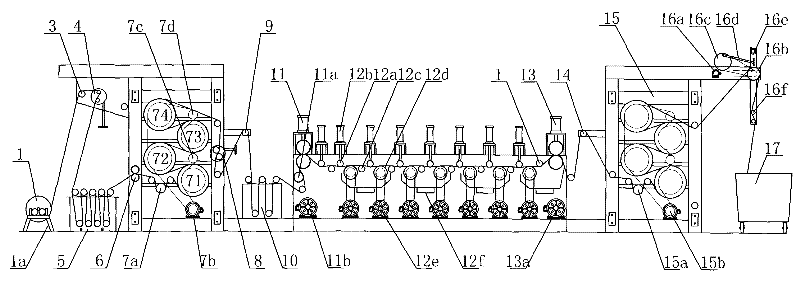

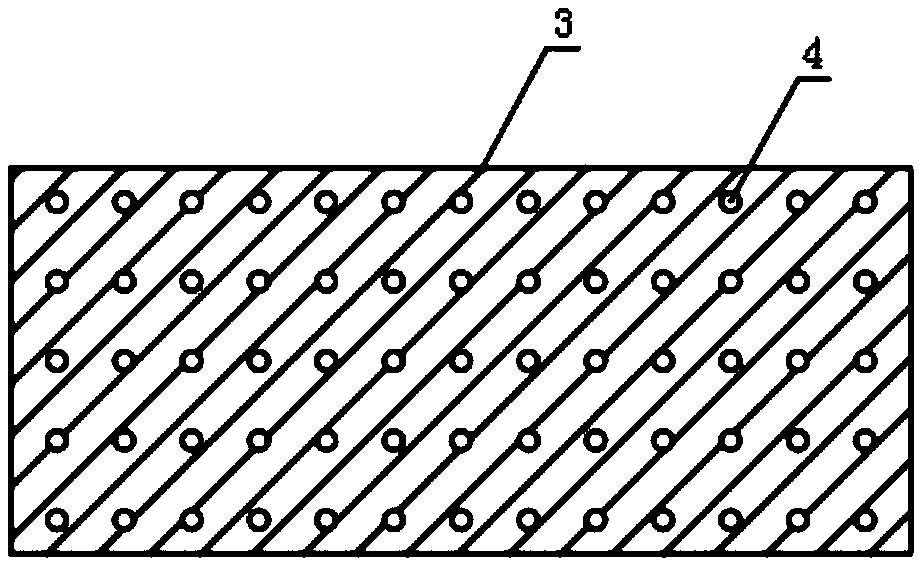

Prewetting and drying sueding machine

InactiveCN102936822AConsistent tensionTightness can be adjustedLiquid/gas/vapor removal by squeezing rollersStretchingEngineeringMechanical engineering

The invention discloses a prewetting and drying sueding machine, and belongs to the field of textile machinery technology. The prewetting and drying sueding machine comprises a machine frame, a sueding area, a cloth feeding mechanism and a cloth discharge mechanism, wherein the sueding area is provided with a plurality of groups of sueding rolls; a dust suction hood is arranged below the sueding rolls; and a spray device is arranged above the sueding rolls; padders are arranged before and behind the sueding area respectively; a centering limited rod and a high position cloth extension roller are disposed at the forefront end of the cloth feeding mechanism in sequence; a front drying device is arranged before the sueding area; a cold water tank is arranged between the front drying device and the sueding area; and a front tension swing rod is arranged between the front drying device and the cold water tank; a back drying device is arranged behind the sueding area; and a back tension swing rod is arranged between the back drying device and the back padder; a tension regulator is arranged between the front drying device and the front tension swing rod; both the front drying device and the back drying device have four drying cylinders; and the cloth is successively wound on the first drying cylinder, the second drying cylinder, the third drying cylinder and the fourth drying cylinder from low to high.

Owner:陈素萍

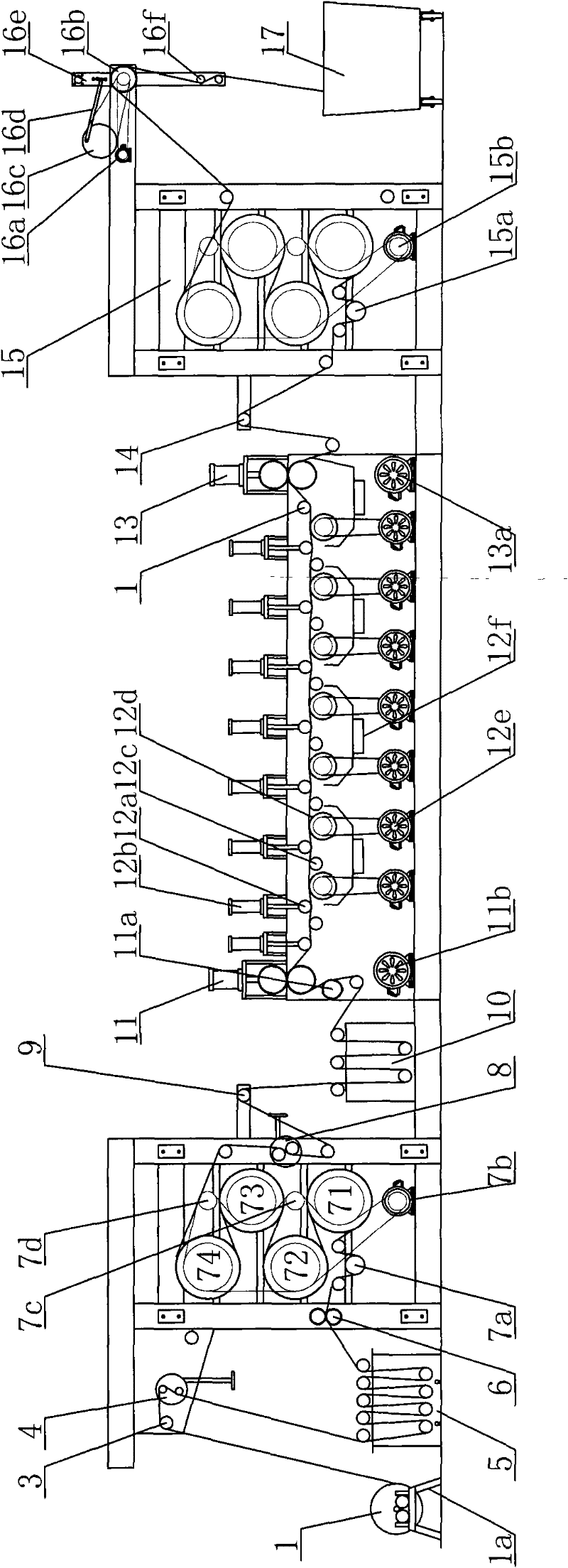

Package fabric-feed prewetting and drying roughening machine

InactiveCN102535076AConsistent tensionFull draftLiquid/gas/vapor removal by squeezing rollersStretchingEngineeringMechanical engineering

The invention discloses a package fabric-feed prewetting and drying roughening machine, belonging to the technical field of textile machinery. The fabric-feed prewetting and drying roughening machine comprises a frame, a roughening area, a fabric feed mechanism and fabric discharge mechanism, wherein the roughening area is provided with a plurality of sets of roughening rolls, a dust suction hood is arranged below the roughening rolls, and a spray device is arranged above the roughening rolls; a padder is respectively arranged before and behind the roughening area, a front drying device is arranged before the roughening area, a cold water tank is arranged between the front drying device and the roughening area, and a front tension swing rod is arranged between the front drying device and the cold water tank; the front drying device is provided with a hot water tank, and rolls are arranged between the hot water tank and front drying expanding rolls; a back drying device is arranged behind the roughening area, and a back tension swing rod is arranged between the back drying device and the back padder; drying cylinders of the back drying device and the front drying device have identical structure and arrangement; a tension regulator is arranged between the front drying device and the front tension swing rod; the front drying device has four drying cylinders, and the back drying device also has four drying cylinders; and the fabric is sequentially wound on the first drying cylinder, the second drying cylinder, the third drying cylinder and the fourth drying cylinder from low to high.

Owner:杨忠芳

Plastic valve end port grinding device

ActiveCN106695493AReduce riskAchieve the effect of rotationEdge grinding machinesRevolution surface grinding machinesEngineering

The invention discloses a plastic valve end port grinding device which comprises a base. A controller is fixedly installed on the left side of the top of the base. A fixed base is fixedly connected to the top of the base and located on the right side of the controller. The top of the fixed base is fixedly connected with a fixed ring. A fixed plate is fixedly connected to the left side of the fixed ring. A first motor is fixedly installed on the left side of the fixed plate. The output end of the first motor penetrates through the fixed plate, extends into the fixed ring and is fixedly connected with a first gear. A second gear used in cooperation with the first gear is arranged inside the fixed ring. A stabilizing plate is fixedly connected to the left side of the second gear. A first roller is movably installed on the left side of the stabilizing plate through a support. A first sliding rail is fixedly connected to the inner wall of the fixed ring, and the first roller is in sliding connection with the first sliding rail. According to the plastic valve end port grinding device, operation is easy, the effect of even grinding can be achieved by automatically rotating a plastic valve, and risks during work are reduced for workers.

Owner:吴江市强塑阀门管件厂

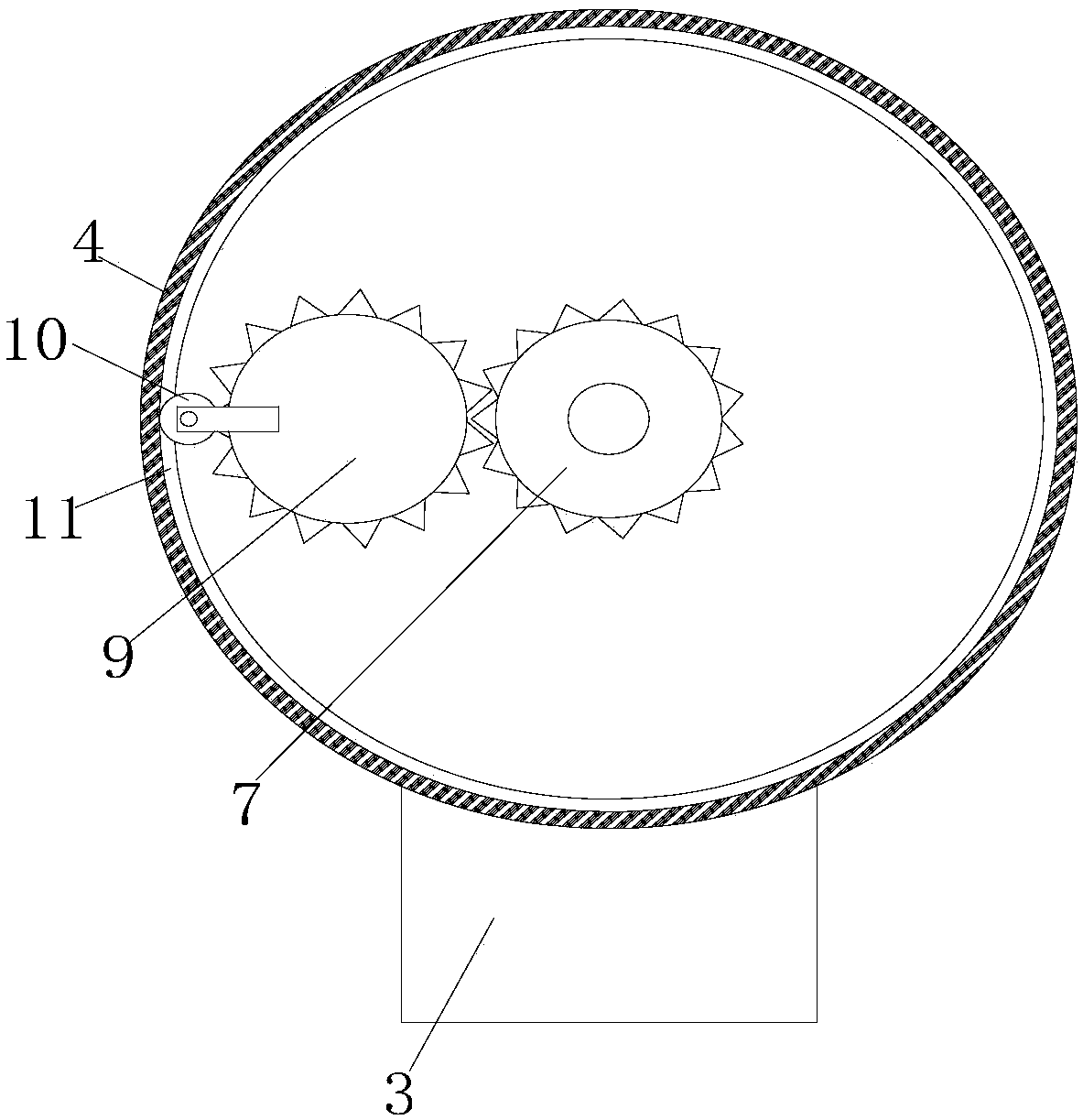

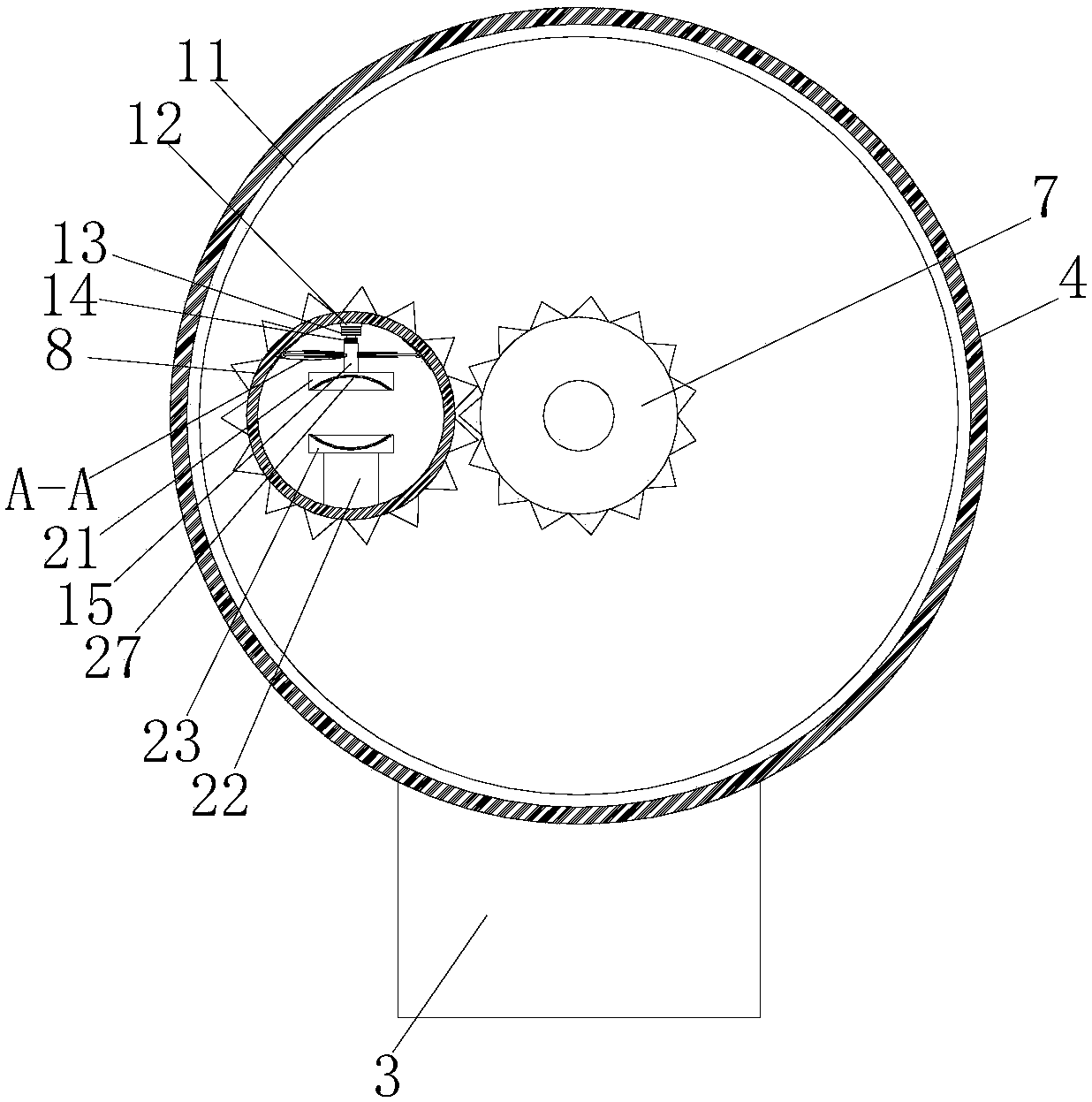

Automobile part grinding device

InactiveCN108296930AAchieve grindingTo achieve the purpose of grindingGrinding drivesSpherical surface grinding machinesHydraulic cylinderEngineering

The invention particularly discloses an automobile part grinding device which comprises a rack. A base is arranged in the center of the bottom of the rack, and a first motor is arranged on the base. Arotary disc is arranged on an output shaft of the first motor, and a grinding groove with the middle provided with a spherical sunken part is fixedly formed in the rotary disc. An abrasive layer is arranged on the inner wall of the grinding groove. Hydraulic cylinders are symmetrically mounted on the side walls of the two sides of the rack, and supporting rods are arranged at the output ends of the hydraulic cylinders. Rotary wheels are mounted at the output ends of a second motor and a third motor correspondingly, and dents are evenly distributed in the surfaces of the rotary wheels. The rotary wheels can make contact with the surface of a to-be-ground automobile part in the grinding groove, and the contacting positions of the rotary wheels and the to-be-ground spherical automobile partare located below the horizontal plane where the sphere center of the automobile part is located. The depth of the spherical sunken part of the grinding groove is smaller than the radius of the groundspherical automobile part. According to the scheme, the spherical automobile part is automatically ground, grinding devices do not need to be manually operated, the working efficiency is improved, and the working intensity is reduced.

