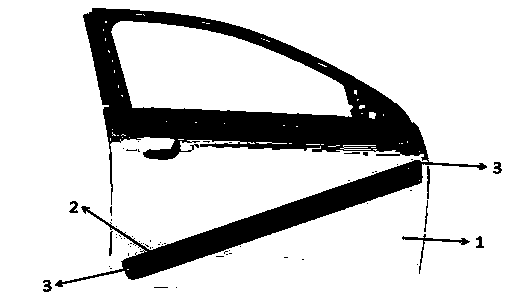

Preparation method of resin fiber composite material vehicle door anti-collision component and method for connecting resin fiber composite material vehicle door anti-collision component with vehicle door

A composite material and resin fiber technology, which is applied in the field of auto parts manufacturing, can solve problems such as poor connection strength between anti-collision components and inner door panels, inability to meet the high temperature baking of car body coating, and poor high temperature resistance of carbon fiber materials, etc., to achieve Promotes a wide range of applications, high joint fastening strength, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

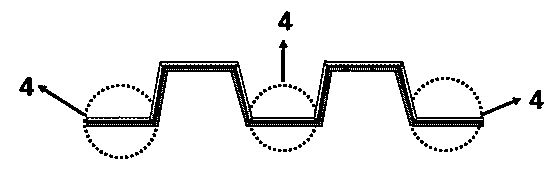

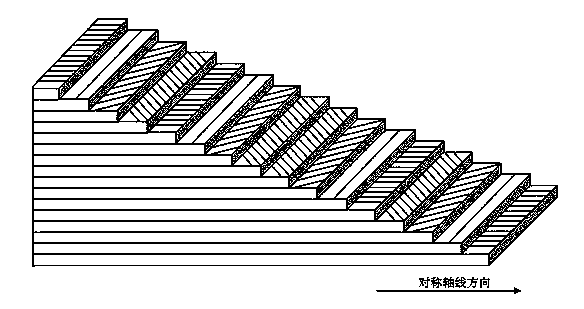

[0047]In this embodiment, polyphenylene sulfide (PPS) is used as thermoplastic resin, and unidirectional fabric is used as carbon fiber fabric to prepare a resin fiber composite door anti-collision component, including the following steps:

[0048] (1) Treat the PPS resin and the unidirectional fabric with the yarn manager to keep its orientation consistent. The PPS resin is a continuous fibrous resin, and then the unidirectional prepreg sheet is prepared by the melt impregnation method. Specifically, the PPS resin and The unidirectional fabric passes through the heating roller together (the temperature of the heating roller is kept at 320°C), so that the PPS resin is heated and becomes molten and impregnated on the unidirectional fabric, and then kept air-cooled on the production line to obtain the PPS / unidirectional fabric unidirectional prepreg. Impregnate the sheet, and use cutting equipment to cut the PPS / unidirectional fabric unidirectional prepreg sheet into appropriate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com