Patents

Literature

54results about How to "Limited throughput" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

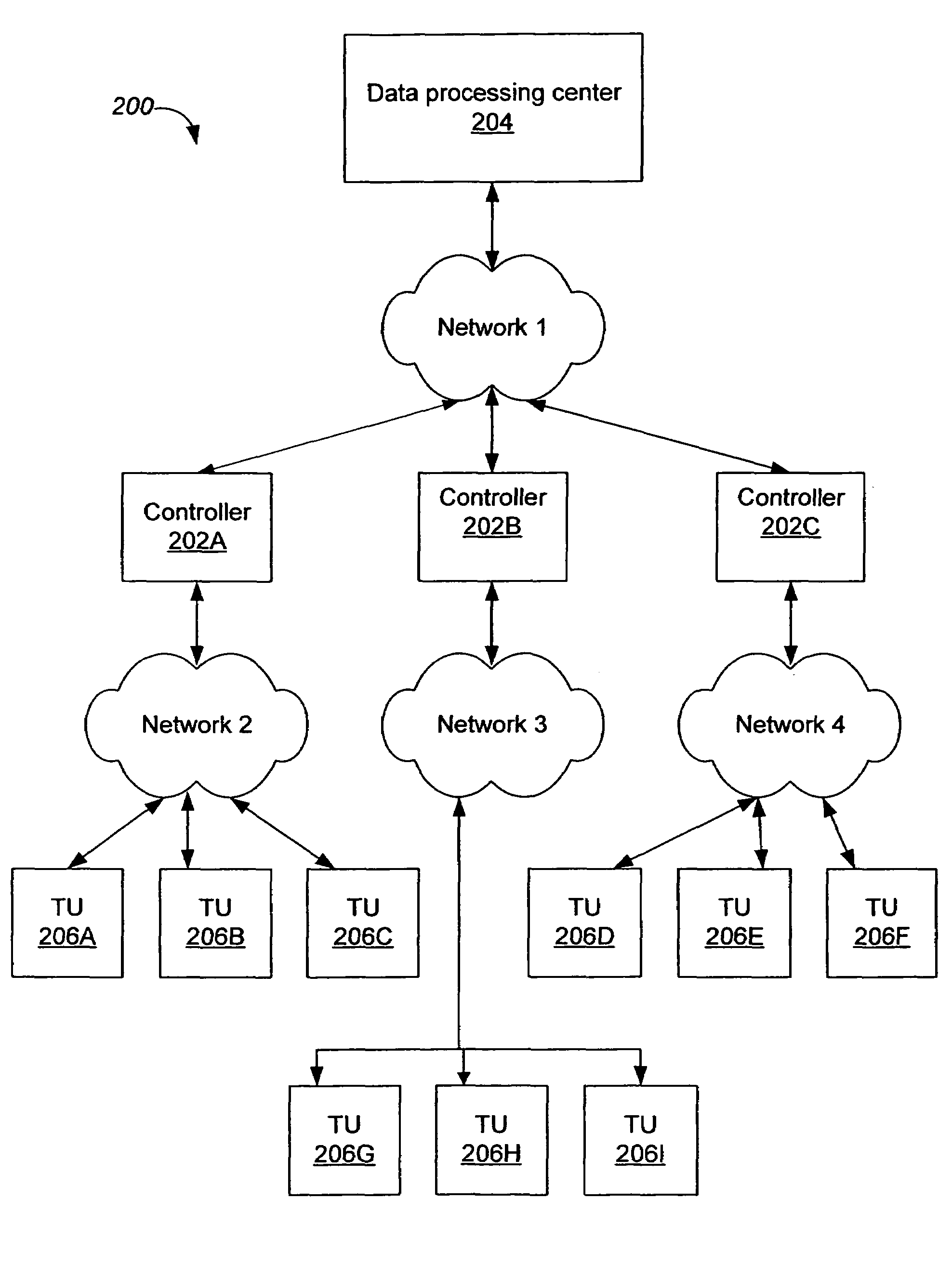

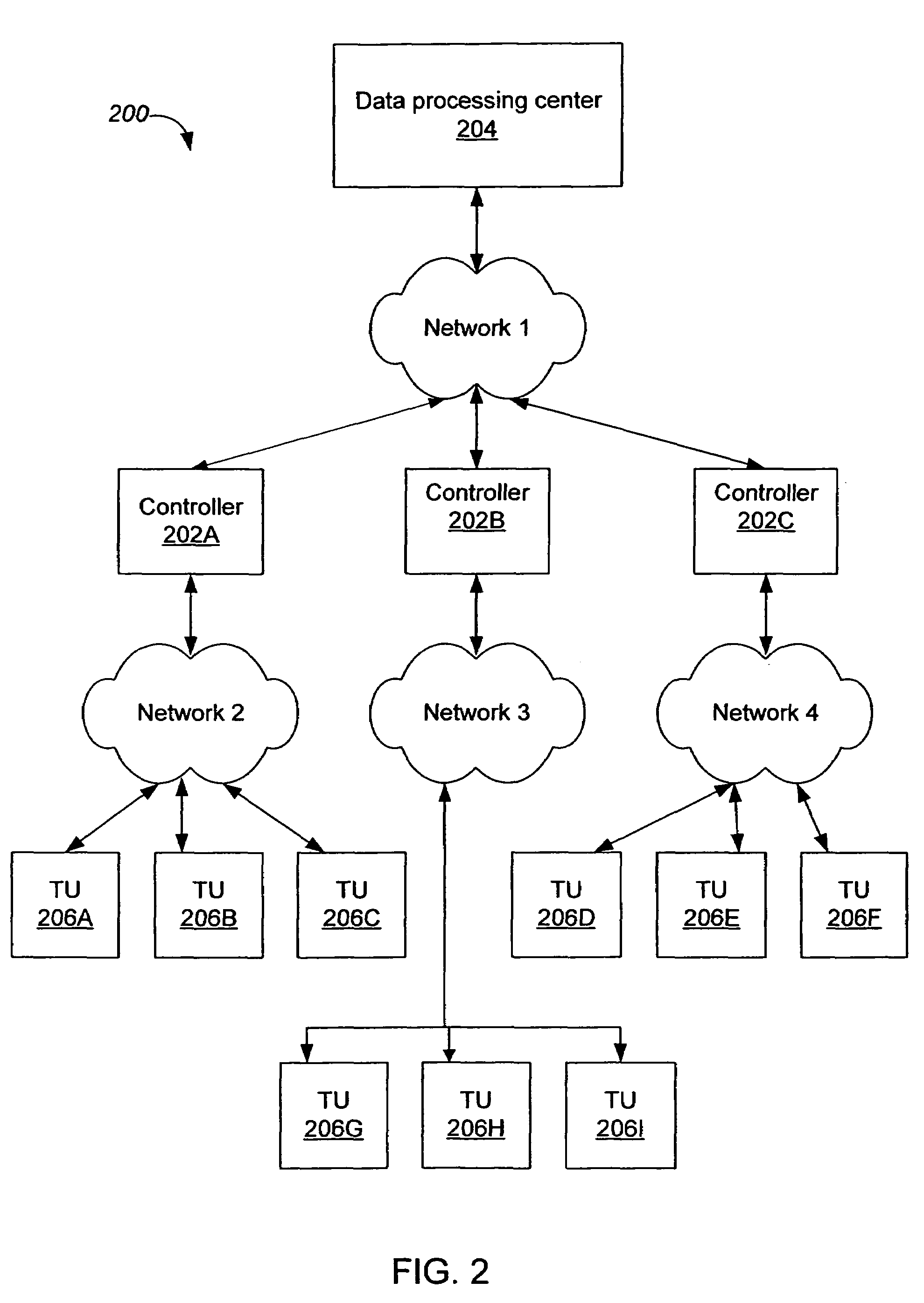

Intelligent two-way telemetry

InactiveUS7230544B2Reduce data congestionSimple and efficient and economical approachElectric signal transmission systemsLevel controlEngineeringTelemetry Equipment

Methods and apparatus, including computer program products, implementing and using techniques for intelligent two-way telemetry. A telemetry system in accordance with the invention includes one or more telemetry units that can receive and send data. The system further includes one or more controllers that includes intelligence for processing data from the one or more telemetry units and for autonomously communicating with the one or more telemetry units. The controllers are separately located from a data processing center of the telemetry system such that the controllers alleviate data congestion going to and coming from the data processing center.

Owner:LANDISGYR INNOVATIONS INC

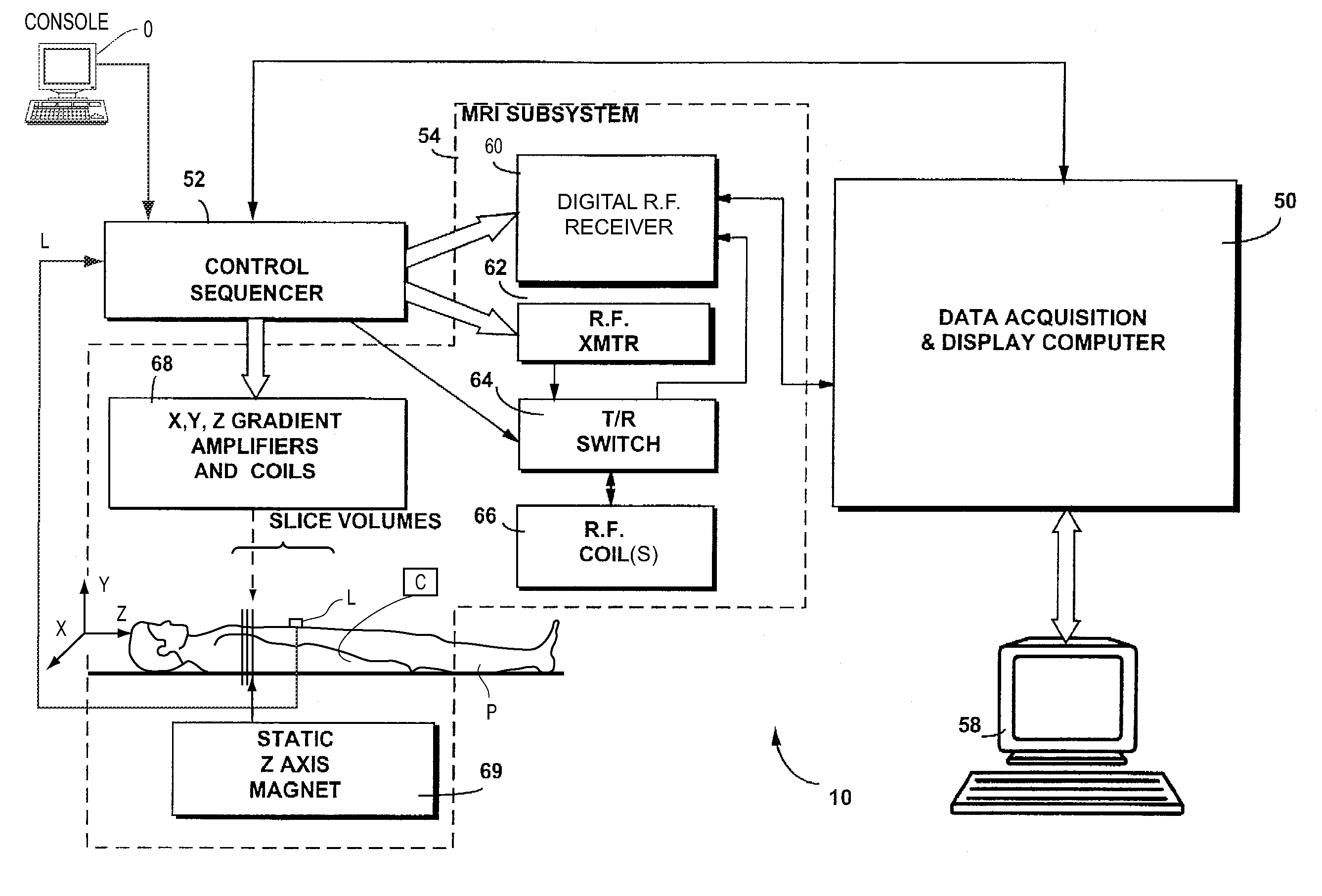

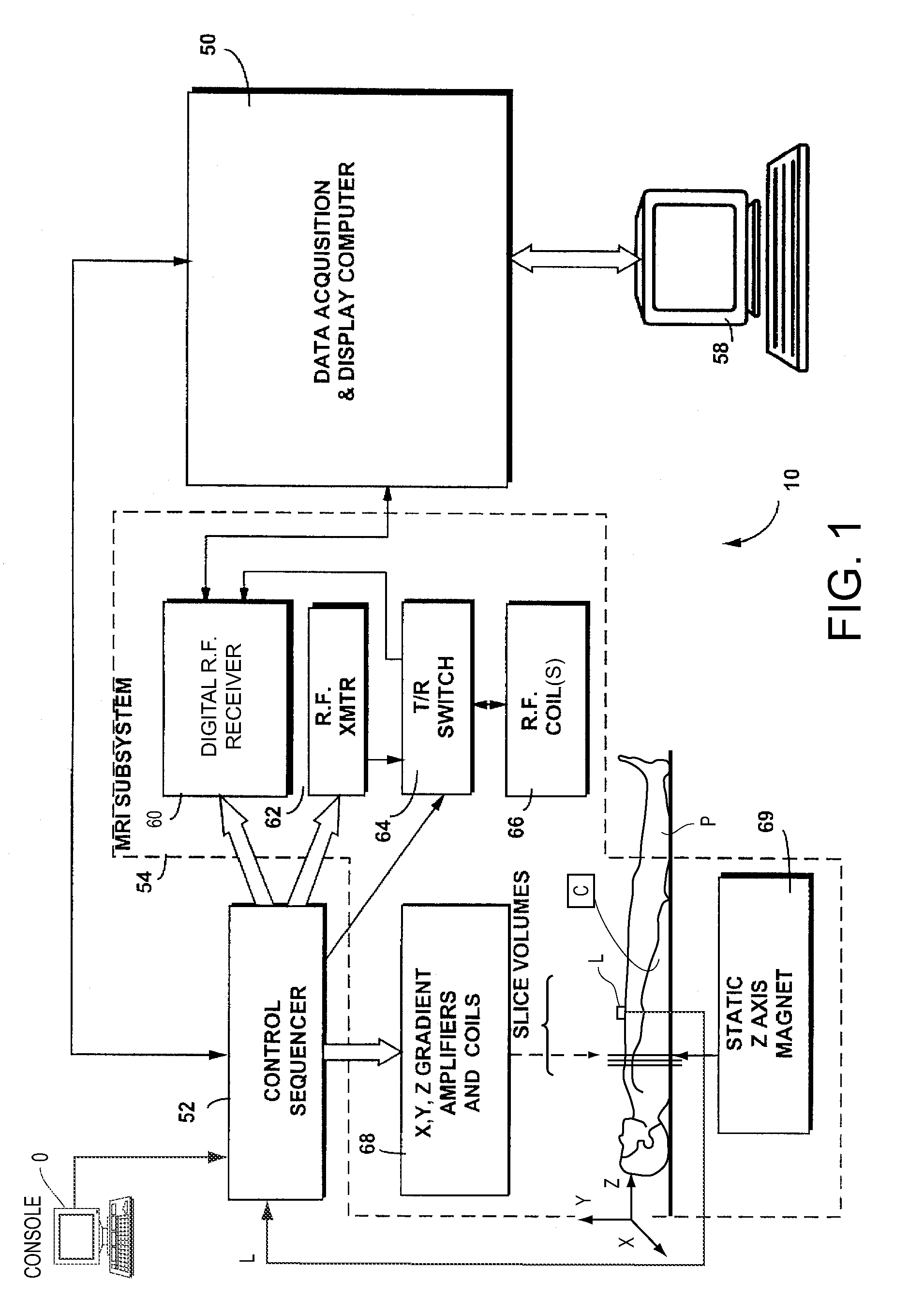

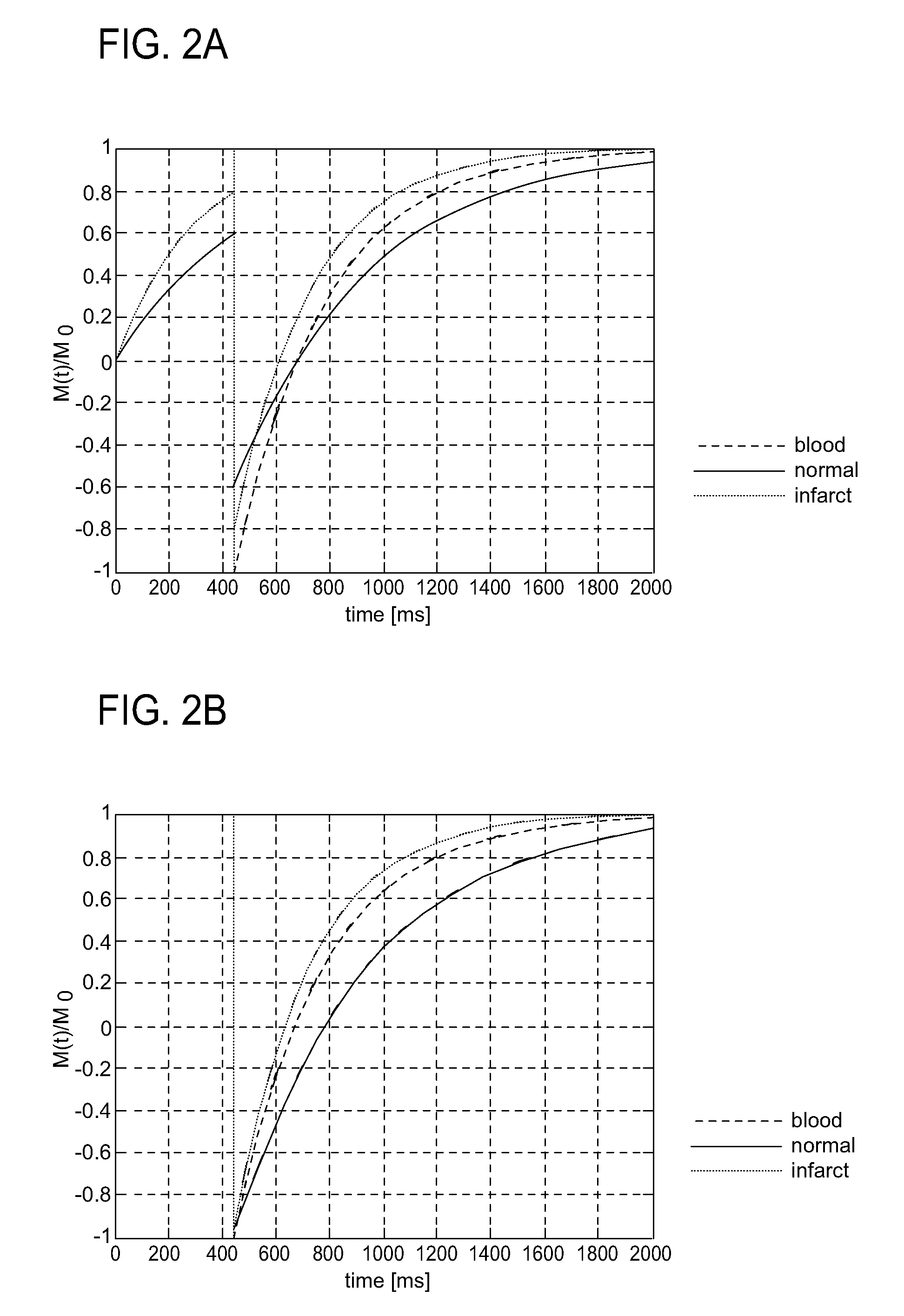

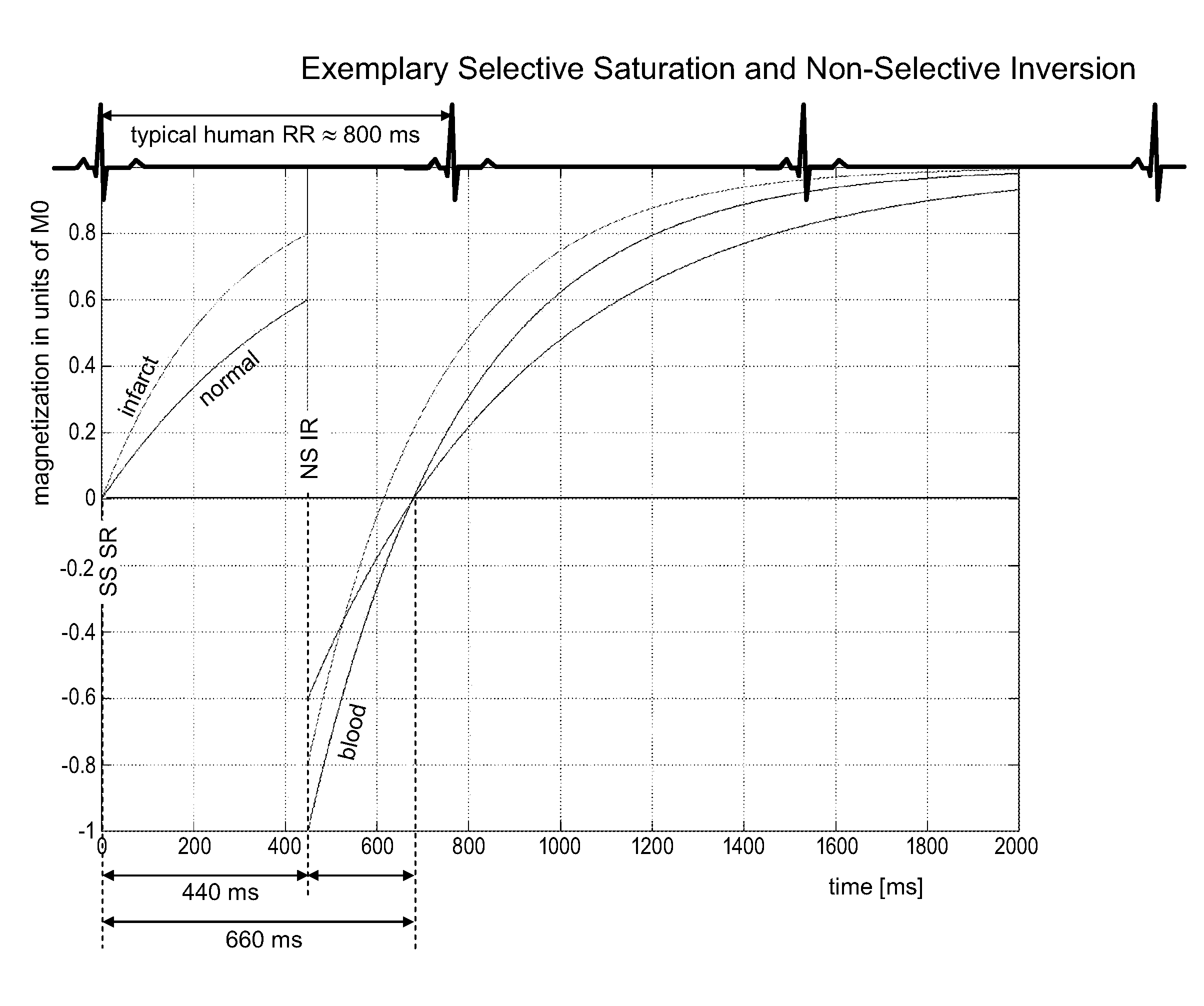

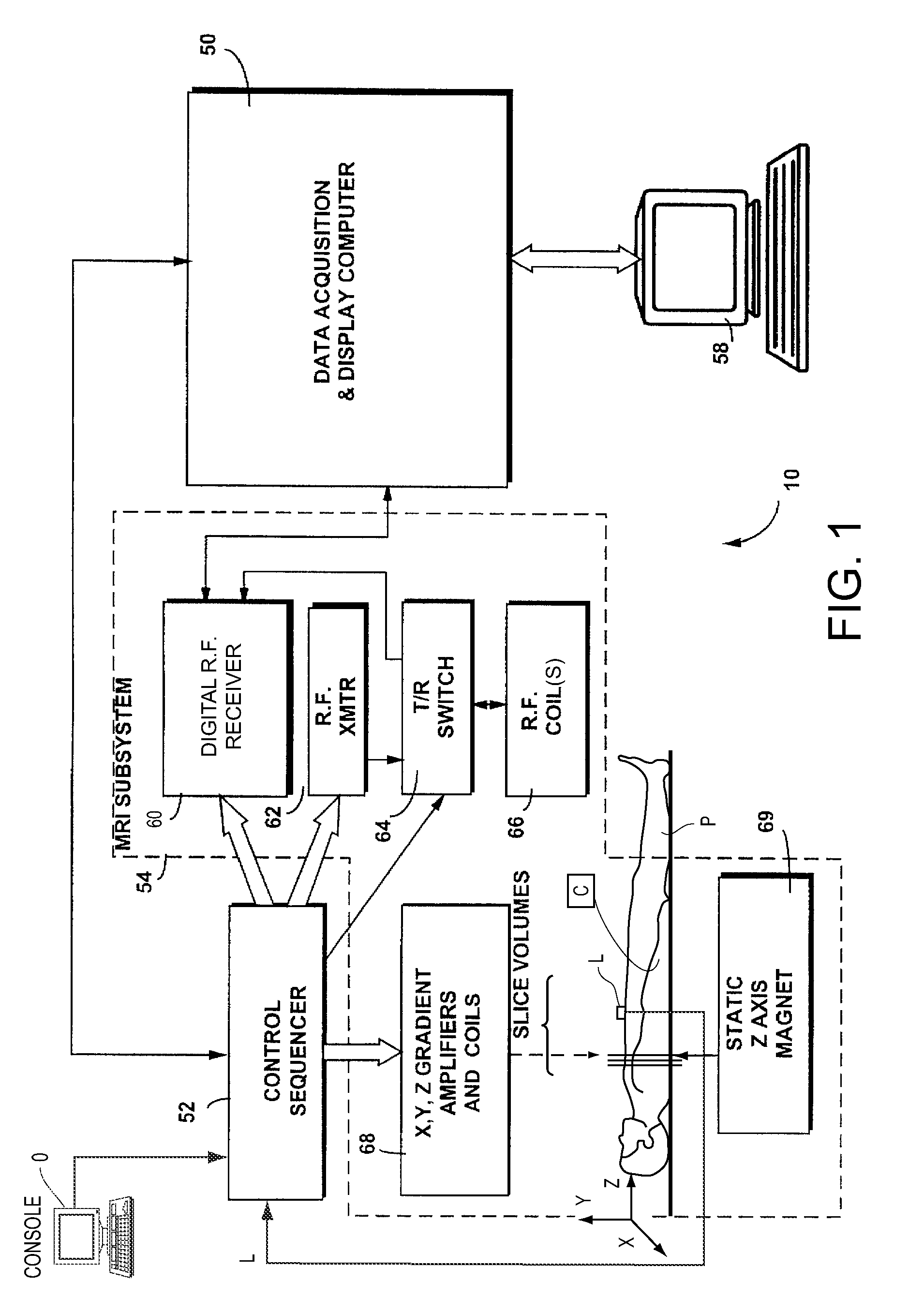

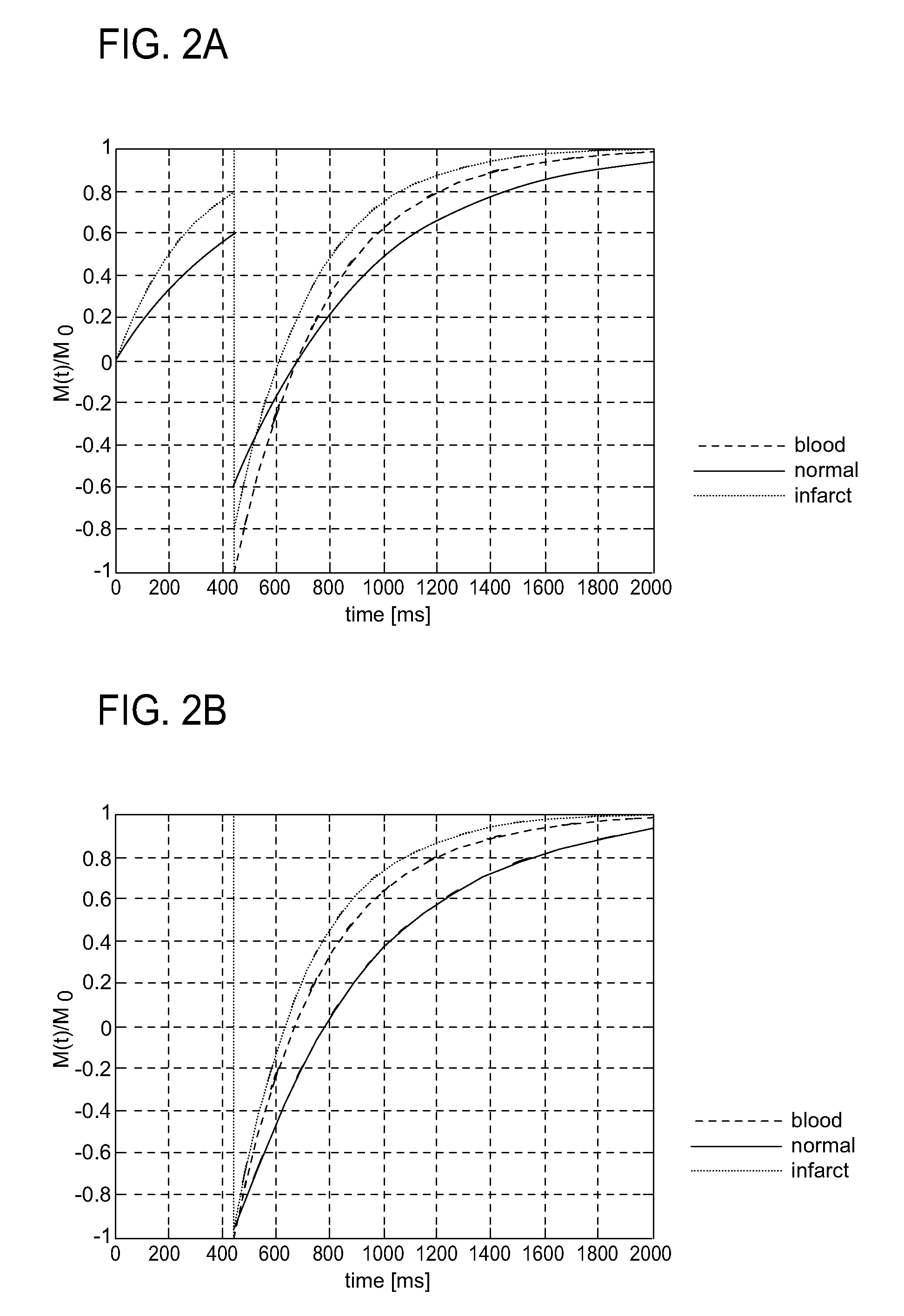

Dark blood delayed enhancement magnetic resonance viability imaging techniques for assessing subendocardial infarcts