Owner:CHONGQING JIANAN IND & TRADE

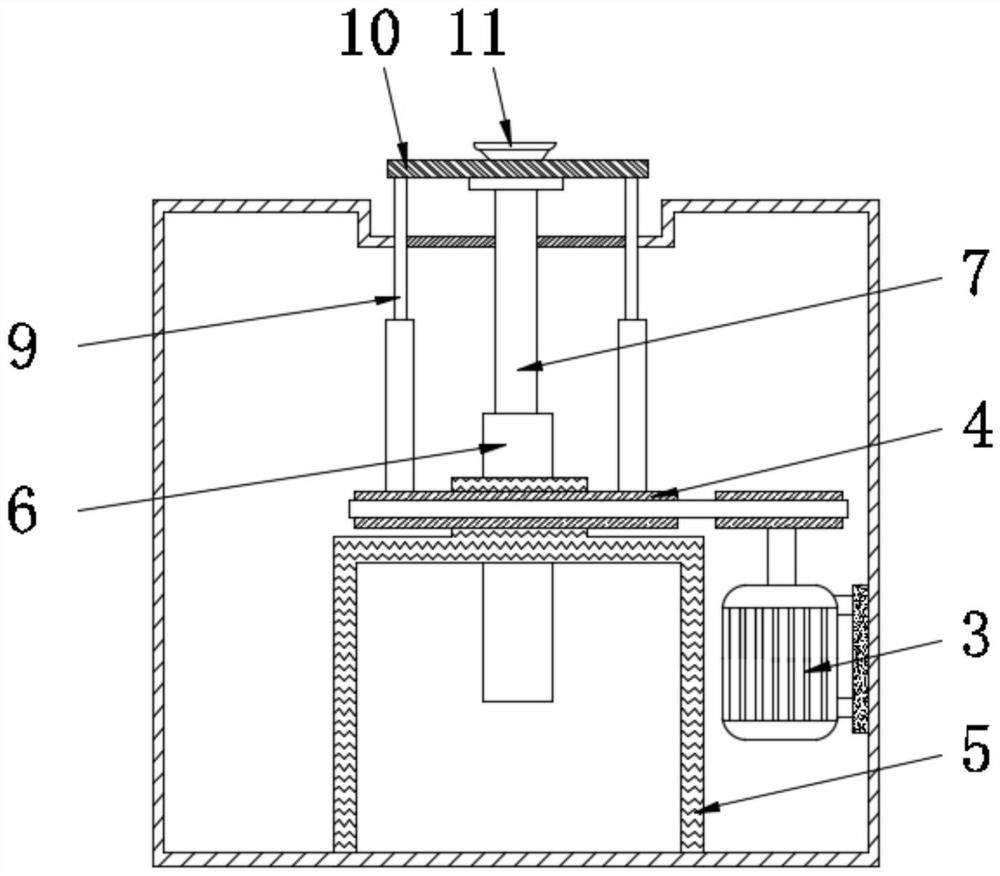

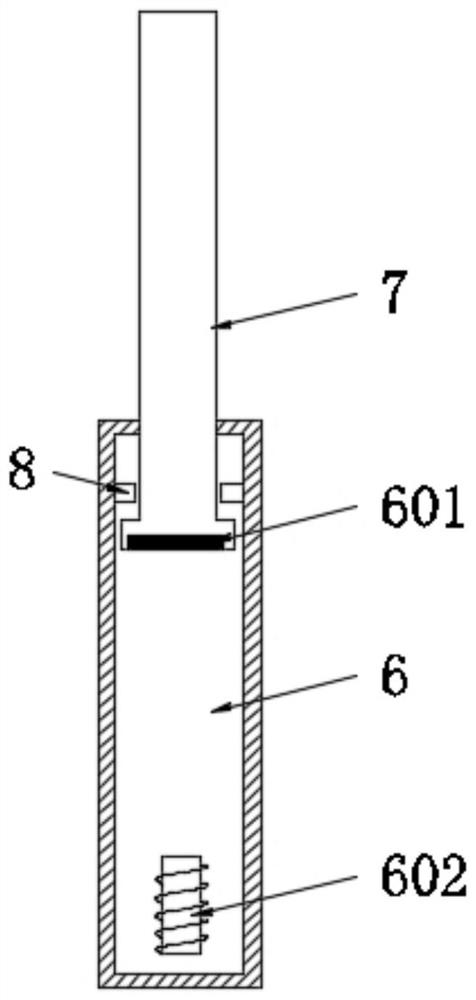

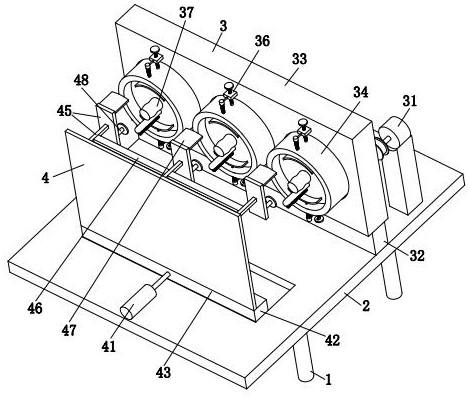

Automatic grinding and polishing device for high speed rail sleeper production

InactiveCN108406516ASave human effortGrinding speed is fastGrinding carriagesGrinding machinesEngineeringWater spray

The invention relates to an automatic grinding and polishing device for high speed rail sleeper production. The device comprises a supporting foot and a second transverse grinding stone; a waste box is arranged on the right side of the supporting foot, a containing table is arranged at the upper end of the supporting foot, a supporting frame is fixed to the two sides of the upper end of the containing table, water tanks are arranged on the two sides of the upper end of the interior of the supporting frame, telescopic water pipes are connected to the lower ends of the right sides of the water tanks, water spraying heads are embedded on the lower ends of the telescopic water pipes, and the second transverse grinding stone is arranged on the right sides of first transverse grinding stones. Transverse sliding blocks slide on a second transverse sliding rail, three first transverse grinding stones and a longitudinal grinding stone are driven to slide on the second transverse sliding rail left and right, the first transverse grinding stones and the longitudinal grinding stone can carry out sliding grinding on a sleeper on the second transverse sliding rail, sliding of the first transverse grinding stones and the longitudinal grinding stone does not need to be manually controlled, manpower is saved, the grinding speed is increased, and grinding is more uniform.

Owner:DONGGUAN UNIV OF TECH

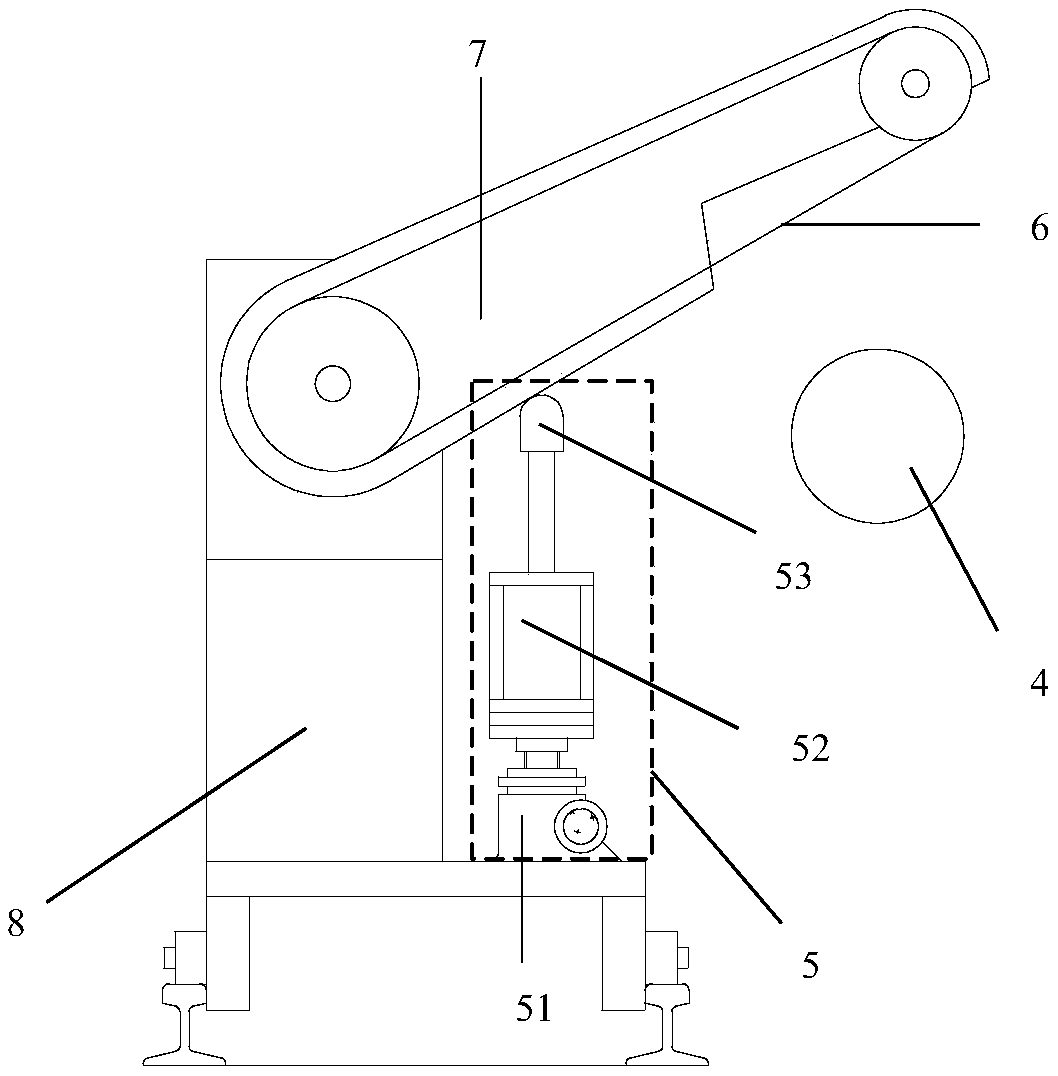

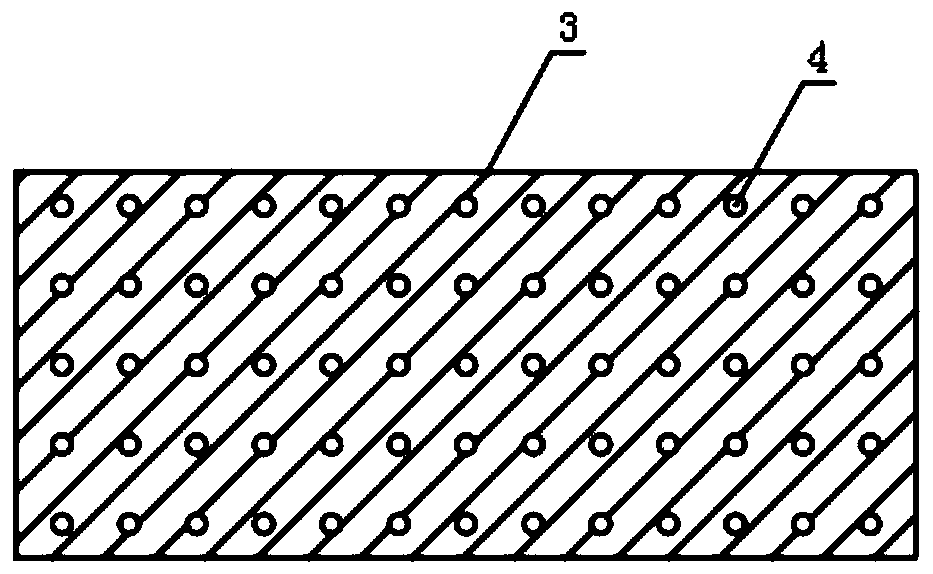

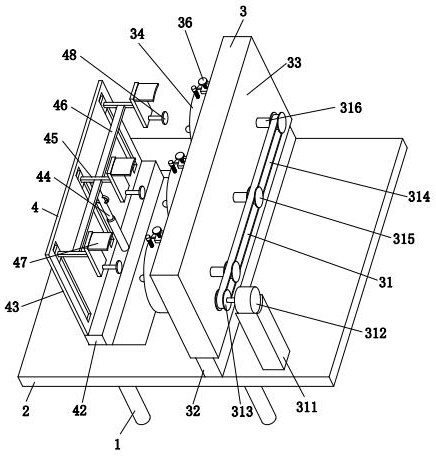

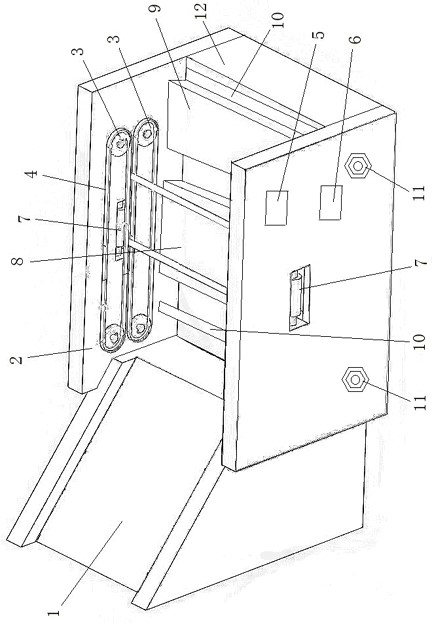

Fusion epoxy powder coating surface processing device and adjusting method thereof

InactiveCN103128632AEven sanding effectEven contactBelt grinding machinesPretreated surfacesEpoxyCoated surface

The invention relates to a fusion epoxy powder coating surface processing device which is characterized by comprising a support device, a guide rod support, a lifting support, an idler wheel adjusting device, a screw adjusting assembly and a driving device. The support device comprises a base frame, a pin roll and a hinge plate. The guide rod support comprises a rotating base plate with a shaft sleeve. The rotating base plate is connected onto the base frame through the shaft sleeve, four guide rods are arranged on the rotating base plate, two pairs of limit rods are arranged between the four guide rods, and two sides of the top of the base frame are connected with an air bag respectively through an air bag base. The lifting support comprises a ship base frame and a pair of idler wheel support seats which are symmetrically connected. Each idler wheel support seat is symmetrically provided with a sliding groove and a guide groove. The idler wheel adjusting device comprises a pair of idler wheels. A grinding belt is sleeved on the two idler wheels, and the idler wheels are inserted in the guide grooves correspondingly through two sliding plates which are integrally connected. The rotating base plate adjusts grinding angle through a screw adjusting assembly. The driving device comprises a speed reducer and a motor. The fusion epoxy powder coating surface processing device can be widely used in pipe coating surface processing.

