Force position coupling micro-motion precise polishing device and online force detection and control method

A precision polishing and force position technology, applied in the direction of workpiece feed motion control, adaptive control, general control system, etc., can solve the problem of sharp increase in the contact force between the tool and the workpiece, the inability to perform feedback adjustment, and the difficulty in controlling the surface roughness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

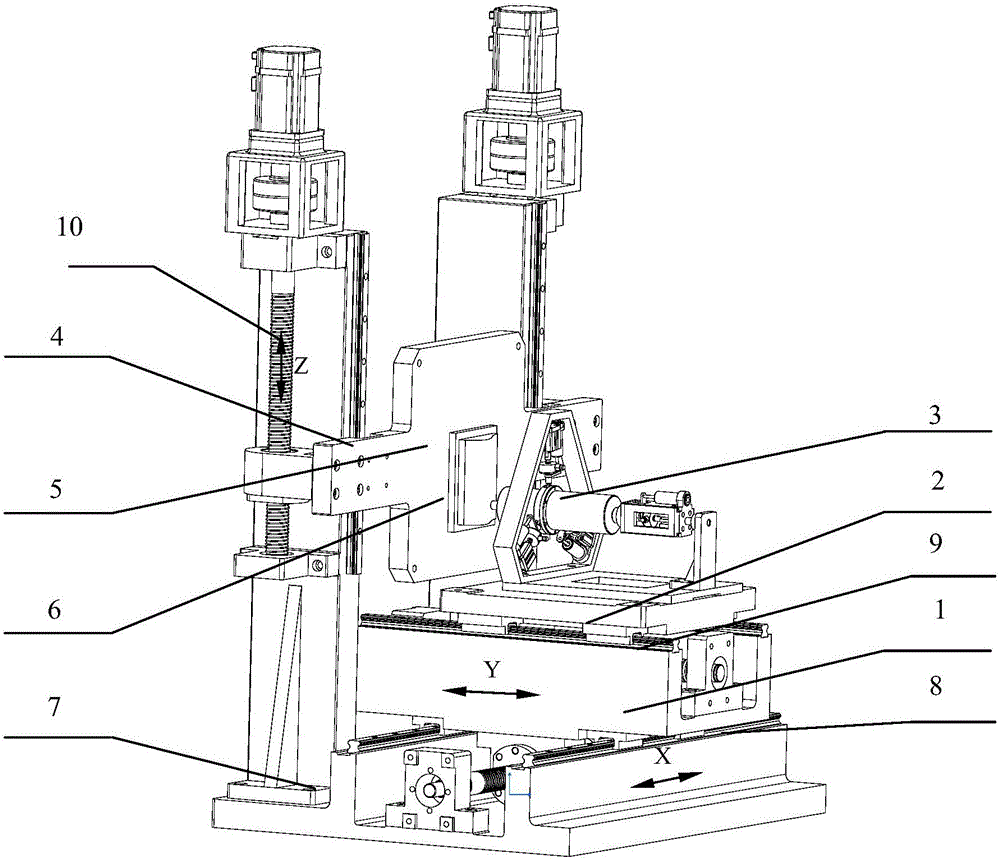

[0074] The X-axis guide rail 8 is fixedly installed on the bed 7, the Y-axis guide rail is installed on the X-axis guide rail upper slide plate 1, the Y-axis guide rail upper slide plate 2 is slidingly connected with the Y-axis guide rail 9, and the micro-movement polishing tool system 3 is installed on the Y-axis guide rail. On the slide plate 2 on the axis guide rail, the Z-axis guide rail 10 is fixedly installed on the bed 7, the Z-axis guide rail slide plate 4 is slidingly connected with the Z-axis guide rail, and the workpiece fixture 5 is fixed on the Z-axis guide rail slide plate 4;

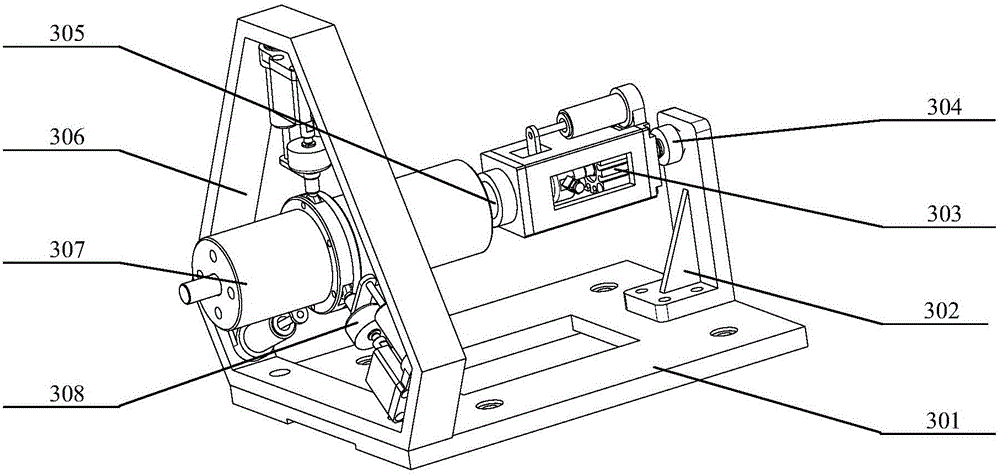

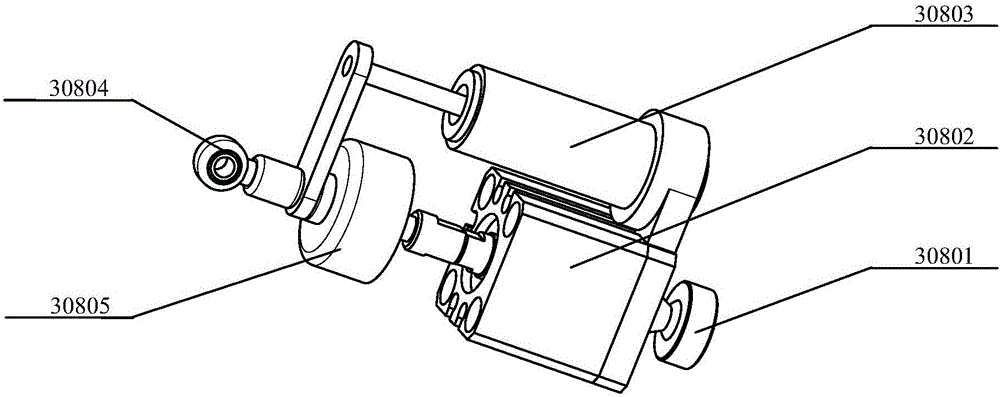

[0075] The fretting polishing tool system 3 is composed of a connecting plate 301, a spindle base 302, an axial force-position coupling unit 303, a cage coupling 304, a ball spline 305, a fixed bracket 306, an electric spindle 307, and three sets of radial The force-position coupling unit 308 is composed of the fixed bracket 306 and the connecting plate 301. The three sets of force-position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com