A simple deburring platform

A deburring and platform technology, applied in the direction of large-scale fixed members, filing/filing devices, manufacturing tools, etc., can solve the problems of increased fatigue strength of operators, long logistics distance, and quality decline, and achieve simple structure and smooth grinding High efficiency and uniform grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

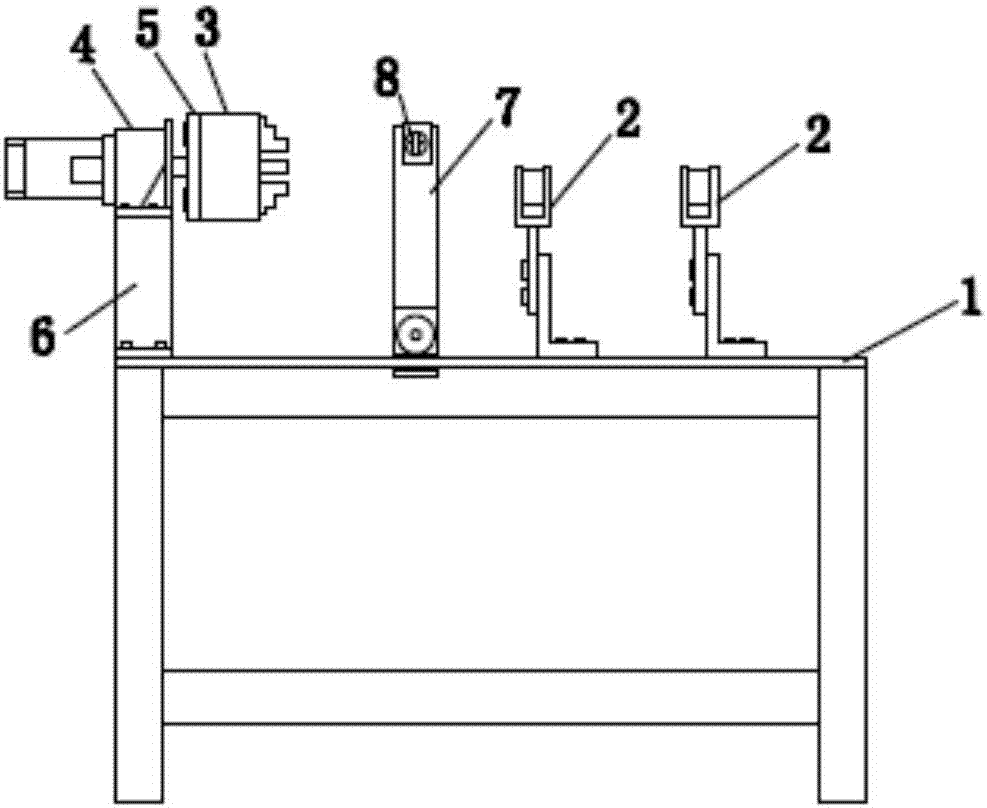

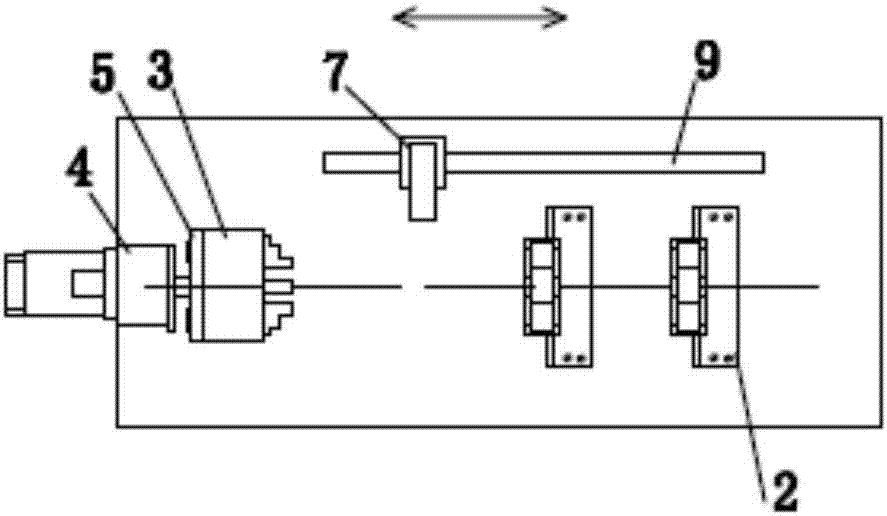

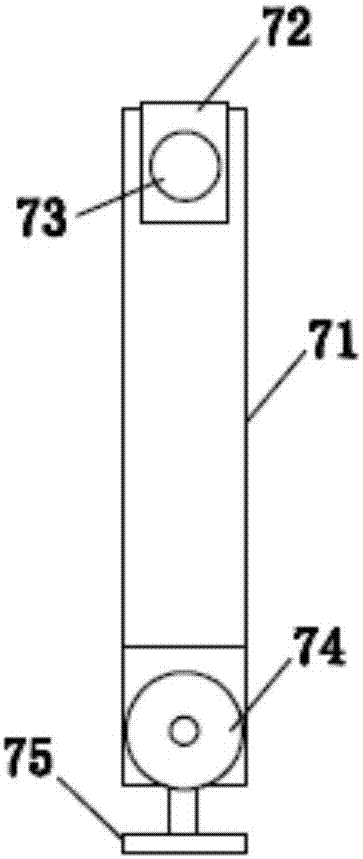

[0035] The specific embodiment of the present invention is as figure 1 and figure 2 As shown, a simple deburring platform includes a platform 1 and two roller support frames 2 arranged side by side installed on it, and each of the roller support frames 2 is provided with a joint for supporting the camshaft, and the shaft To the two rollers 22 parallel to the axial direction of the camshaft. One side of the platform 1 is provided with a chuck rotation mechanism for fixing one end of the camshaft. The chuck rotation mechanism includes a padding frame 6 vertically arranged on the platform 1, a chuck 3 mounted on the top of the padding frame 6, and a motor 4 for driving the chuck 3 to rotate. In this embodiment, the chuck 3 is a three-jaw chuck, the motor 4 is a geared motor, and the chuck 3 and the motor 4 are connected through a flange 5 . The platform 1 is also provided with a file mounting seat 7 for installing a file and adjusting the grinding pressure of the file. A posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com