Owner:CNOOC RES INST +1

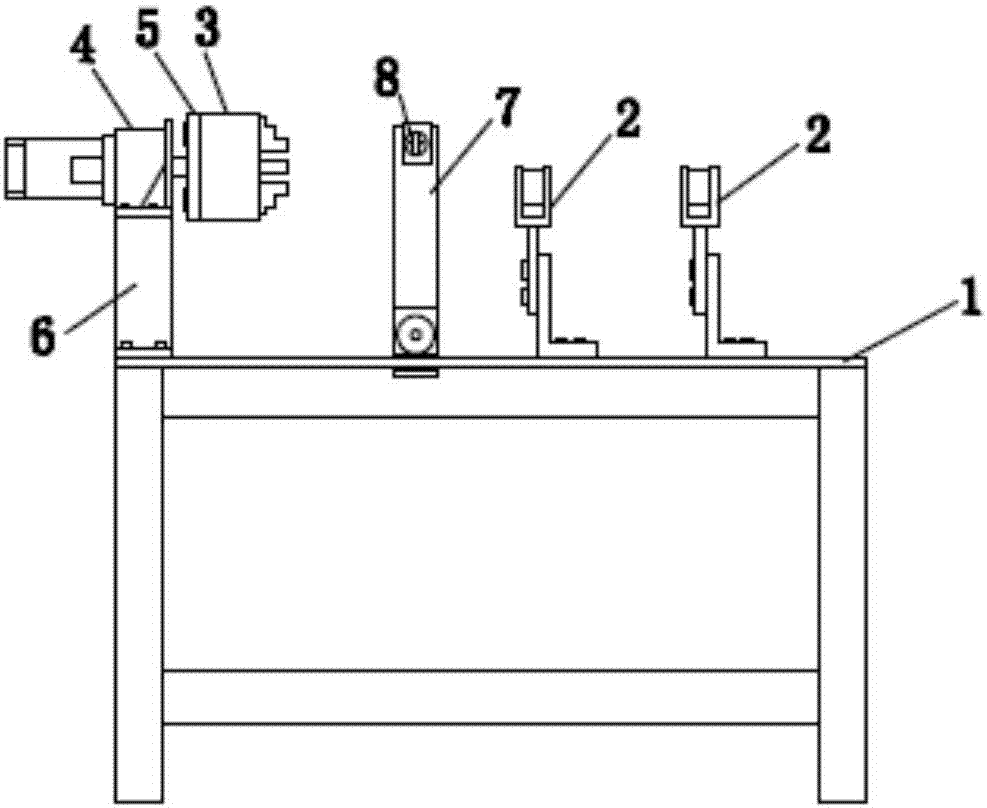

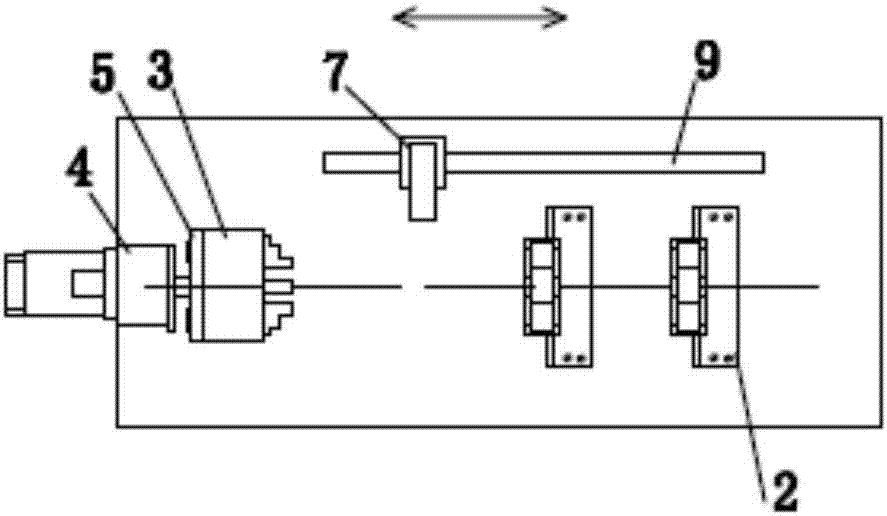

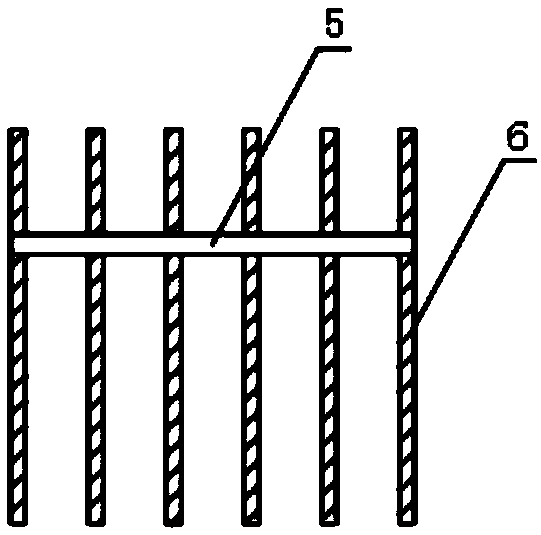

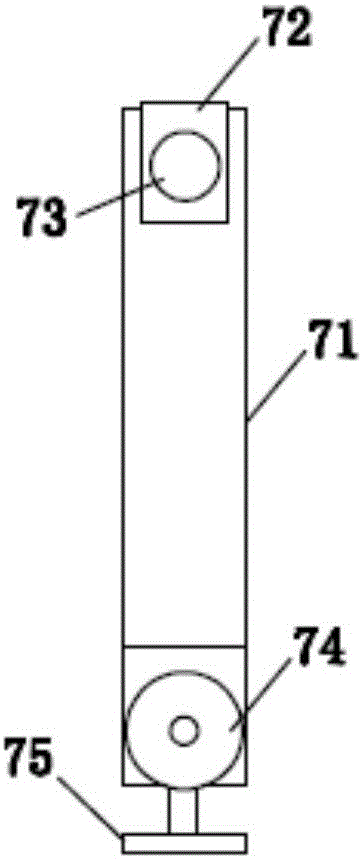

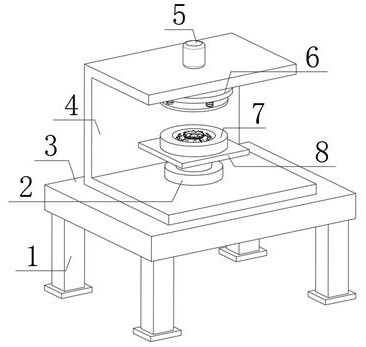

A simple deburring platform

ActiveCN106424947BGrinding pressure can be adjustedEven sanding effectFiling/rasping devicesLarge fixed membersEngineeringCam

The invention discloses a simple deburring platform. The simple deburring platform comprises a platform and roller supporting frames which are mounted on the platform; a rollers which is used for supporting a cam shaft is arranged on each roller supporting frame; a clamping disc rotating mechanism which is used for fixing one end of each cam shaft is arranged on one side of the platform; a file mounting seat which is used for mounting a file and can adjust the grinding pressure of the file is also arranged on the platform; a position adjustment mechanism which makes the file mounting seat moves in the axial direction of a clamping disc thereof is also arranged between the file mounting seat and the platform. According the simple deburring platform disclosed by the invention, the cam shafts rotate along with the clamping disc rotating mechanism, and the grinding can be realized by adjusting the grinding pressure of the file on the cam shafts, so that the operation is convenient and labour-saving, the grinding is uniform, and the position which is required to be grounded can be adjusted as required.

Owner:GUANGXI YUCHAI MASCH CO LTD

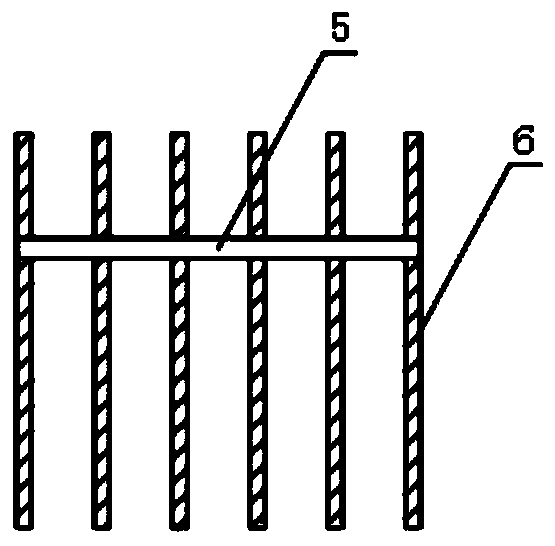

Stripping device of wicker stripping machine

The invention discloses a stripping device of a wicker stripping machine. The stripping device comprises lathe bodies, a conveying roller set is arranged between the lathe bodies, the outer side of the conveying roller set is sleeved with a conveying belt in a connected manner, a slag outlet hole penetrates the conveying belt, an installing support is fixedly arranged on the tops of the lathe bodies, a plurality of separating plates are fixedly arranged on the bottom end of the installing support, a first grinding roller is arranged on one side of the installing support, a second grinding roller is arranged on one side of the first grinding roller, a skin removing roller is arranged on one side of the second grinding roller, a third grinding roller is arranged on one side of the skin removing roller, and a polishing roller is arranged on one side of the third grinding roller. By means of the stripping device, wickers roll back and forth on the conveying belt, and therefore wicker surface layer fiber looseness and cracking are facilitated; and meanwhile, it can be guaranteed that the wicker outer surfaces can be in contact with a steel brush layer, and therefor the good surface layer removing effect is achieved, the polishing effect can be more even, and the quality of the polished wickers is guaranteed.

Owner:霍邱县淮美奇工艺品有限公司

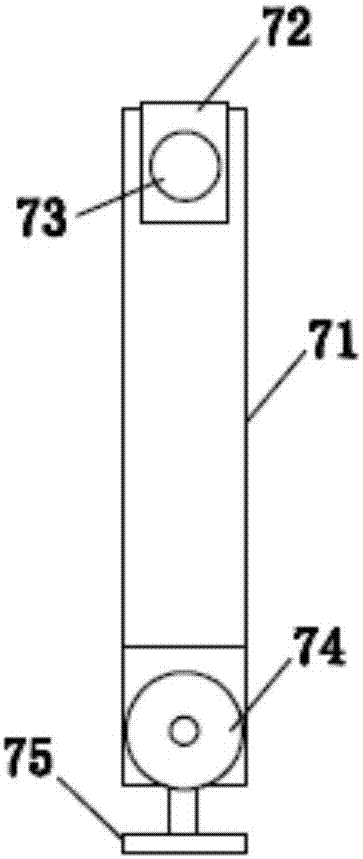

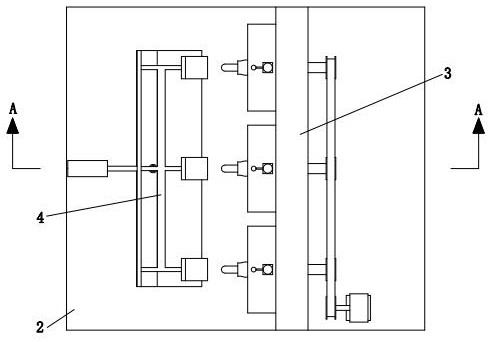

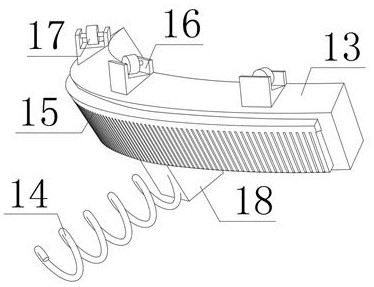

Tension mechanical arm tire polishing device

ActiveCN106736920AEven sanding effectGuaranteed tightRevolution surface grinding machinesGrinding drivesManipulatorEngineering

The invention discloses a tension mechanical arm tire polishing device which comprises a rotary boss and two tension mechanical arms symmetrically arranged on the two sides of the rotary boss. Each tension mechanical arm comprises a sanding roller and two tensioners arranged at the upper end and the lower end of the sanding roller correspondingly; each tensioner comprises two torsional springs symmetrically arranged on a frame body; each torsional spring is connected with the first end of a torsion beam; the second end of each torsion beam is hinged to one end of a grinding arm; and the other ends of the two grinding arms are hinged together through the corresponding sanding roller. Twisting force is applied through the torsional springs, the sanding rollers can be attached to the side face of a tire with certain tension, the effect that the sanding roller is in close contact with the side face of the tire all the time is guaranteed, and even if the tire or equipment shakes, the sanding roller can conduct polishing operation. The two tensioners apply tension to the upper end and the lower end of the sanding roller correspondingly, the sanding roller can be stably attached to the surface of the tire in the vertical direction, the effect that the upper end and the lower end of the sanding roller are attached to the surface of the tire with uniform tension all the time is guaranteed, and the polishing effect us more uniform.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

