Constant tension control device based on time calculation rolling diameter

A control device and time calculation technology, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem that the speed cannot be increased automatically, the wire rope is twisted unevenly, and it is not enough to ensure the constant pay-off speed and constant tension pay-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

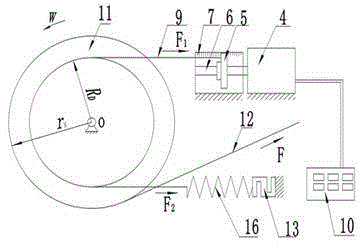

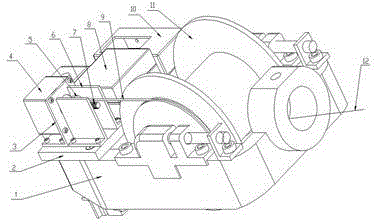

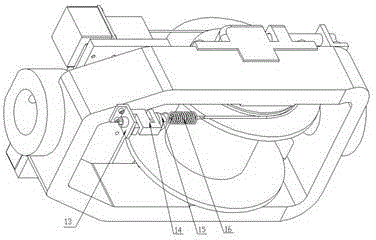

[0017] The present invention is realized by following measures, and its method is, set up the winding model of steel wire 12 on the I-shape wheel 11, calculate the size of real-time volume diameter value with the method based on time in the unwinding process, then, the volume diameter of calculation The value is put into the control program, and a control signal is sent to control the rotation direction and step distance of the screw stepper motor 4, thereby adjusting the tightness of the damping rope 9 to achieve constant tension control.

[0018] Specifically, the implementation process of each step includes the following:

[0019] 1. Determine the winding model of the steel wire 12

[0020] The steel wire 12 is wound on the I-shaped wheel 11 and adopts a wire arrangement mechanism. The function of the wire arrangement mechanism is to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com