ActiveUS20090005673A1Improve image contrastRaise modalDiagnostic recording/measuringMeasurements using NMR imaging systemsRelaxation curveCardiac cycle

The technology herein provides a dark blood delayed enhancement technique that improves the visualization of subendocardial infarcts that may otherwise be disguised by the bright blood pool. The timed combination of a slice-selective and a non-selective preparation improves the infarct / blood contrast by decoupling their relaxation curves thereby nulling both the blood and the non-infarcted myocardium. This causes the infarct to be imaged bright and the blood and non-infarct to both be imaged dark. The slice-selective preparation occurs early enough in the cardiac cycle so that fresh blood can enter the imaged slice.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC +1

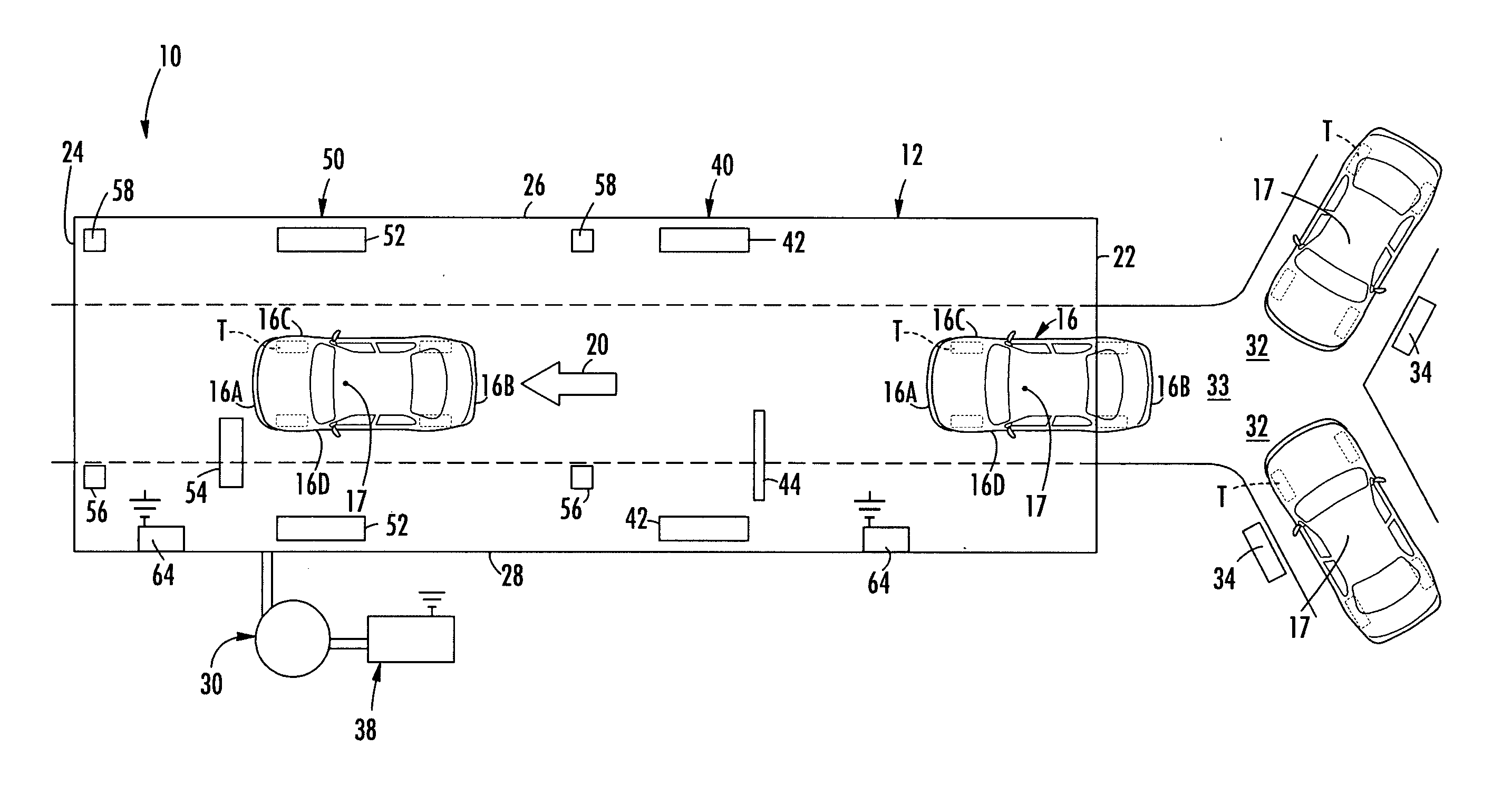

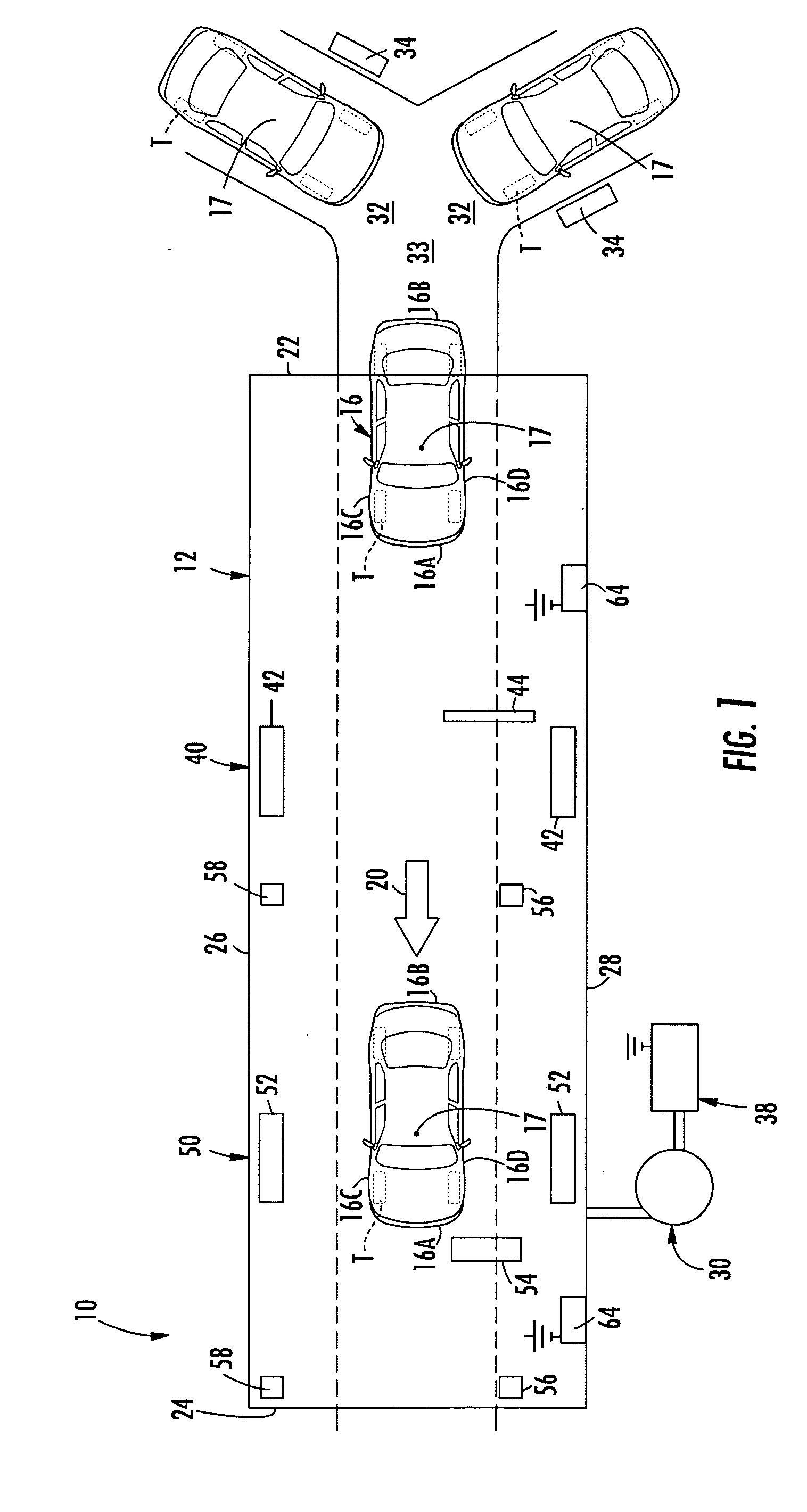

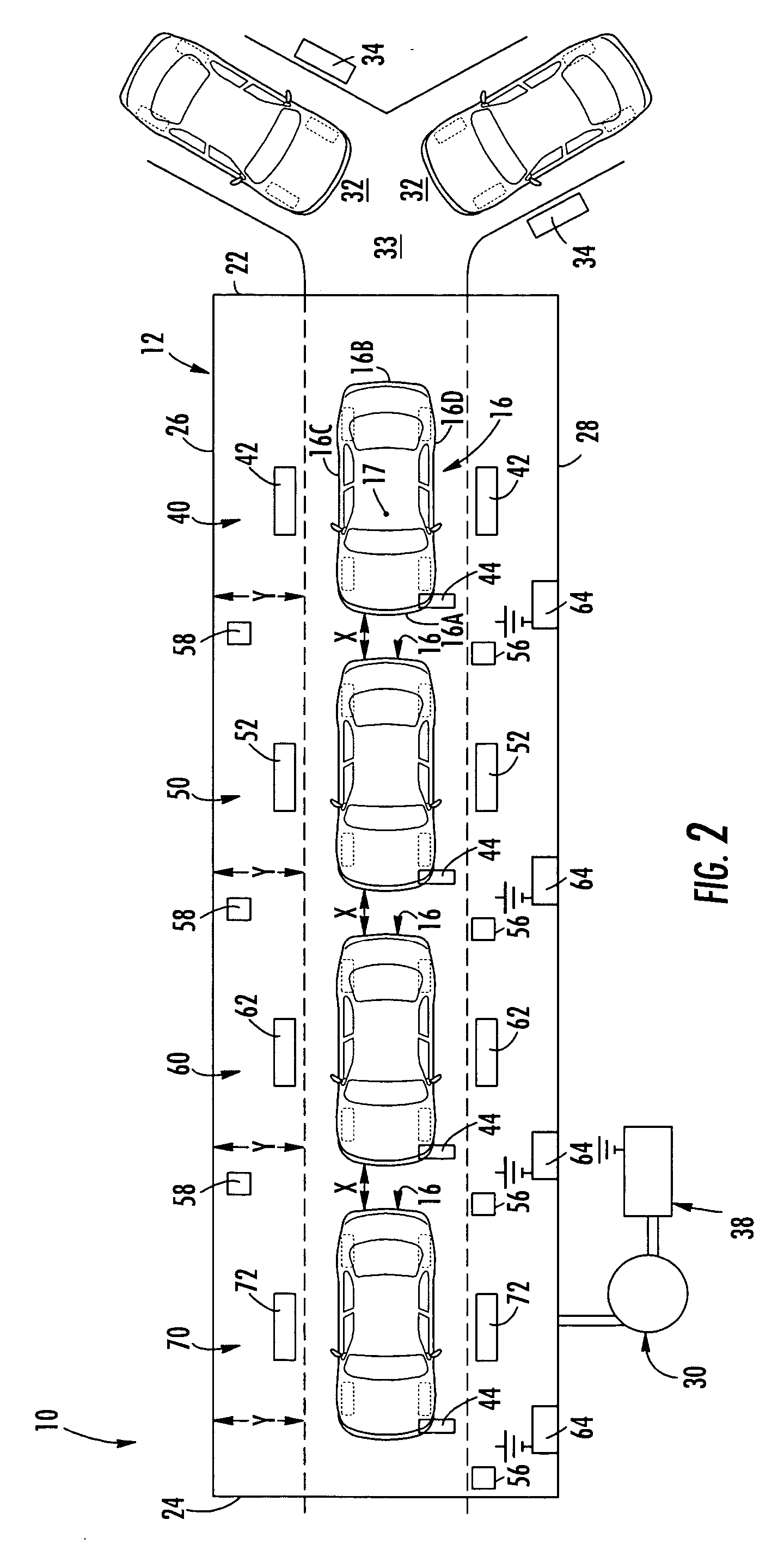

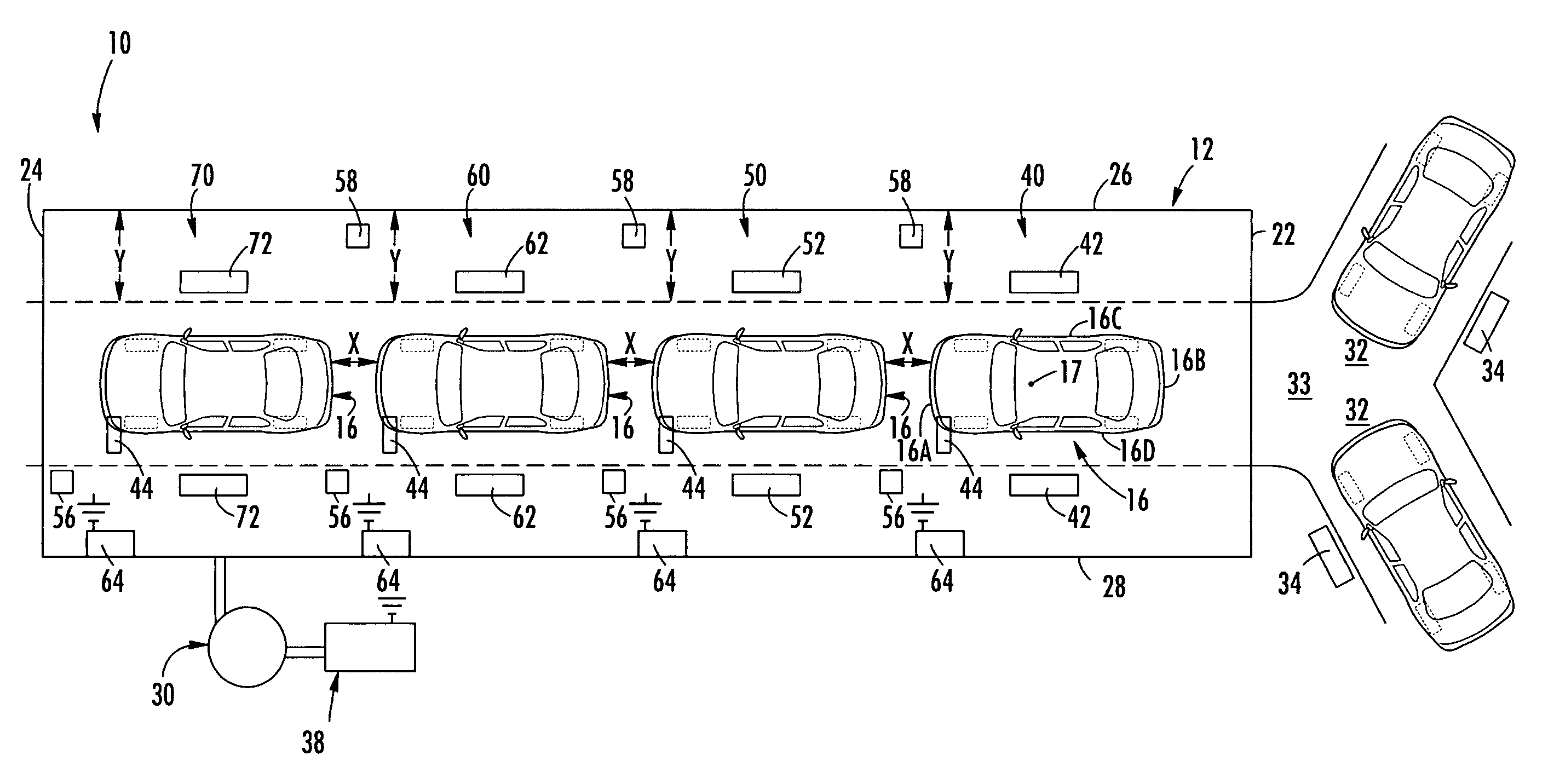

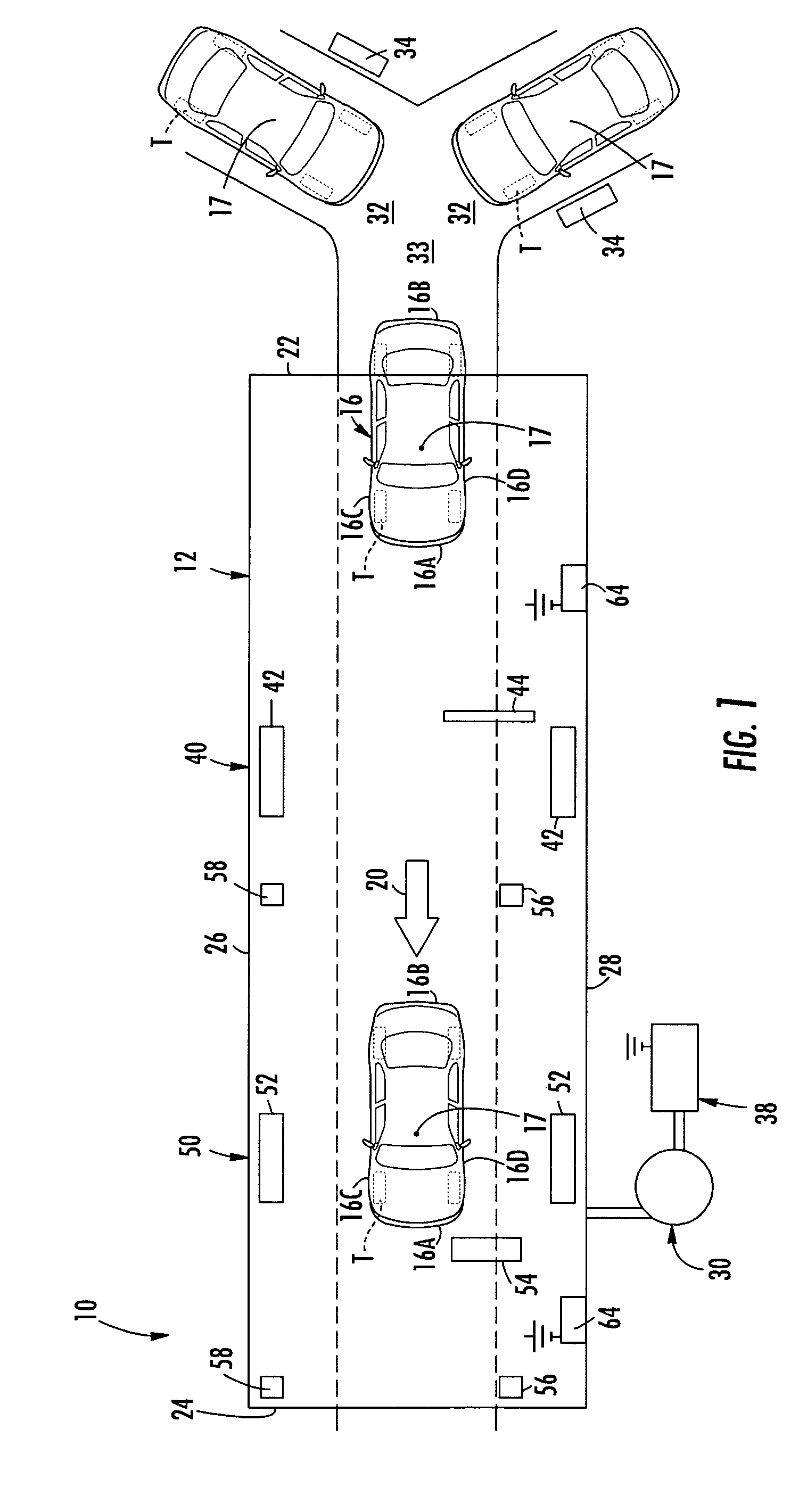

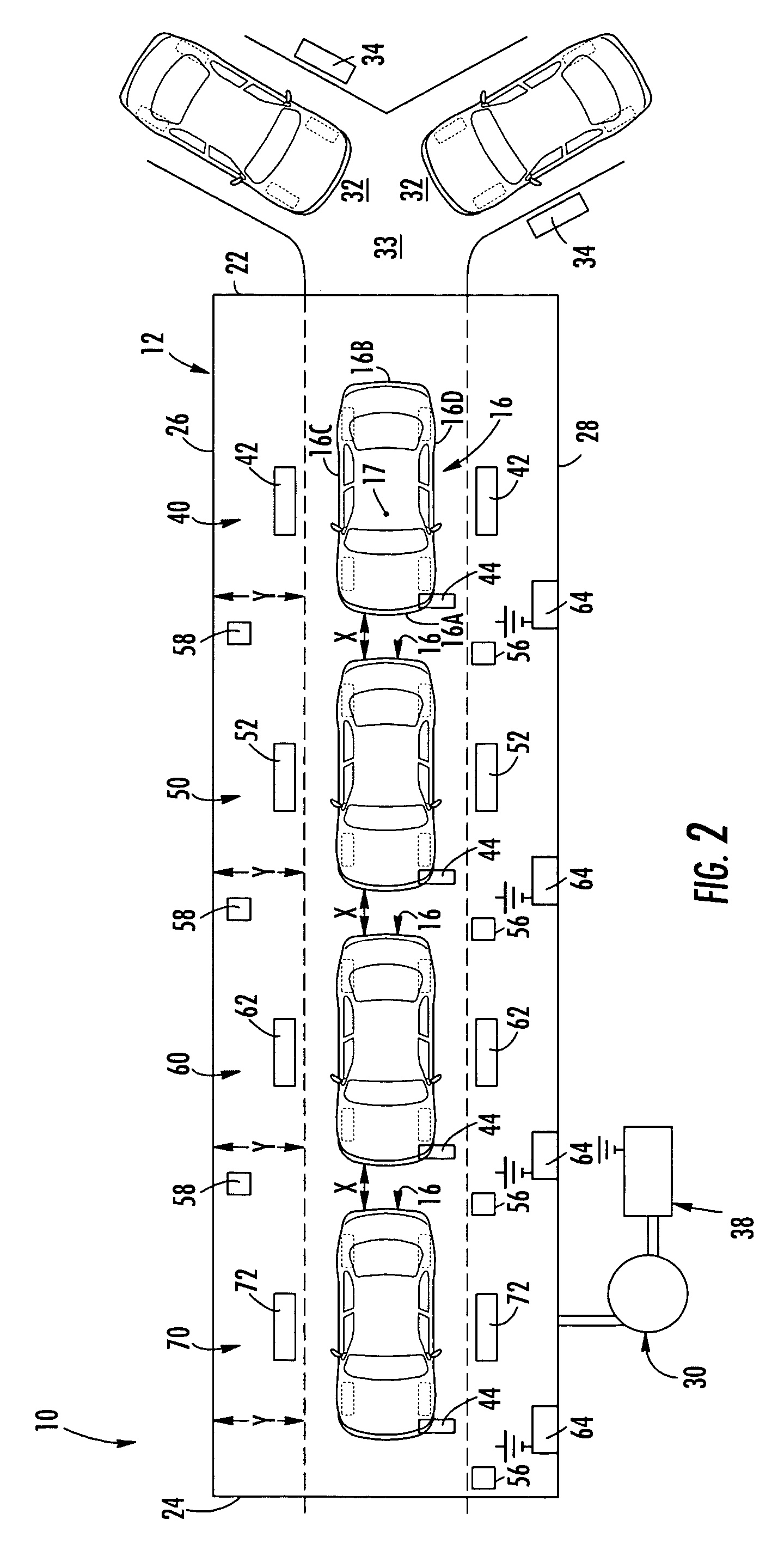

Automatic car wash system

InactiveUS20050229808A1Improve throughputAvoid disadvantagesCleaning apparatus with conveyorsMovable spraying apparatusDriver/operatorRadiotransmitter

An automatic car wash system is provided for processing multiple vehicles simultaneously. The system according to one embodiment includes an elongate path, a plurality of stations for processing the vehicle, at least two detectors for indicating the presence of the vehicles. The system provides instructions to the drivers of the vehicles so that the vehicles travel through the system under their own power, and thus conveyor systems can be avoided, yet throughput remains high. In one embodiment, the system includes a radio transmitter that is operable to direct specific information to each of the vehicles via radio signals.