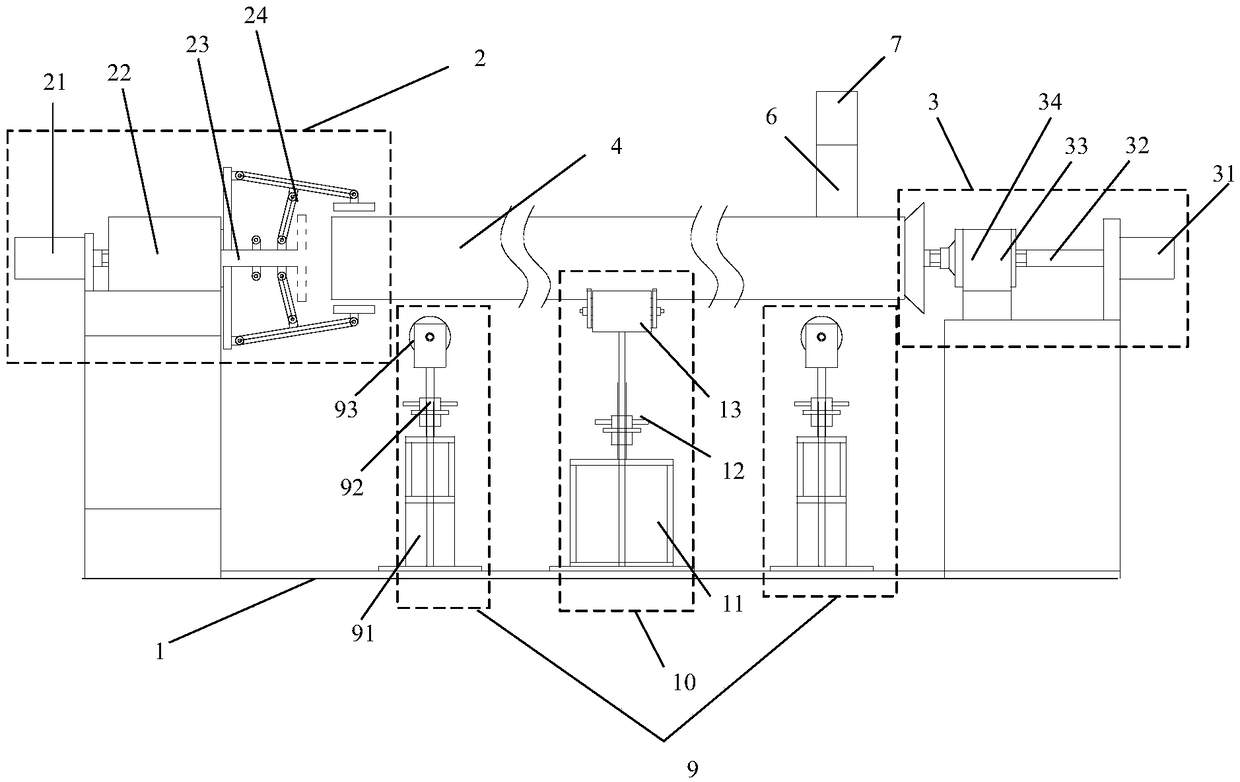

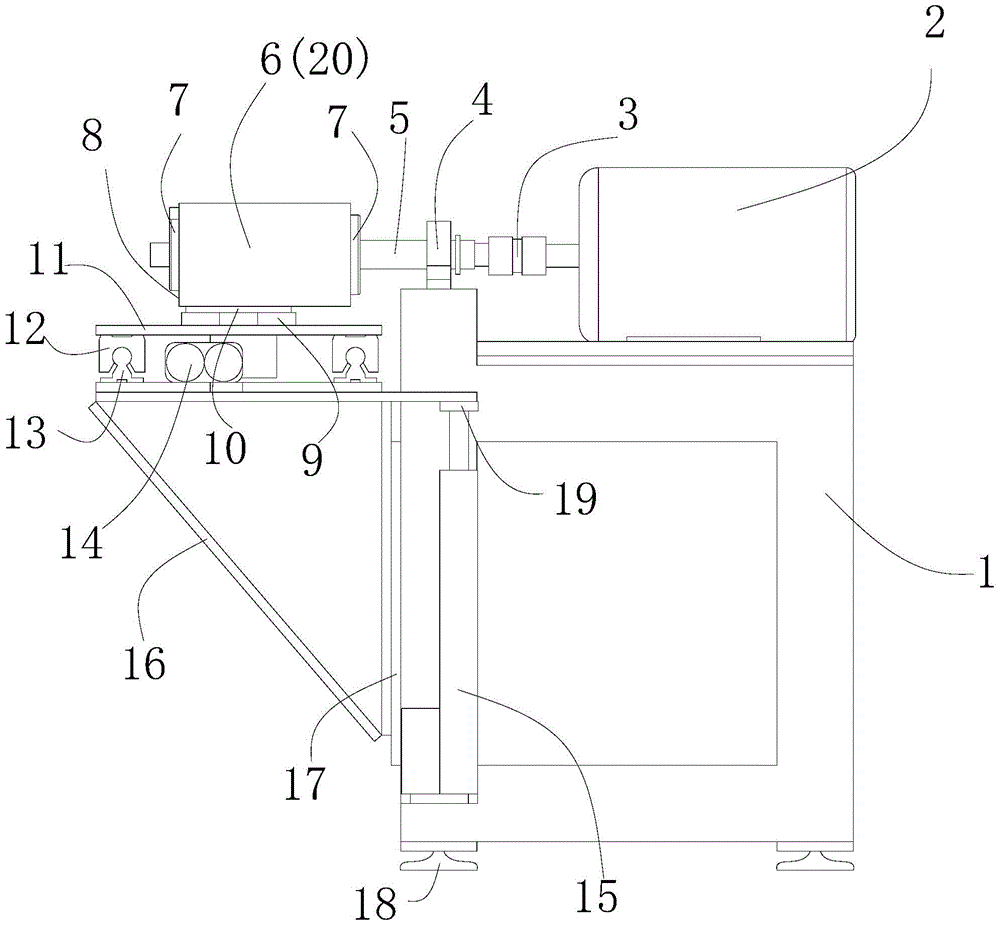

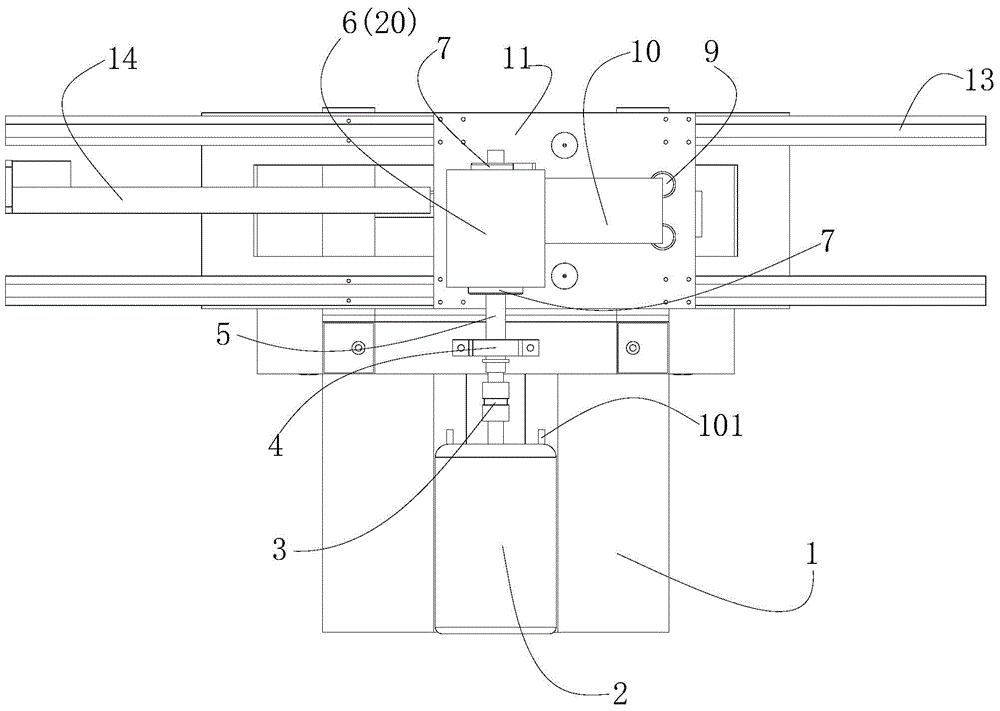

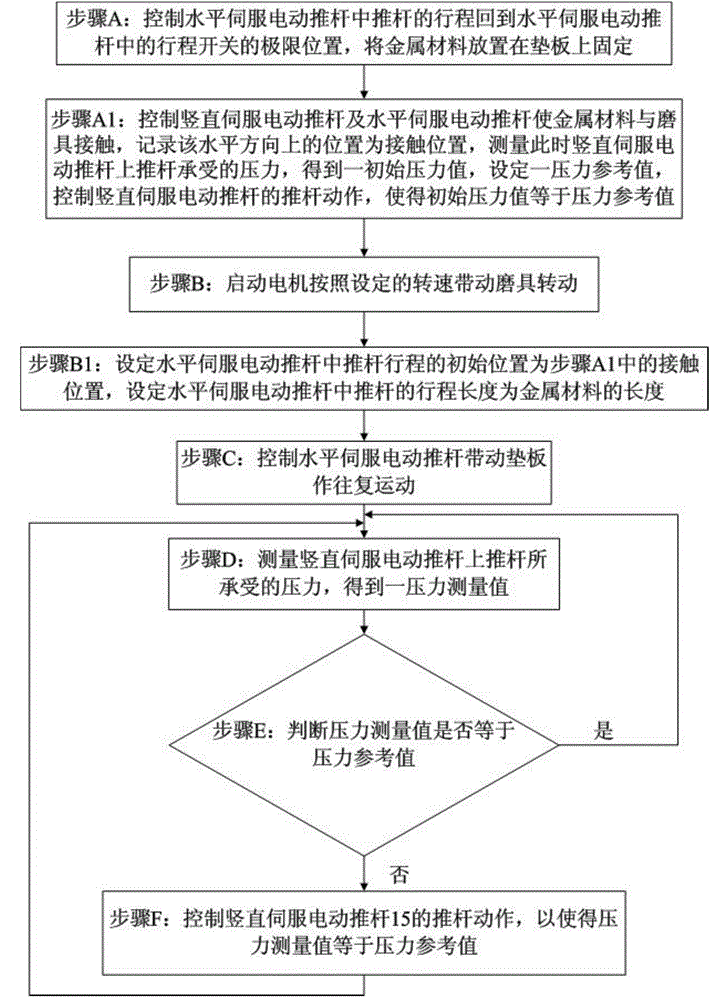

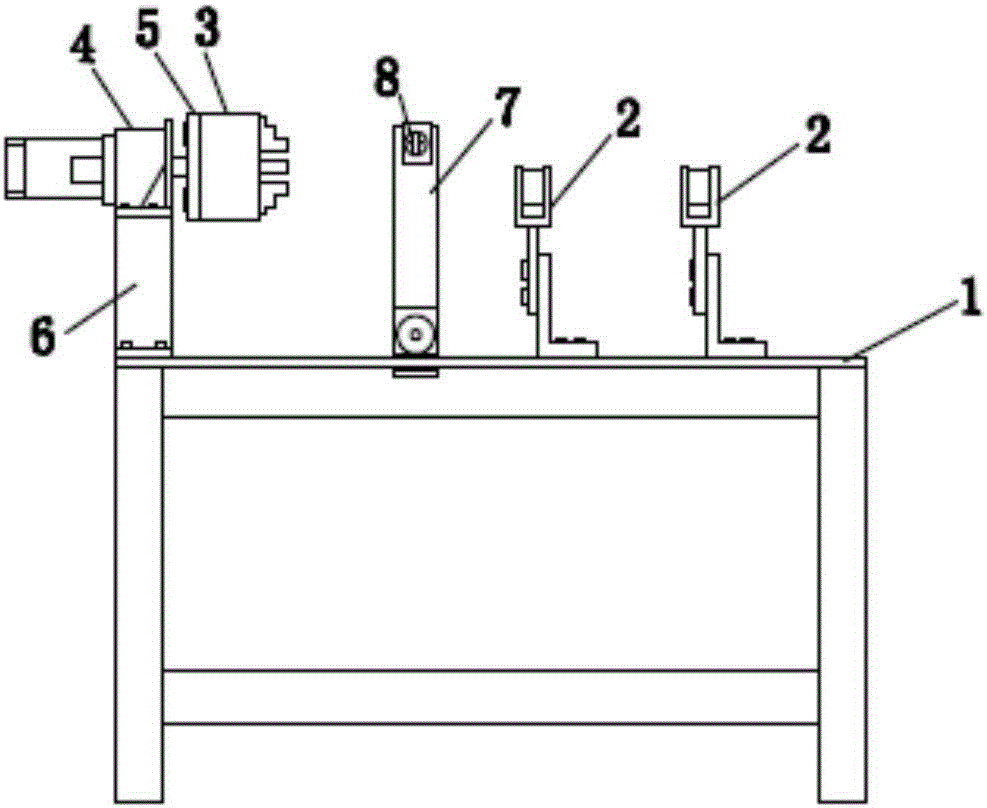

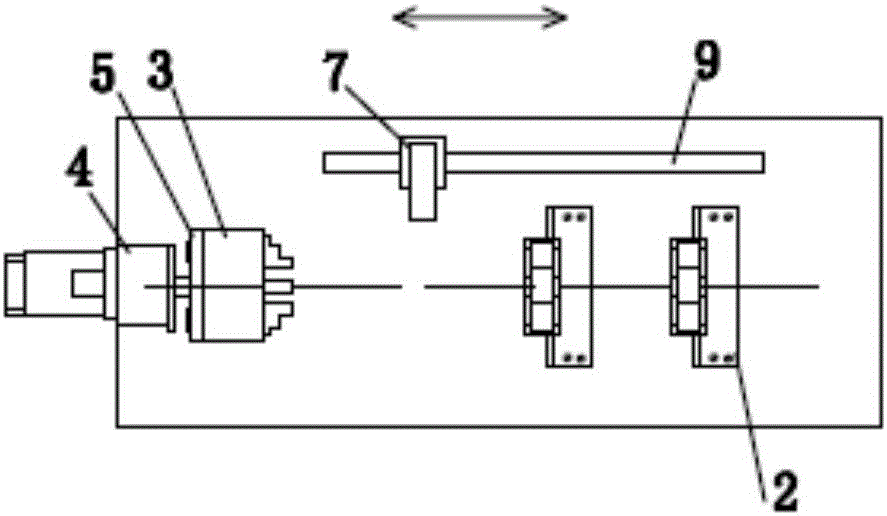

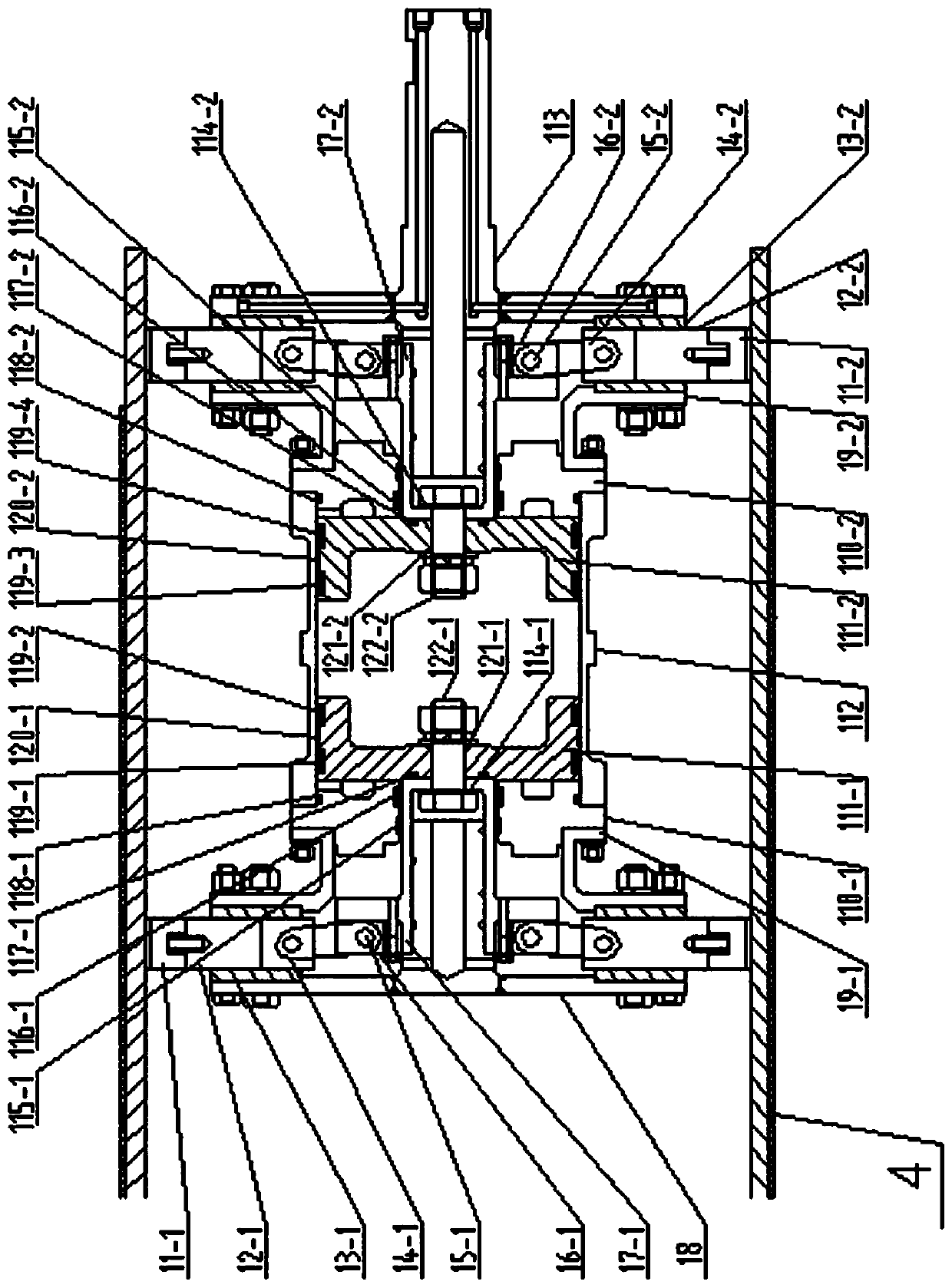

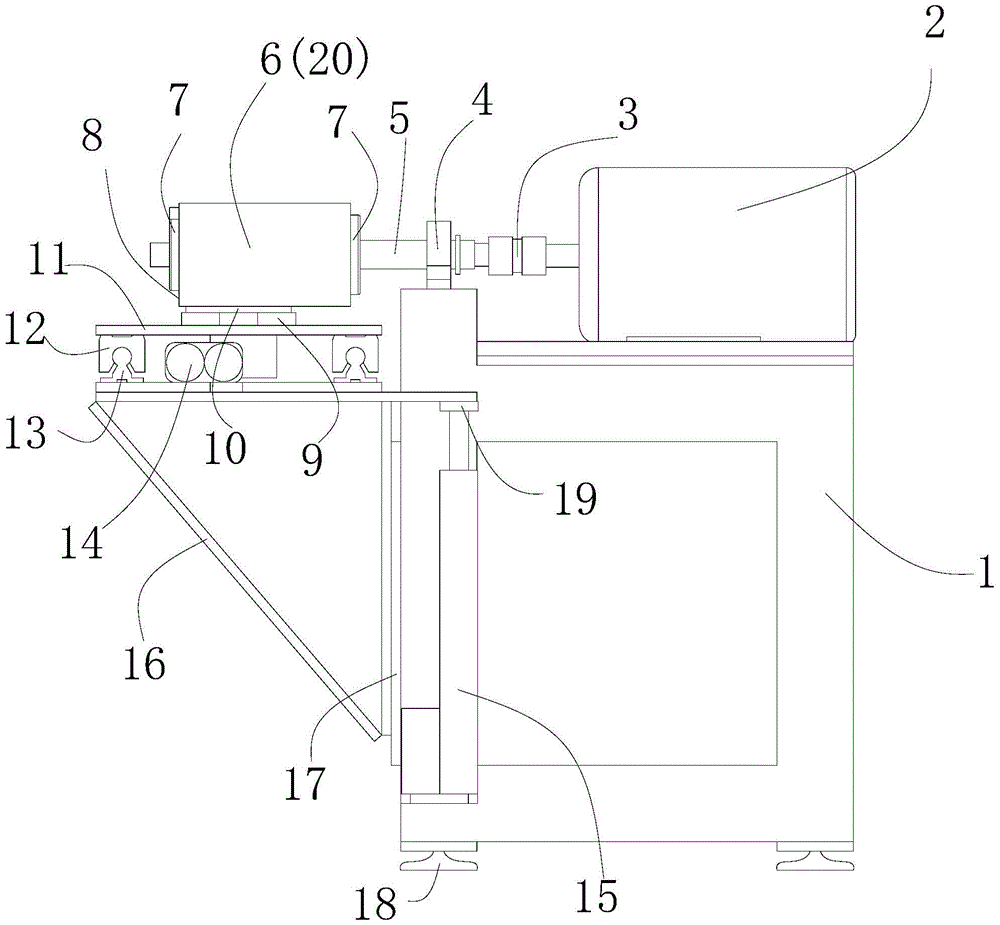

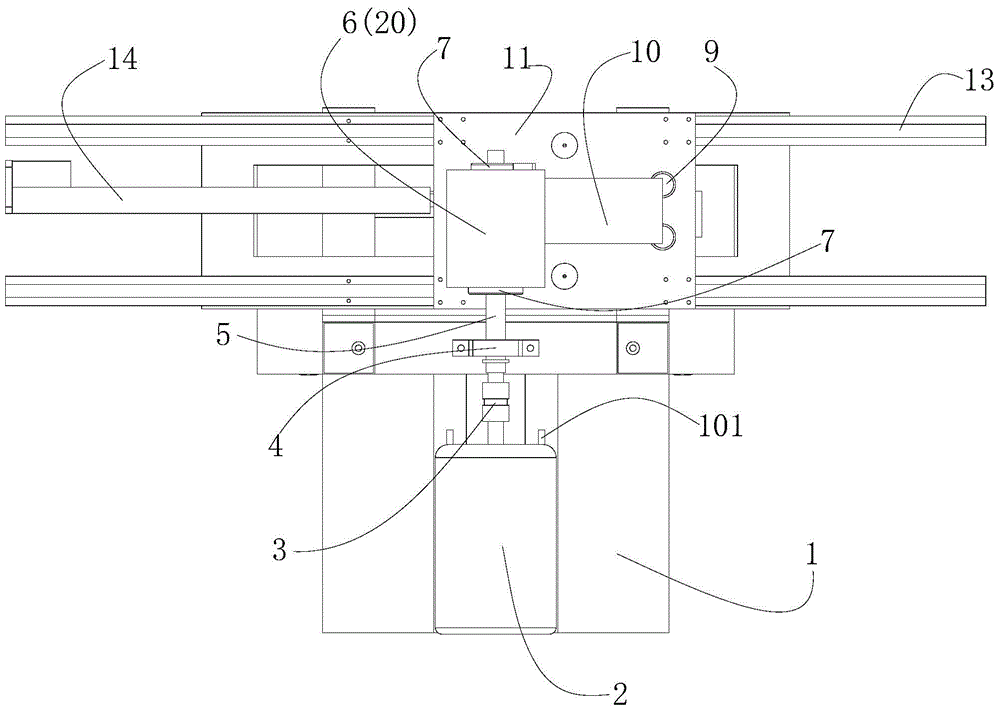

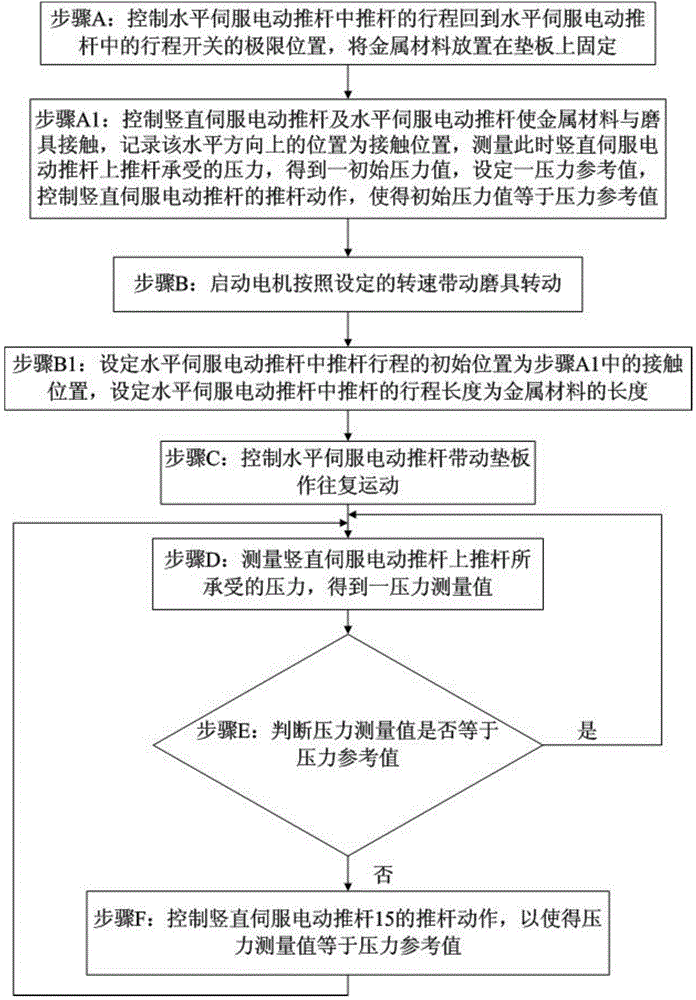

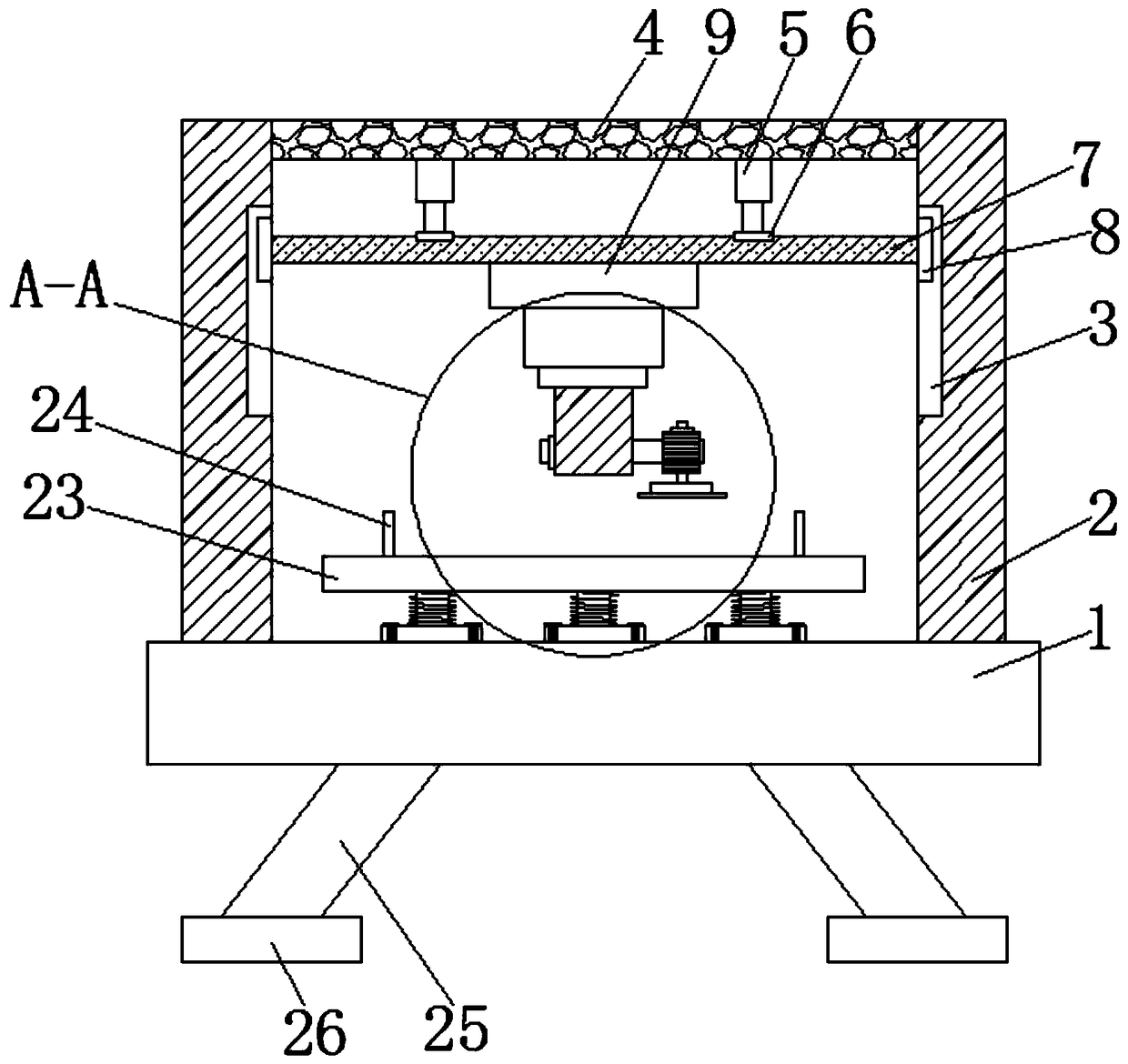

Grinding machine and method for surface pre-processing of special metallic composite materials for laboratory

ActiveCN104148999AConsistent sandingPolished evenlyGrinding drivesAutomatic grinding controlReciprocating motionControl system

Disclosed are a grinding machine and method for surface pre-processing of special metallic composite materials for a laboratory. The grinding machine comprises a machine frame, a motor, a spindle, a grinding tool, a base plate, a support and a control system, wherein the motor and the spindle are arranged on the machine frame, the base plate is provided with a horizontal servo electric push rod, and the support is provided with a vertical servo electric push rod and a pressure sensor. An output shaft of the motor is connected with the spindle, the grinding tool is arranged on the spindle in a sleeved mode, the base plate is arranged below the grinding tool, the support is arranged at the bottom of the base plate and can slide upwards and downwards along the machine frame, a plurality of sucking disks used for fixing the metallic composite materials are arranged on the base plate, the control system is in signal connection with the motor, the horizontal servo electric push rod, the pressure sensor and the vertical servo electric push rod, and therefore the control system can control the rotation speed of the motor and reciprocating movement of the horizontal servo electric push rod, and can further adjust movement of the vertical servo electric push rod according to pressure signals received by the pressure sensor. The grinding machine and method can conduct even and reciprocating grinding on the surfaces of the metallic materials to enable the surfaces of the metallic materials to be ground more evenly.

Owner:银邦(安徽)新能源材料科技有限公司

Efficient convenient grinding device

InactiveCN108214298AMeet different needsUp and down height adjustmentGrinding drivesGrinding work supportsEngineeringGrinding wheel

The invention discloses an efficient convenient grinding device. The device comprises a rack, a through connection base and a screw rod; a fixing plate is fixed to the rack, a protection cover is arranged on the edge of the fixing plate, a grinding wheel is arranged above the fixing plate, and is fixed to an output shaft of a motor, the motor is arranged on the rack, one side of the through connection base is in rotation connection with one end of a rotating shaft, the other end of the rotating shaft is connected to the top of a supporting arm, the supporting arm is fixed to the rack, the other side of the through connection base is fixedly provided with a connection base, and a casing rod is fixed to the bottom of the connection base; the screw rod is in threaded connection with the connection base, the bottom end of the screw rod stretches into the interior of the casing rod, the bottom end of the screw rod is connected to the top end of a top rod through a guide rod, and a clampingbase is arranged at the bottom end of the top rod. The grinding angle and the grinding thickness of a workpiece can be adjusted, the grinding effect is uniform, and different needs of workpiece machining can be met.

Owner:苑令乾

Optical lens processing device

PendingCN112496944AAvoid wear and tearEven sanding effectEdge grinding machinesGrinding drivesEngineeringFan blade

The invention provides an optical lens processing device, which is characterized in that fixed blocks are fixedly mounted on the upper surface of a workbench; movable rods are movably mounted on the inner sides of the adjacent fixed blocks; rollers are rotatably mounted at the tail ends of the movable rods, and compression springs are fixedly connected to the upper surfaces of the adjacent rollers; and the rollers are arranged on the left and right side surfaces of a moving seat. In the process that a sliding plate pushes a mounting base, the rollers roll inwards at the same time through a compression spring and the inclined face of the moving seat to drive the movable rods to be folded inwards till the movable rods and a grinding wheel at the top end of the moving seat coincide and are tightly attached to the edge of an optical lens, and clamping and loosening of the optical lenses of different sizes and shapes are achieved; and during grinding, fan blades are driven to rotate throughrotation of the grinding wheel, generated powder is introduced into a hollow bearing and conveyed into a collecting box through a hose, the uniform grinding effect of the optical lens is guaranteed,meanwhile, the personnel cleaning amount is reduced, and the surface of the optical lens is prevented from being polluted greatly.

