Driving front axle of large-speed ratio mining vehicle

A mining vehicle with high speed ratio technology, which is applied to axles, wheels, brakes, etc., can solve the problems of high wear probability and poor effect, and achieve the effects of reduced processing costs, compact structure, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

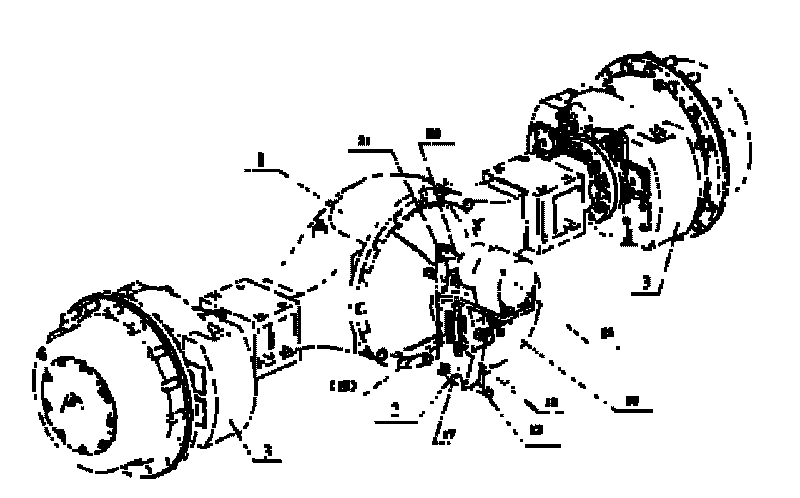

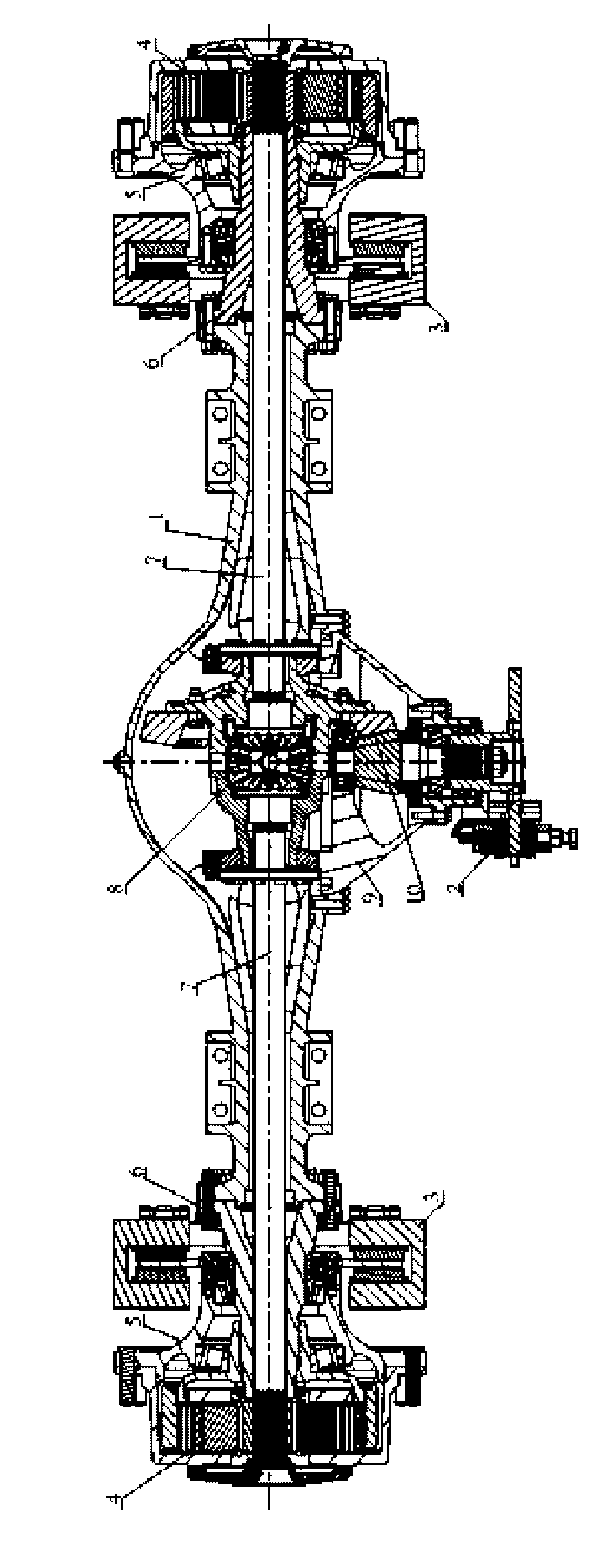

[0022] as attached figure 1 And attached figure 2 Shown: The drive axle assembly is mainly composed of axle housing assembly 1, central disc brake assembly 2, wheel service brake assembly 3, wheel side reducer 4, wheel hub 5, half shaft bushing 6, half shaft 7, The differential gear 8, the final reducer housing 9, the final reducer 10 and its accessories are composed. The axle housing assembly 1 is cast integrally at one time.

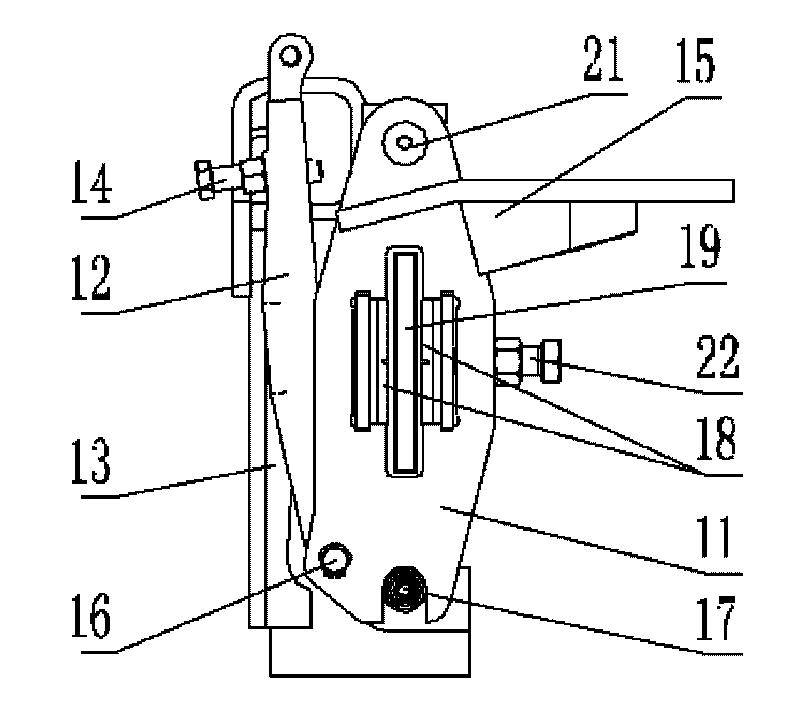

[0023] Such as image 3 , Figure 4 central disc brake shown, and combined figure 1 , due to the limited space of the axle housing assembly, in order to double the brake execution force without changing the size of the brake cylinder, the present invention designs a clamp-type self-energizing mechanism. The principle of the pliers-type self-energizing mechanism is similar to a hand pliers, except that the jaws and the handle are on the same side of the fulcrum. When the brake is released, the external air pressure acts on the vacuum booster cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com