Two-stage spring type tunnel detecting radar tray device

A detection radar and spring-type technology, which is applied in the field of tunnel radar detection, can solve the problems of being separated from the top lining surface or being hard pressed, labor-intensive, left and right deviation of the detection radar, etc., to achieve accurate and stable detection data, installation and removal. Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

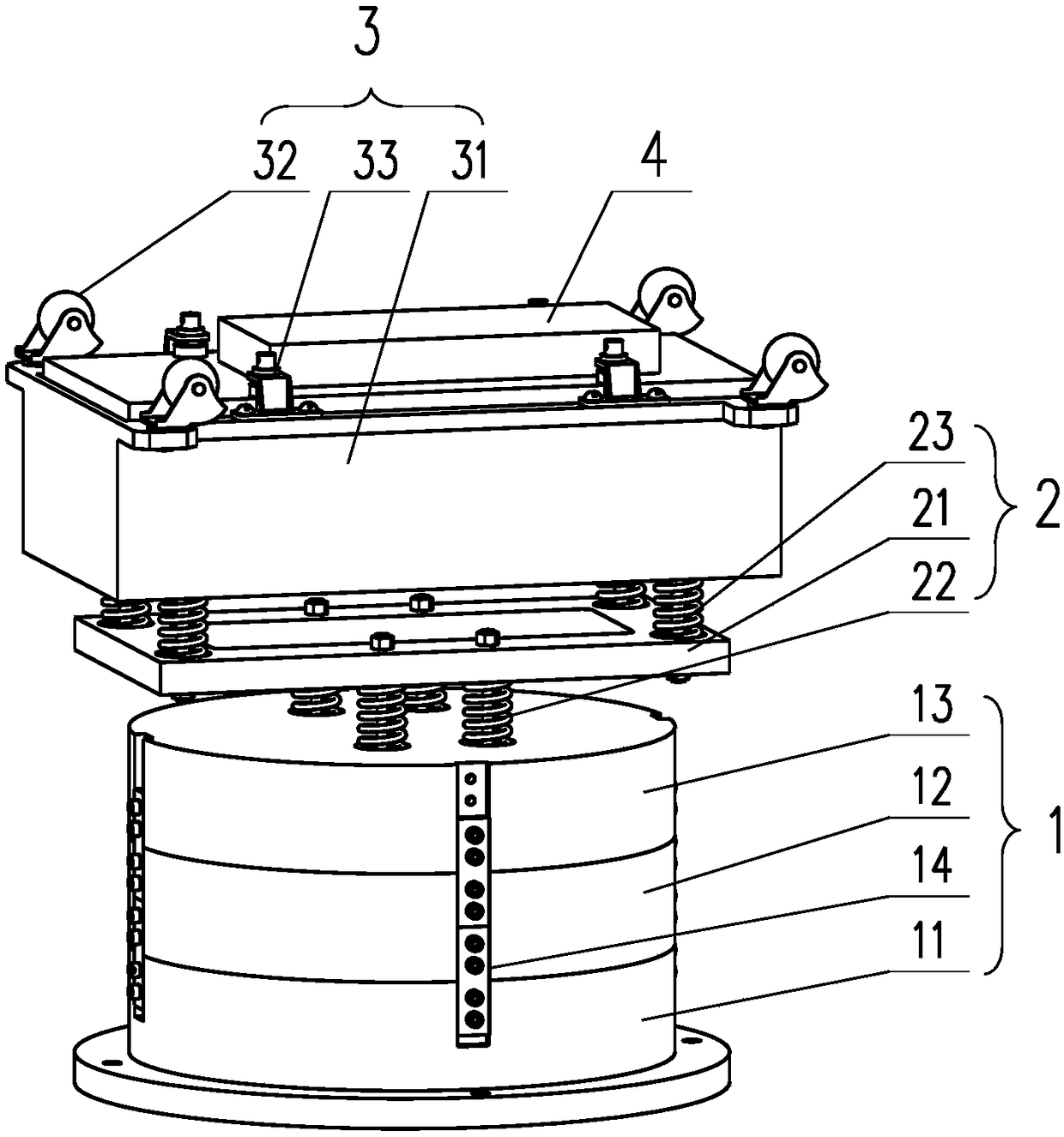