Owner:彭广荣

A stripping device of a wicker stripping machine

The invention discloses a stripping device of a wicker stripping machine. The stripping device comprises lathe bodies, a conveying roller set is arranged between the lathe bodies, the outer side of the conveying roller set is sleeved with a conveying belt in a connected manner, a slag outlet hole penetrates the conveying belt, an installing support is fixedly arranged on the tops of the lathe bodies, a plurality of separating plates are fixedly arranged on the bottom end of the installing support, a first grinding roller is arranged on one side of the installing support, a second grinding roller is arranged on one side of the first grinding roller, a skin removing roller is arranged on one side of the second grinding roller, a third grinding roller is arranged on one side of the skin removing roller, and a polishing roller is arranged on one side of the third grinding roller. By means of the stripping device, wickers roll back and forth on the conveying belt, and therefore wicker surface layer fiber looseness and cracking are facilitated; and meanwhile, it can be guaranteed that the wicker outer surfaces can be in contact with a steel brush layer, and therefor the good surface layer removing effect is achieved, the polishing effect can be more even, and the quality of the polished wickers is guaranteed.

Owner:霍邱县淮美奇工艺品有限公司

Simple deburring platform

ActiveCN106424947AGrinding pressure can be adjustedEven sanding effectFiling/rasping devicesLarge fixed membersEngineeringCam

The invention discloses a simple deburring platform. The simple deburring platform comprises a platform and roller supporting frames which are mounted on the platform; a rollers which is used for supporting a cam shaft is arranged on each roller supporting frame; a clamping disc rotating mechanism which is used for fixing one end of each cam shaft is arranged on one side of the platform; a file mounting seat which is used for mounting a file and can adjust the grinding pressure of the file is also arranged on the platform; a position adjustment mechanism which makes the file mounting seat moves in the axial direction of a clamping disc thereof is also arranged between the file mounting seat and the platform. According the simple deburring platform disclosed by the invention, the cam shafts rotate along with the clamping disc rotating mechanism, and the grinding can be realized by adjusting the grinding pressure of the file on the cam shafts, so that the operation is convenient and labour-saving, the grinding is uniform, and the position which is required to be grounded can be adjusted as required.

Owner:GUANGXI YUCHAI MASCH CO LTD

Tension manipulator tire grinding device

ActiveCN106736920BGuaranteed tightGuaranteed close contactRevolution surface grinding machinesGrinding drivesEngineeringManipulator

The invention discloses a tension mechanical arm tire polishing device which comprises a rotary boss and two tension mechanical arms symmetrically arranged on the two sides of the rotary boss. Each tension mechanical arm comprises a sanding roller and two tensioners arranged at the upper end and the lower end of the sanding roller correspondingly; each tensioner comprises two torsional springs symmetrically arranged on a frame body; each torsional spring is connected with the first end of a torsion beam; the second end of each torsion beam is hinged to one end of a grinding arm; and the other ends of the two grinding arms are hinged together through the corresponding sanding roller. Twisting force is applied through the torsional springs, the sanding rollers can be attached to the side face of a tire with certain tension, the effect that the sanding roller is in close contact with the side face of the tire all the time is guaranteed, and even if the tire or equipment shakes, the sanding roller can conduct polishing operation. The two tensioners apply tension to the upper end and the lower end of the sanding roller correspondingly, the sanding roller can be stably attached to the surface of the tire in the vertical direction, the effect that the upper end and the lower end of the sanding roller are attached to the surface of the tire with uniform tension all the time is guaranteed, and the polishing effect us more uniform.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

