Sliding type gear shifter

A shifter, sliding technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of high cost, false induction, etc., and achieve low cost, good hand feeling, and reliable guarantee sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific embodiments, but the present invention is not limited to the following specific embodiments.

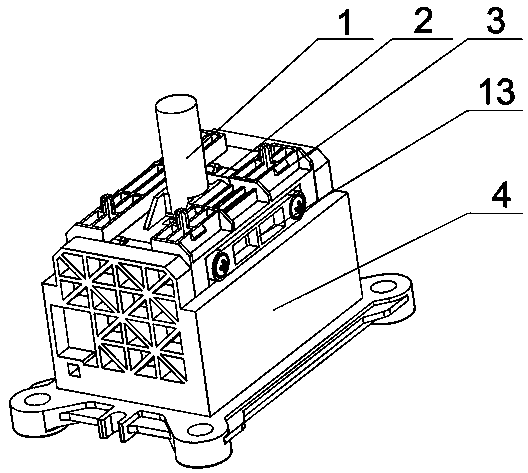

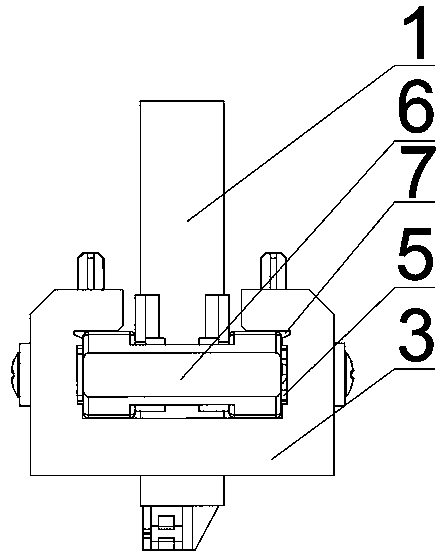

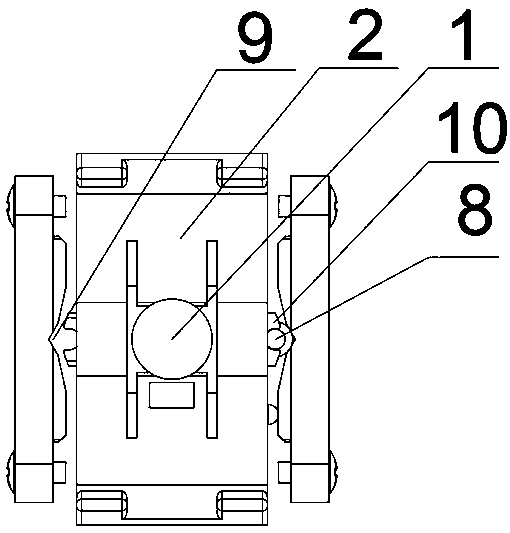

[0029] A sliding shifter, comprising a shift lever 1, a slider 2, a slide seat 3 and a shifter seat 4, the slide seat 3 is fixed on the shifter seat 4, and the shift lever 1 is fixed on On the slider 2, and the slider 3 is provided with a chute 5, the slider 2 is slidingly fitted on the chute 5, the shifter seat 4 is provided with a control circuit board, and the control circuit board is provided with a Hall Inductive element, in this specific embodiment, Hall inductive element is common switch Hall, and cost is relatively low, is provided with magnetic piece at the bottom of shift lever 1, as Figure 6 As shown, it is a comparison diagram of the prior art rotary shifter and the sliding shifter of the present application. It can be clearly seen from the figure that the distance between each Hall sensing ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com