Electromagnetic and electric push rod mixed-loading tool rest reliability testbed

An electric push rod and mixed loading technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of tool holder loading and the inability to simulate the working conditions of the tool holder on the inclined bed, etc. Achieve the effects of avoiding difficult adjustment, realizing automatic loading, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing:

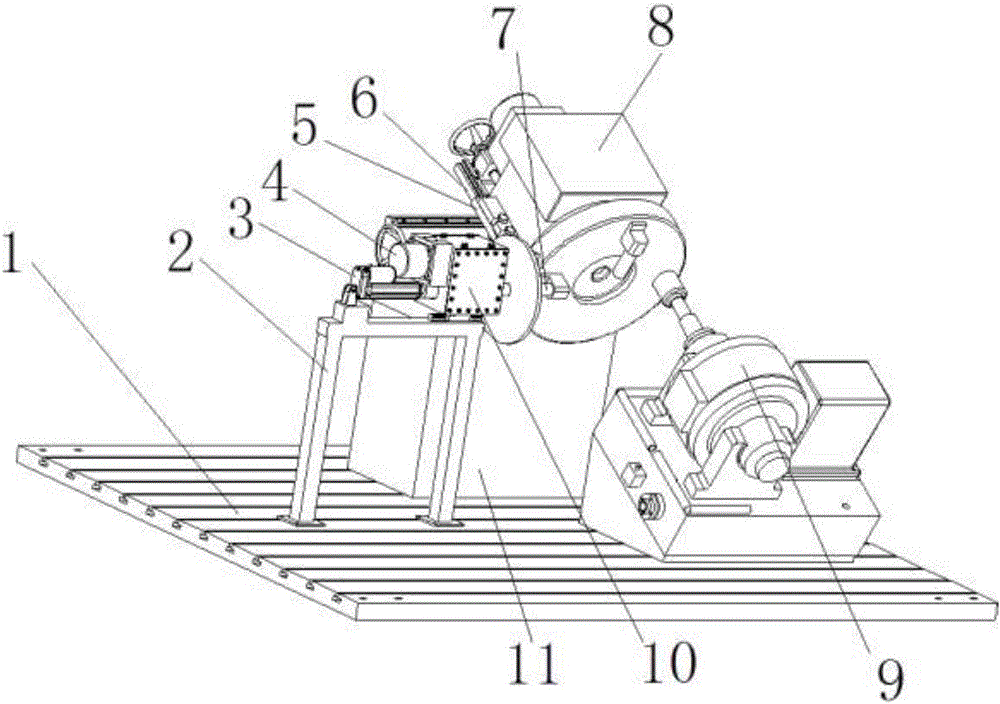

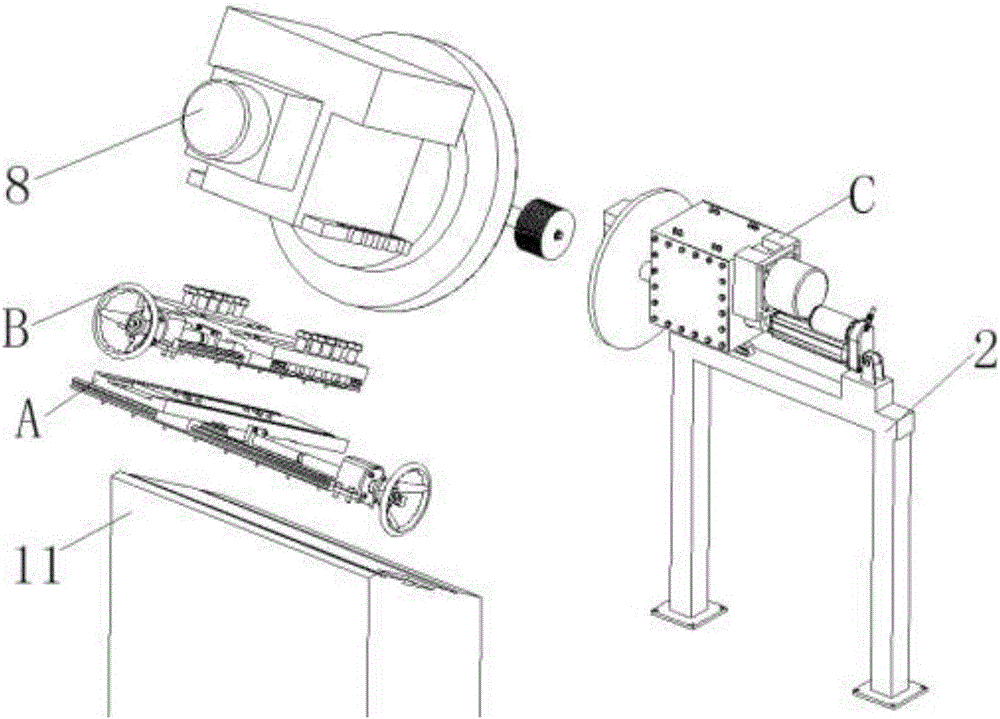

[0050] The electromagnetic and electric push rod hybrid loading tool holder reliability test bench of the present invention is composed of a tool holder supporting part, a cutting force loading part, a tool bar part and a torque loading part.