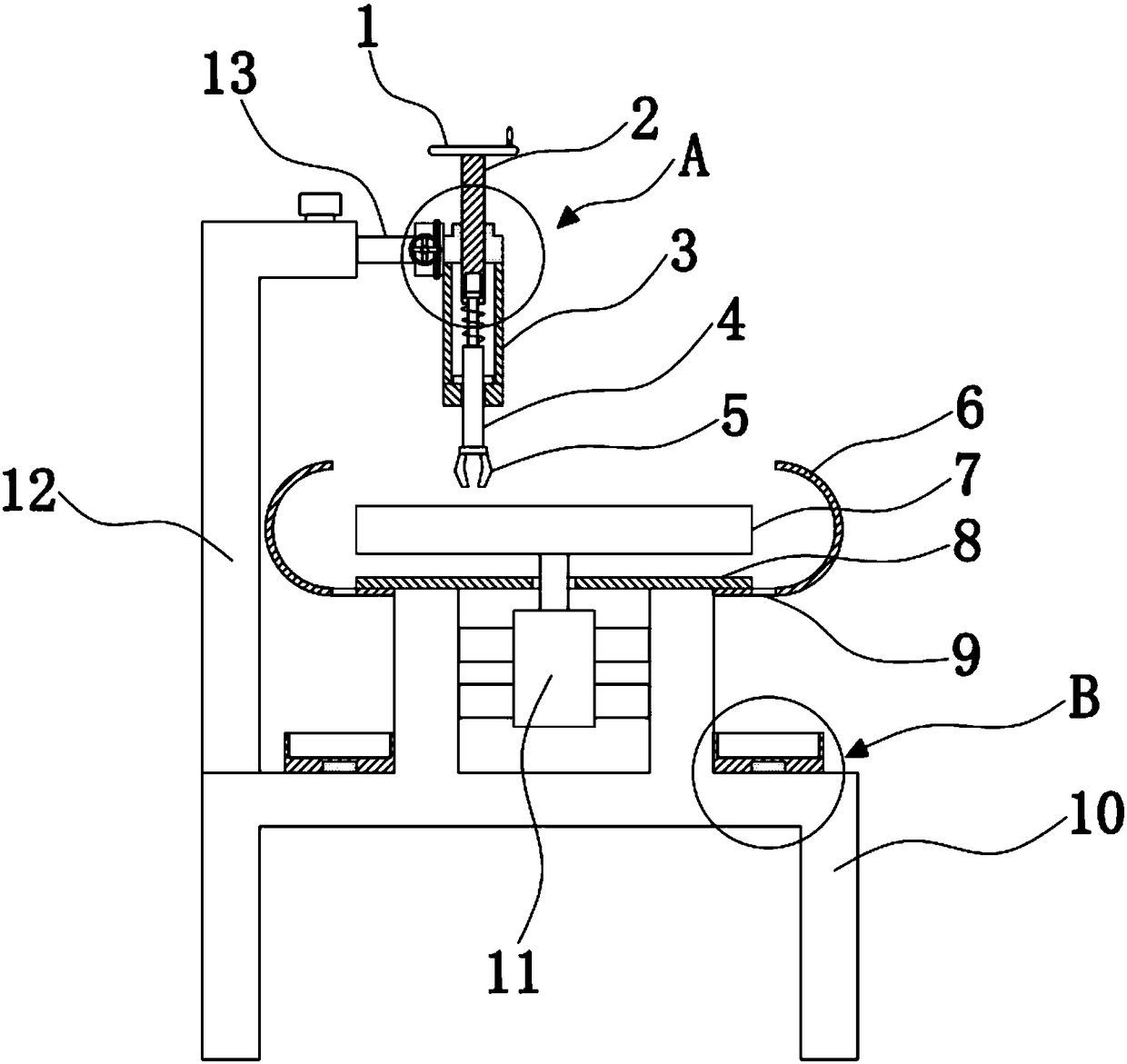

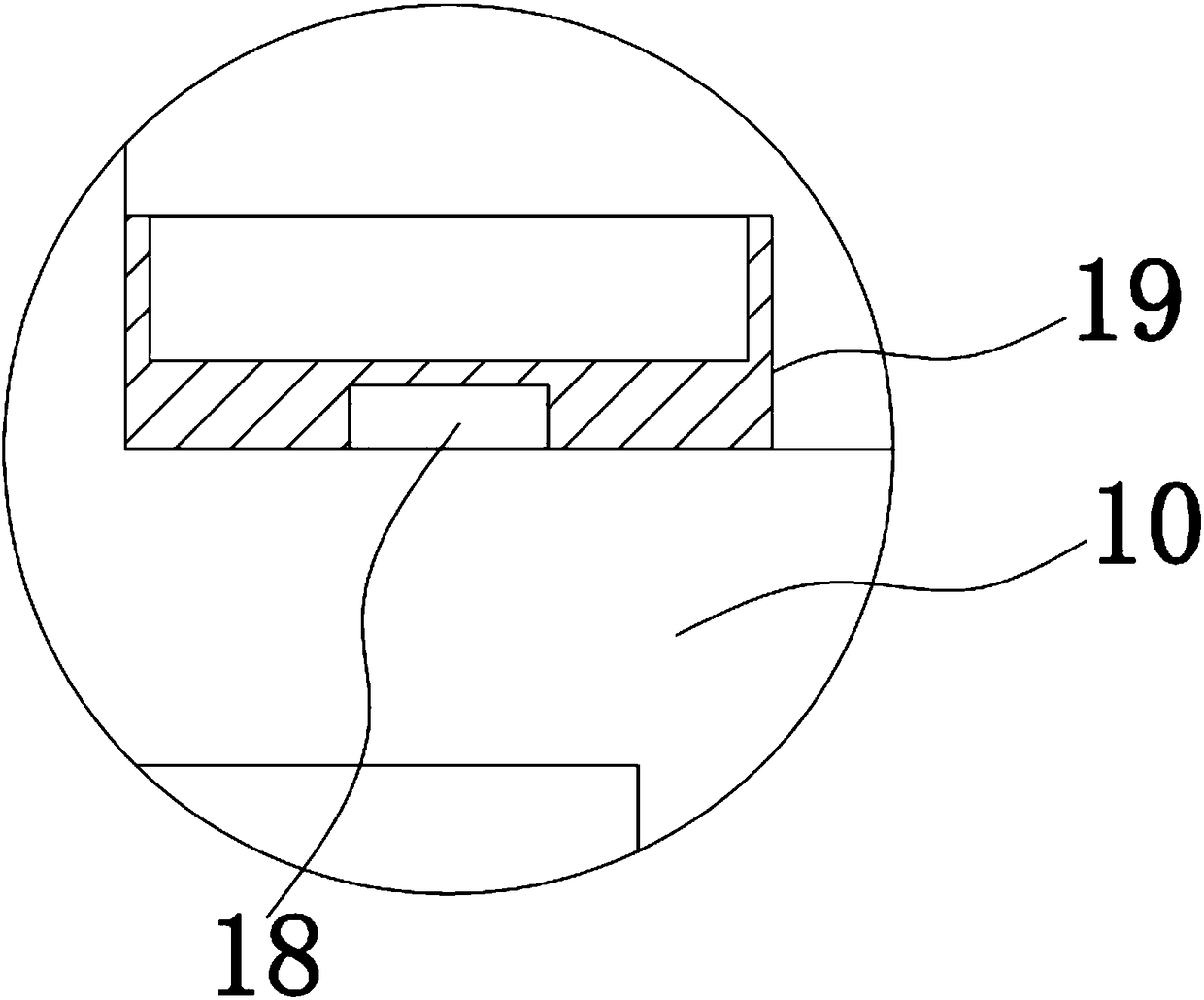

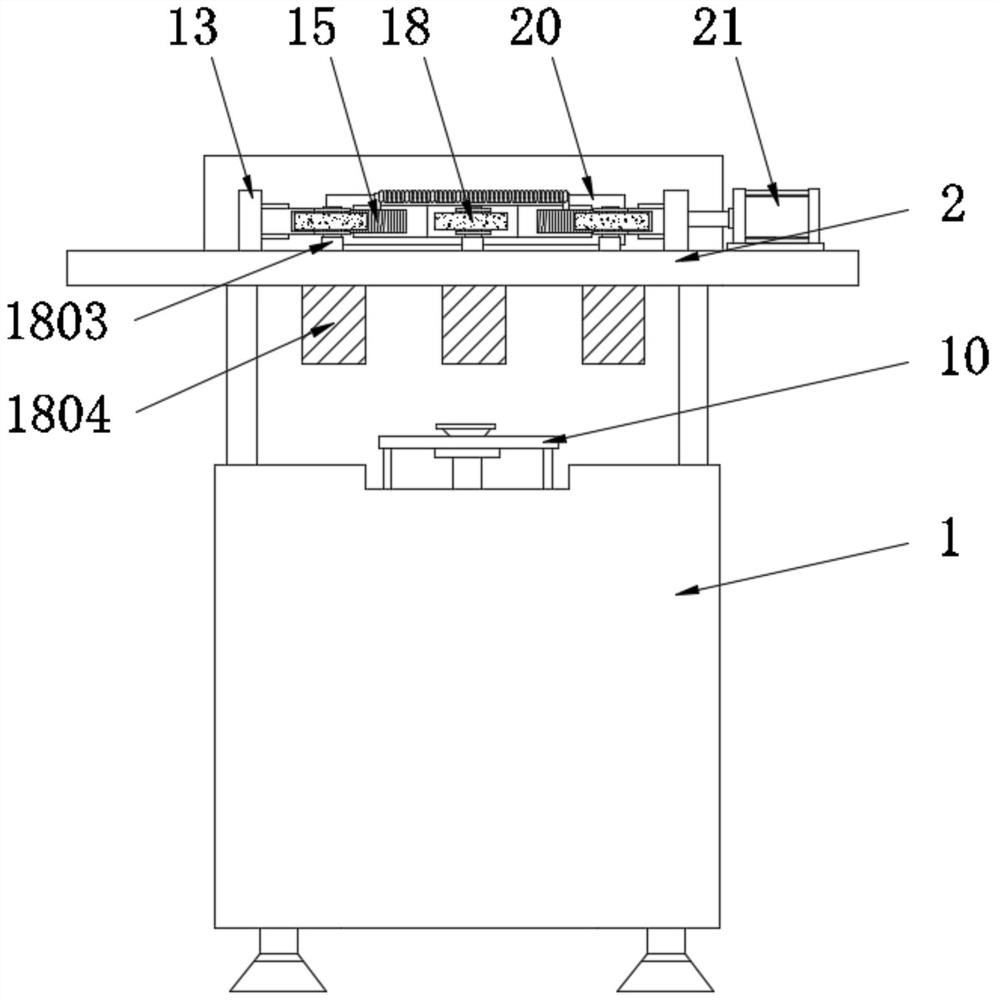

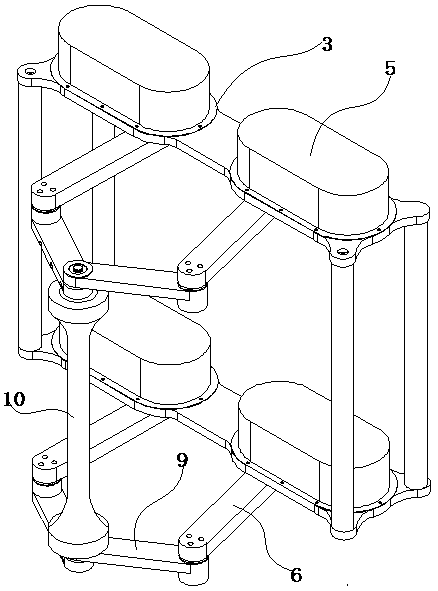

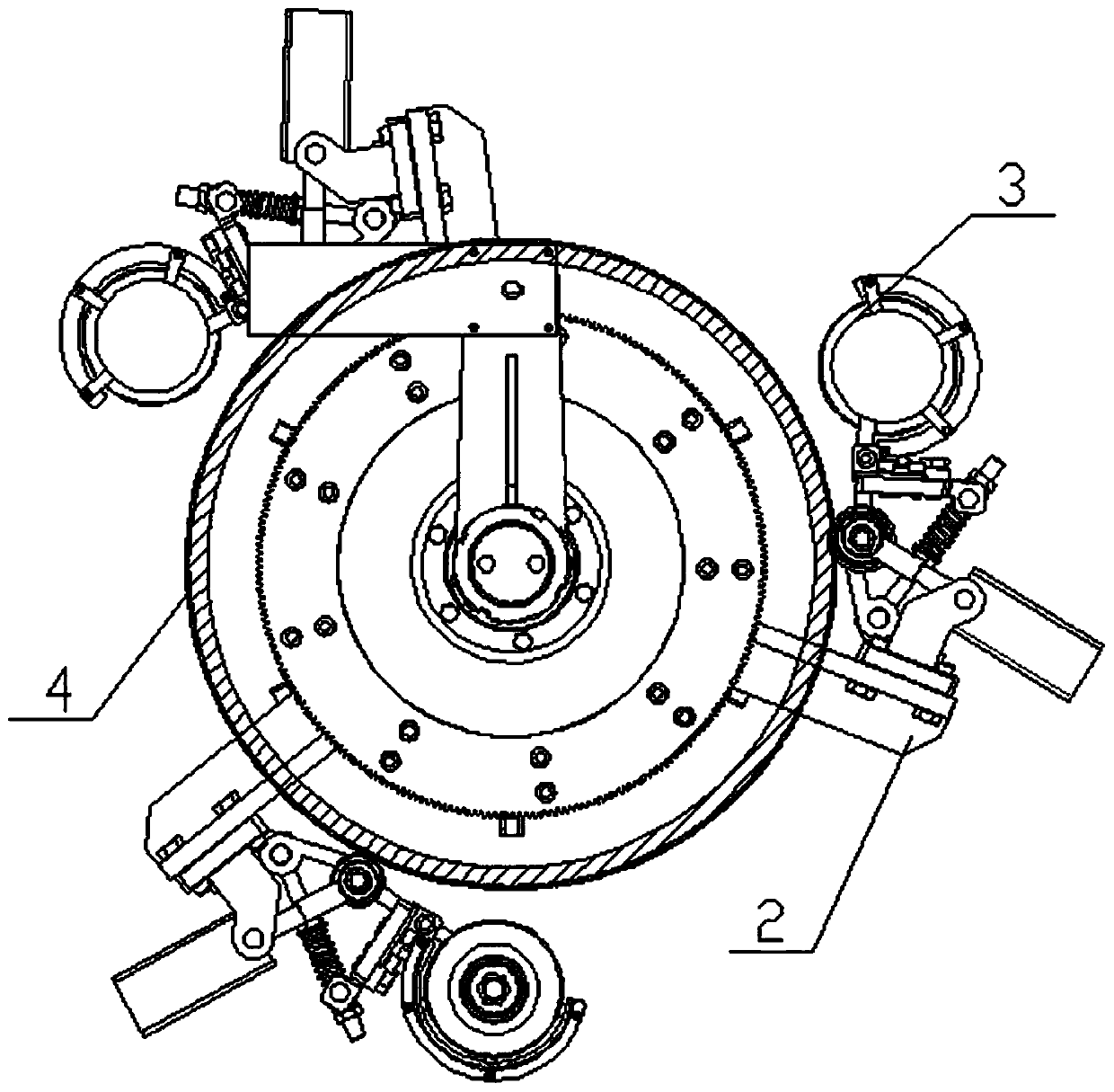

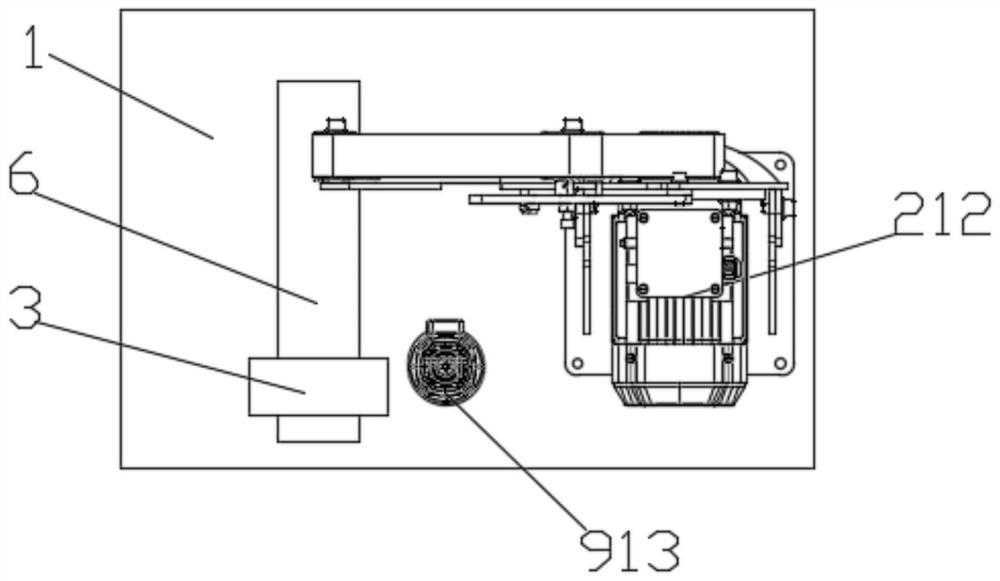

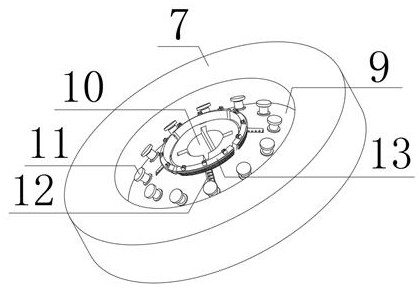

Efficient automatic pipe end derusting equipment

InactiveCN107900878BEven sanding effectNo entanglementEdge grinding machinesGrinding carriagesPositive pressureGrinding wheel

The invention relates to efficient full-automatic pipe end rust removing equipment. The efficient full-automatic pipe end rust removing equipment is composed of a machine head supporting device, a rotation grinding device and a plurality of rust removing devices, and the procedure of rust removal on the pipe end of a pipe joint which is about to be subjected to rust removal. Air inflow is achievedthrough a cylinder barrel air inlet of the machine head supporting device, pressing blocks are supported and pressed on the inner wall of the pipe joint, and the efficient full-automatic pipe end rust removing equipment and the pipe joint are relatively fixed through the positive pressure of the machine head supporting device. The rotation grinding device is connected with the machine head supporting device through a positioning plate, and a revolution motor of the rotation grinding device drives a small gear to be engaged with a large gear ring, and the rotation grinding device rotates around the positioning plate. The three rust removing devices are connected with the rotation grinding device through beams, the rust removing devices integrally rotate around the pipe joint, and a grinding motor is used for driving a grinding wheel to rotate at a high speed so that the grinding work can be finished. The efficient full-automatic pipe end rust removing equipment achieves automatic pipeend rust removal, and the pipe end rust removal efficiency is improved.

Owner:LUOYANG DEPING TECH

A laboratory-specific metal composite material surface pretreatment grinding machine and grinding method

ActiveCN104148999BConsistent sandingPolished evenlyGrinding drivesAutomatic grinding controlControl systemReciprocating motion

Disclosed are a grinding machine and method for surface pre-processing of special metallic composite materials for a laboratory. The grinding machine comprises a machine frame, a motor, a spindle, a grinding tool, a base plate, a support and a control system, wherein the motor and the spindle are arranged on the machine frame, the base plate is provided with a horizontal servo electric push rod, and the support is provided with a vertical servo electric push rod and a pressure sensor. An output shaft of the motor is connected with the spindle, the grinding tool is arranged on the spindle in a sleeved mode, the base plate is arranged below the grinding tool, the support is arranged at the bottom of the base plate and can slide upwards and downwards along the machine frame, a plurality of sucking disks used for fixing the metallic composite materials are arranged on the base plate, the control system is in signal connection with the motor, the horizontal servo electric push rod, the pressure sensor and the vertical servo electric push rod, and therefore the control system can control the rotation speed of the motor and reciprocating movement of the horizontal servo electric push rod, and can further adjust movement of the vertical servo electric push rod according to pressure signals received by the pressure sensor. The grinding machine and method can conduct even and reciprocating grinding on the surfaces of the metallic materials to enable the surfaces of the metallic materials to be ground more evenly.