Owner:MACDOWELL MICHAEL

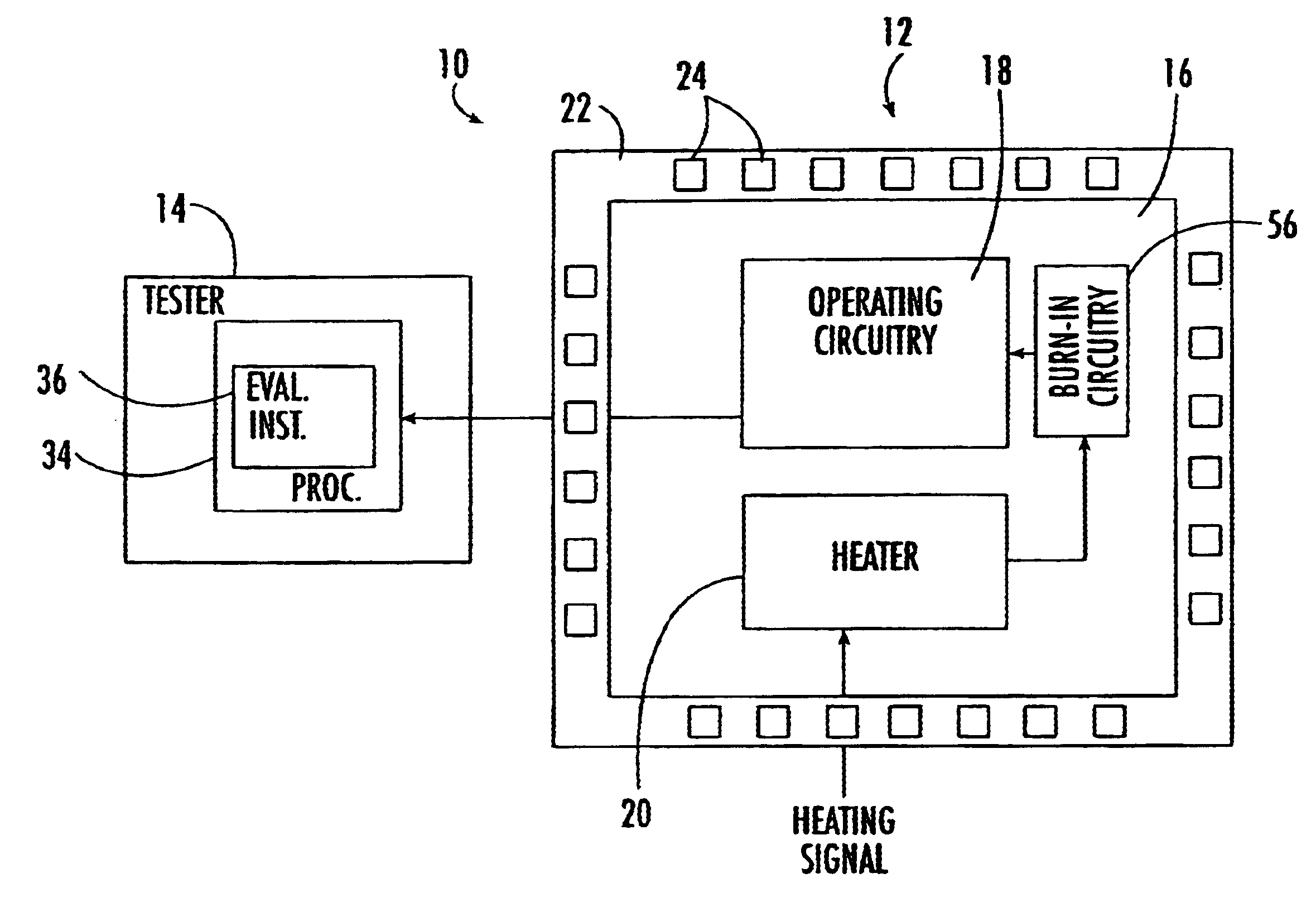

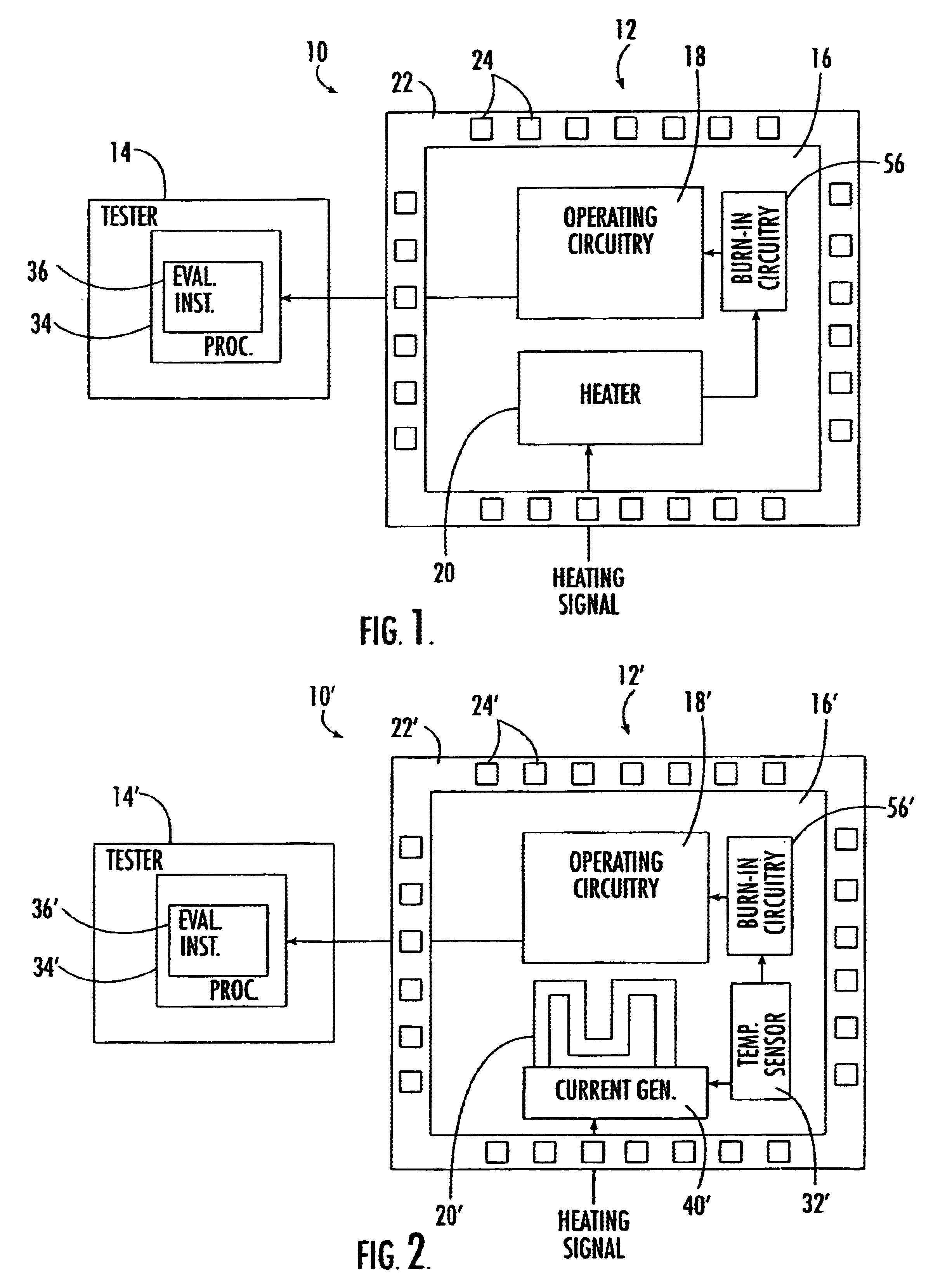

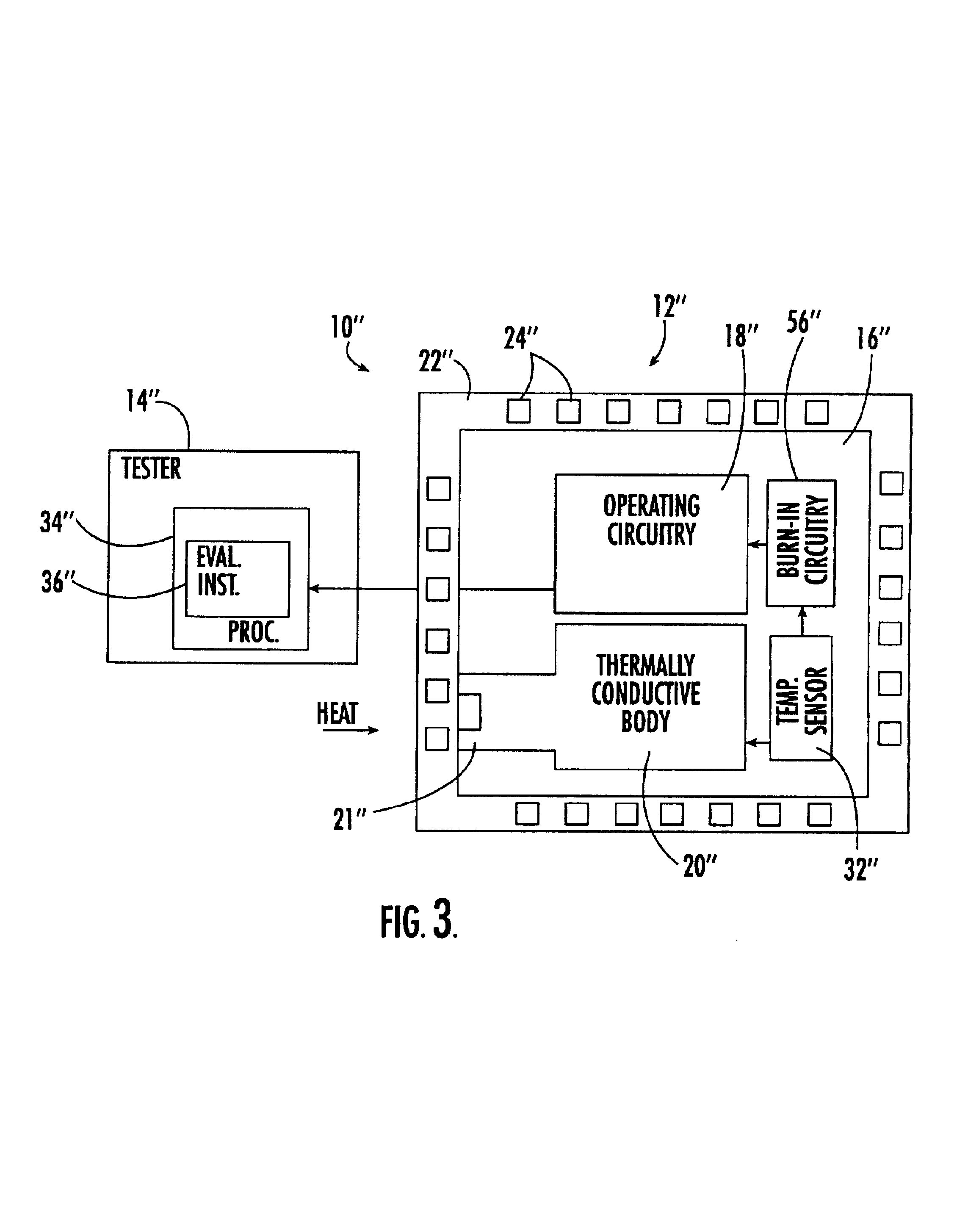

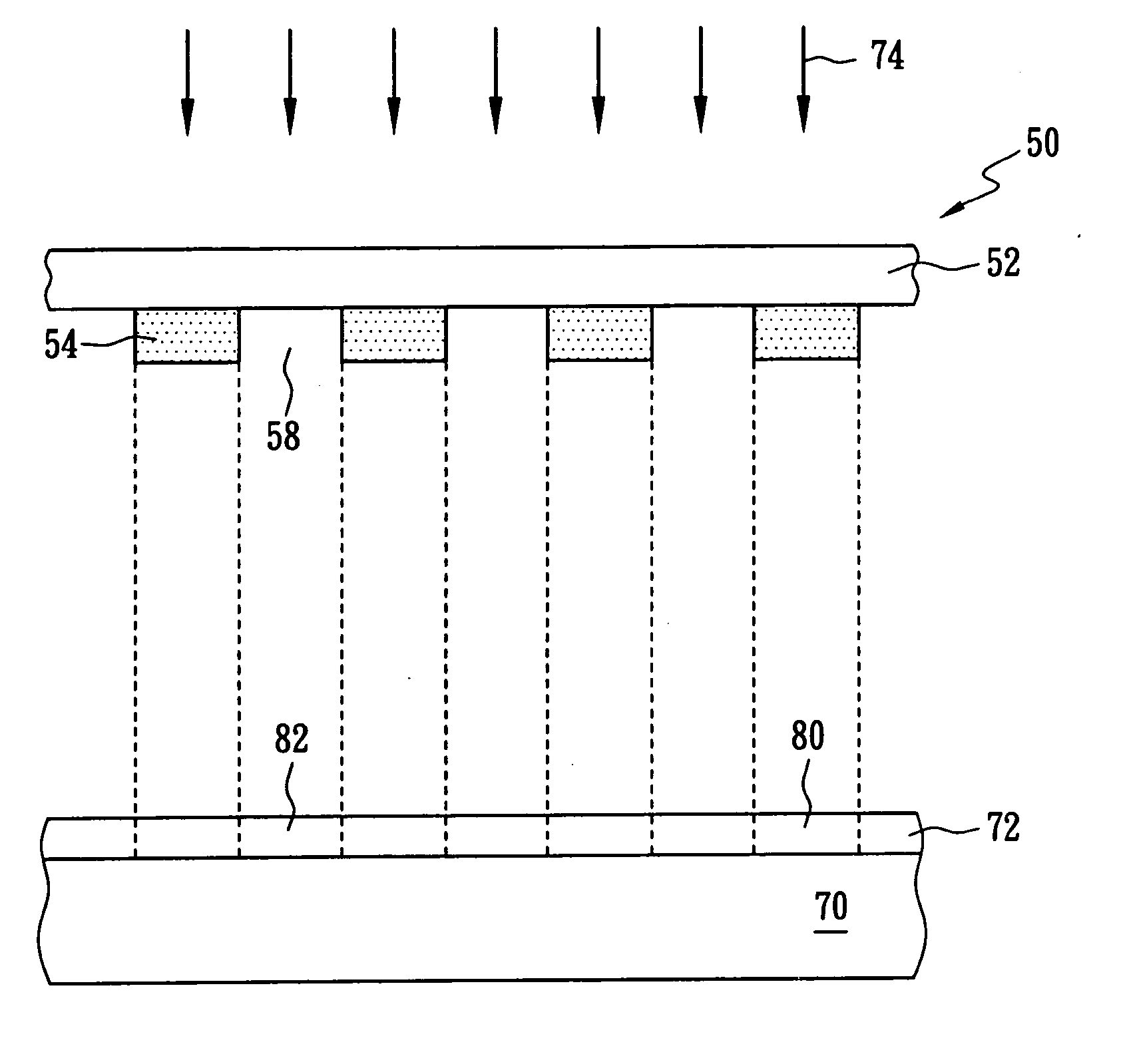

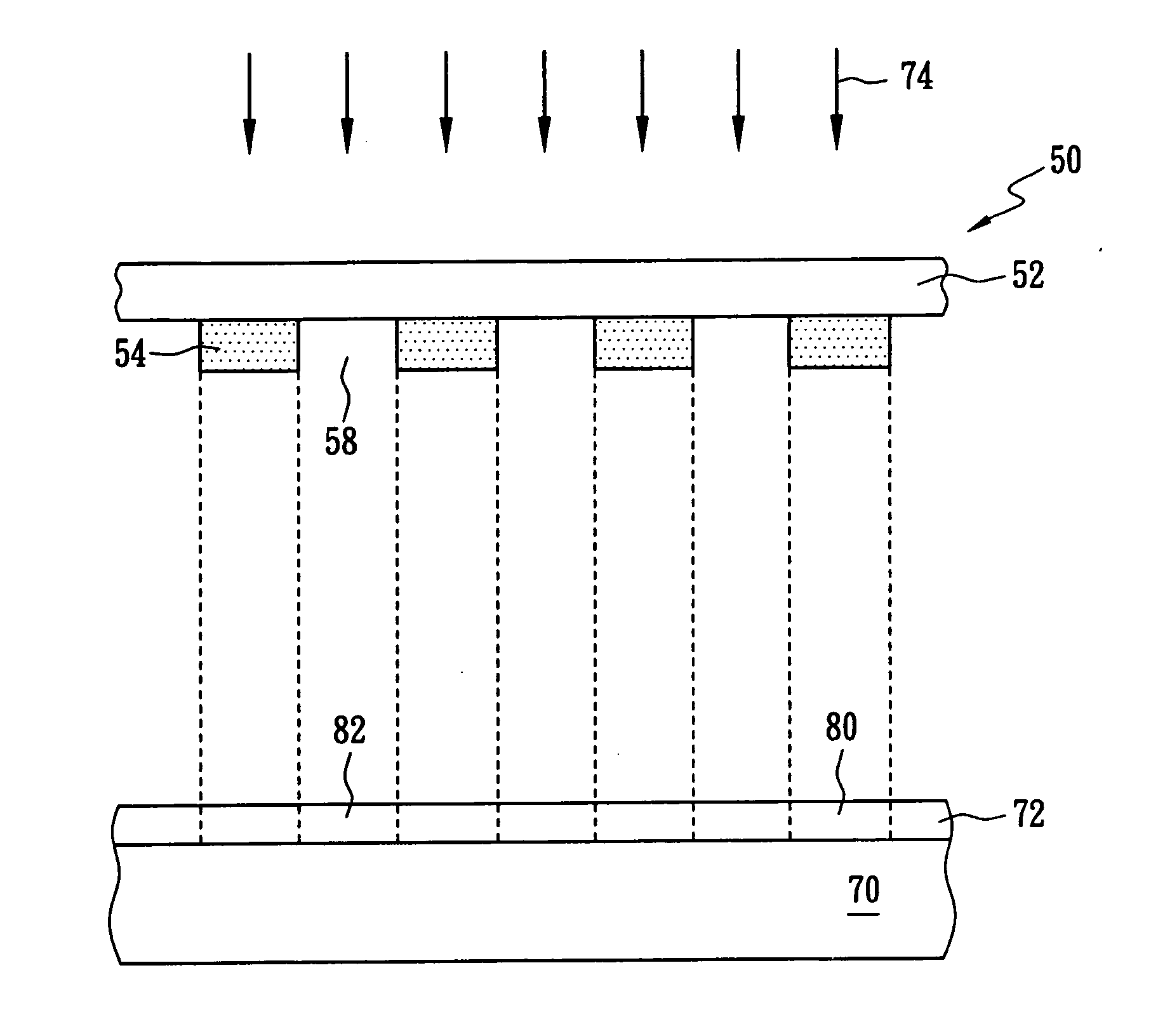

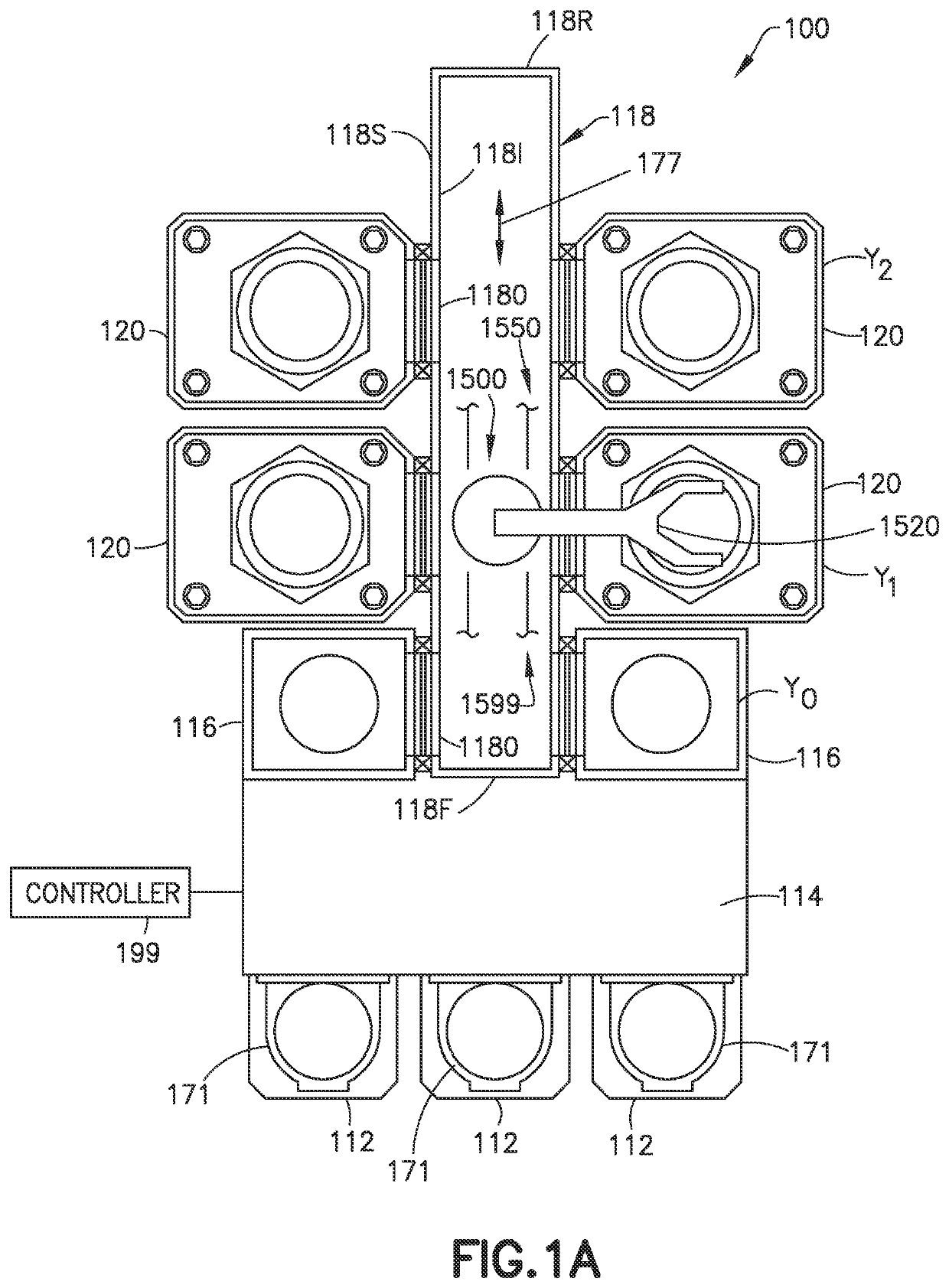

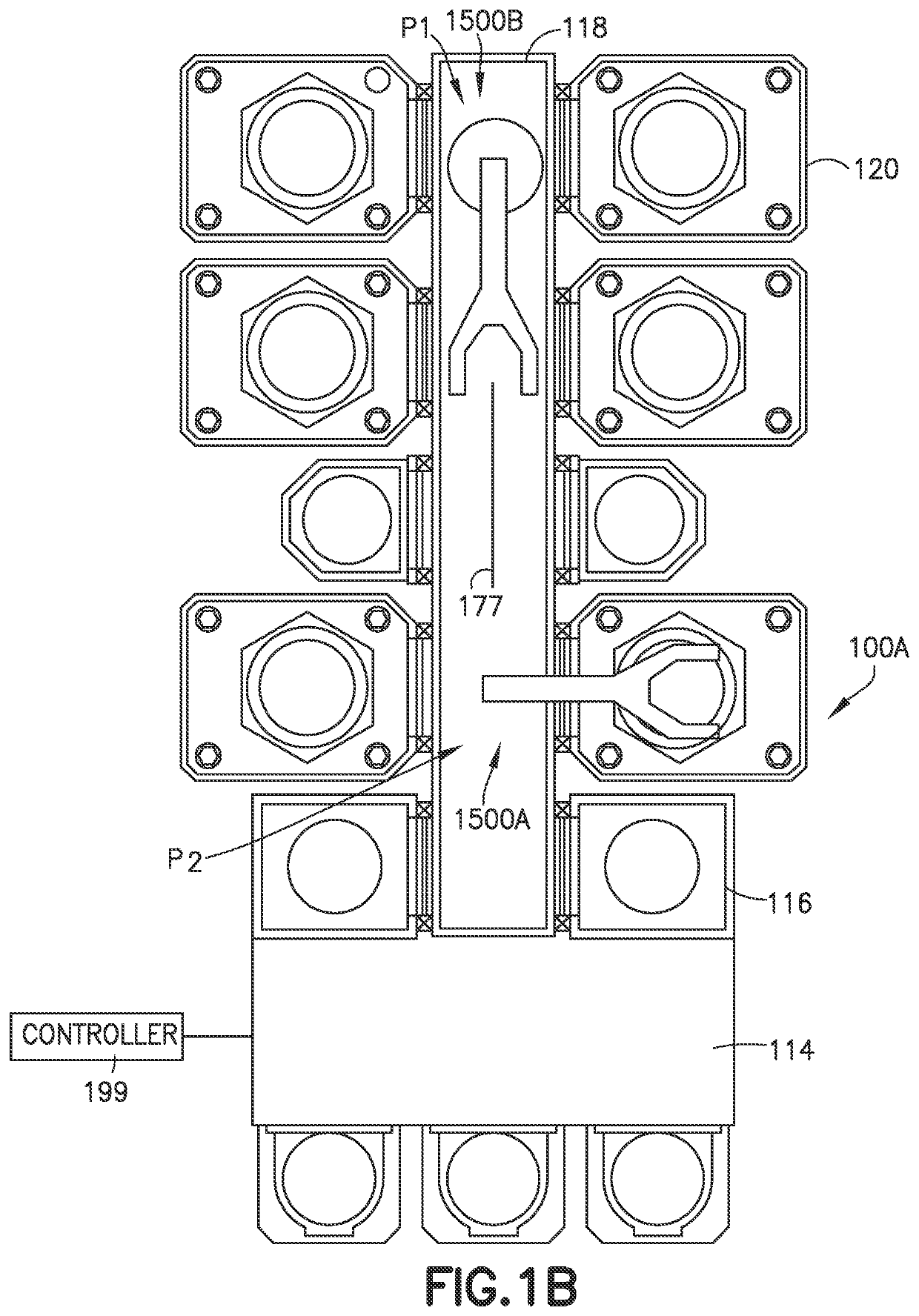

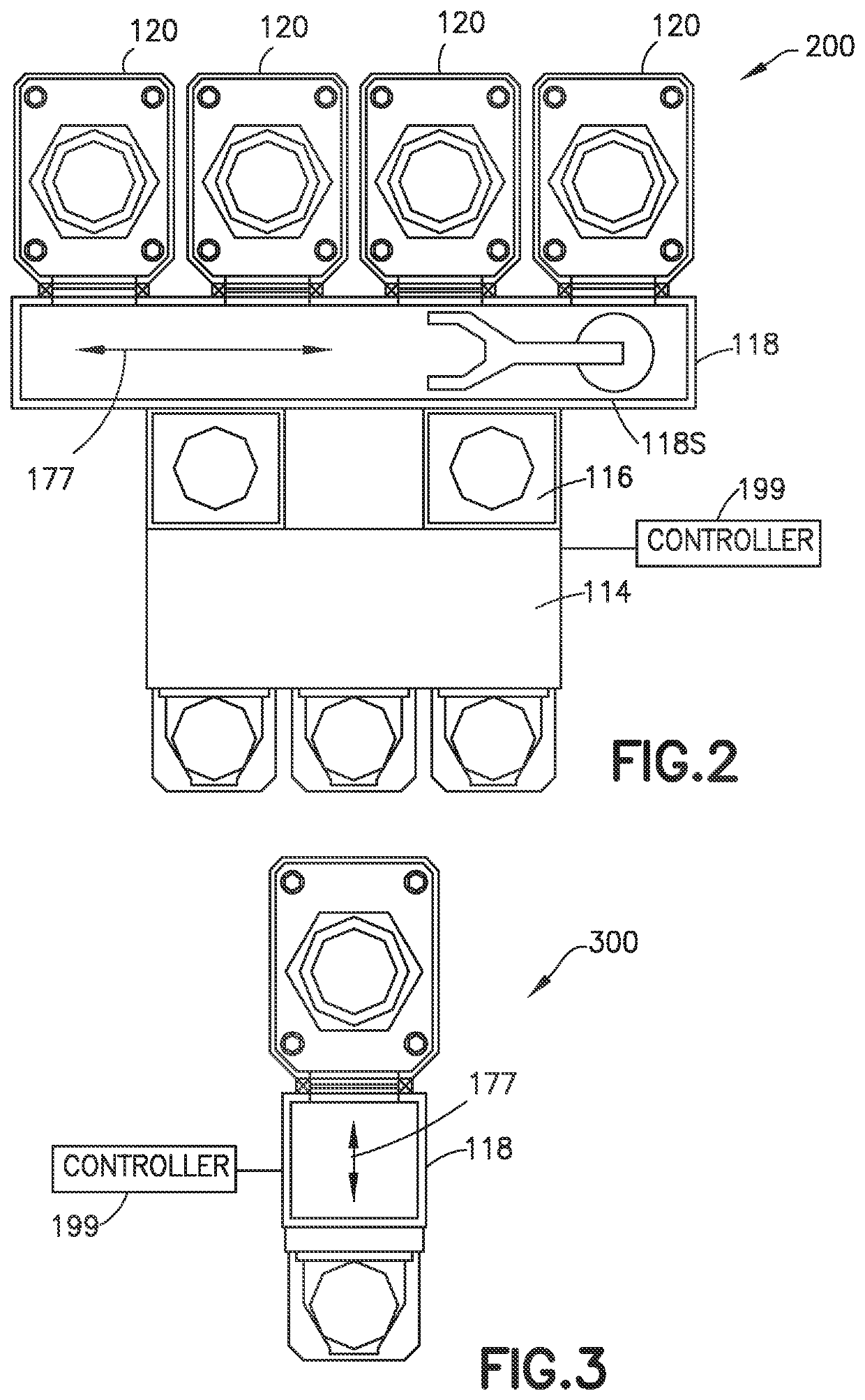

Integrated circuit burn-in test system and associated methods

InactiveUS6861860B2Simple equipmentLimited throughputElectronic circuit testingFault location by increasing destruction at faultEngineeringIntegrated circuit

An integrated circuit burn-in test system includes an integrated circuit and a tester. The integrated circuit includes operating circuitry, a heater for heating the operating circuitry, and burn-in test circuitry for testing the operating circuitry while being heated. A package surrounds the operating circuitry, the heater and the burn-in test circuitry. The burn-in test circuitry causes the operating circuitry to operate and generate data related thereto. The tester receives data from the burn-in test circuitry. The heater may be configured within the package to heat at least one predetermined portion of the operating circuitry.

