Pneumatic scraper mechanism capable of automatically regulating degree of parallelism between milling roll bus and scraper blade surface

A technology of parallelism and self-adjustment, applied in the field of flaking machine machinery, can solve the problems of inconsistent wear degree, unclean scraping of green flakes, affecting the quality of green flakes, etc., and achieve the effect of constant contact force, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

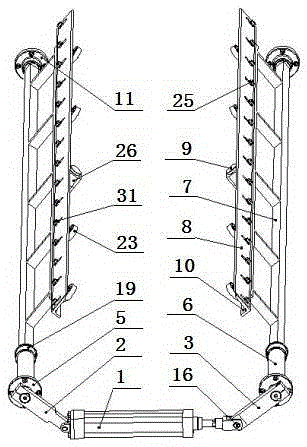

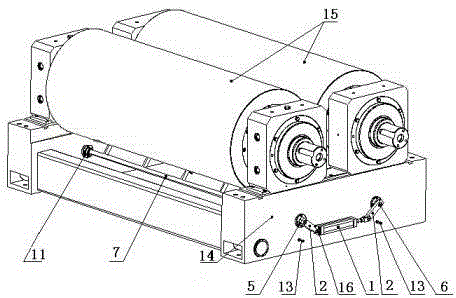

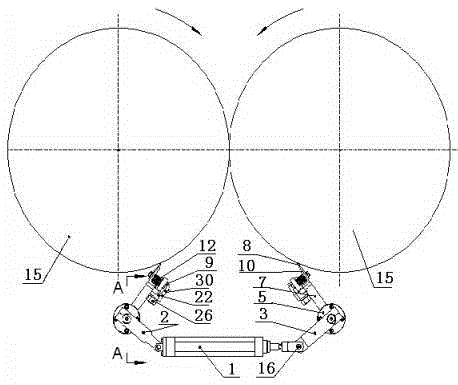

[0016] Specific embodiments of the present invention, such as Figure 1-4 As shown, a pneumatic scraper mechanism that self-adjusts the parallelism with the roll generatrix is characterized in that it has a double-acting cylinder 1, and the front rocker arm 2 and the rear rocker arm 3 arranged on both sides of the cylinder 1 pass through the gland 5 And gland screw 17, support seat 11 and support shaft sliding bearing 28 and support seat screw 29, transmission shaft 6 and transmission shaft sliding bearing 19 are provided with the scraper device installed, meanwhile, set and install scraper guide on the scraper seat 10 of scraper device mechanism, wherein the transmission shaft 6 is hinged to the rolling mill base 14 through the transmission shaft sliding bearing 19, the outer ends of the transmission shaft 6 are respectively connected to the front rocker arm 2 and the rear rocker arm 3 through keys 18, and the front rocker arm 2 and the rear rocker The arm 3 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com