Support frame of automobile forecabin and automobile forecabin applying same

A technology of automobile and left connection, which is applied in the field of automobile front cabin, which can solve the problems of easy resonance, affecting the NVH performance of the whole vehicle, and low modal frequency, and achieve the effect of improving lateral stiffness, improving NVH performance, and being easy to manufacture and realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

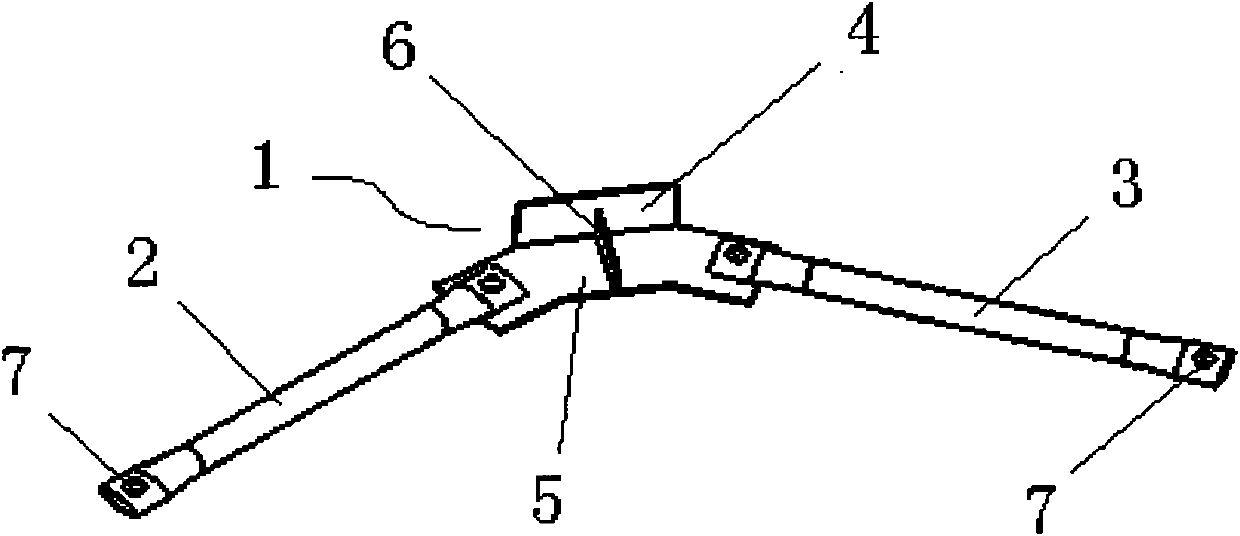

[0022] Such as figure 1 As shown, the car front cabin support of the present embodiment is made up of base 1, left connecting rod 2 and right connecting rod 3, base 1 is made up of base plate 4 and connecting plate 5 vertically fixed on base plate 4, base plate 4 and connecting plate 5 Reinforcement plate 6 is welded between, and reinforcement plate 6 is perpendicular to bottom plate 4, connecting plate 5 respectively; 2. The included angle between the right connecting rod 3 is an obtuse angle; the ends of the left connecting rod 2 and the right connecting rod 3 are provided with bolt holes 7 .

