Metal surface uniform film-removing device based on self-compensation

A metal surface, self-compensating technology, applied in the direction of grinding drive devices, metal processing equipment, grinding machine tool parts, etc., can solve the problems of high manual adjustment experience requirements, heavy workload of workers, and affecting production efficiency, etc., to achieve Improve production efficiency and economic benefits, simple structure, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

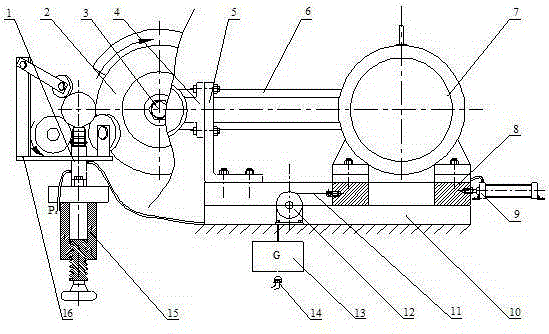

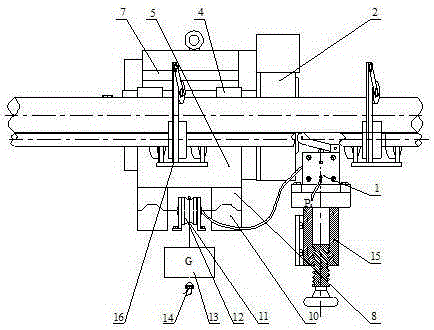

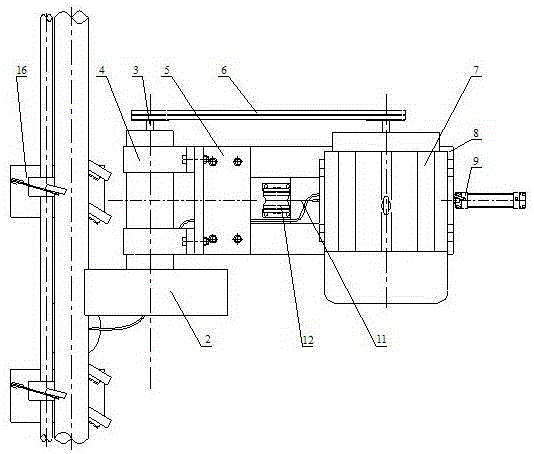

[0037] A device based on self-compensation for uniform film removal on metal surfaces. like figure 1 , figure 2 and image 3 As shown, the device includes stroke valve 1, wire brush 2, transmission shaft 3, belt 6, motor 7, guide rail pair 8, cylinder 9, guide rail 10, steel wire rope 11, fixed pulley 12, weight block 13, alarm switch 14, Height regulator 15 and indicator light 18.

[0038] like figure 1 , figure 2 and image 3 As shown, the guide rail 10 is horizontally fixed on the frame, and the guide rail pair 8 is movably installed on the guide rail 10 . Motor 7 is fixed on the upper plane of guide rail pair 8 right-hand sides, transmission shaft bearing seat 4 is installed on the upper plane of guide rail pair 8 left ends by bearing seat holder 5, and power transmission shaft 3 is installed in the transmission shaft bearing seat 4. Wire brush 2 is installed on one end of transmission shaft 3, and the belt pulley that is installed in transmission shaft 3 other en...

Embodiment 2

[0049] A self-compensation-based uniform film removal device for metal surfaces. Except the following technical parameters, all the other are the same as in Example 1:

[0050] The distance between the initial position of the weight block 13 and the alarm switch 14 is 47-50 mm.

[0051] The included angle between the axis of the fixed wheel 22 and the axis of the driving wheel 23 is 30-45°, and the included angle between the axis of the driven wheel 24 and the axis of the driving wheel 23 is 25-35°.

[0052] The distance between the roller of the stroke valve 1 and the front side of the wire brush 2 is 35-50 mm.

[0053] The cylinder stroke of the cylinder 9 is 70-90 mm.

[0054] The working process of this specific embodiment is: install the rod to be removed on the transmission frame 16, adjust the height adjuster 15 so that the roller of the stroke valve 1 is just pressed down by the rod to be removed, so that the valve core of the stroke valve 1 is pressed down by the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com