Speed changer and lubricating oil feeding device

A supply device, lubricating oil technology, applied in transmission parts, gear lubrication/cooling, belt/chain/gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

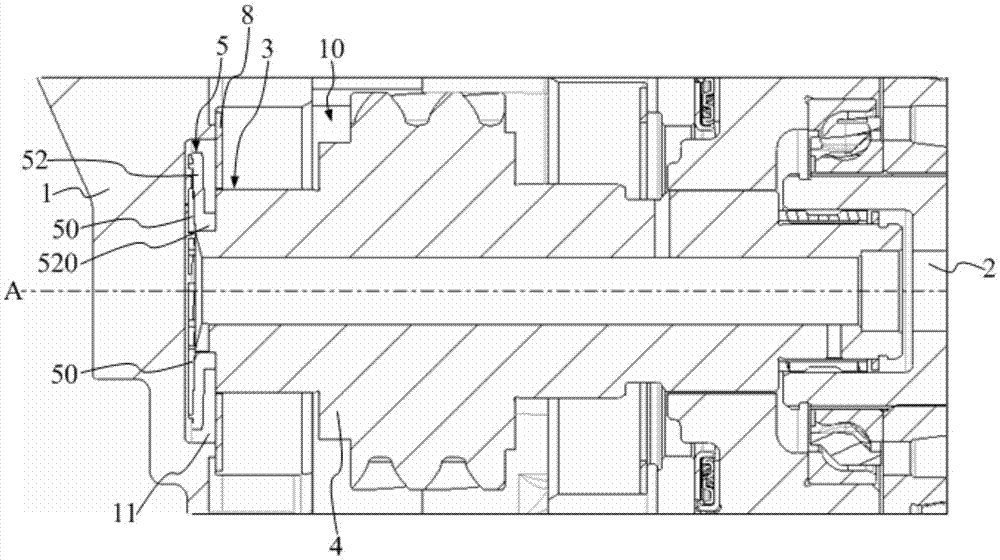

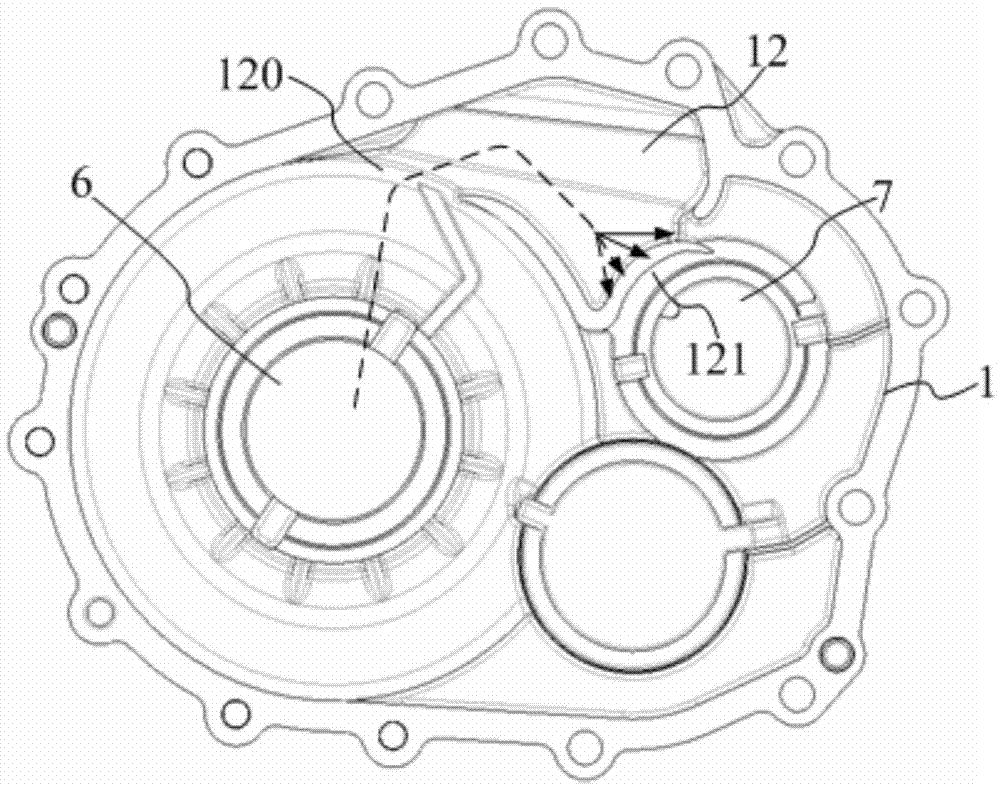

[0031] Reference figure 1 , The transmission includes: a transmission housing 1; an input shaft 2 and an output shaft (not shown in the figure) located in the transmission housing 1, which are arranged side by side; and a lubricating oil supply device 3.