Owner:STMICROELECTRONICS SRL

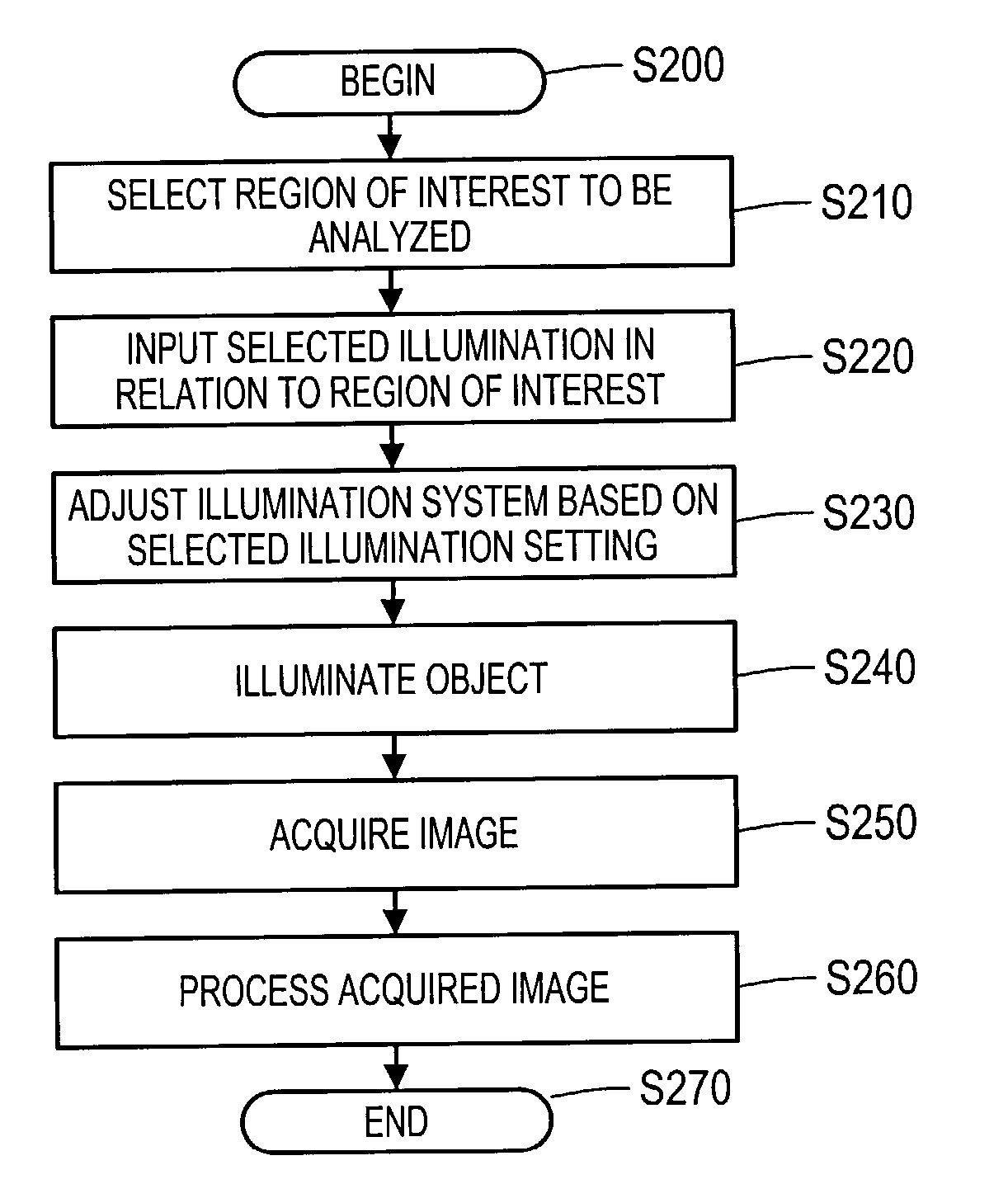

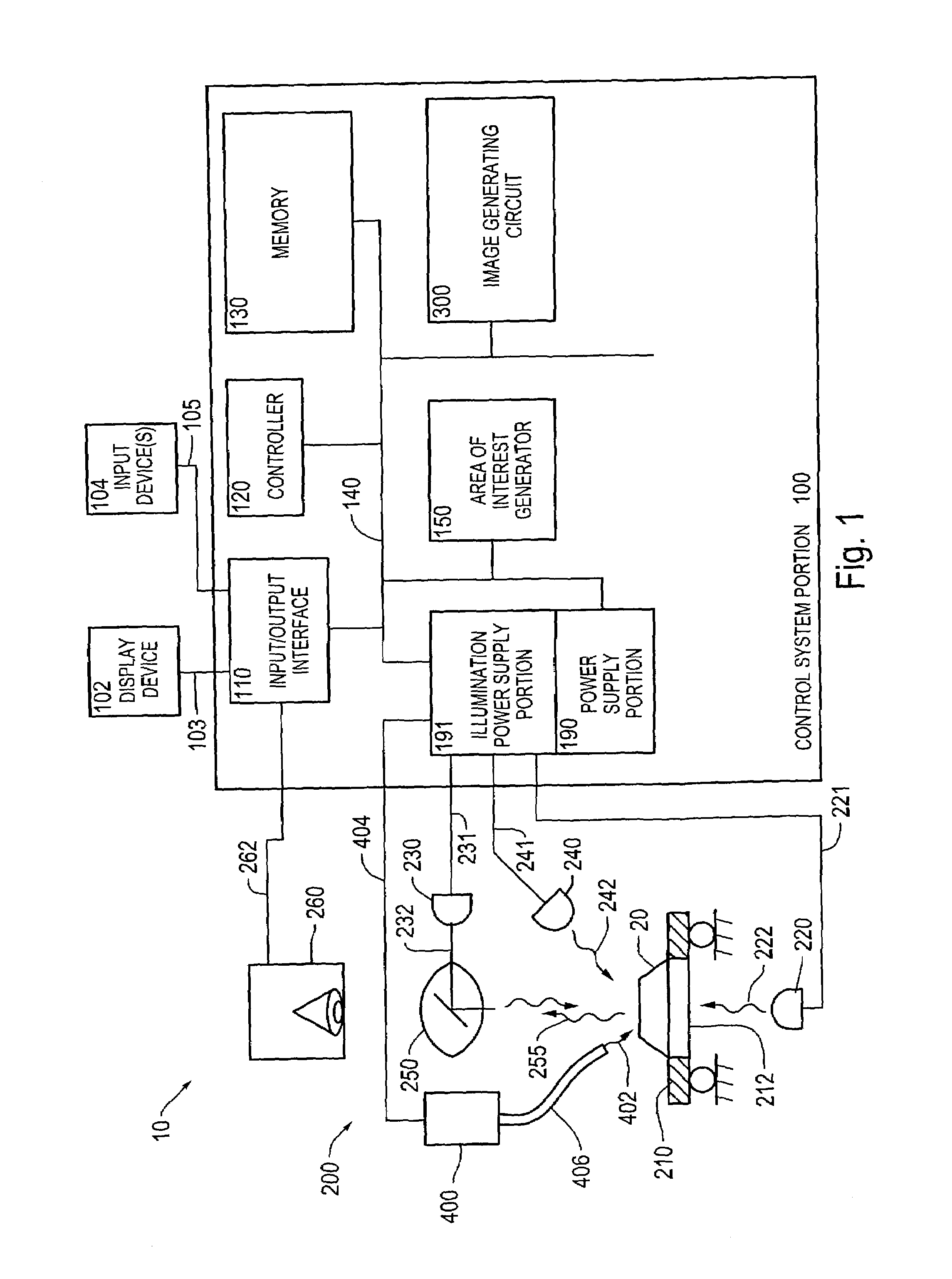

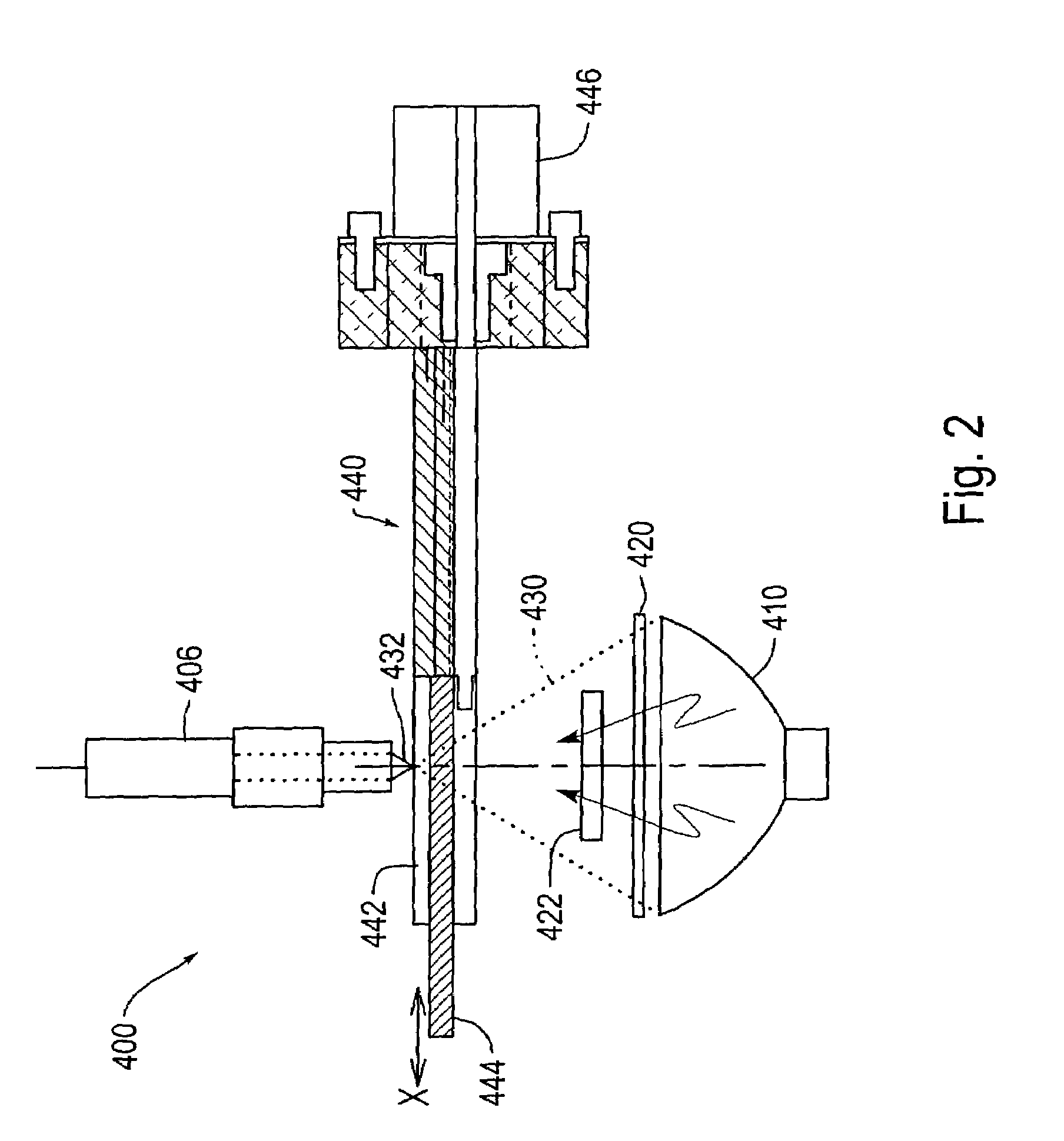

Systems and methods for continuously varying wavelength illumination

InactiveUS7016525B2Time consumingLimited throughputCharacter and pattern recognitionUsing optical meansLength waveVisual perception

Systems and methods for operating a vision system to provide a desired illumination wavelength for an inspection operation on workpiece include illuminating a workpiece using narrowband illumination from a continuously variable filter, and modifying the narrowband illumination and evaluating resulting images until a narrowband illumination is found that reliably supports the inspection operation. The initial narrowband illumination may be based on spectral sensing.