Owner:银邦(安徽)新能源材料科技有限公司

Fusion epoxy powder coating surface processing device and adjusting method thereof

InactiveCN103128632BEven sanding effectEven contactBelt grinding machinesPretreated surfacesEpoxyCoated surface

The invention relates to a fusion epoxy powder coating surface processing device which is characterized by comprising a support device, a guide rod support, a lifting support, an idler wheel adjusting device, a screw adjusting assembly and a driving device. The support device comprises a base frame, a pin roll and a hinge plate. The guide rod support comprises a rotating base plate with a shaft sleeve. The rotating base plate is connected onto the base frame through the shaft sleeve, four guide rods are arranged on the rotating base plate, two pairs of limit rods are arranged between the four guide rods, and two sides of the top of the base frame are connected with an air bag respectively through an air bag base. The lifting support comprises a ship base frame and a pair of idler wheel support seats which are symmetrically connected. Each idler wheel support seat is symmetrically provided with a sliding groove and a guide groove. The idler wheel adjusting device comprises a pair of idler wheels. A grinding belt is sleeved on the two idler wheels, and the idler wheels are inserted in the guide grooves correspondingly through two sliding plates which are integrally connected. The rotating base plate adjusts grinding angle through a screw adjusting assembly. The driving device comprises a speed reducer and a motor. The fusion epoxy powder coating surface processing device can be widely used in pipe coating surface processing.

Owner:CNOOC RES INST +1

A finishing device for making the air outlet panel of a cylindrical air purifier

ActiveCN114310512BGuarantee the appearance qualityImprove grinding efficiencyRevolution surface grinding machinesGrinding drivesAir purifiersProcess engineering

The invention relates to the field of grinding and manufacturing of air purifier accessories, in particular to a device for finishing the air outlet panel of a cylindrical air purifier, which includes legs, a workbench, a fixing part and a grinding part. The present invention can achieve the effect of synchronously grinding the outer sidewalls of multiple cylindrical air outlet panels through the mutual cooperation of the clamping unit and the driving unit, which improves the grinding efficiency and meets the needs of mass production. Secondly, in the grinding process In the process, the wet sponge block can not only scrape off the grinding debris generated during the grinding process in time, but also cool down the side wall of the cylindrical air outlet panel, preventing the grinding debris from sticking to the cylindrical outlet due to frictional heat. The phenomenon on the side wall of the air panel reduces the difficulty of cleaning and improves the grinding effect. At the same time, the T-shaped stamping head can cooperate with the air blowing unit to blow out the grinding debris in the air inlet and outlet to the outside, avoiding the blockage of the air inlet and outlet, thereby improving The product quality of cylindrical air outlet panels.

Owner:徐州高鑫电子科技有限公司

Barb removing mechanism for rattan plaited case and using method of barb removing mechanism

InactiveCN113547403AEven sanding effectEasy loading and installationEdge grinding machinesGrinding carriagesDrive wheelElectric machinery

The invention discloses a barb removing mechanism for a rattan plaited case and a using method of the barb removing mechanism. The barb removing mechanism comprises a mounting base, a fixing device is fixedly mounted on one side of the top of the mounting base, a sliding way is formed in the other side of the top of the mounting base, a mounting groove is formed in the bottom of the sliding way, a transmission mechanism is fixedly mounted in the mounting groove, the transmission mechanism drives a connecting column to transversely move, a movable seat is fixedly connected to the middle section of the connecting column, the movable seat is in sliding connection with the top of the mounting base, a grinding device is rotationally connected to the top of the connecting column, two ends of a rattan are connected through a fixing clamp and the rattan is connected to the fixing device in a sleeving manner, the rattan is fixed into a circle through the fixing clamp, the rattan is connected to a driving wheel, a tensioning wheel and two movable wheels in a sleeving manner, a telescopic air cylinder is started, a movable rod rotates, the whole rattan is tensioned through the tensioning wheel, and meanwhile, a first motor is started to enable the rattan to rotate; and the grinding device is integrally rotated until two grinding wheels abut against the two sides of the rattan, and barbs on the two sides of the rattan are removed.

Owner:安徽嘉美工艺品有限公司

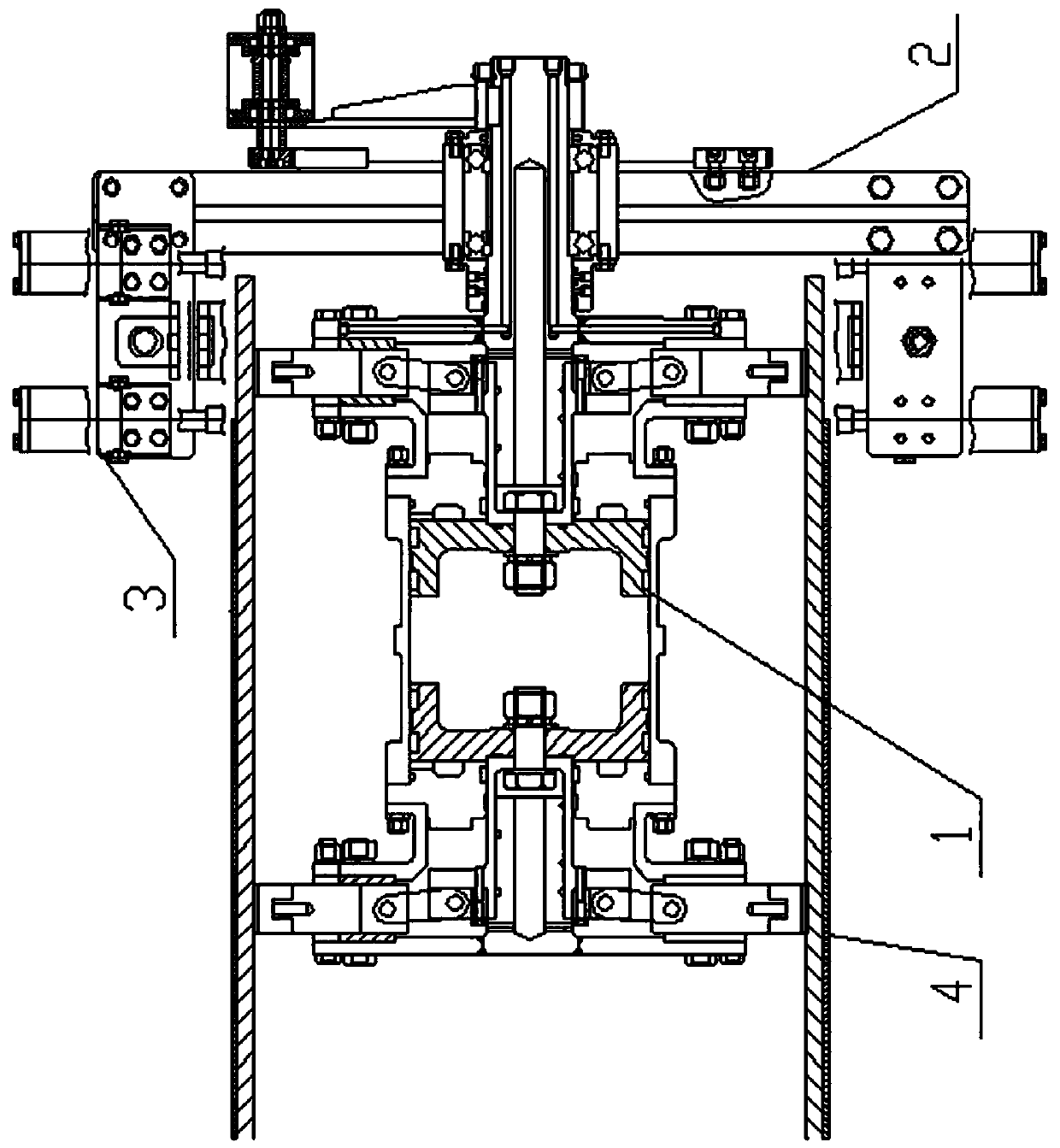

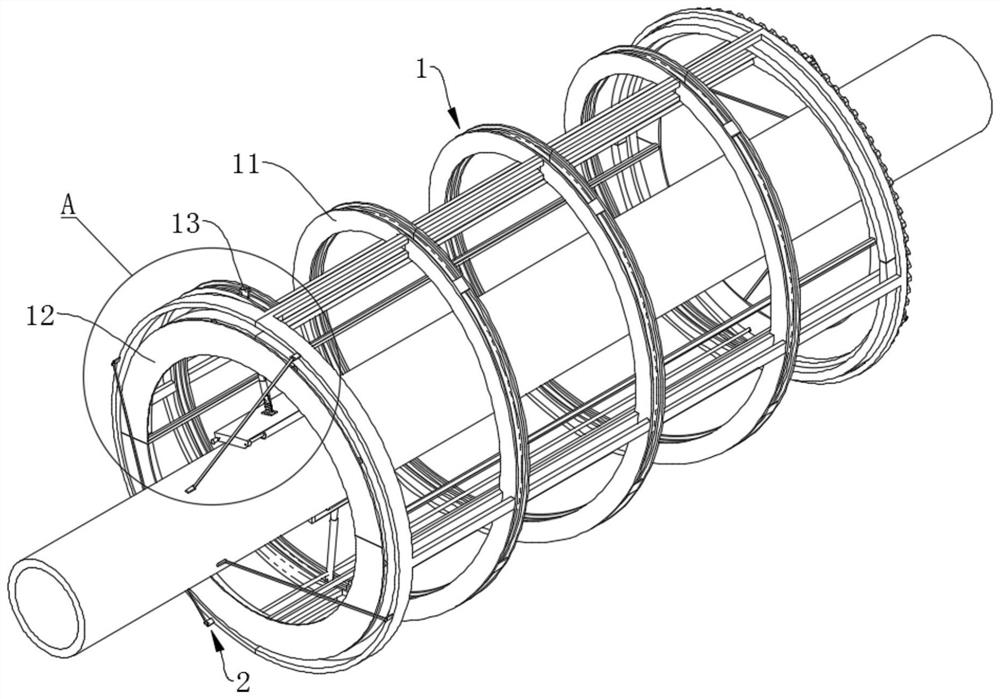

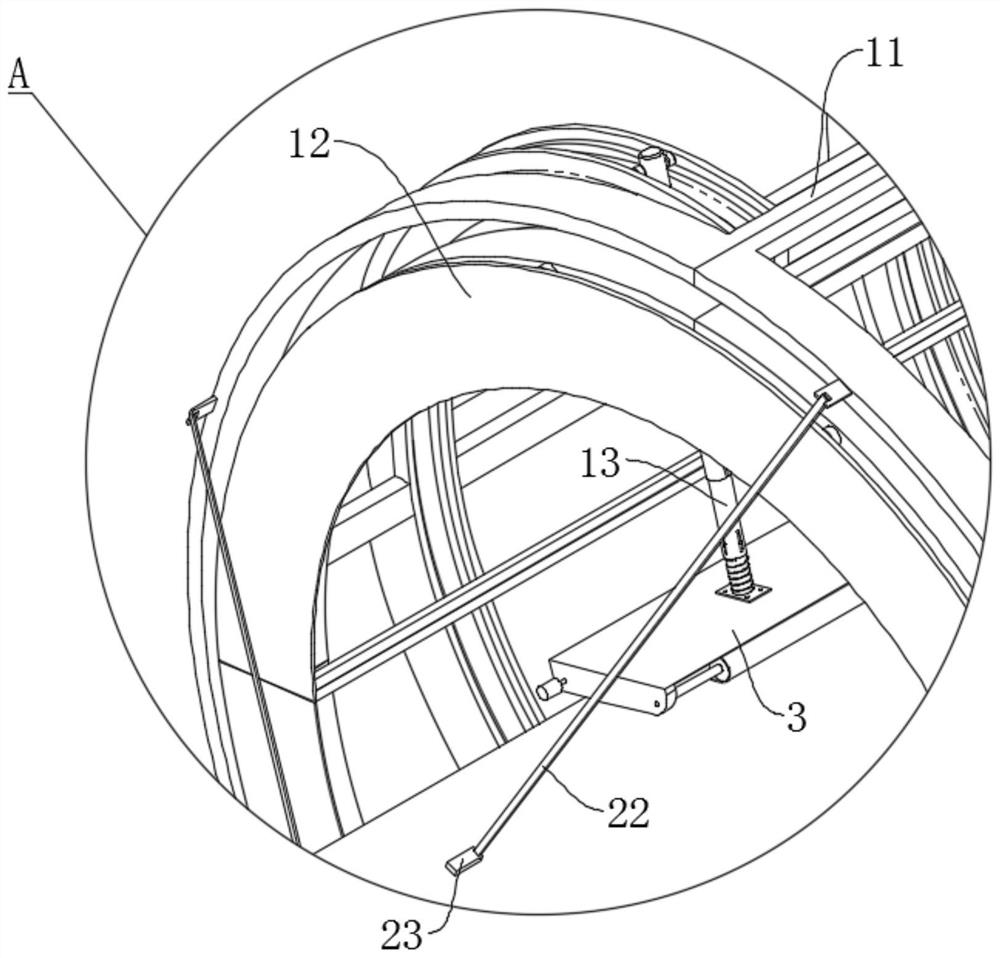

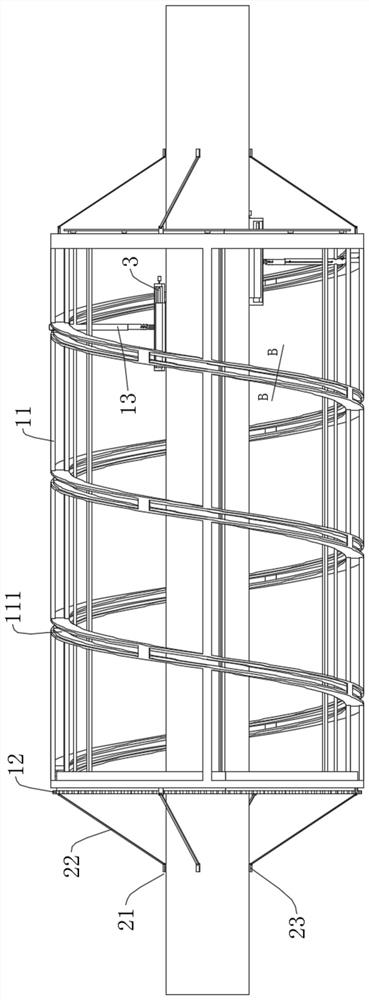

A pressure pipe weld seam grinding device

ActiveCN112792658BImprove efficiencyEven sanding effectEdge grinding machinesGrinding drivesEngineeringWeld seam

The invention discloses a pressure pipe welding seam grinding device, which includes a centering positioning mechanism, a screw feeding mechanism and a grinding head, wherein: the screw feeding mechanism includes a track piece, a driving piece and a moving piece, and the track piece and the driving piece are the same The shaft is set, the moving part has an outer moving end and an inner moving end, and the outer moving end cooperates with the spiral track and moves along the spiral track; the two ends of the screw feeding mechanism are respectively connected to two centering positioning mechanisms, and the centering positioning mechanism has a positioning end. The screw feeding mechanism is fixed on the outside of the pipeline, and one end of the corresponding screw feeding mechanism is arranged concentrically with the pipeline; the grinding head is connected to the inner moving end for grinding the outside of the pipeline. The driving part of the invention drives the moving part to move along the spiral track. After the grinding head is turned on, the grinding head continuously rubs against the outer wall of the pipeline for grinding, which effectively replaces manual grinding, and has high efficiency and uniform grinding effect.

Owner:湖北特种设备检验检测研究院

Part grinding device for mechanical production and using method thereof

ActiveCN112139872AStrong automationEven sanding effectRevolution surface grinding machinesEngineeringGrinding process

The invention discloses a part grinding device for mechanical production. The part grinding device aims at solving the problem that sleeve type small parts need to be manually clamped and ground, andthe parts are relatively difficult to clamp in the grinding process. According to the scheme, the part grinding device comprises a bottom plate and a mounting frame, wherein a fixing plate is fixedlyconnected to the center of the outer wall of the top of the bottom plate; an electric telescopic rod is fixedly connected to the inner wall of the bottom of the fixing plate; one end of an extension rod of the electric telescopic rod is fixedly connected with a placing table; a tenon is fixedly connected to the center of the outer wall of the top of the placing table; a mortise is formed in the center of the outer wall of the bottom of the mounting frame; the inner wall of the mortise is matched with the outer wall of the tenon; and the mounting frame is inserted into the outer wall of the tenon. According to the part grinding device, a grinding sand disc drives a sleeve part to rotate while grinding the edges and corners of the sleeve part, the outer wall of the rotating sleeve part is incontact with a grinding sand strip for grinding, the overall automation of the device is high, and the grinding effect is uniform.