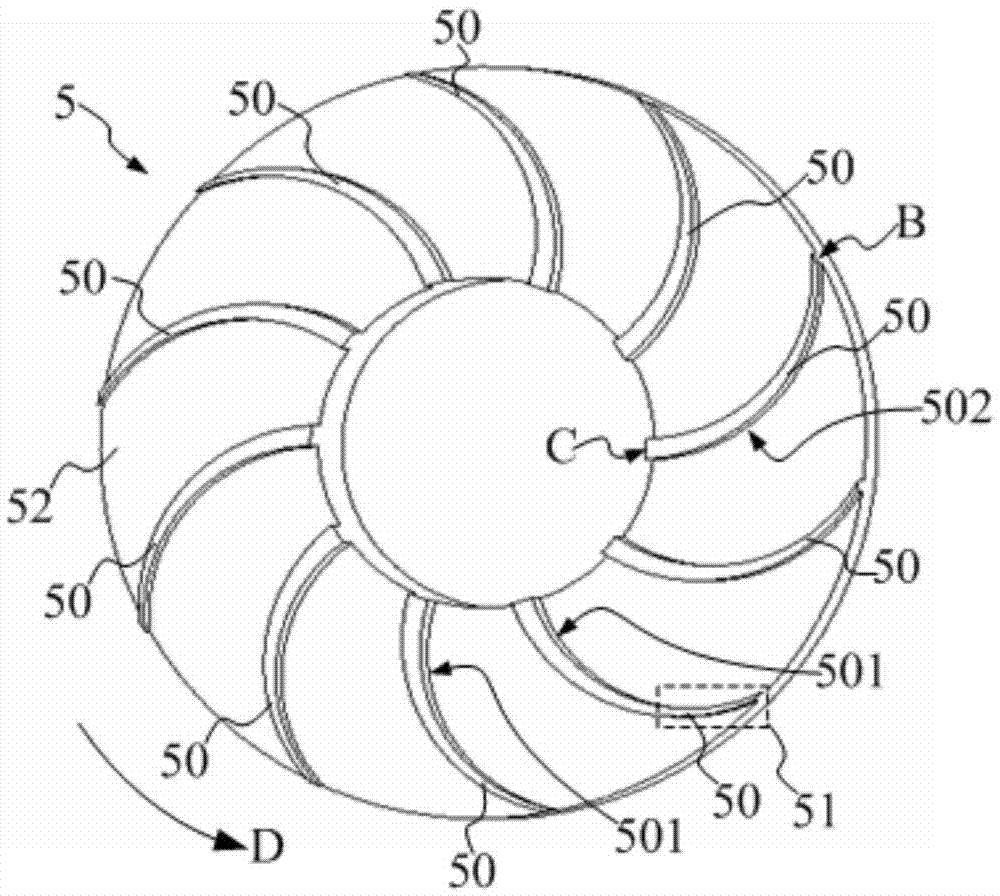

[0032] The lubricating oil supply device includes: a housing with an inner cavity 10, which belongs to a part of the transmission housing 1. The inner wall of the transmission housing 1 is provided with an oil storage chamber 11; a hollow tube 4 is arranged in the inner cavity 10. It is connected to the transmission input shaft 2 and can rotate around its own central axis A under the drive of the transmission input shaft 2; The oil guide member 5 is at least partially located in the oil storage chamber 11 and connected to the hollow tube 4 for rotating around the hollow tube 4 under the drive of the hollow tube 4 to take and guide the lubricating oil in the oil storage chamber 11 to flow into Inside the hollow tube 4.

[0033] T...

no. 2 example

[0056] Compared with the first embodiment, the second embodiment is different in:

[0057] Reference Figure 5 , The blade 50' may have a hollow tube 4 (refer to figure 1 ), the oil guide groove 53 has an oil extraction port 530, and the direction of the oil extraction port 530 is the same as the rotation direction D of the hollow pipe 4. The lubricating oil enters the oil guide groove 53 from the oil extraction port 530 and flows into the hollow pipe 4 along the oil guide groove 53 when the blade 50 ′ rotates around the central axis of the hollow pipe 4. The opening of the oil extraction port 530 is set in the same direction as the rotation direction D of the hollow tube 4, so that the lubricating oil can enter the oil guide groove 53 through the oil extraction port 530 when the blade 50' rotates, and at the same time, when the blade 50' rotates from the lowest position During the rotation at the highest position, the lubricating oil will not leak from the oil guide groove 53. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com