Cleaning device and method for chemical grouting pipeline

A chemical grouting and cleaning device technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of ineffective removal of dirt, unsatisfactory cleaning effect, single cleaning method, etc., to achieve easy replacement, Improved stability and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

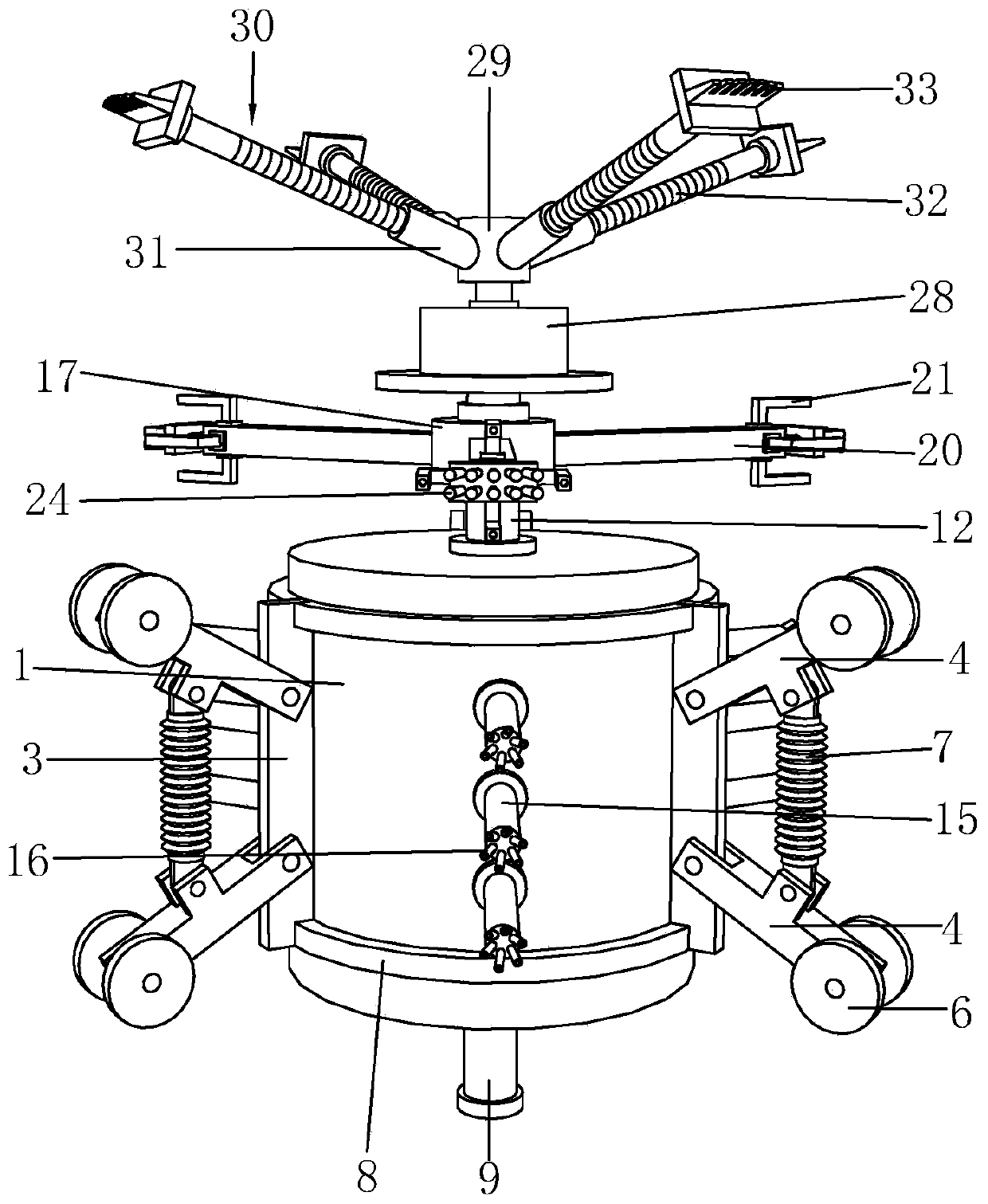

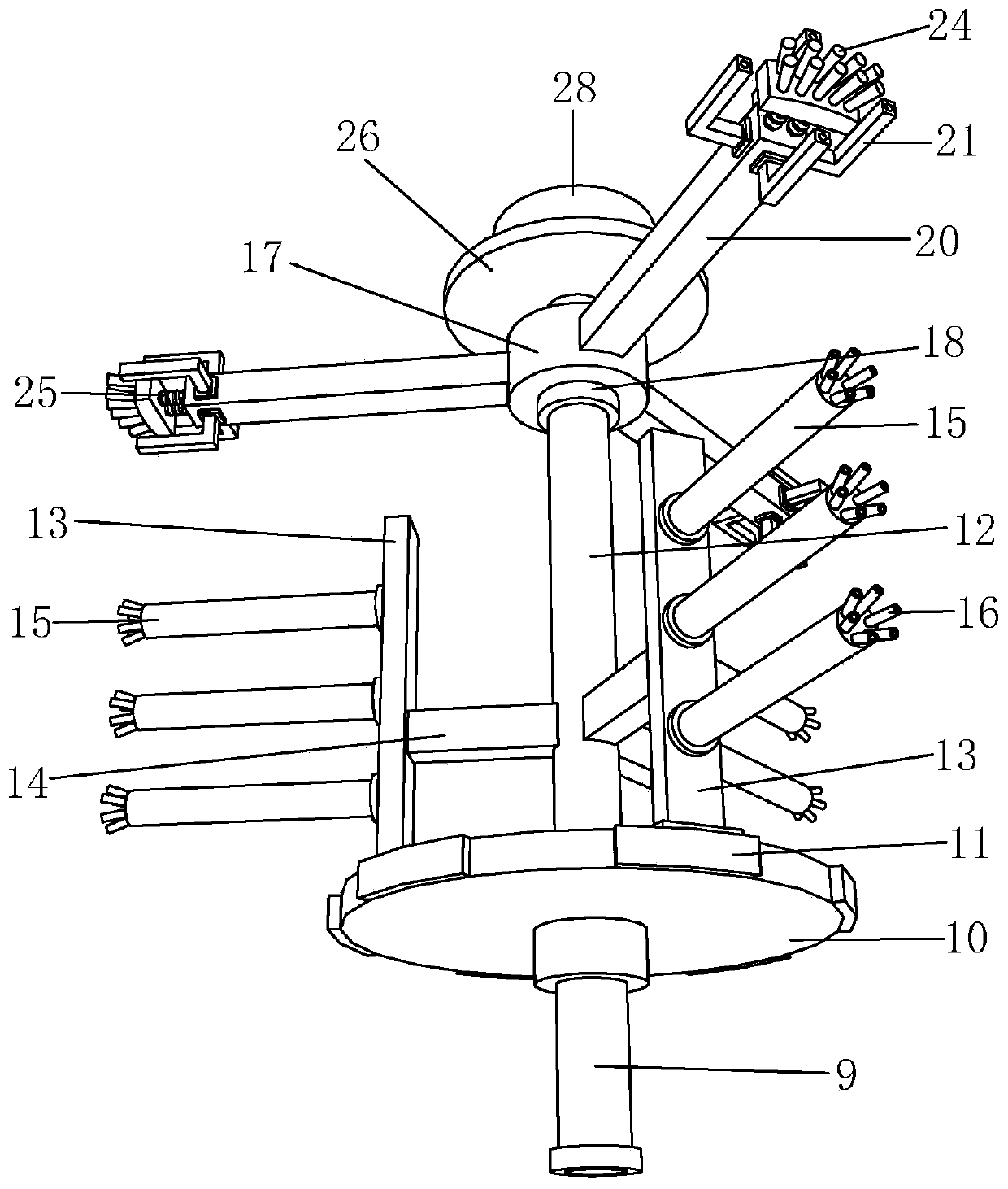

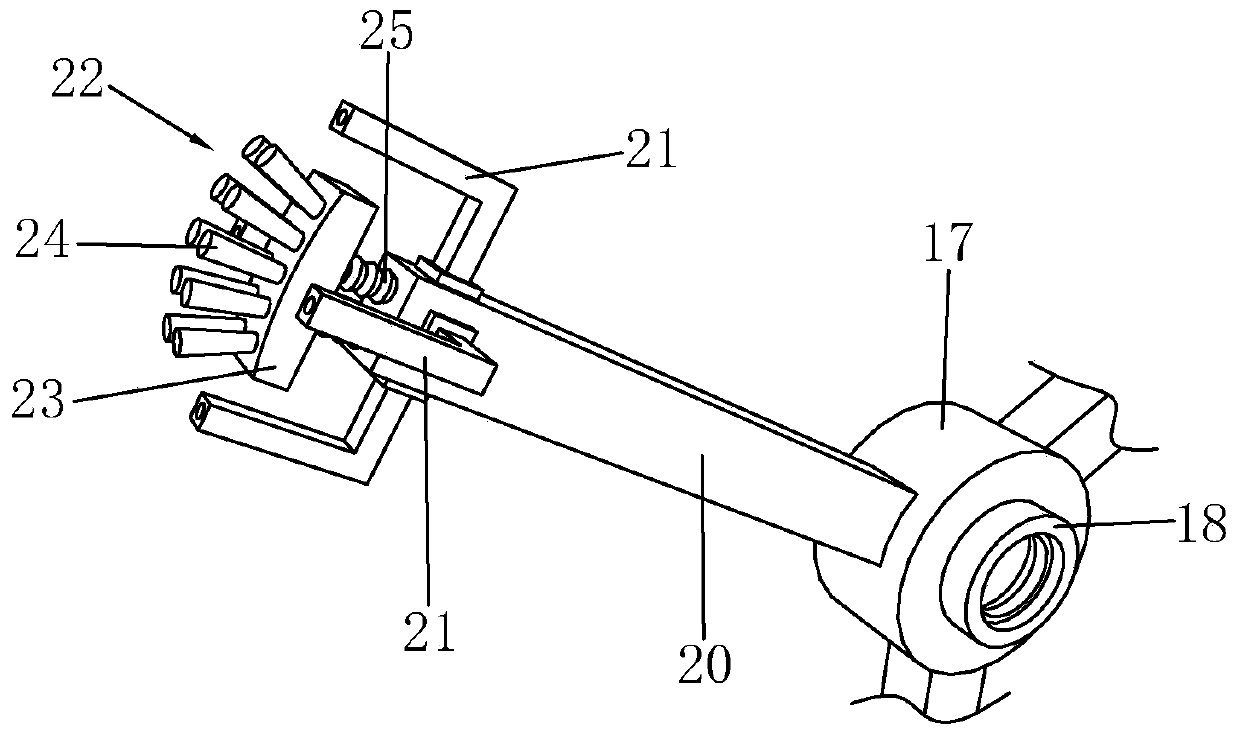

[0044] Such as Figure 1 to Figure 6 As shown, it is a cleaning device for chemical grouting pipelines according to the present invention, which includes a cylinder body 1, a running mechanism 2 is distributed on the outer wall of the cylinder body 1, and the running mechanism 2 includes a mounting seat 3, two mounting shells 4, Servo motor 5, runner 6 and spring pull rod 7, spring pull rod 7 is connected between two mounting shells 4, servo motor 5 is arranged in mounting shell 4, runner 6 is connected to one end of mounting shell 4 in rotation, servo motor 5 The output end of the motor is connected to the runner 6, the mounting seat 3 is arranged on the outer wall of the cylinder 1, the mounting seat 3 is rotated and connected to the mounting shell 4, and the servo motor 5 is controlled by an external controller to start, driving the runner 6 to rotate, so that the whole device moves along the The chemical grouting pipeline is moved to clean different positions of the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com