Owner:MITUTOYO CORP

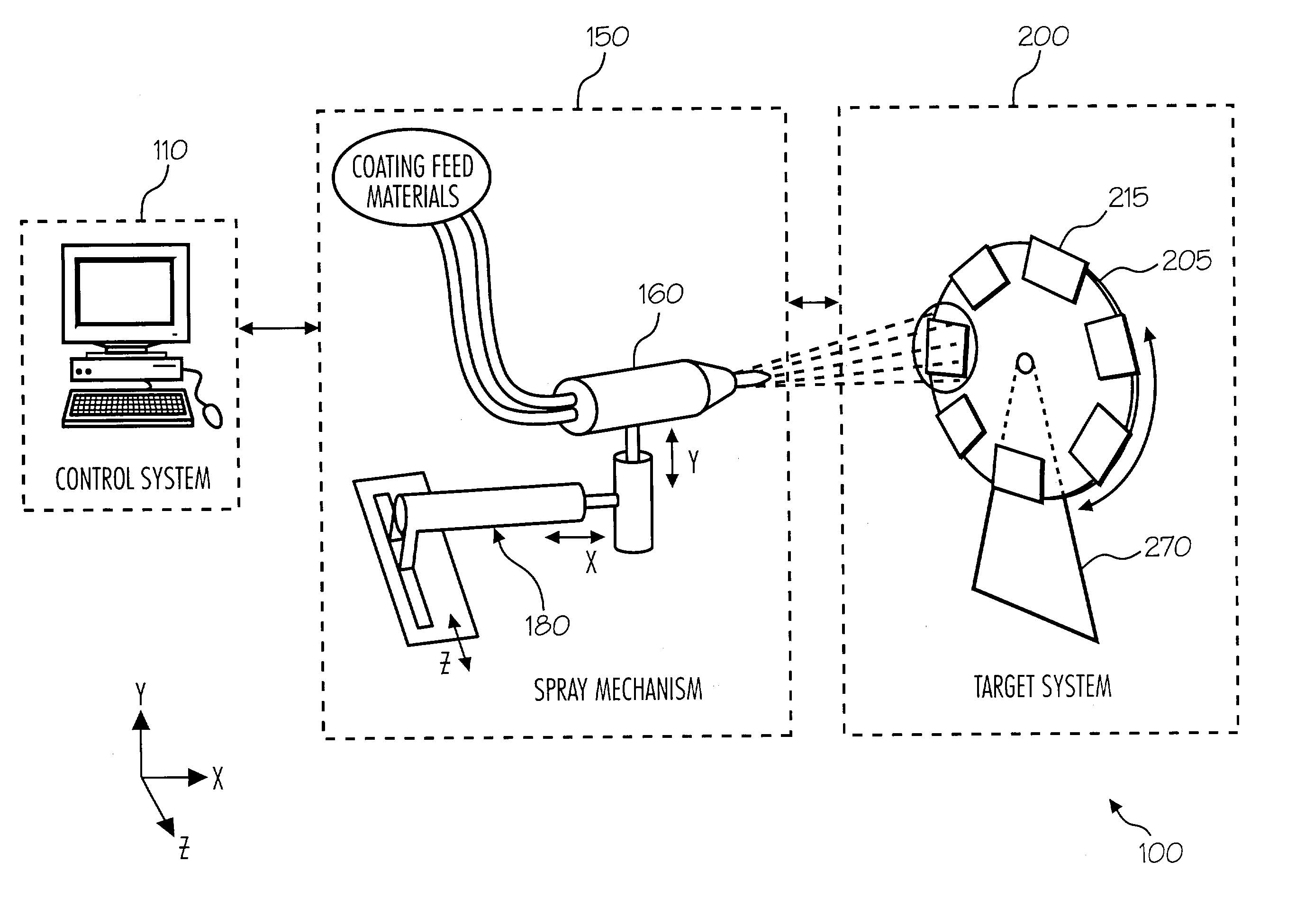

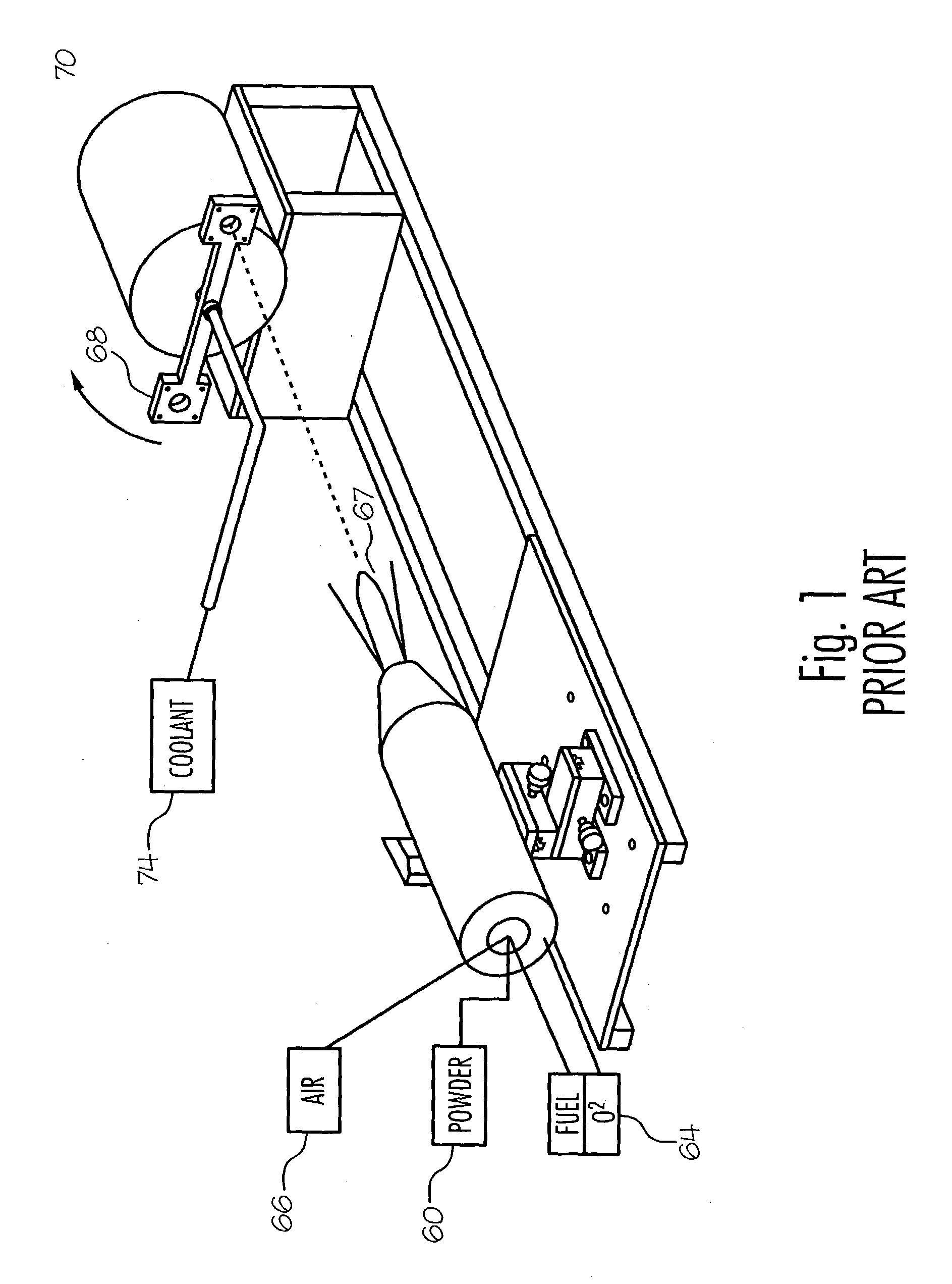

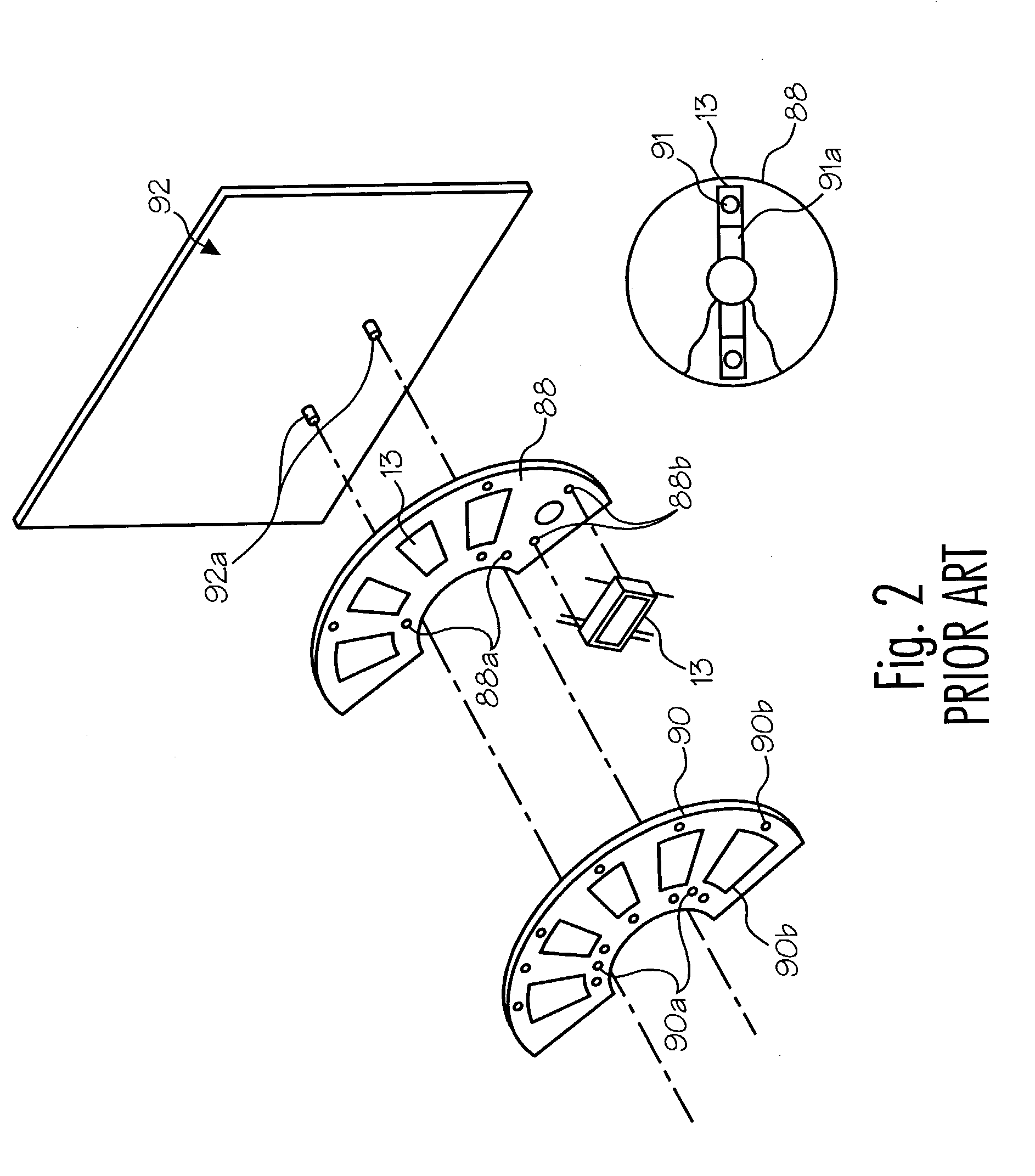

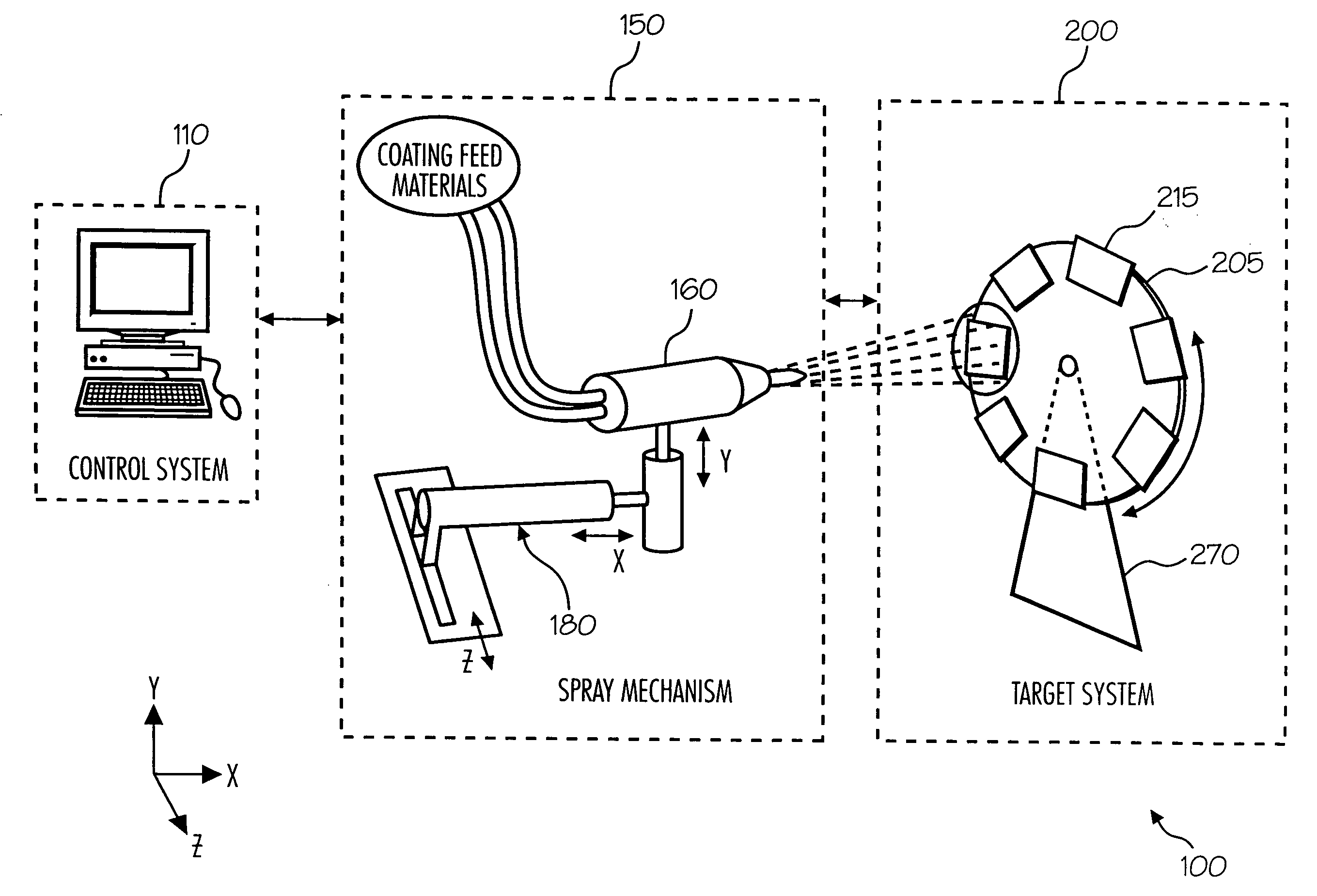

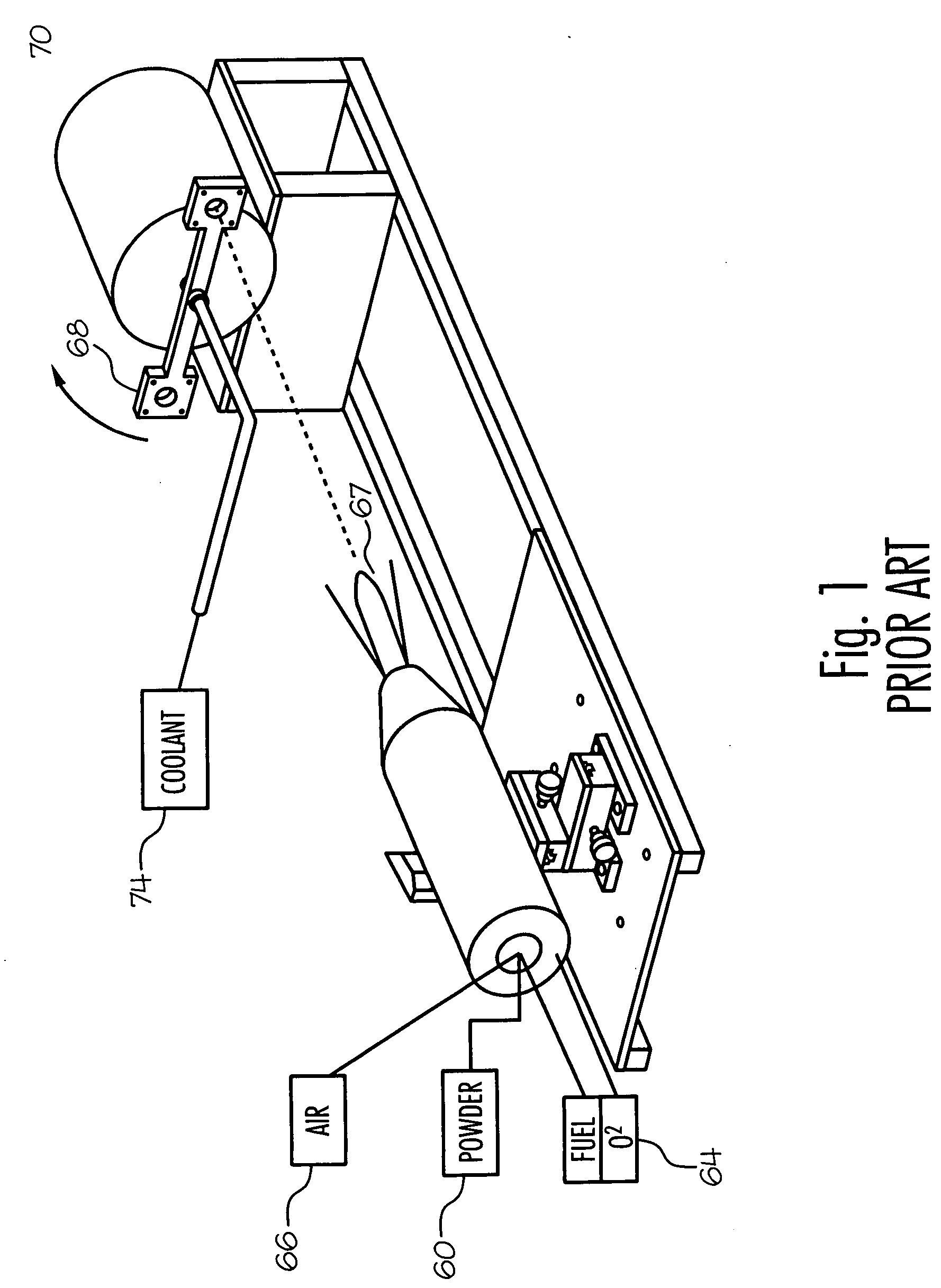

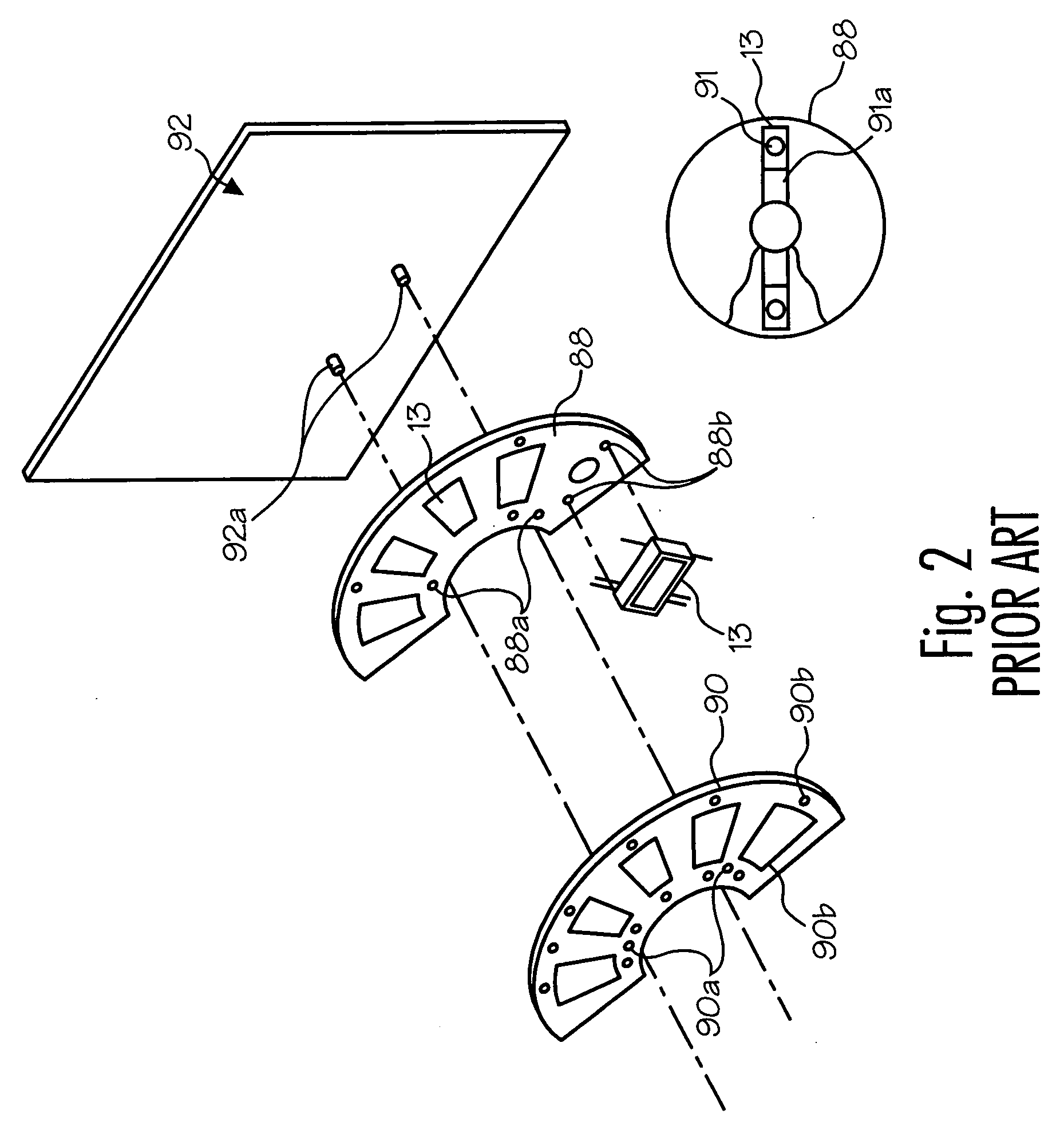

Spray coating apparatus and fixtures

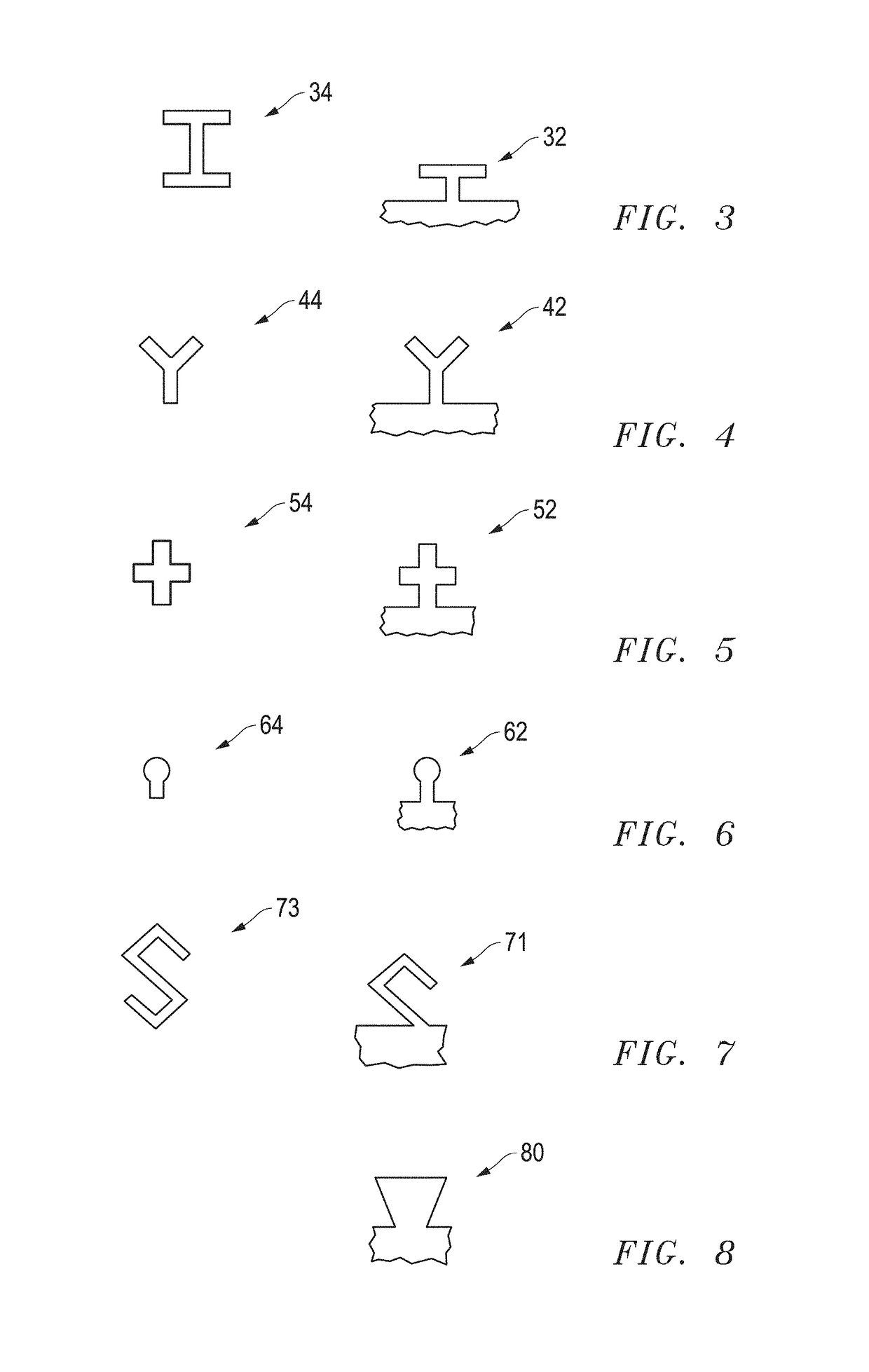

InactiveUS7208046B1Low costLimited throughputLiquid surface applicatorsSemiconductor/solid-state device detailsThermal sprayingSpray coating

A system for applying a sprayed coating includes a spray mechanism operative to spray a liquefied coating material; a target system including a rotatable spray target wheel; and one or more device-holding fixtures configured to be mounted onto the spray target wheel without requiring either an unattached threaded fastener or a locking pin. Preferred embodiments of the system are configured for thermal spray application of Tamper Resistant Coatings (TRCs).

Owner:MICROSEMI CORP MEMORY & STORAGE SOLUTIONS

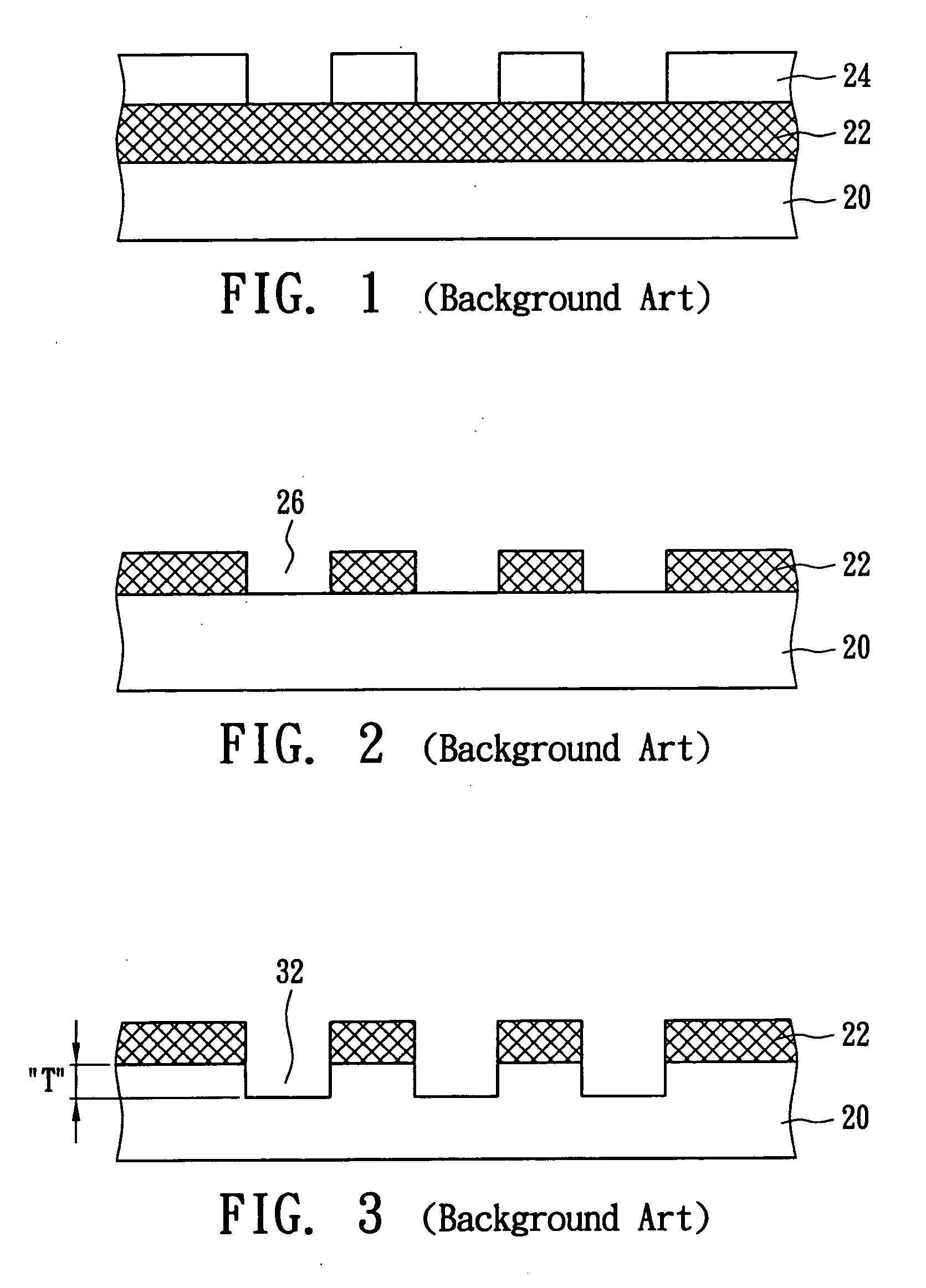

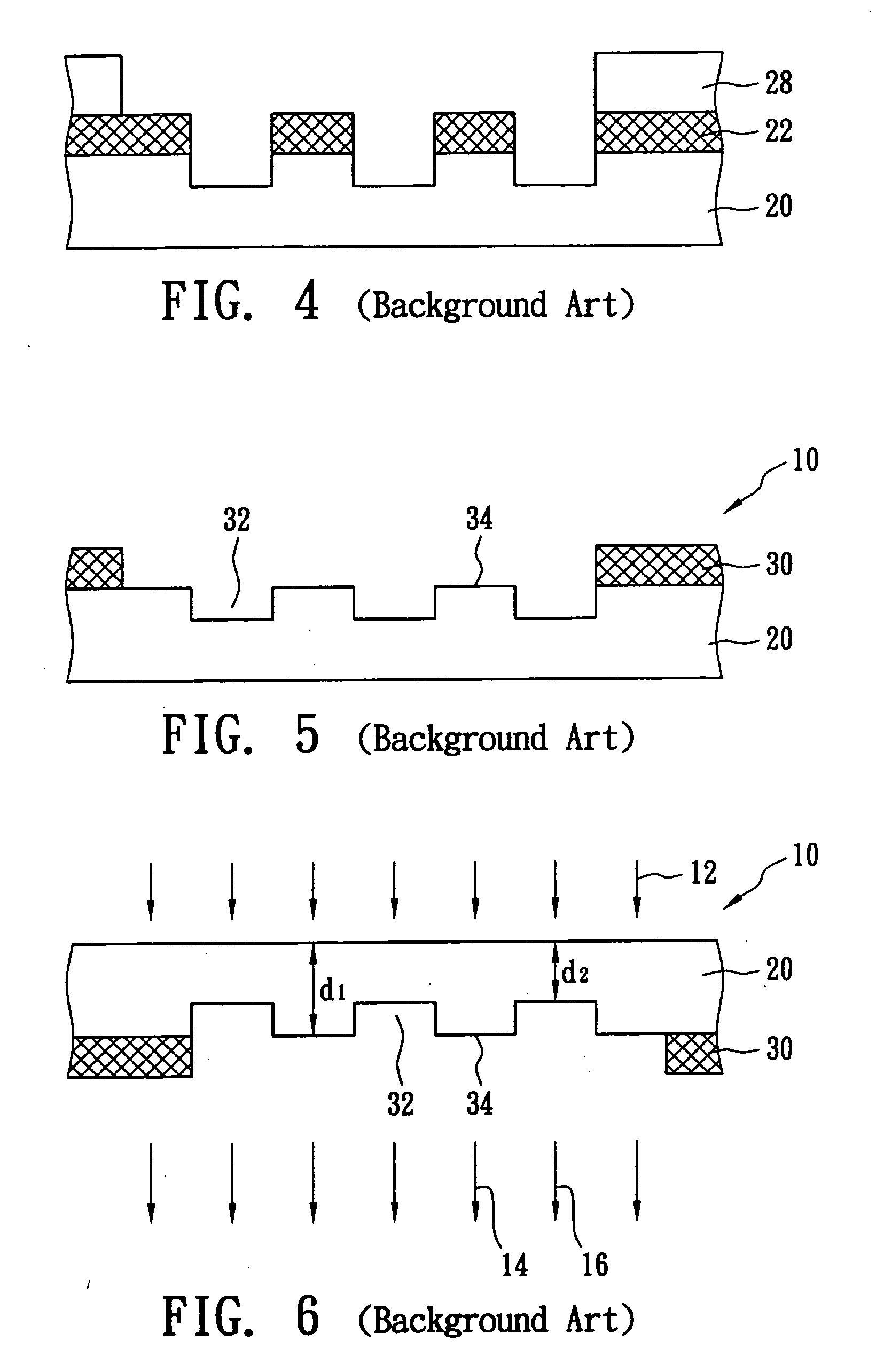

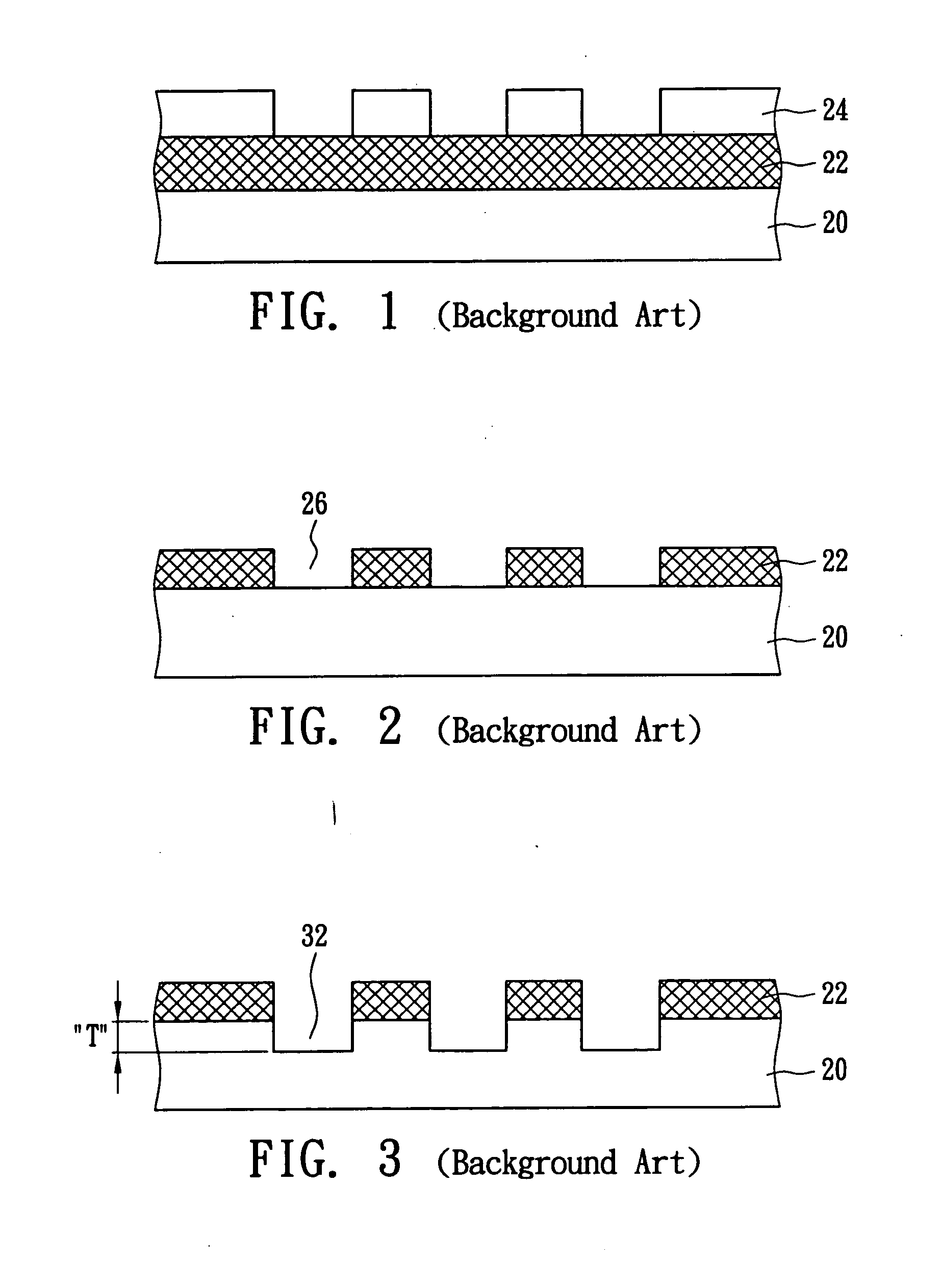

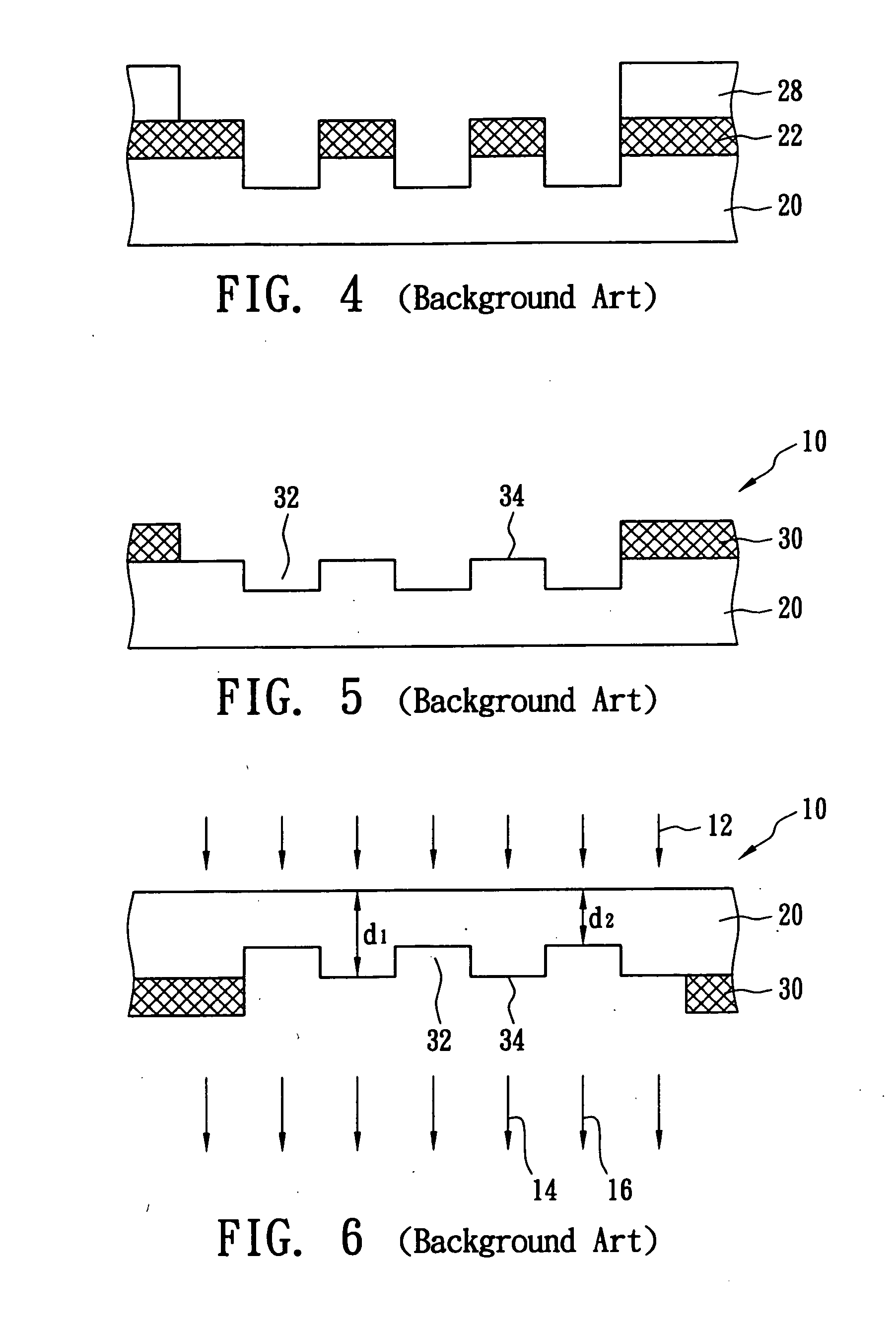

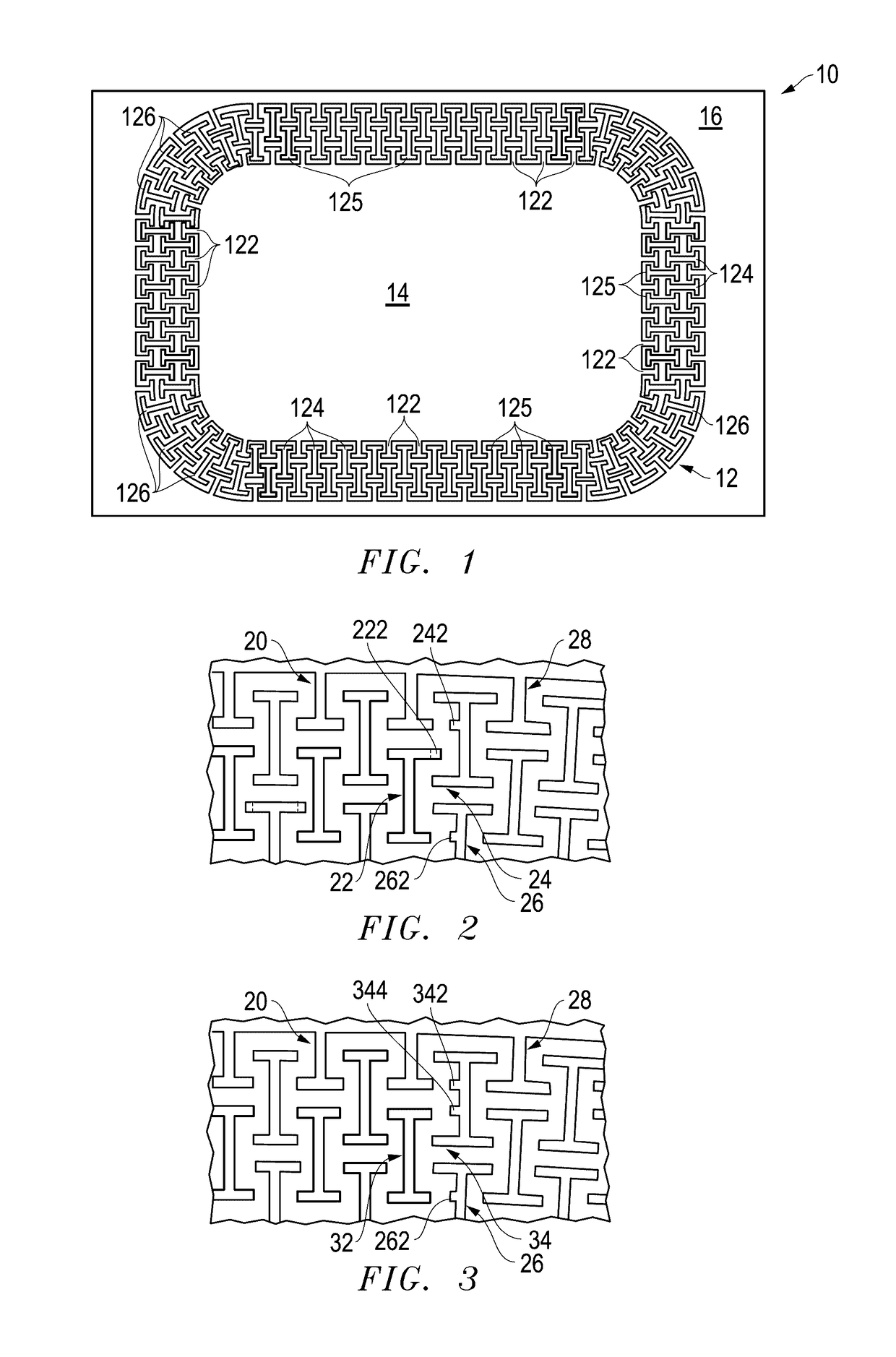

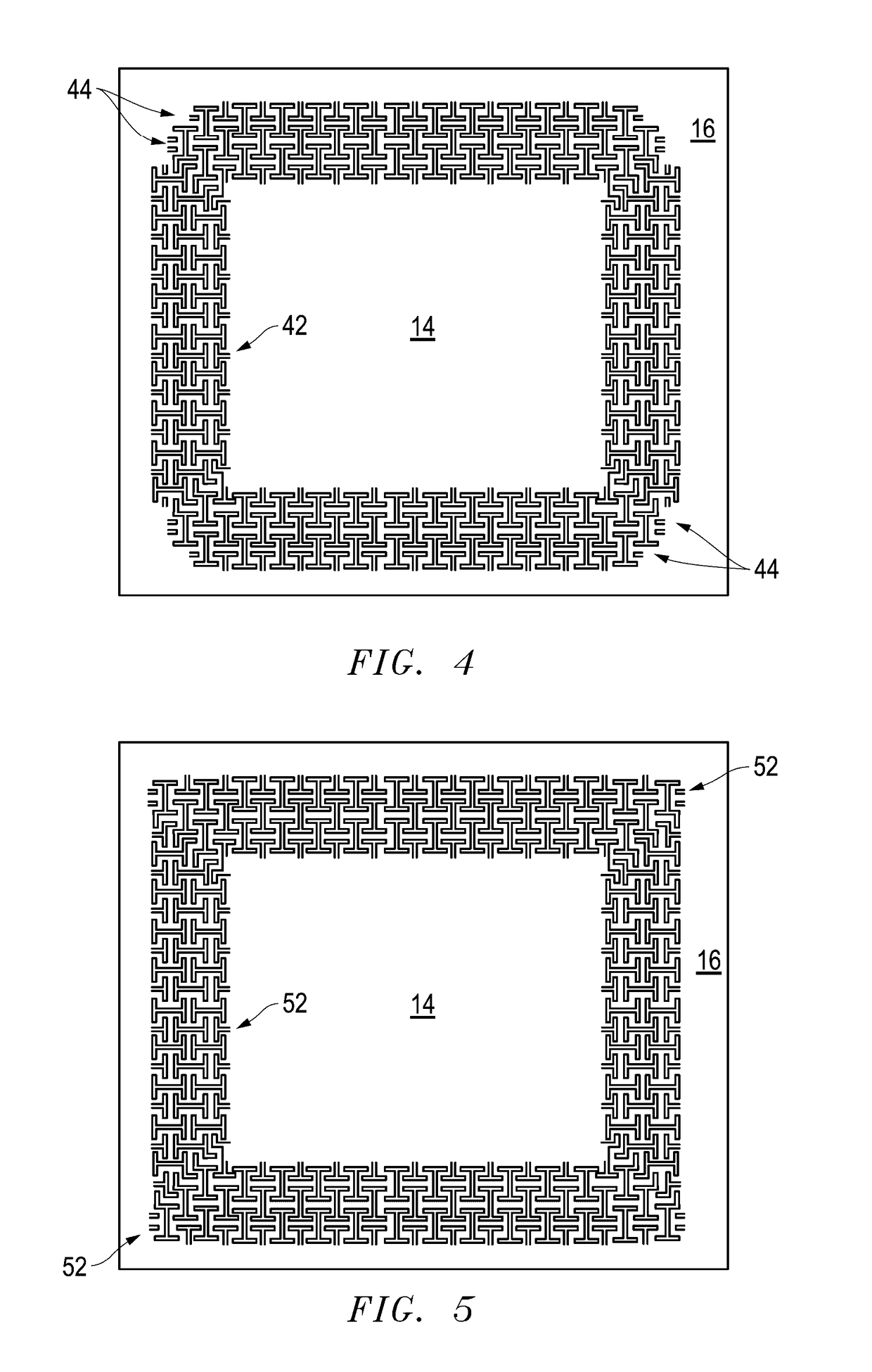

Phase-shifting mask

InactiveUS20070087271A1Increase mask throughputEliminate phase error problemPhotomechanical apparatusOriginals for photomechanical treatmentPresent methodEngineering

The present phase-shifting mask comprises a substrate and a plurality of phase-shifting patterns made of polymer material and positioned on the substrate in an array manner. Preferably, the space between phase-shifting patterns is smaller than the width of the phase-shifting pattern along a first direction, and the space between two line-shaped patterns consisting of phase-shifting patterns is substantially equal to the width of the line-shaped pattern along a second direction perpendicular to the first direction. The present method for preparing the phase-shifting mask comprises steps of forming a polymer layer on a substrate, changing the molecular structure the polymer layer in a plurality of predetermined regions, and removing a portion of the polymer layer outside these predetermined regions. The polymer layer can be made of hydrogen silsesquioxane, methylsilsesquioxane or hybrid organic siloxane polymer.