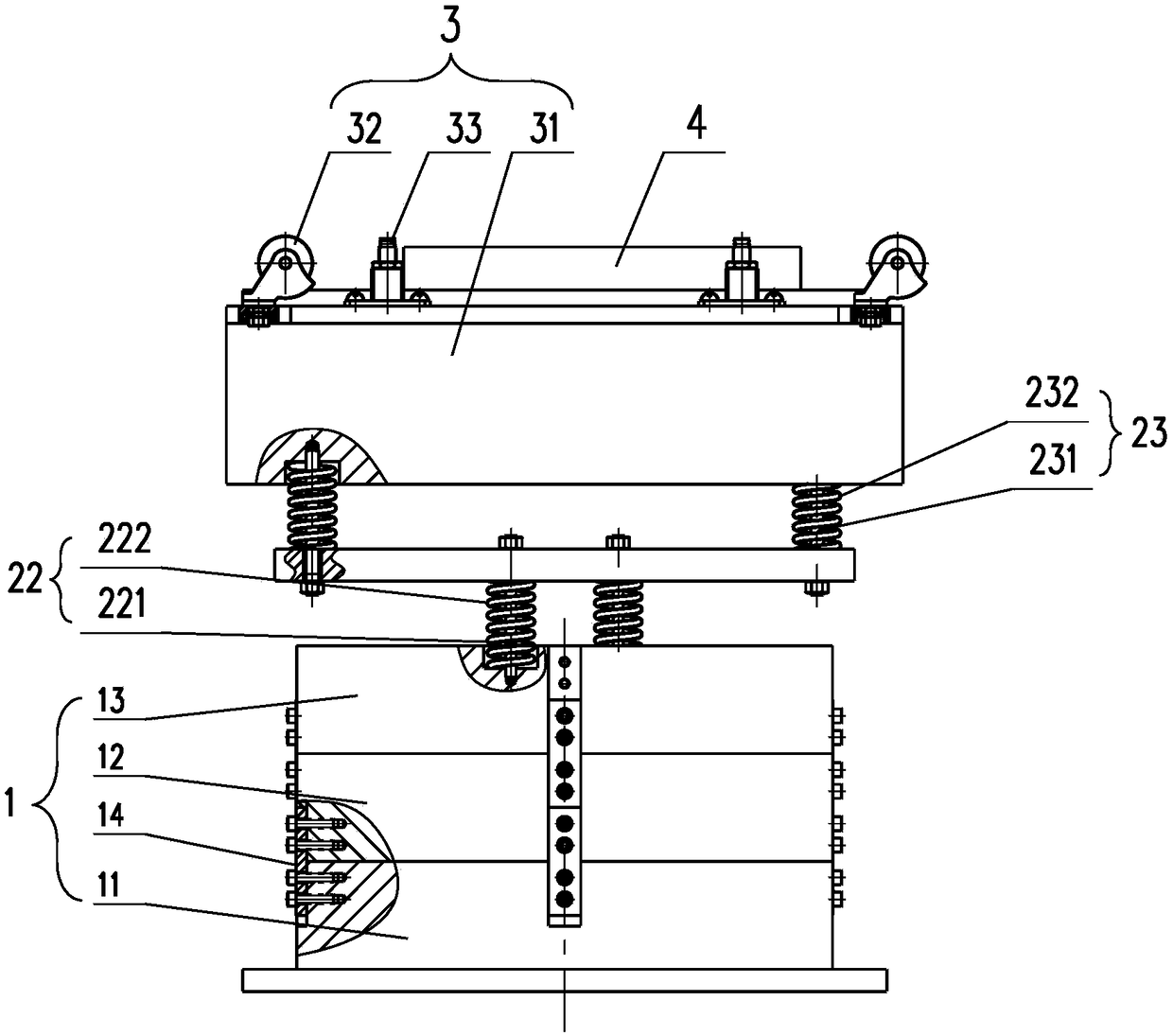

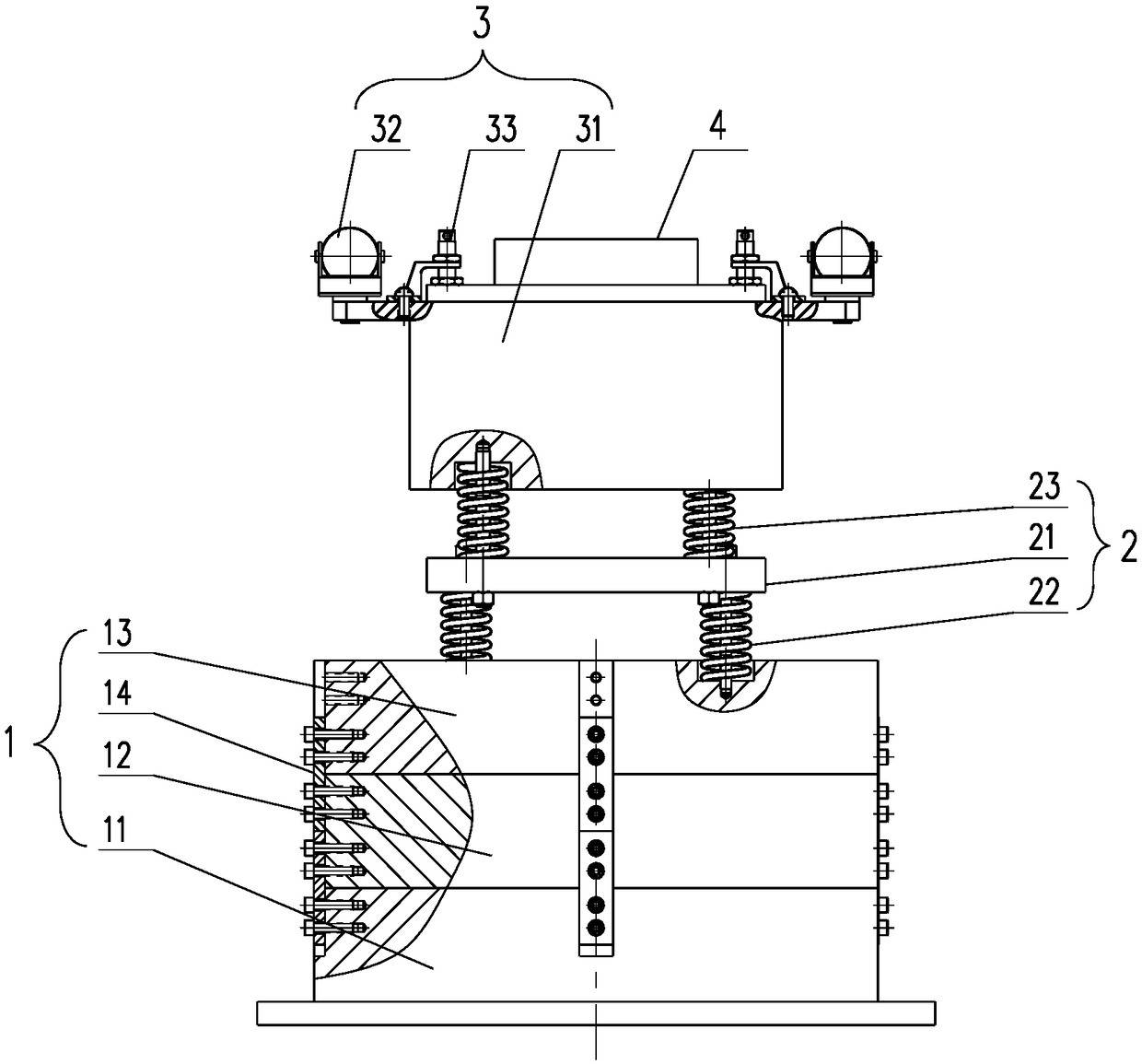

[0021] Such as Figure 1-4 As shown, a dual-stage spring-type tunnel detection radar tray device includes a bottom height adjustment support 1, an elastic self-adaptive mechanism 2, a loading mechanism 3 and a detection radar 4;

[0022] The bottom height-adjusting support 1, the elastic adaptive mechanism 2 and the loading mechanism 3 are arranged in sequence from bottom to top, and the loading mechanism 3 is connected to the bottom height-adjusting support 1 through the elastic adaptive mechanism 2;

[0023] The elastic adaptive mechanism 2 includes a spring transition bracket 21, several hard spring assemblies 22 and several soft spring assemblies 23, and the hard spring assembly 22 includes a hard spring guide rod 221 and is sleeved on the hard spring guide rod 221. The hard spring 222 on the top, the soft spring assembly 23 includes a soft spring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com