Package fabric-feed prewetting and drying roughening machine

A sanding machine and pre-wetting technology, applied in textile processing machine accessories, liquid/gas/vapor removal with squeeze rollers, treatment of textile material carriers, etc. Inconsistent hair effect, affecting the sanding effect, etc., to achieve uniform sanding effect, reduce consumption, and prevent raw grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

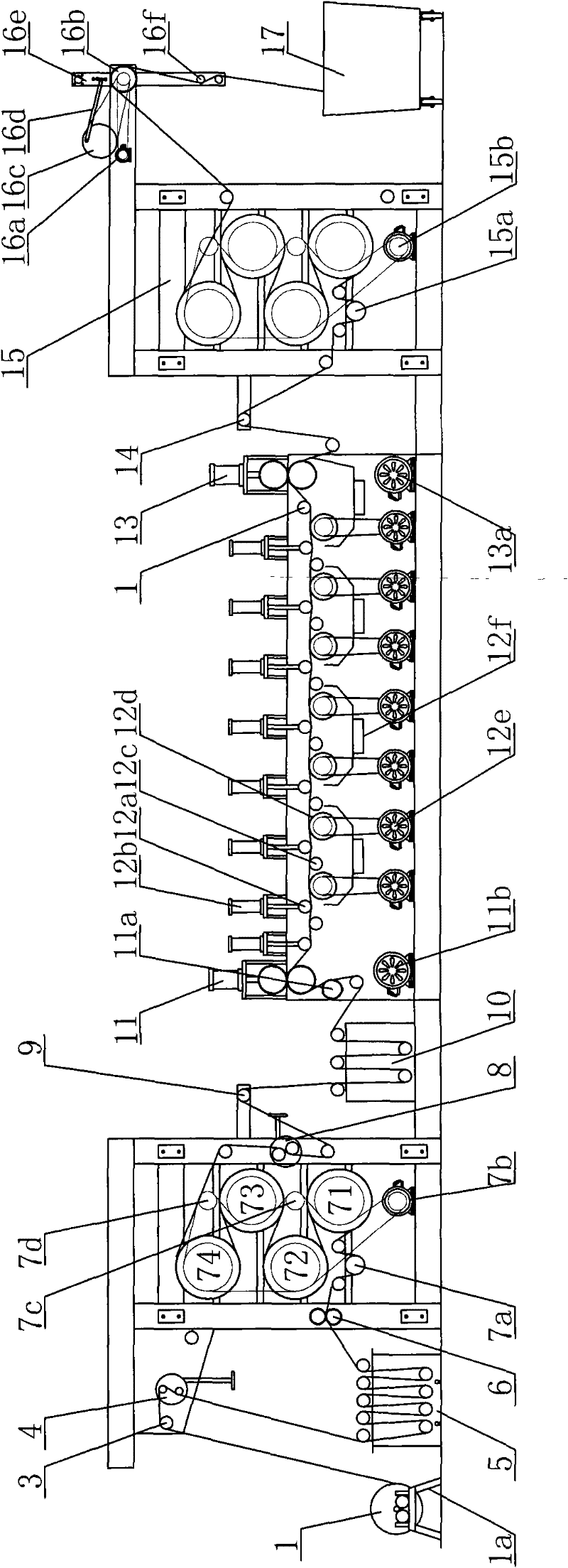

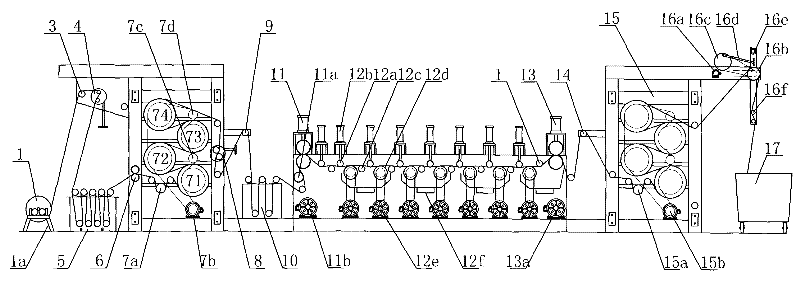

[0011] Such as figure 1 As shown, the pre-wet drying and sanding machine of the present invention includes a frame, a cloth feeding mechanism, a hot water tank 5, a roll 6, a front drying 7, a tension regulator 8, a front tension swing rod 9, and a cold water tank 10. The front rolling car 11, the sanding area 12 and the cloth outlet and control mechanism 16.

[0012] The sanding area 12 is provided with multiple groups of sanding rollers 12d, the bottom of the sanding rollers 12d is provided with a dust cover 12f, and the top is provided with a spray device; the front of the sanding area 12 is provided with a front rolling car 11, and the front rolling car motor 11b Drive: After the roughening area 12, there is a rear rolling car 13, which is driven by the rear rolling car motor 13a. The sides of each group of sanding rollers 12d are equipped with supporting rollers 12c and pressing rollers 12a. Adjusting the height of the supporting rollers 12c can control the contact angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com