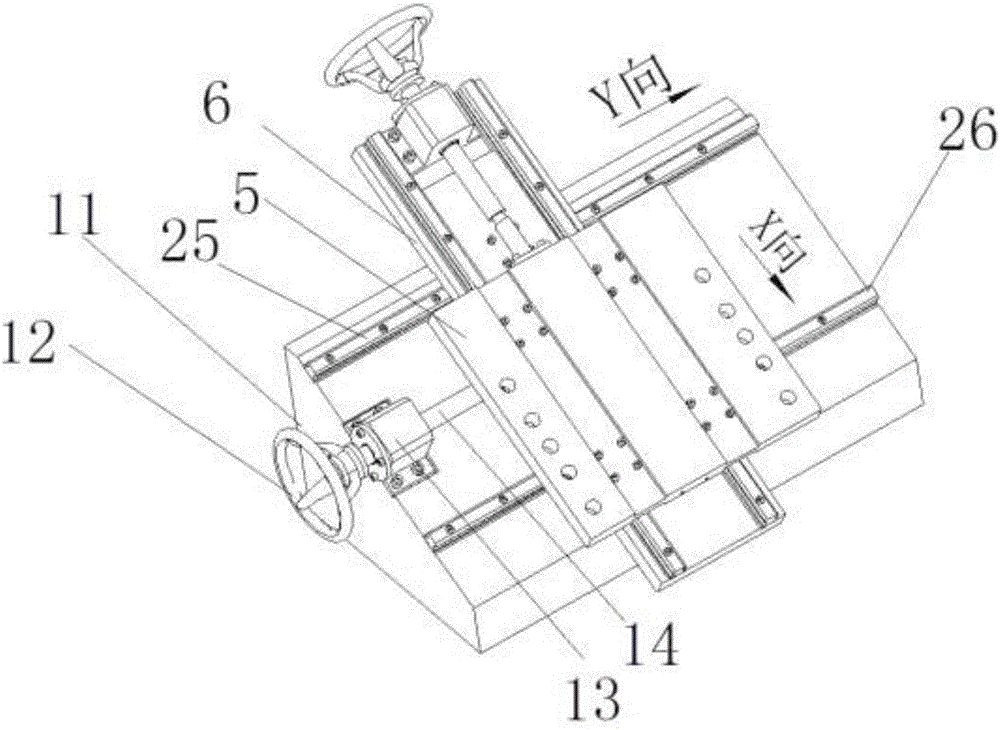

[0051] 1. Tool post support parts

[0052] refer to figure 1 Referring to FIG. 4 , the tool holder supporting component includes a tool holder support seat 11 , an X-direction moving unit, and a Y-direction moving unit. The position of the tool post is changed by the position movement of the X and Y moving units. (in the present invention, the X-direction and Y-direction of the supporting part are referred to figure 2 shown). The upper surface of the tool rest support seat 11 has an included angle with the ground, which can simulate the working conditions of the tool rest of the inclined bed lathe. The X-direction mobile unit and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com