Owner:武汉市科迈机械制造有限责任公司

A plastic valve port grinding device

ActiveCN106695493BReduce riskAchieve the effect of rotationEdge grinding machinesRevolution surface grinding machinesEngineering

Owner:吴江市强塑阀门管件厂

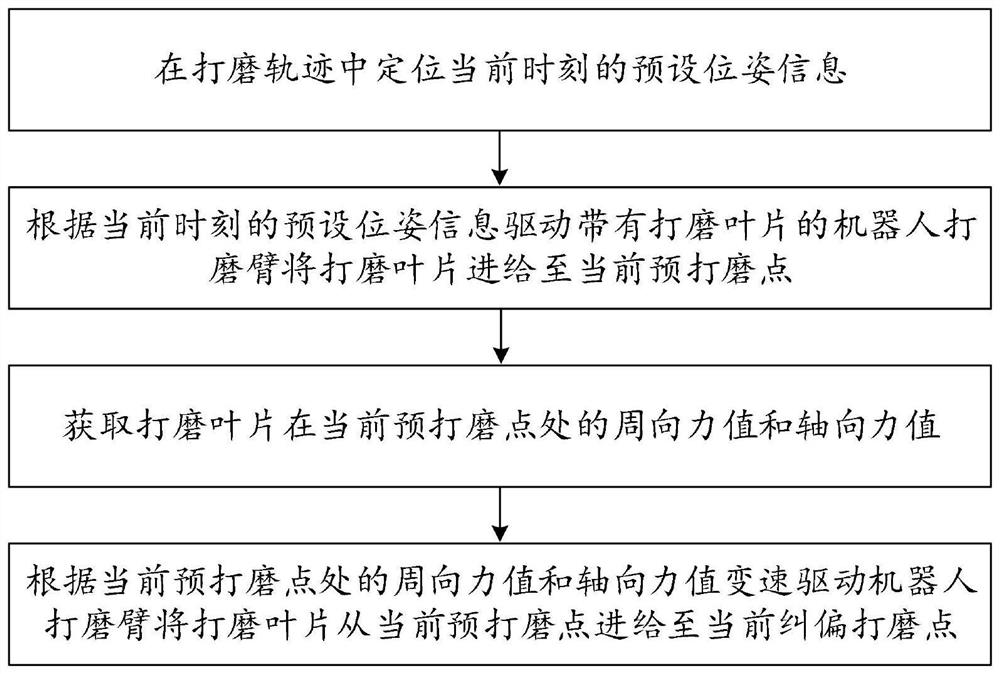

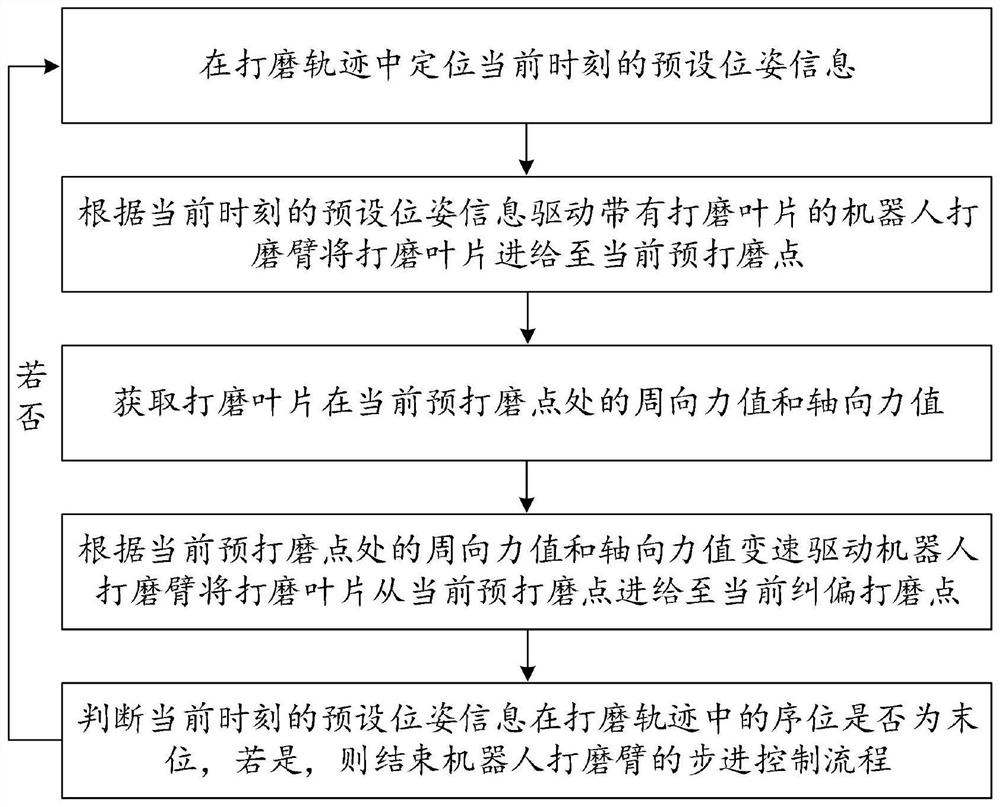

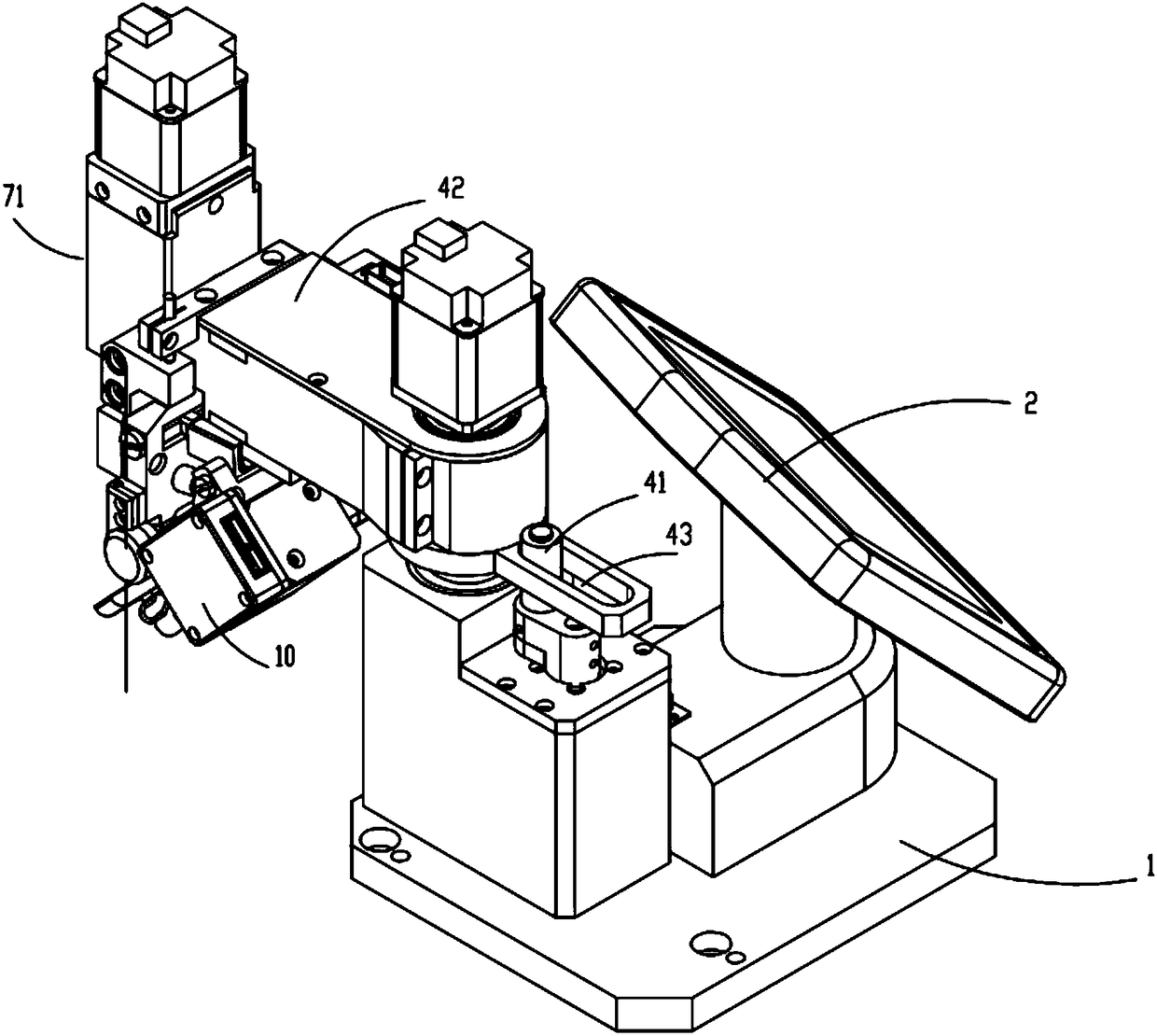

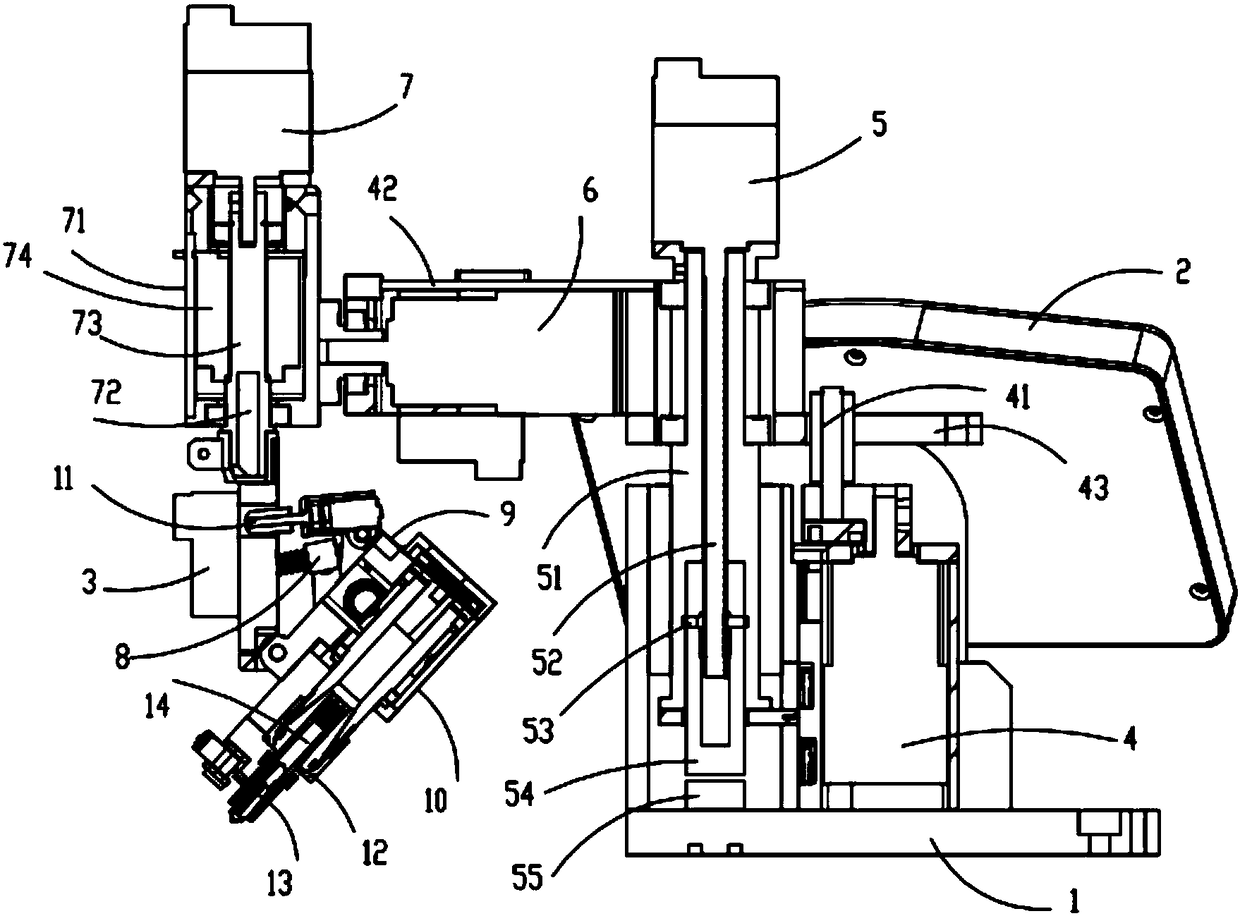

A step control method, device, polishing robot and readable storage medium

ActiveCN110549332BImprove sanding effectEven sanding effectProgramme-controlled manipulatorControl engineeringProcess engineering

The invention relates to the technical field of robot automatic grinding, and provides a robot grinding arm stepping control method and device, a grinding robot and a computer-readable storage medium.The method includes the steps of locating preset pose information at the current moment in a grinding trajectory; driving a robot grinding arm with a grinding blade to feed the grinding blade to a current pre-grinding point according to the preset pose information at the current moment; obtaining the circumferential force value and the axial force value of the grinding blade at the current pre-grinding point; and driving the robot grinding arm at variable speeds according to the circumferential force value and the axial force value to feed the grinding blade from the current pre-grinding point to a current deviation-correcting grinding point. The dynamical feed speed adjusting capacity and the dynamic grinding position deviation correcting capacity of the robot grinding arm in the grinding process can be improved, and the uniform, accurate and efficient grinding ability of the robot grinding arm is better improved.

Owner:武汉库柏特科技有限公司

Omni-directional rotary diamond automatic grinding machine

ActiveCN105798732BEven sanding effectEdge grinding machinesGrinding work supportsElectric machineryControl theory

The invention discloses an automatic polisher capable of rotating diamonds at all-dimensional angles. The automatic polisher comprises a base, a control center arranged on the base, a motor driver connected to the control center, a swing control motor connected to the motor driver, a lift control motor, a grinding head automatic lift control motor, a direction control motor, a grinding head dip angle control motor, a worm drive motor, a swing arm rod, a lift arm connected to the swing arm rod, a swing control rod in pin connection with the swing arm rod, a direction adjusting arm and a grinding head; the grinding head is provided with a diamond angle worm, the motor driver connected to the control center drives the motors to correspondingly act on the swing arm rod, the lift arm, the direction adjusting arm and the diamond angle worm through setting of the control center, and therefore the grinding head clamping the diamonds can rotate at all-dimensional angles, and the uniform grinding effect can be realized.

Owner:周生生钻石(广东)有限公司

Grinding machine for agricultural mechanical parts

InactiveCN108714830ASmooth rotationQuality improvementGrinding machinesGrinding/polishing safety devicesElectric machineryAgricultural engineering

The invention discloses a grinding machine for agricultural mechanical parts. The grinding machine comprises a workbench, wherein support frames are respectively installed on both sides of the top ofthe workbench, one side of one support frame is fixedly connected with one side of the other support frame by virtue of a baffle, telescopic rods are respectively installed on both sides of the bottomof the baffle, a connecting block is installed at the bottoms of the telescopic rods, the bottom of the connecting block is fixedly connected with a support plate, a support seat is installed at thebottom of the support plate, the bottom of the support seat is fixedly connected with a connecting seat, a fastening shaft is fixedly connected to the bottom of the connecting seat, a rotating shaftpenetrates through the bottom of an inner cavity of the fastening shaft, a motor is connected to one end of the rotating shaft in a penetrating mode, an output shaft at the bottom of the motor is fixedly connected with a grinding disc, a positioning plate is installed in the middle of the top of the workbench, a bumper post is fixedly connected to the top of the positioning plate, and the top of the bumper post is fixedly connected with a storage plate. According to the grinding machine, the connecting seat, the fastening shaft and the rotating shaft are used cooperatively, so that the motor and the grinding disc can be conveniently driven to rotate, and the parts can be ground in all directions.

Owner:盱眙新都科技发展有限公司

Rapid deburring device

PendingCN112008533AEven sanding effectGood effectEdge grinding machinesGrinding carriagesElectric machineryGrinding

The invention discloses a rapid deburring device. The rapid deburring device comprises two supporting plates arranged at the discharging end of a material frame through a base, and a removing mechanism is arranged on the inner sides of the supporting plates; the removing mechanism comprises two gear sets arranged on the inner sides of the supporting plates in parallel up and down and a brush arranged between the gear sets, and the opposite gear sets on the two supporting plates are located on the same horizontal plane; each gear set comprise two gears which are horizontally arranged, and beltsare arranged on the two gears in a sleeving mode; a first motor and a second motor are arranged on the outer side of the supporting plates, motor shafts of the first motor and the second motor are connected to the corresponding gears respectively, and the rotating directions of the first motor and the second motor are opposite; and a guide rail penetrating through the supporting plates is arranged on the base. According to the rapid deburring device, the motors drive the belts to rotate for conveying, burrs at the end of a circular pipe are removed through the brush, the circumferential grinding effect is uniform, the deburring effect is good, and the product quality is guaranteed.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com