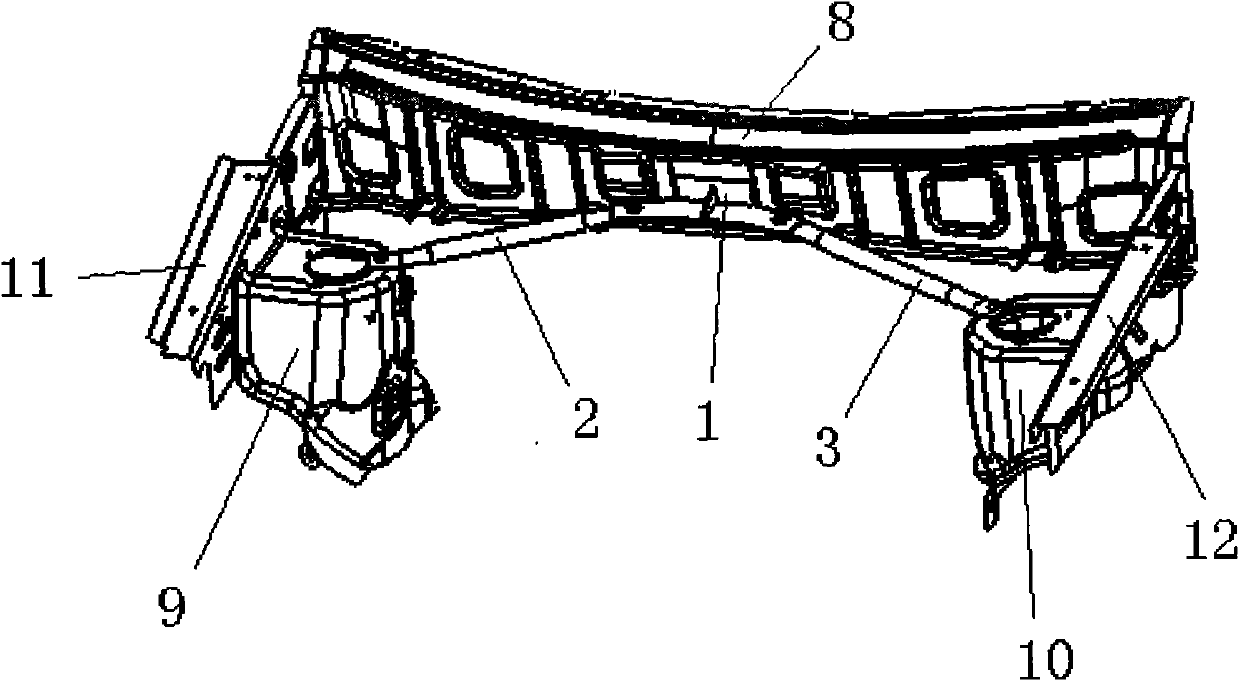

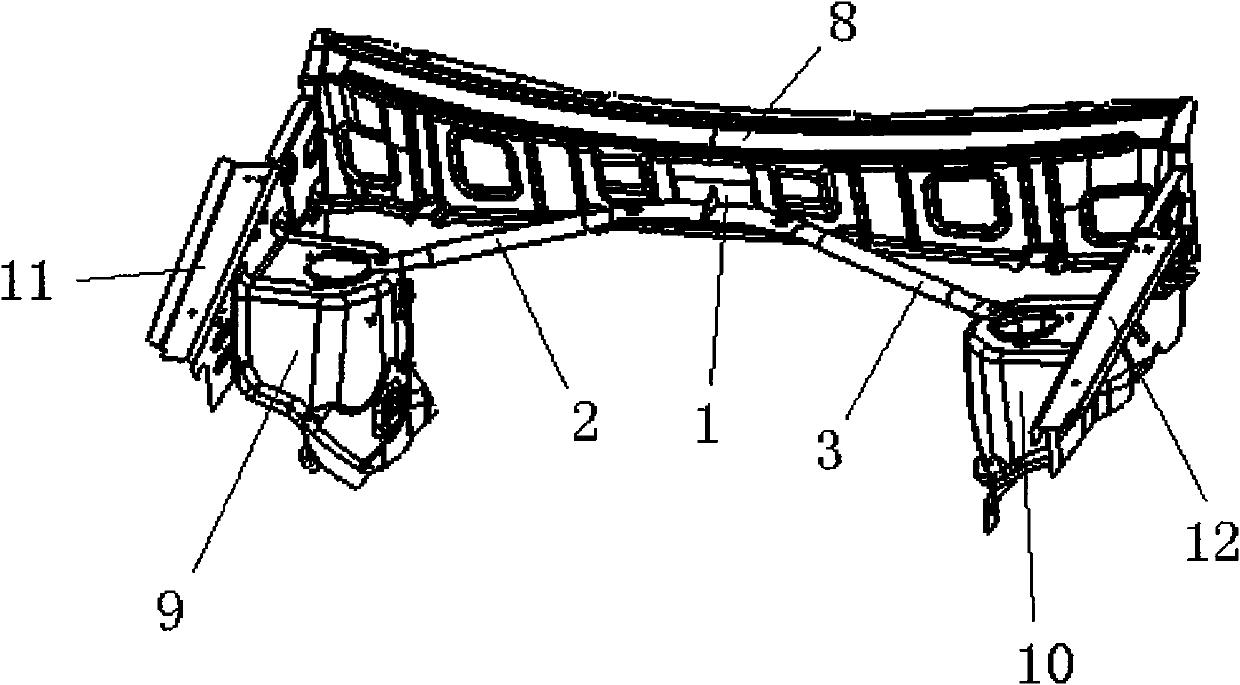

[0023] Such as figure 2 Shown, the structure of the automobile front compartment of the above-mentioned automobile front compartment support of the present embodiment is as follows: the base 1 of the front compartment support is welded and fixed on the front fender 8 of the automobile front compartment, and the left connecting rod 2 and the shock absorber on the left side of the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com