Owner:PROMOS TECH INC

Dark blood delayed enhancement magnetic resonance viability imaging techniques for assessing subendocardial infarcts

ActiveUS8086297B2Raise modalIncreases length and complexityDiagnostic recording/measuringSensorsContrast levelRelaxation curve

The technology herein provides a dark blood delayed enhancement technique that improves the visualization of subendocardial infarcts that may otherwise be disguised by the bright blood pool. The timed combination of a slice-selective and a non-selective preparation improves the infarct / blood contrast by decoupling their relaxation curves thereby nulling both the blood and the non-infarcted myocardium. This causes the infarct to be imaged bright and the blood and non-infarct to both be imaged dark. The slice-selective preparation occurs early enough in the cardiac cycle so that fresh blood can enter the imaged slice.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC +1

Method for preparing a phase-shifting mask and method for preparing a semiconductor device using the phase-shifting mask

InactiveUS20070087272A1Increase mask throughputEliminate phase error problemPhotomechanical apparatusOriginals for photomechanical treatmentPresent methodDevice material

A phase-shifting mask comprises a substrate and a plurality of phase-shifting patterns made of polymer material and positioned on the substrate in an array manner. Preferably, the space between phase-shifting patterns is smaller than the width of the phase-shifting pattern along a first direction, and the space between two line-shaped patterns consisting of phase-shifting patterns is substantially equal to the width of the line-shaped pattern along a second direction perpendicular to the first direction. The present method for preparing the phase-shifting mask comprises steps of forming a polymer layer on a substrate, changing the molecular structure the polymer layer in a plurality of predetermined regions, and removing a portion of the polymer layer outside these predetermined regions. The polymer layer can be made of hydrogen silsesquioxane, methylsilsesquioxane or hybrid organic siloxane polymer.

Owner:PROMOS TECH INC

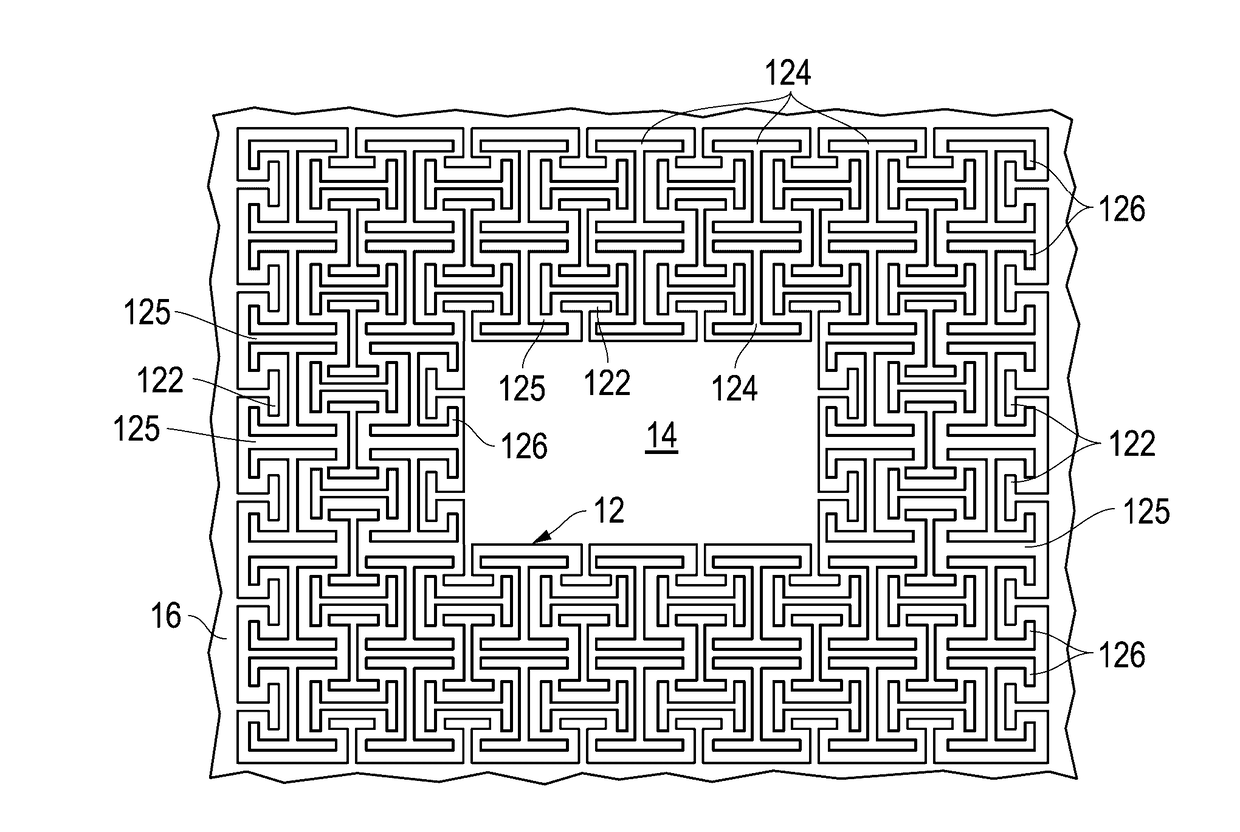

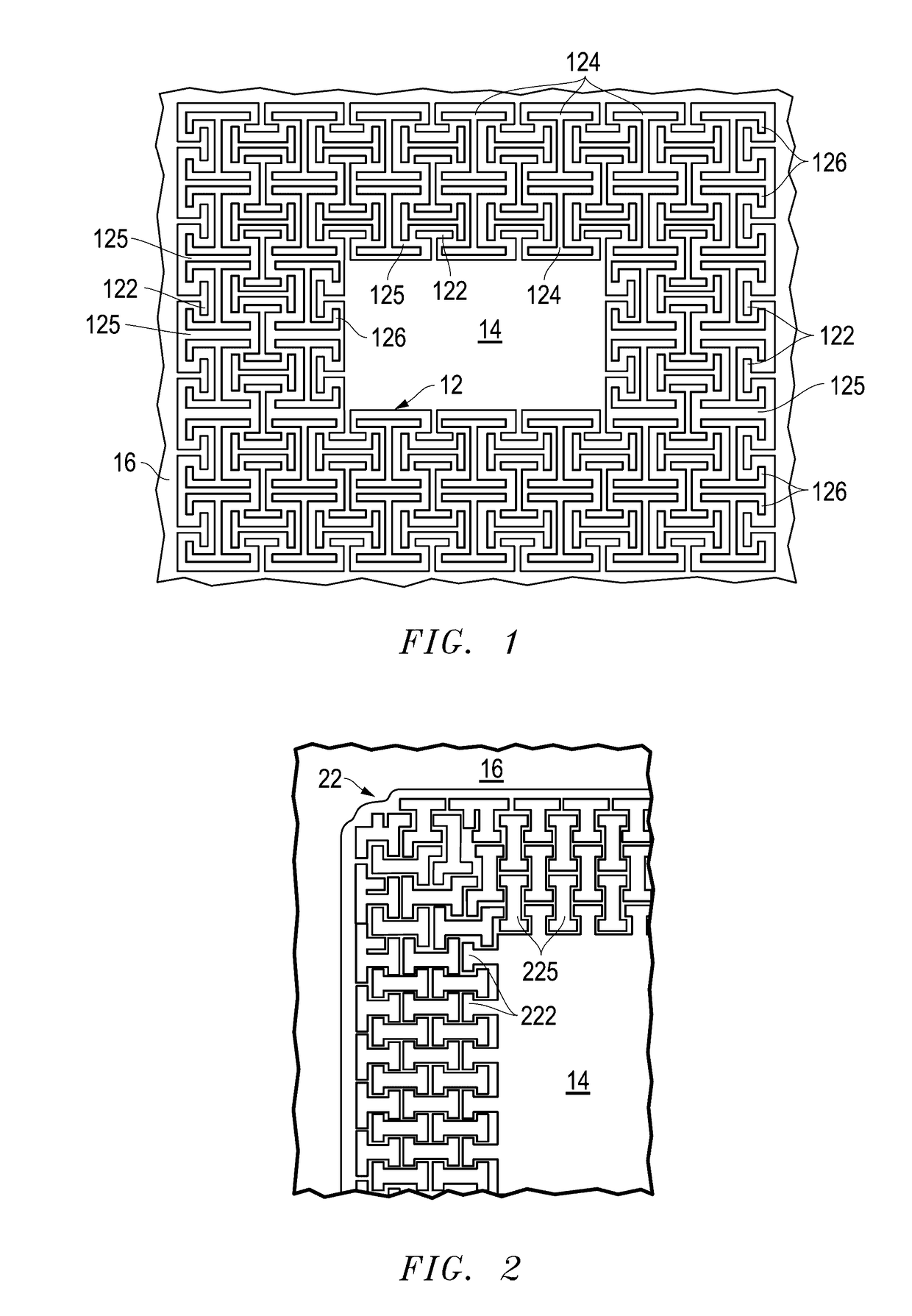

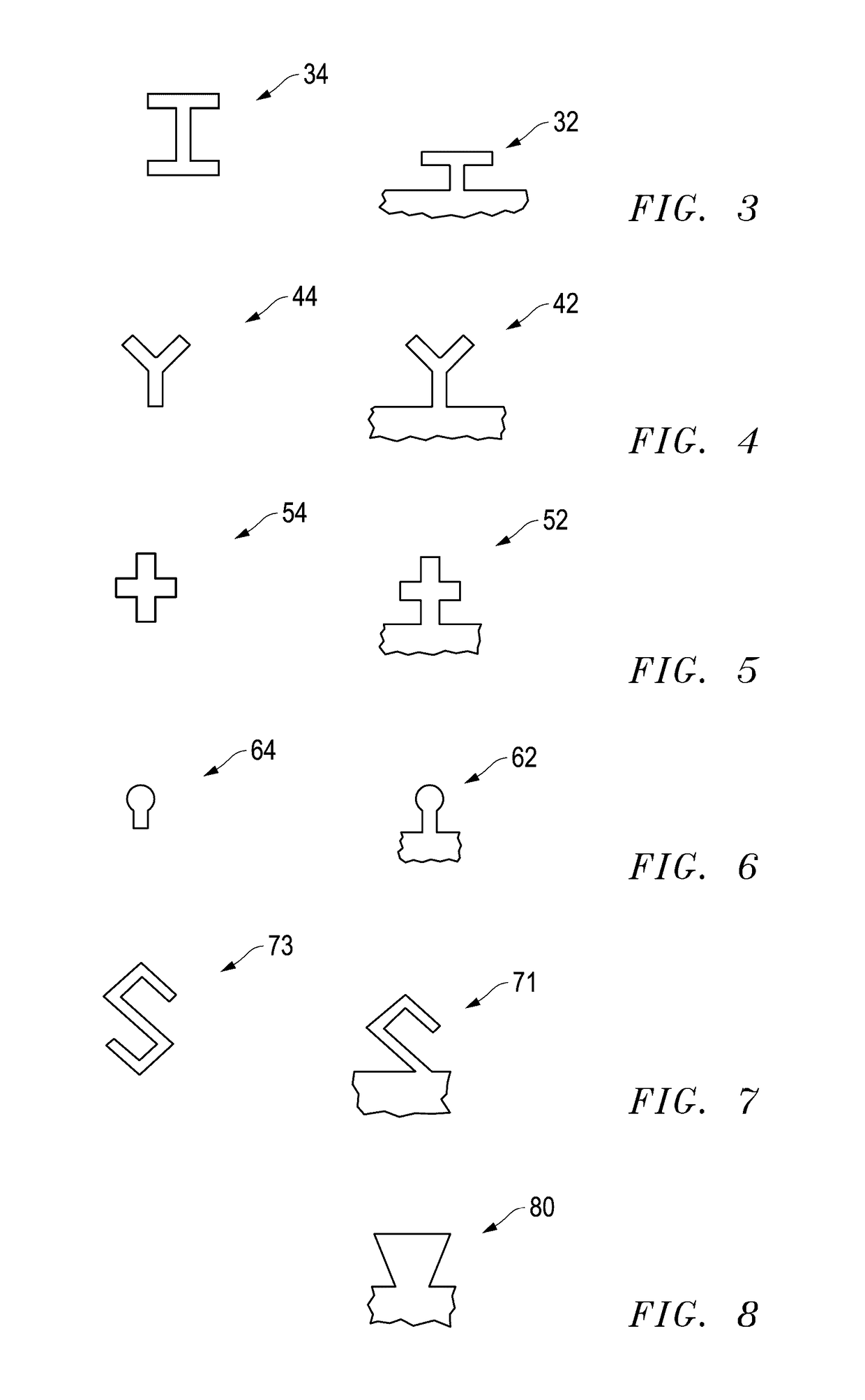

Electronic device including an insulating structure and a process for forming the same

ActiveUS20170084687A1Reduced flexibilityLimited throughputSemiconductor/solid-state device manufacturingInductancesEngineeringElectron

An electronic device can include a substrate and an insulating structure. In an aspect, an anchor can include a portion of the substrate that extends into the insulating structure or a portion of the insulating structure that extends into the substrate. In another aspect, a process of forming an electronic device can include patterning a substrate to define a trench and a first anchor; and forming an insulating structure within the trench and adjacent to the first anchor. In a further aspect, a process of forming an electronic device can include patterning a substrate to define a trench having a sidewall and a first pillar spaced apart from the sidewall; doping the first pillar to change a conductivity type of the first pillar; and forming an insulating structure that surrounds the first pillar.

Owner:SEMICON COMPONENTS IND LLC

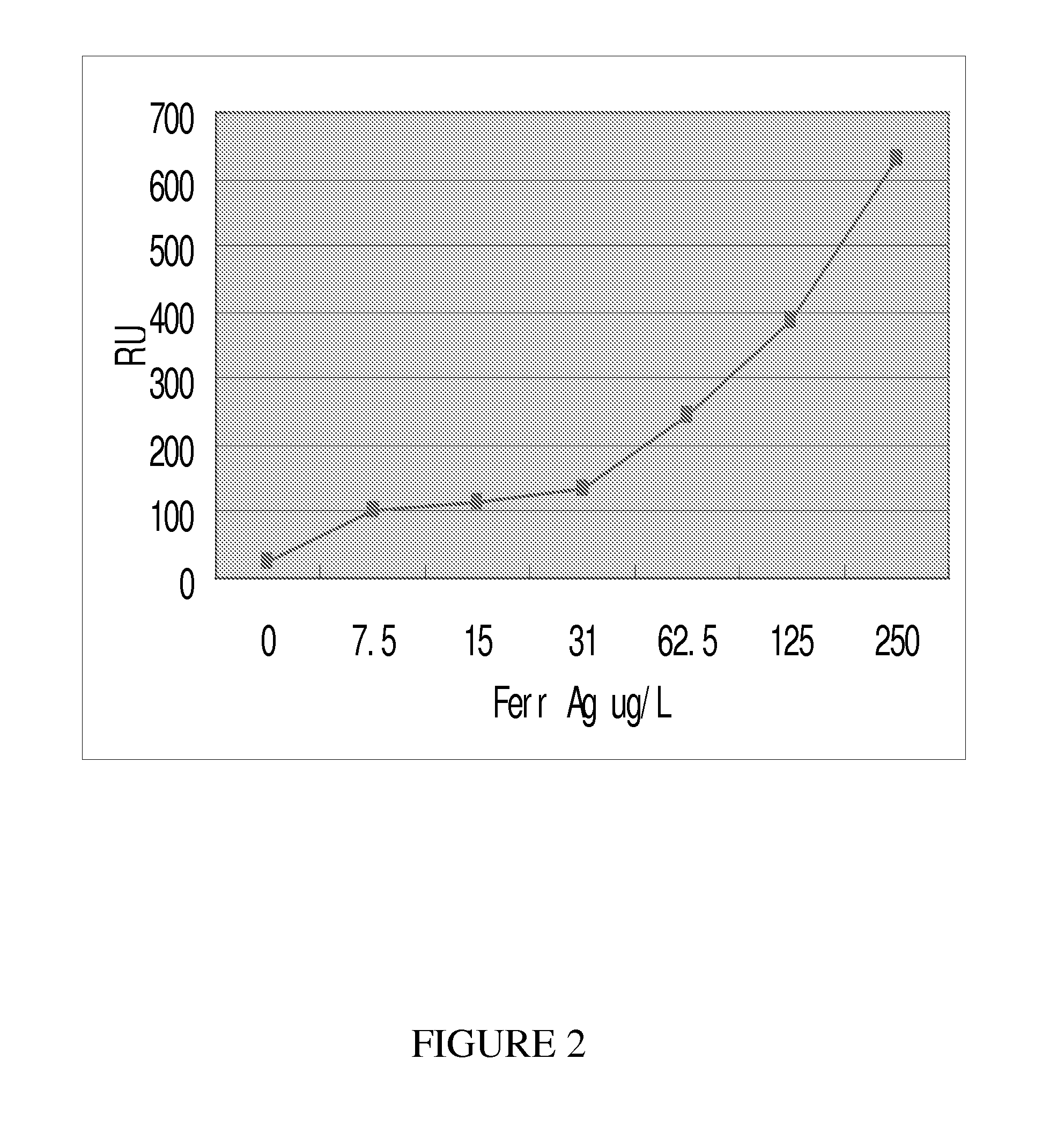

Method for the quantitative evaluation of sex hormones in a serum sample

InactiveUS20100009464A1Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsSerum samplesHormones regulation

This invention discloses using SPR technology to simultaneously and quantitatively measure the concentrations of different sex hormones in a serum sample, which can be used to evaluate different clinical situations. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of relevant antibodies used for the detection of representative sex hormones in a serum sample.

Owner:CMED TECH

Automatic car wash system

InactiveUS7318442B2Improve throughputAvoid disadvantagesCleaning apparatus with conveyorsMovable spraying apparatusDriver/operatorRadiotransmitter

An automatic car wash system is provided for processing multiple vehicles simultaneously. The system according to one embodiment includes an elongate path, a plurality of stations for processing the vehicle, at least two detectors for indicating the presence of the vehicles. The system provides instructions to the drivers of the vehicles so that the vehicles travel through the system under their own power, and thus conveyor systems can be avoided, yet throughput remains high. In one embodiment, the system includes a radio transmitter that is operable to direct specific information to each of the vehicles via radio signals.

Owner:MACDOWELL MICHAEL

Substrate process apparatus

ActiveUS20210265188A1Increase the number ofMinimal impactMagnetic circuitSemiconductor/solid-state device manufacturingLevitationElectric machine

A linear electrical machine comprising a frame with a level reference plane and an array of electromagnets, connected to the frame to form a drive plane at a predetermined height relative to the reference plane. The array of electromagnets being arranged so that a series of electromagnets of the array of electromagnets define at least one drive line within the drive plane, and each of the electromagnets being coupled to an alternating current power source energizing each electromagnet. At least one reaction platen of paramagnetic, diamagnetic, or non-magnetic conductive material disposed to cooperate with the electromagnets of the array of electromagnets so that excitation of the electromagnets with alternating current generates levitation and propulsion forces against the reaction platen that controllably levitate and propel the reaction platen along at least one drive line, in a controlled attitude relative to the drive plane.

Owner:BOOKS AUTOMATION US LLC

Spray coating apparatus and fixtures

InactiveUS20070261635A1Low costLimited throughputLiquid surface applicatorsSemiconductor/solid-state device detailsThermal sprayingSpray coating

A system for applying a sprayed coating includes a spray mechanism operative to spray a liquefied coating material; a target system including a rotatable spray target wheel; and one or more device-holding fixtures configured to be mounted onto the spray target wheel without requiring either an unattached threaded fastener or a locking pin. Preferred embodiments of the system are configured for thermal spray application of Tamper Resistant Coatings (TRCs).

Owner:MICROSEMI CORP

Method for quantitative measurement of thyroid hormones and related antibodies in a serum sample

InactiveUS20090280575A1Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenDisease

This invention discloses using SPR technology to simultaneously and quantitatively measure the concentrations of thyroid hormones and related antibodies in a serum sample, which can be used to evaluate thyroid functions and to diagnose thyroid diseases. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of relevant antibodies and antigens used for the detection of respective thyroid hormones and related antibodies in a serum sample.

