A large-scale plastic extrusion granulation unit underwater pelletizing system

A technology of extrusion granulation and underwater granulation, which is applied in the field of underwater granulation system of large-scale plastic extrusion granulation units, can solve the problems of continuous operation of the production line, material loss, etc., to avoid knife breakage accidents, prolong service life, Avoid the effect of tangled knives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

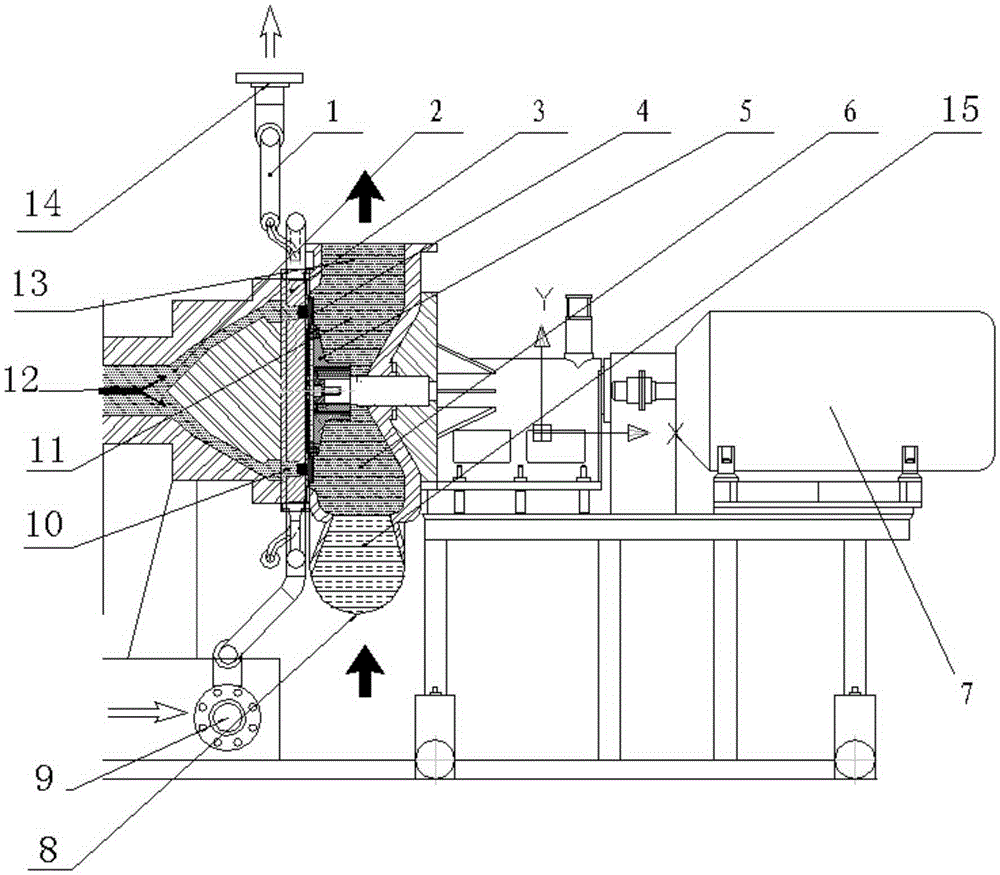

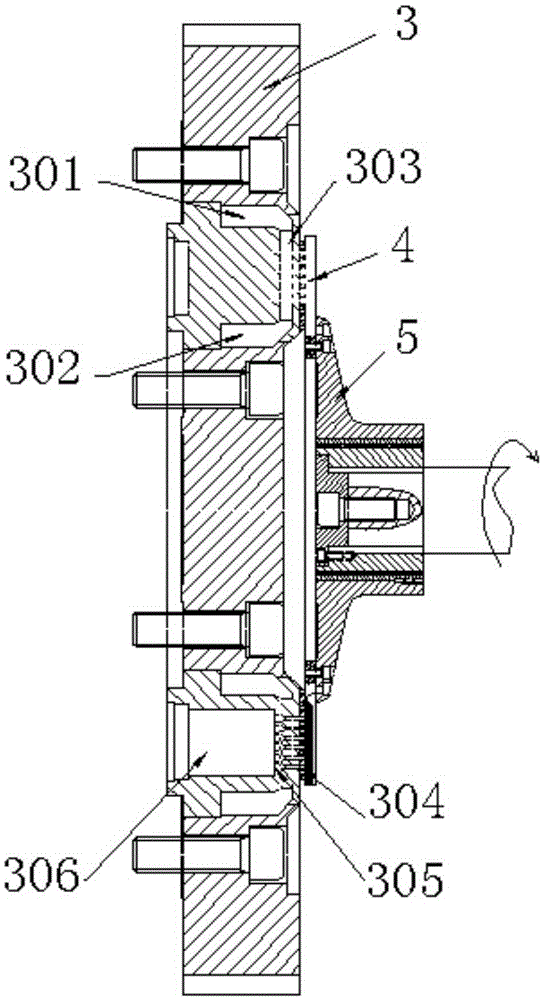

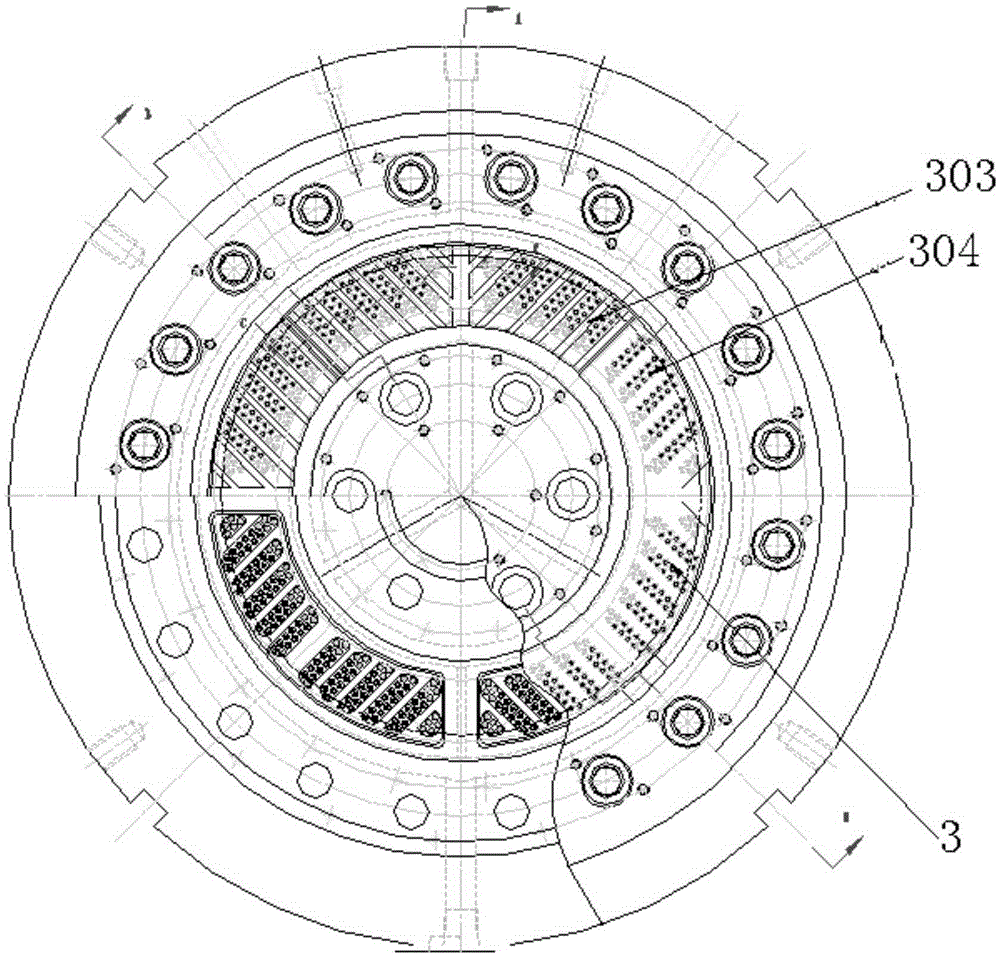

[0034] This embodiment provides an underwater pelletizing system for a large-scale plastic extrusion and granulation unit, which is characterized in that: the underwater pelletization system for a large-scale plastic extrusion and granulation unit includes a pipeline 1, a molten polymer inlet 2, a cermet Composite granulation template 3, cermet composite pelletizing knife 4, follow-up flexible cutter head 5, polymer particle and cooling water mixing tank 6, motor 7;

[0035] Wherein: the metal-ceramic composite granulation template 3 is installed at the rectifying cone box at the incoming material end of the granulation unit, the heating system is connected to the hot channel interface of the metal-ceramic composite granulation template 3 through the pipeline 1, and the metal-ceramic composite granulation The knife 4 is installed on the follow-up flexible cutter head 5 with follow-up flexible performance, which can transmit torque and axial force, and the follow-up flexible cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com