Owner:CMED TECH

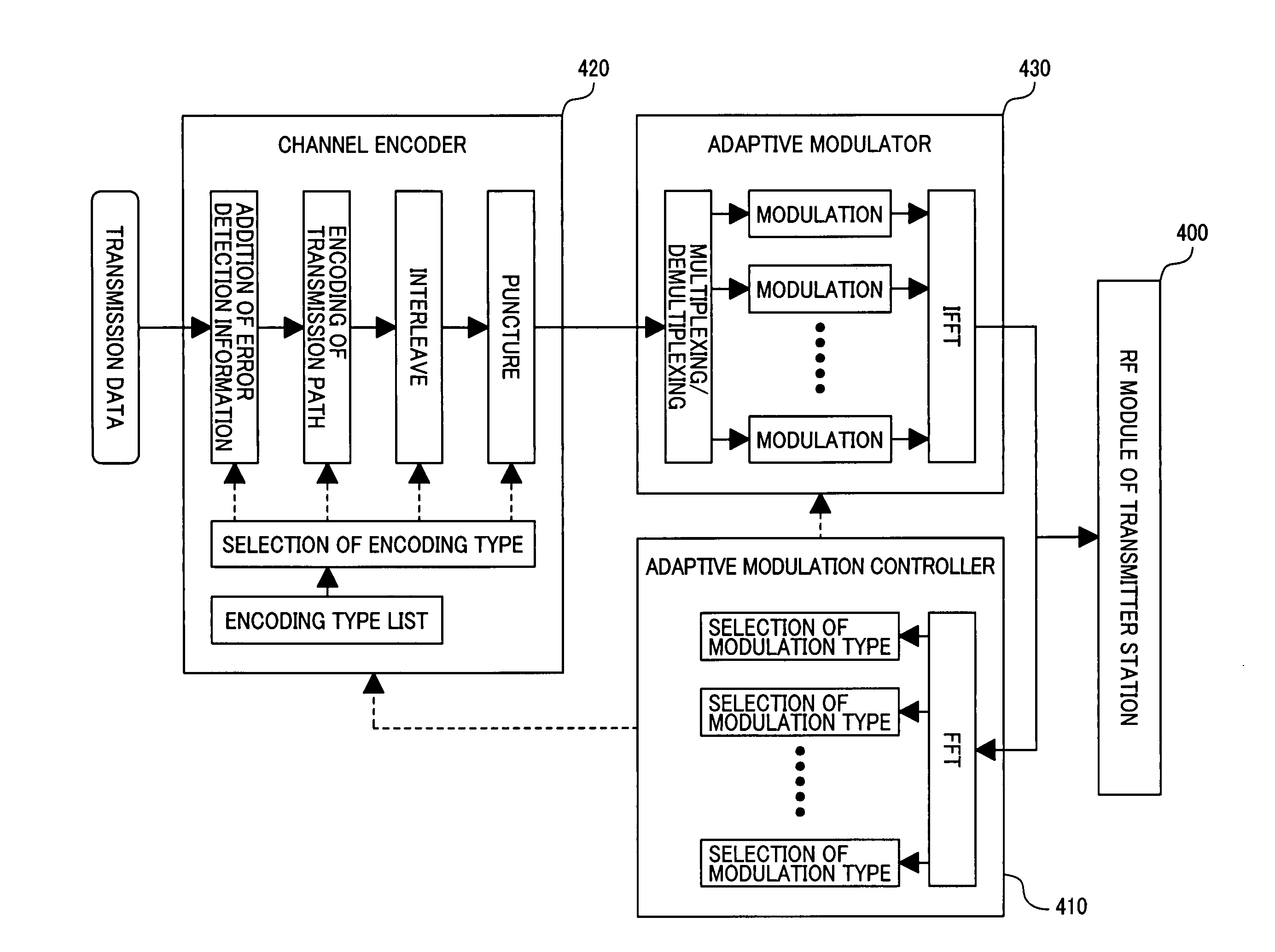

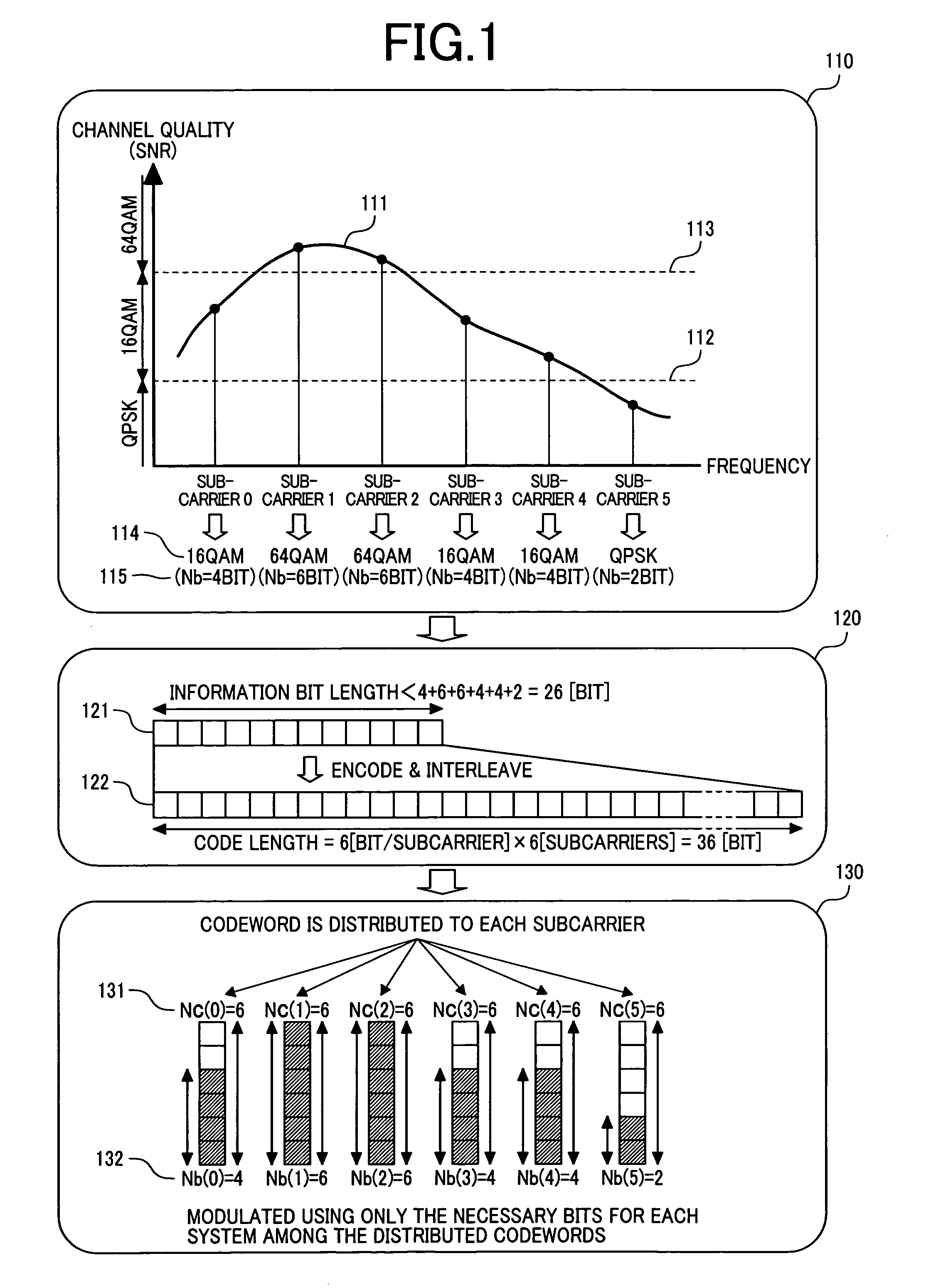

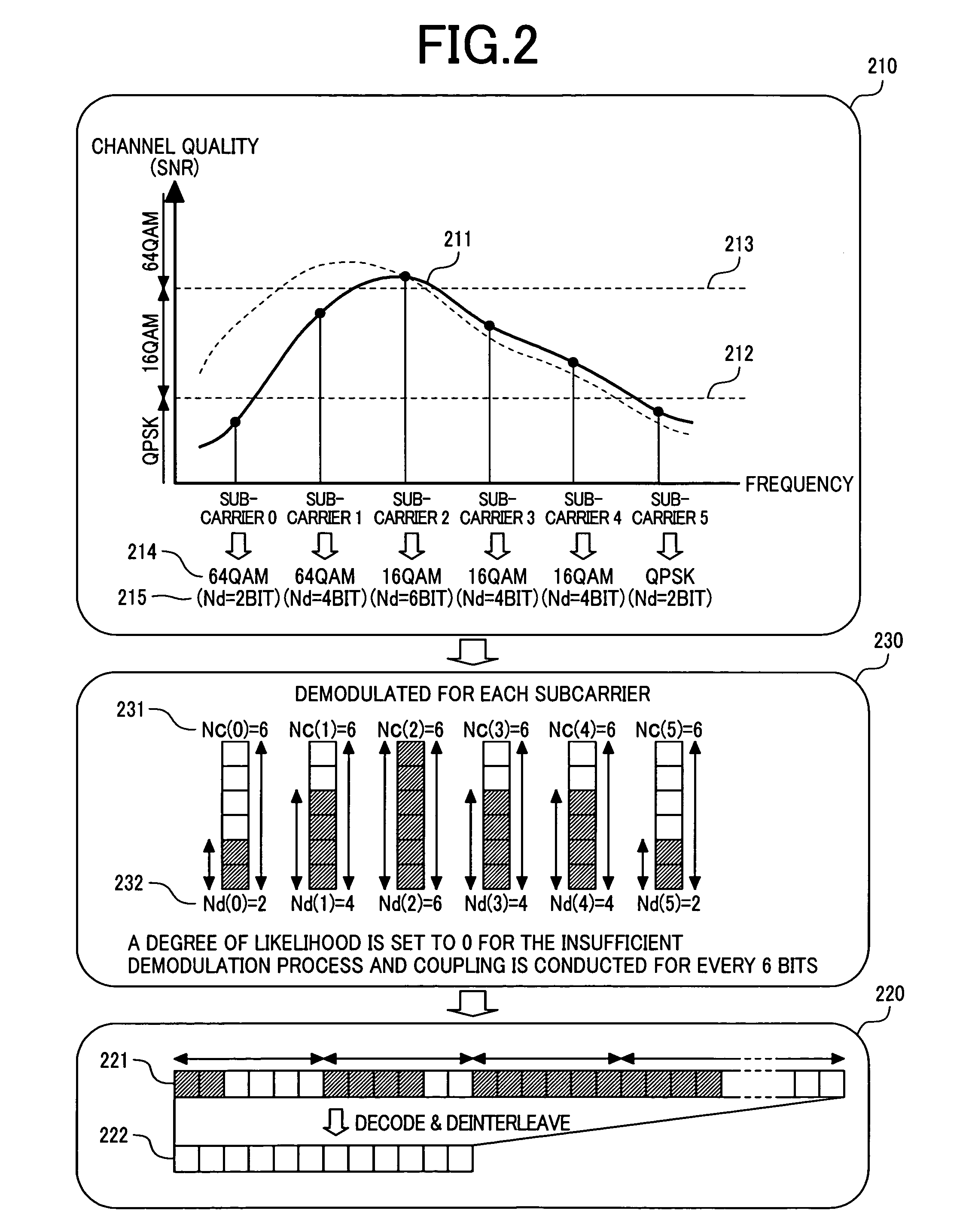

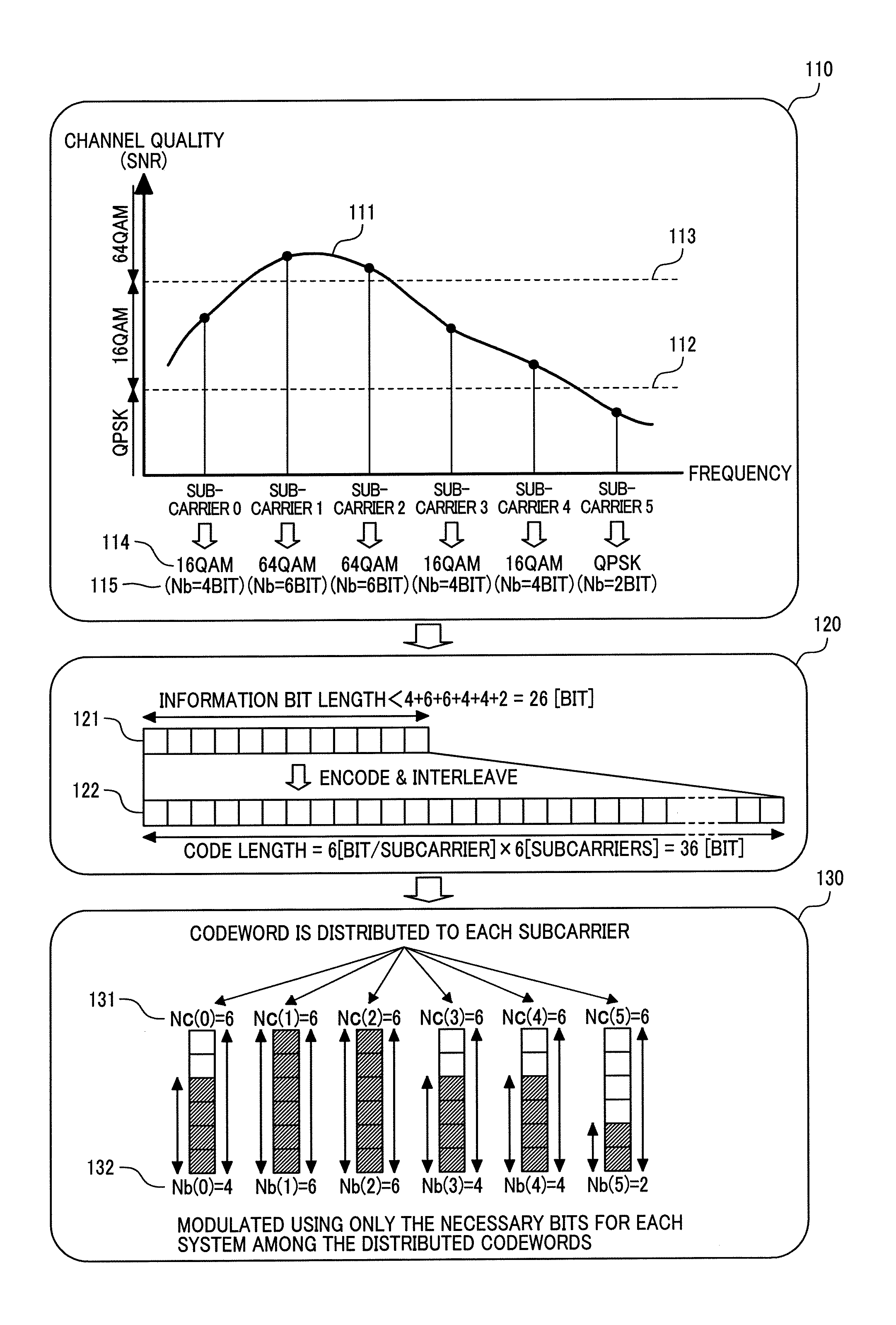

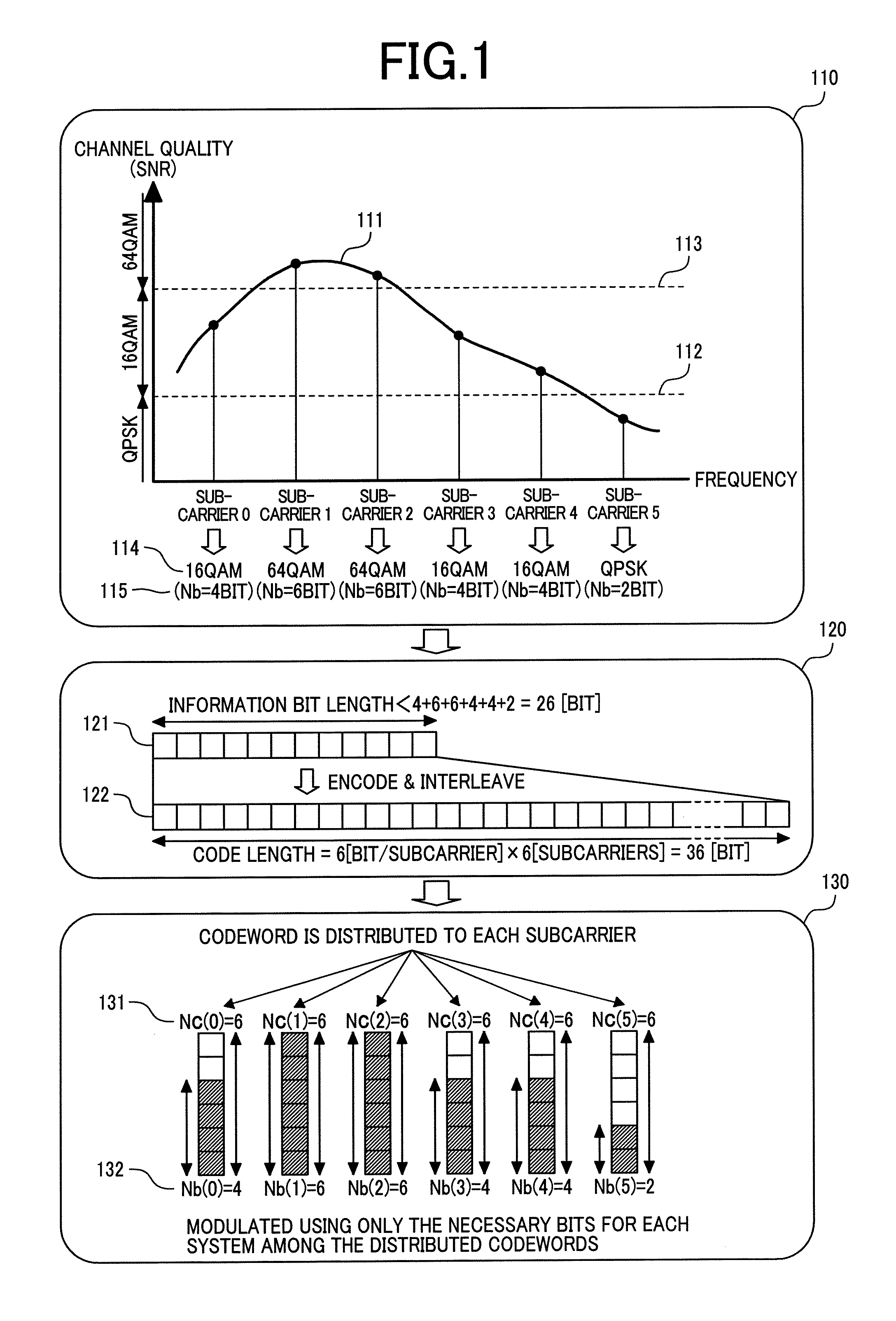

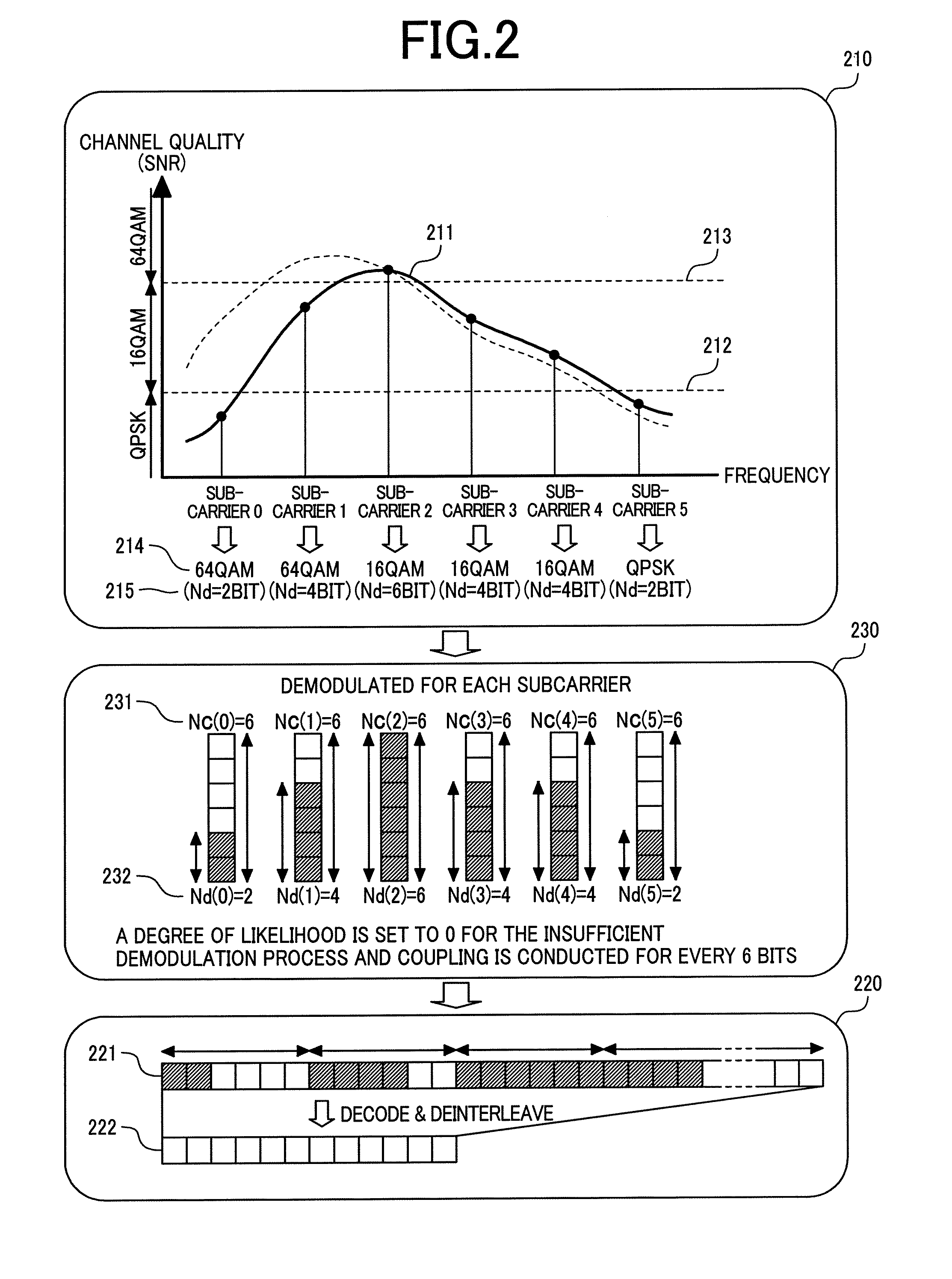

Adaptive modulation scheme and data rate control method

InactiveUS7801236B2Reduce in quantityLimited throughputMultiple modulation transmitter/receiver arrangementsCriteria allocationCarrier signalData rate

A transmitter station and receiver station have common maximum number of transmission bits per symbol of each subcarrier and information of encoding types to be selected. The transmitter station selects the modulation type from the propagation path quality of each subcarrier, executes encoding with the encoding type corresponding to the number of bits for communication with the selected modulation type, distributes the maximum number of transmission bits per symbol of each subcarrier by dividing the code, and transmits the data through modulation of only the number of bits for communication with the selected modulation type among distributed bits in each subcarrier. The receiver station executes demodulation by selecting the modulation type used for demodulation from the propagation path quality, summarizes the demodulation result with addition of reception of the signal having a zero degree of likeliness for the number of wanted bits, and executes decoding to the result of demodulation.

Owner:HITACHI LTD

Controlling shopper checkout throughput

InactiveUS8061603B2Limited throughputReduce errorsCash registersVisual presentationComputer scienceThroughput

The present invention provides a solution for controlling checkout throughput. Specifically, under the present invention a set of attributes of an item will be obtained. An analysis of the set of attributes will then be performed to determine whether an inconsistency exists based on a tolerance threshold. Such analysis can include, for example, comparing the weight of the item to its expected weight. This can help determine if a mistake has been made or fraud has been committed. Whether an inconsistency is observed is based on a tolerance threshold. For example, a certain deviation (i.e., the tolerance threshold) from an expected value could be allowed to could be allowed to reduce errors during the checkout process and thereby increase checkout throughput. As such, the present invention allows the tolerance threshold to be tuned based on a desired checkout throughput.

Owner:INT BUSINESS MASCH CORP

Adaptive modulation scheme and data rate control method

InactiveUS20110122957A1Reduce in quantityLimited throughputMultiple modulation transmitter/receiver arrangementsCriteria allocationCommunication unitCommunications system

A radio communication system includes a first radio station for dividing codewords into communication units and transmitting the divided codewords by modulating them in every communication unit, and a second radio station for coupling and decoding signals obtained by demodulating the communication units. The radio stations have common information of first bits, equal to maximum bits per symbol of the communication units, and an encoding type list. The first station modulates and transmits the communication units with a modulation type with second bits. The second radio station receives the communication units modulated by the first radio station, demodulates the communication units with a modulation type with third bits, combines and decodes the demodulated signals with encoding types in the encoding type list, and obtains a result of the decoding, as reception information, by an encoding type in which no error is detected in the result of decoding.

Owner:HITACHI LTD

Method for the identification of human immunodeficiency virus related antibodies in blood

InactiveUS20090239766A1Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenSerum samples

This invention discloses using SPR technology to simultaneously and qualitatively measure the presence of HIV related antibodies in a serum sample for the diagnosis of HIV infection. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of HIV related antigens used for the diagnosis of HIV infection.

Owner:CMED TECH

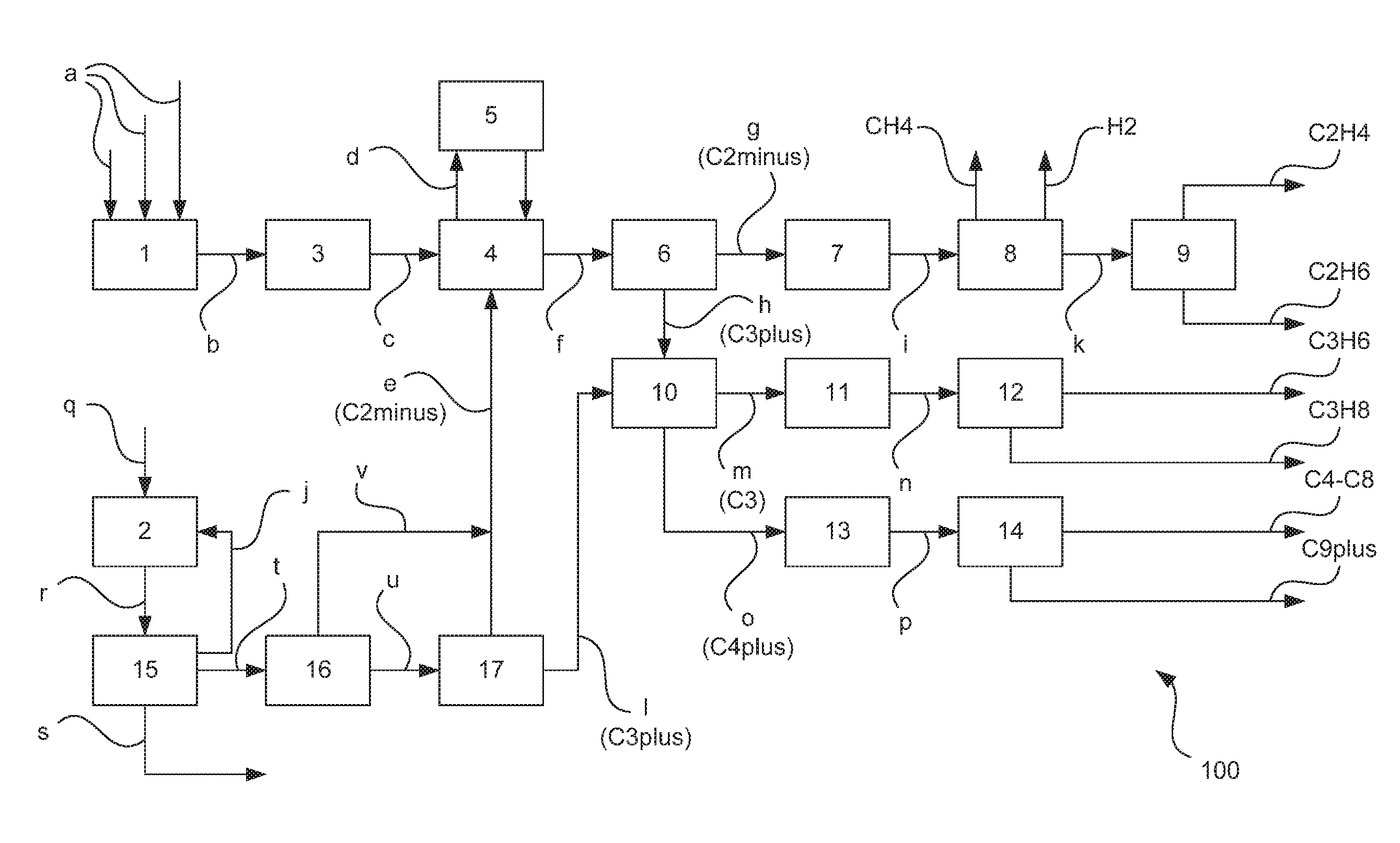

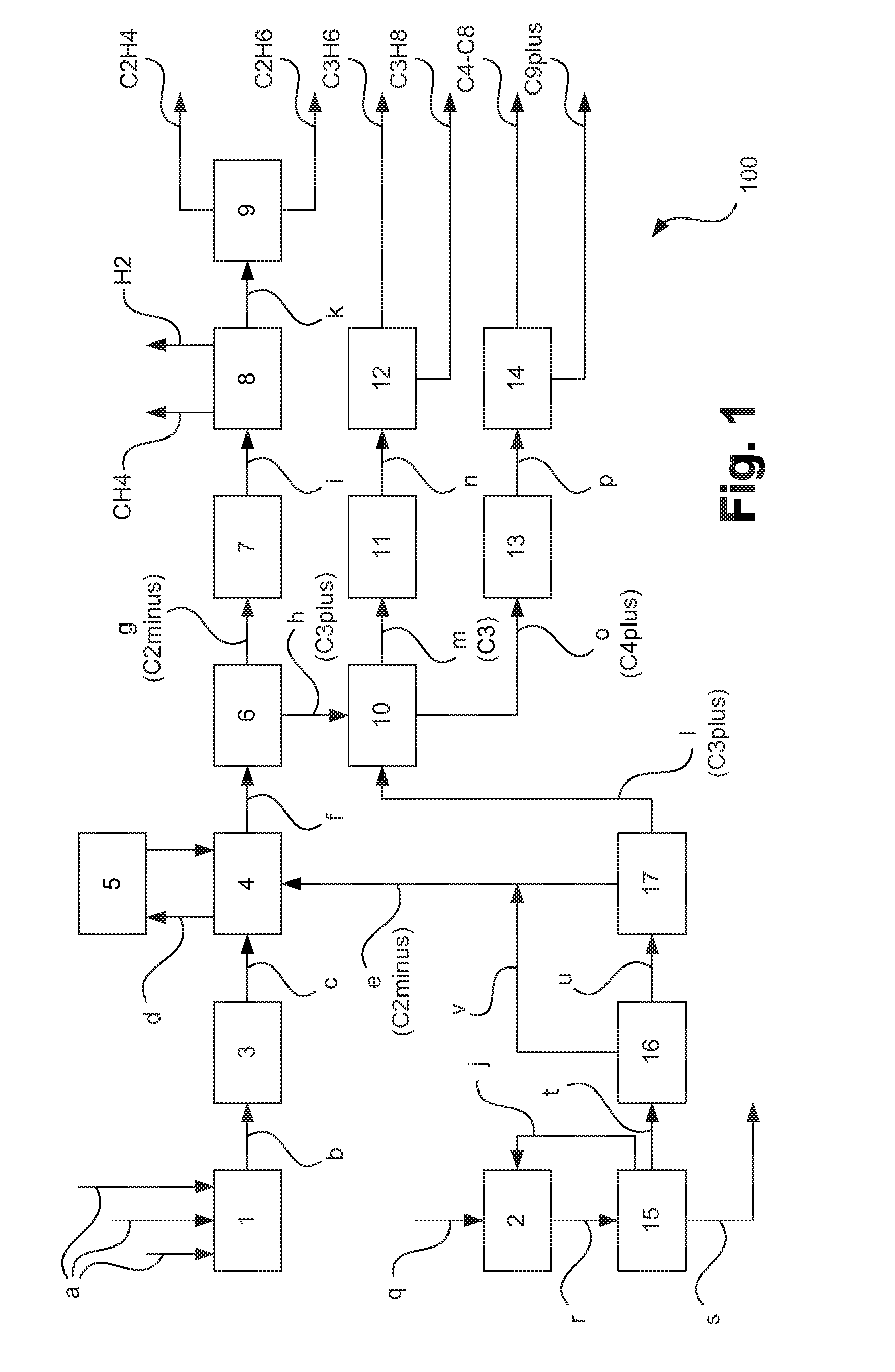

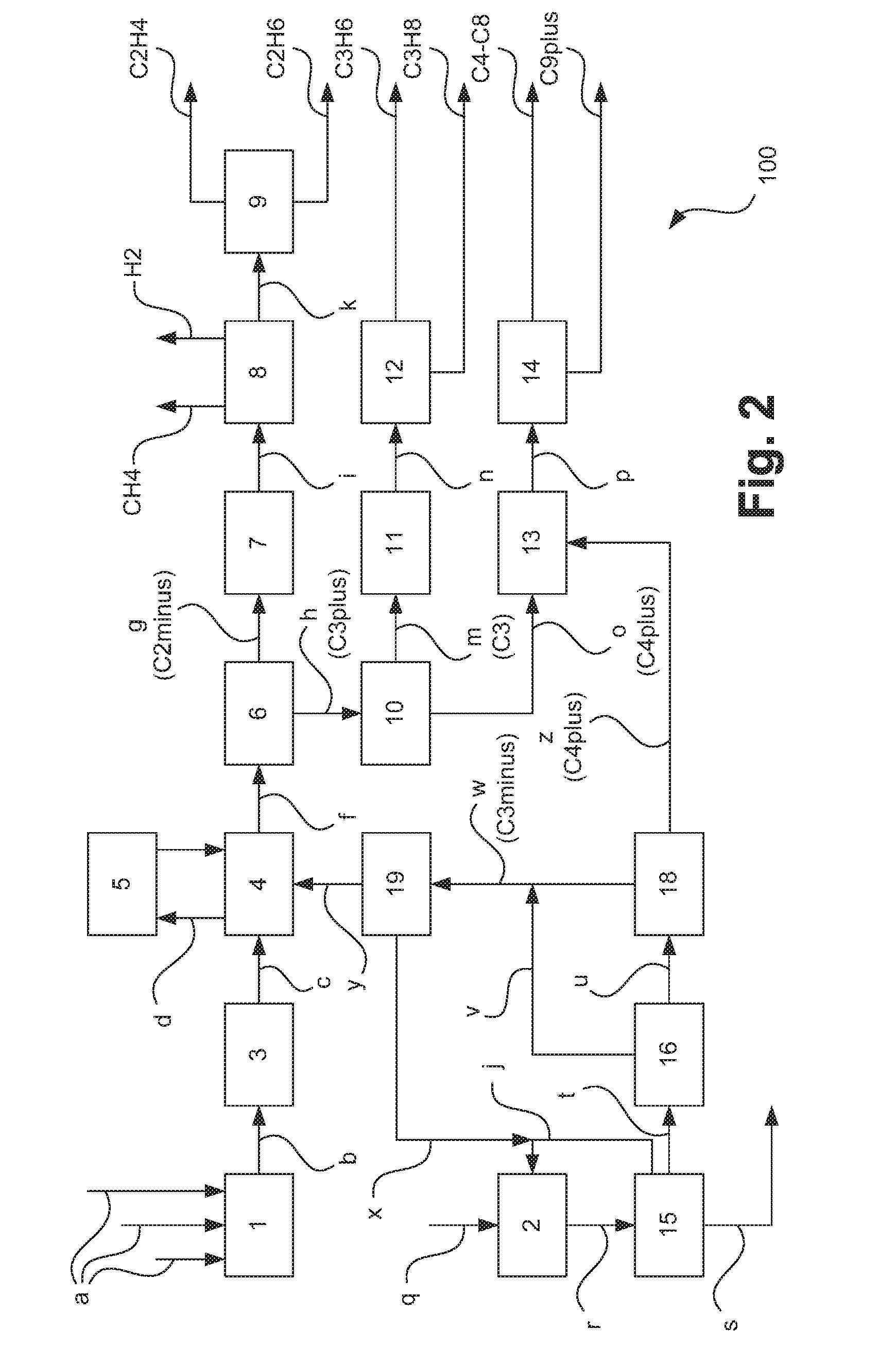

Olefin Production Process

InactiveUS20160347688A1Significant proportionGreat proportionThermal non-catalytic crackingDistillation purification/separationOxygenateAlkene

A method (100) for obtaining olefins is proposed, wherein a first gas mixture (b), which is produced by a steam cracking process (1), is at least partially used to form a first separation feedstock (f) which contains hydrocarbons with one to five carbon atoms, and from which at least a first separation product (g) and a second separation product (h, o) are produced, the first separation product (g) containing at least the greater proportion of the hydrocarbons with one carbon atom and of the hydrocarbons with two carbon atoms contained in the first separation feedstock (f), and the second separation product (h, o) containing at least the greater proportion of the hydrocarbons with four carbon atoms and of the hydrocarbons with five carbon atoms contained in the first separation feedstock (f), and wherein a second gas mixture (r) which is produced by an oxygenate-to-olefin process (2) is used at least partially to form a second separation feedstock (t) which contains hydrocarbons with one to five carbon atoms, and from which at least a third separation product (e, y) and a fourth separation product (l, z) are produced, the third separation product (e, y) containing at least the greater proportion of the hydrocarbons with one carbon atom and of the hydrocarbons with two carbon atoms contained in the second separation feedstock (t), and the fourth separation product (l, z) containing at least the greater proportion of the hydrocarbons with four or five carbon atoms contained in the second separation feedstock (t). The third separation product (e, y) is also at least partially used to form the first separation feedstock (f), and a third separation feedstock (h, l) (o, z) is formed from at least part of the fourth separation product (l, z) and of the second separation product (h, o) and is subjected to a separation (14).

Owner:LINDE AG

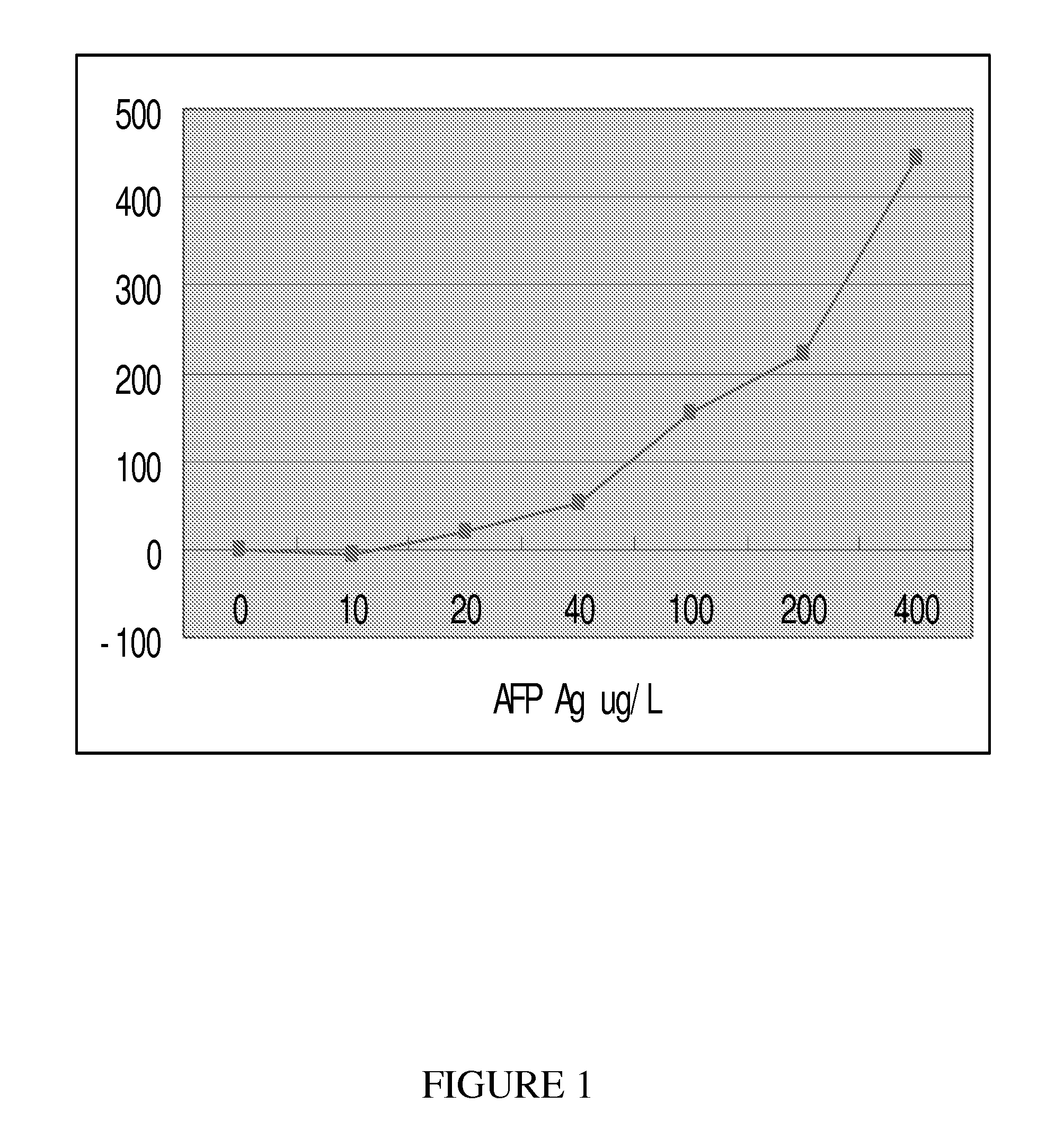

Application of surface plasmon resonance technology to maternal serum screening for congenital birth defects

InactiveUS20100021930A1Limited throughputSimultaneous measurementDisease diagnosisBiological testingSerum markersBiology

This invention discloses using SPR technology to simultaneously and quantitatively detect the presence of serum markers in pregnant women for the purpose of screening for congenital birth defects. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of representative antibodies used to detect the respective serum markers in pregnant women for the purpose of maternal serum screening for congenital birth defects.

Owner:CMED TECH

Method to detect tumor markers and diagnosis of undifferentiated tumors

InactiveUS20100047815A1Detect directlyLimited throughputBiological testingMonoclonal antibodyTumor tissue sample

This invention discloses using SPR technology to simultaneously and quantitatively measure the concentrations of different tumor markers in a protein sample extracted from tumor tissue, which can be used for the diagnosis of undifferentiated tumors. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of monoclonal antibodies used for detecting tumor markers in a tumor tissue sample and for the diagnosis of undifferentiated tumors.

Owner:CMED TECH

Method for quantitative detection of diabetes related immunological markers

InactiveUS20090325190A1Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsImmune markersAntigen

This invention discloses using SPR technology to simultaneously and quantitatively measure the concentrations of diabetes related immunological makers in a serum sample, which can be used to diagnose and / or early diagnose diabetes as well as to predict the onset risk of diabetes in first-degree relatives. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of relevant antigens and antibodies used for the detection of respective diabetes related immunological makers in a serum sample.

Owner:CMED TECH

Method to assess cancer susceptibility and differential diagnosis of metastases of unknown primary tumors

InactiveUS20100086920A1Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsBlood serumWilms' tumor

This invention discloses using SPR technology to simultaneously and quantitatively measure the concentrations of different tumor markers in a serum sample, which can be used to screen for and determine susceptibility to cancer as well as for the differential diagnosis of metastases from an unknown primary tumor. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of monoclonal antibodies used for cancer susceptibility assessment and for differential diagnosis of metastases from an unknown primary tumor.

Owner:CMED TECH

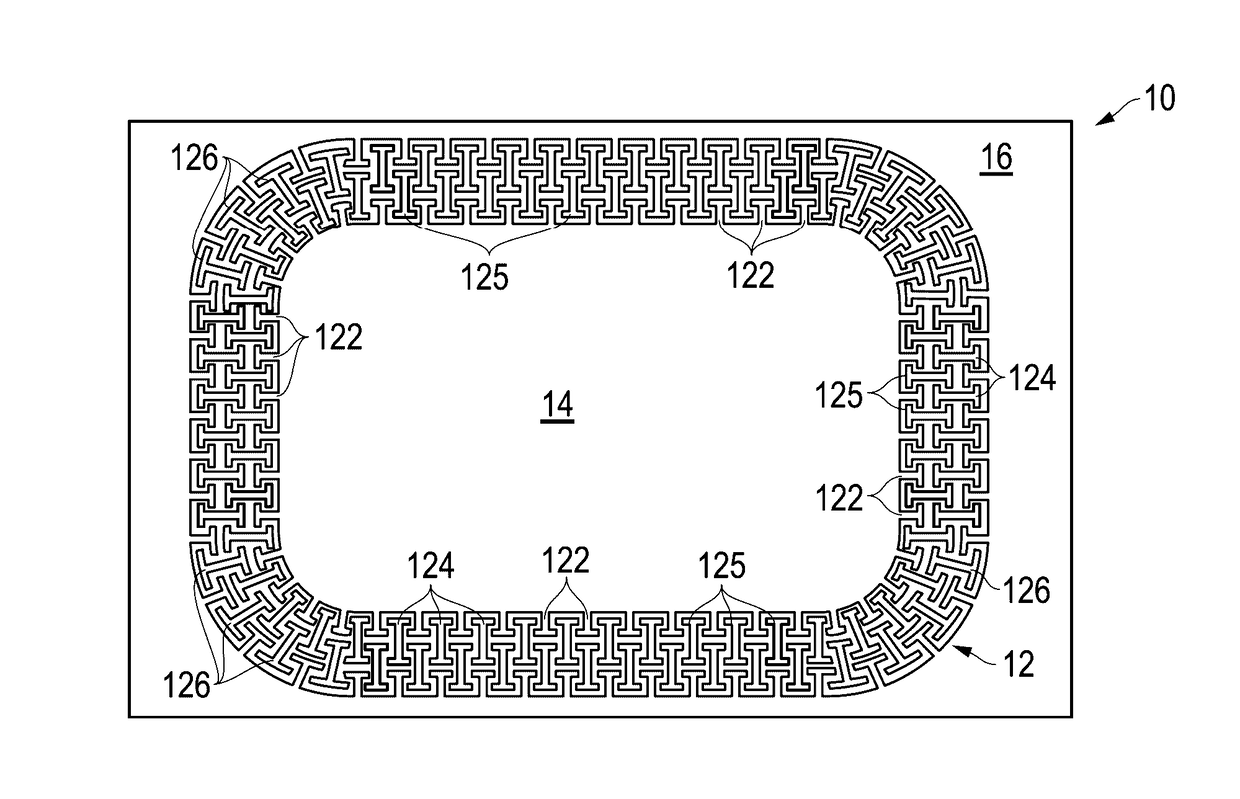

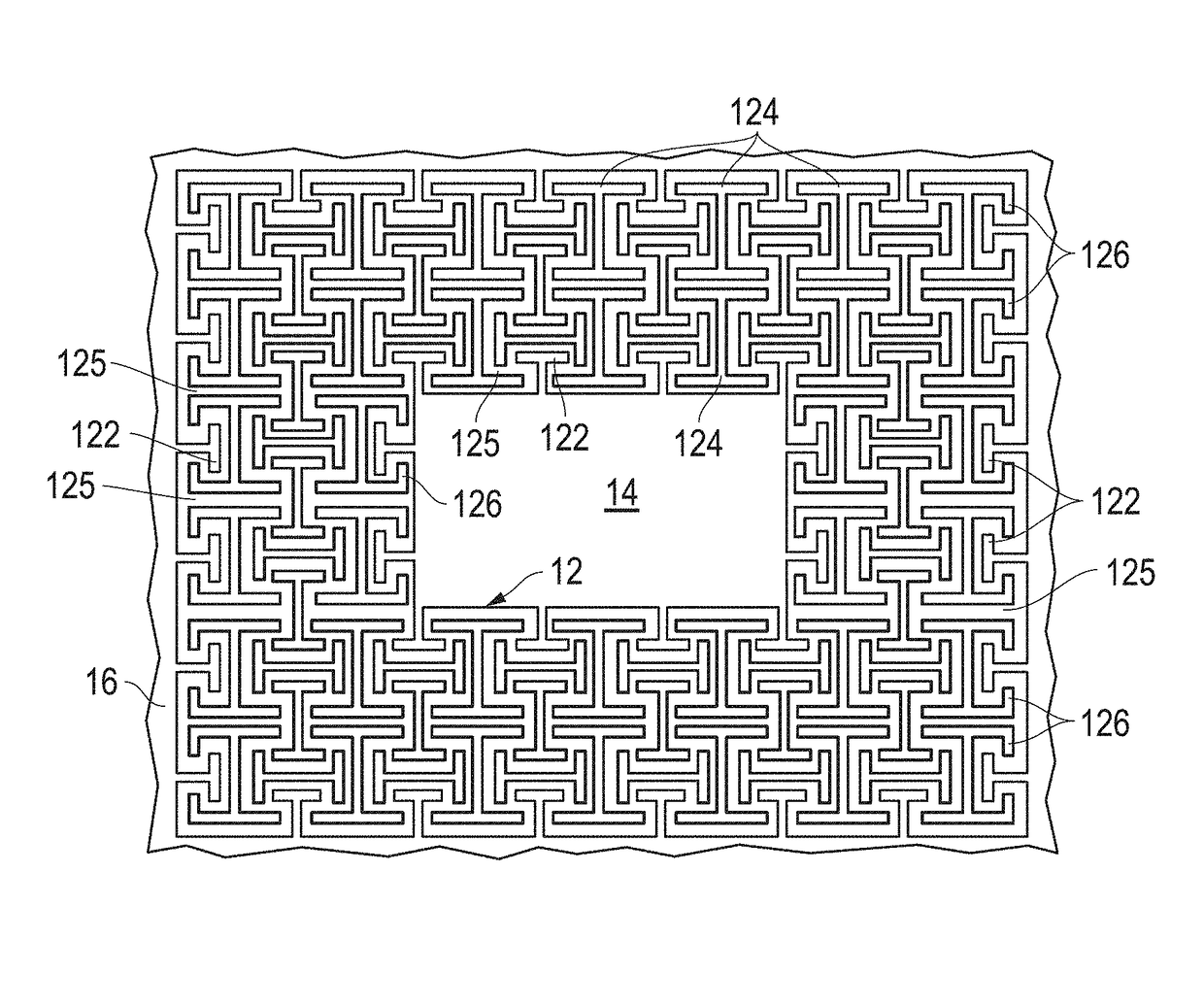

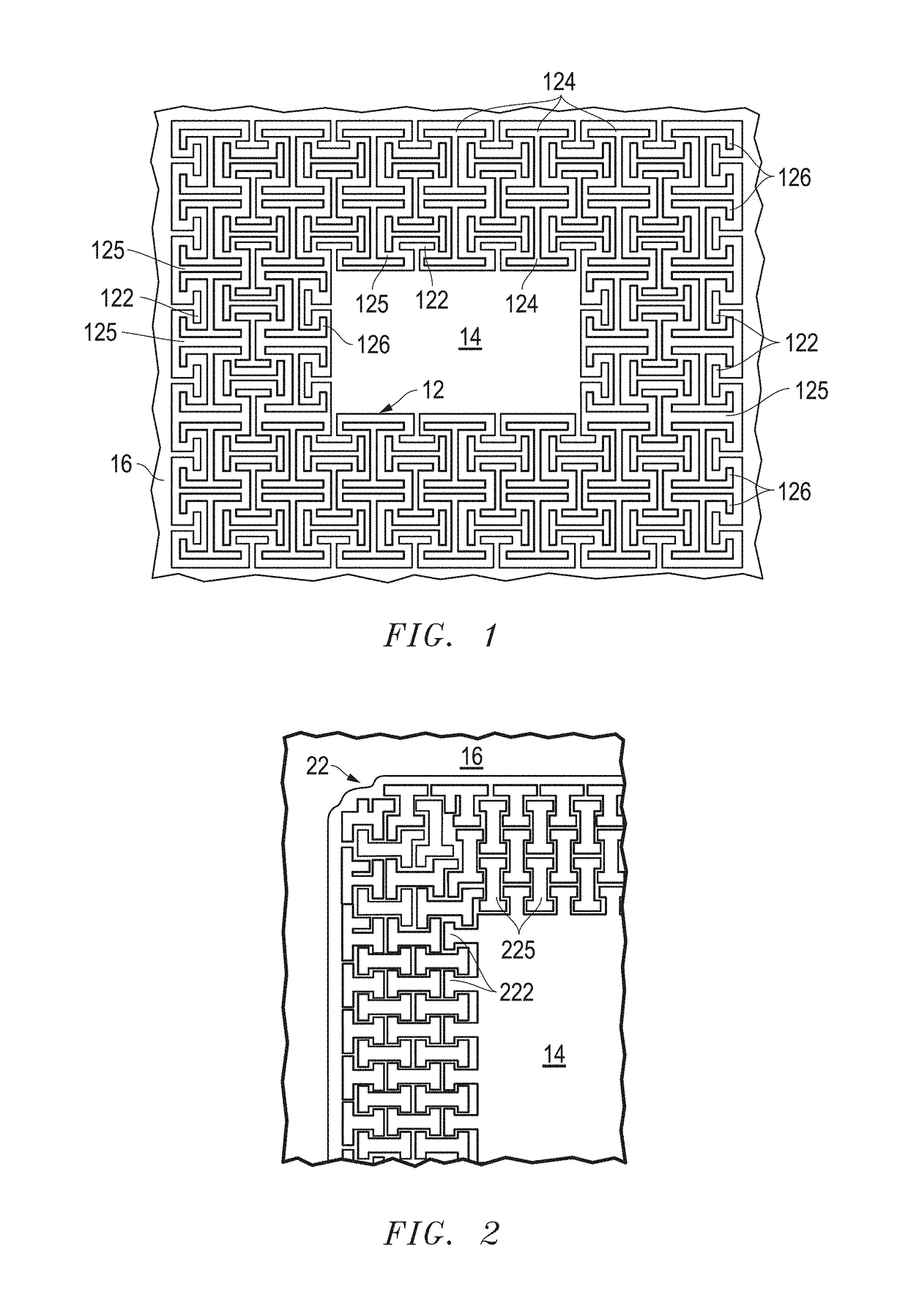

Electronic device including a conductive structure surrounded by an insulating structure and a process for forming the same

ActiveUS20170084705A1Reduced flexibilityLimited throughputSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureInductor

An electronic device can include a substrate and an insulating structure laterally surrounded by the substrate. In an aspect, the electronic device can include a first conductive structure or an active region that is laterally surrounded by the insulating structure and the substrate. In another aspect, the electronic device can include an inductor surrounded by the insulating structure. In a further aspect, a process of forming an electronic device can include patterning a substrate to define a trench and a plurality of features, including a first feature and a second feature, within the trench; forming a first insulating layer within the trench; removing the first feature to create a first cavity; forming a second insulating layer to at least partly fill the first cavity; removing the second feature to create a second cavity; and forming a conductive or semiconductor structure within the second cavity.

Owner:SEMICON COMPONENTS IND LLC

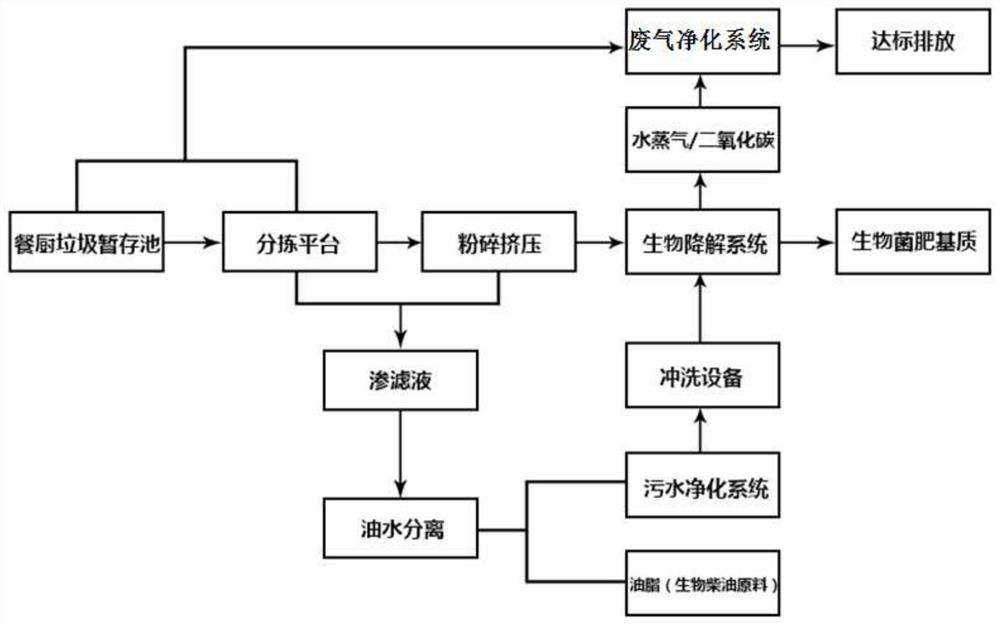

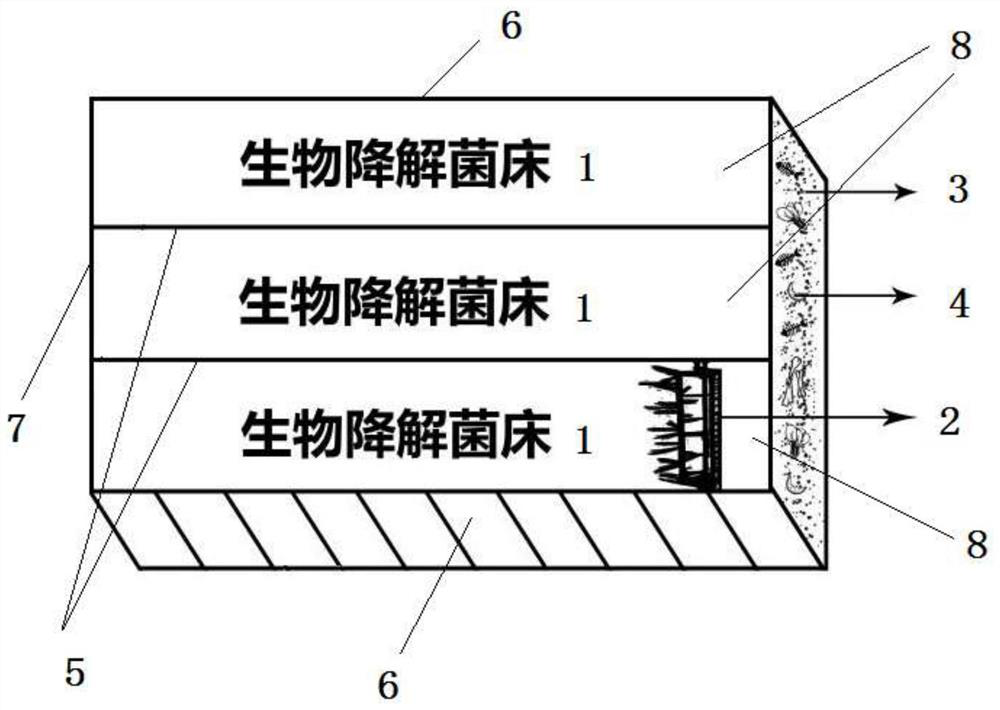

Wet garbage large-capacity centralized treatment three-waste-free rapid decomposition system and rapid decomposition method

InactiveCN112337947ANo obvious smellAchieve reductionSolid waste disposalBacillus licheniformisDecomposition

The invention discloses a wet garbage large-capacity centralized treatment three-waste-free rapid decomposition system and a rapid decomposition method. The system comprises a wet garbage temporary storage pool, a sorting platform, a crushing extruder, a biodegradation system and a waste gas purification system, wherein the biodegradation system comprises a biodegradation bacteria bed and a turning and throwing machine; the biodegradation bacteria bed comprises a padding layer and a wet garbage layer; a mixture of padding and biodegradation flora is laid on the padding layer; the biodegradation flora is mainly a mixture of bacillus subtilis, bacillus pumilus, bacillus licheniformis and acinetobacter calcoaceticus; and the turning and throwing machine is an automatic bottom-making turning and throwing machine with a gear and a shovel, and materials on the biodegradation bacteria bed are turned and thrown once at certain intervals. The wet garbage biodegradation rate can reach 99%, the problem of wet garbage large-capacity centralized treatment is thoroughly solved, the problem of three-waste storage in wet garbage treatment is thoroughly solved, and the three wastes are not reducedbut almost not quantified; and one-time treatment is achieved to reach the standard.

Owner:上海骄茗环境科技有限公司

Method for the identification of human immunodeficiency virus related antibodies in blood

InactiveUS8158342B2Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenSerum samples

Owner:CMED TECH

Electronic device including a conductive structure surrounded by an insulating structure

ActiveUS9991338B2Reduced flexibilityLimited throughputSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureInductor

An electronic device can include a substrate and an insulating structure laterally surrounded by the substrate. In an aspect, the electronic device can include a first conductive structure or an active region that is laterally surrounded by the insulating structure and the substrate. In another aspect, the electronic device can include an inductor surrounded by the insulating structure. In a further aspect, a process of forming an electronic device can include patterning a substrate to define a trench and a plurality of features, including a first feature and a second feature, within the trench; forming a first insulating layer within the trench; removing the first feature to create a first cavity; forming a second insulating layer to at least partly fill the first cavity; removing the second feature to create a second cavity; and forming a conductive or semiconductor structure within the second cavity.

Owner:SEMICON COMPONENTS IND LLC

Method to detect virus related immunological markers for the diagnosis of hepatitis b virus infection

InactiveUS20100028856A1Limited throughputSimultaneous measurementBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenBlood serum

This invention discloses using SPR technology to simultaneously and qualitatively measure the presence of HBV-associated immunological markers in a serum sample for the diagnosis of HBV infection. It also discloses an efficient formula to make a mixed SAM that can greatly enhance the immobilization ability of the metal surface in SPR based techniques, which is good for the immobilization of HBV related antigens or antibodies used for the diagnosis of HBV infection.

Owner:CMED TECH

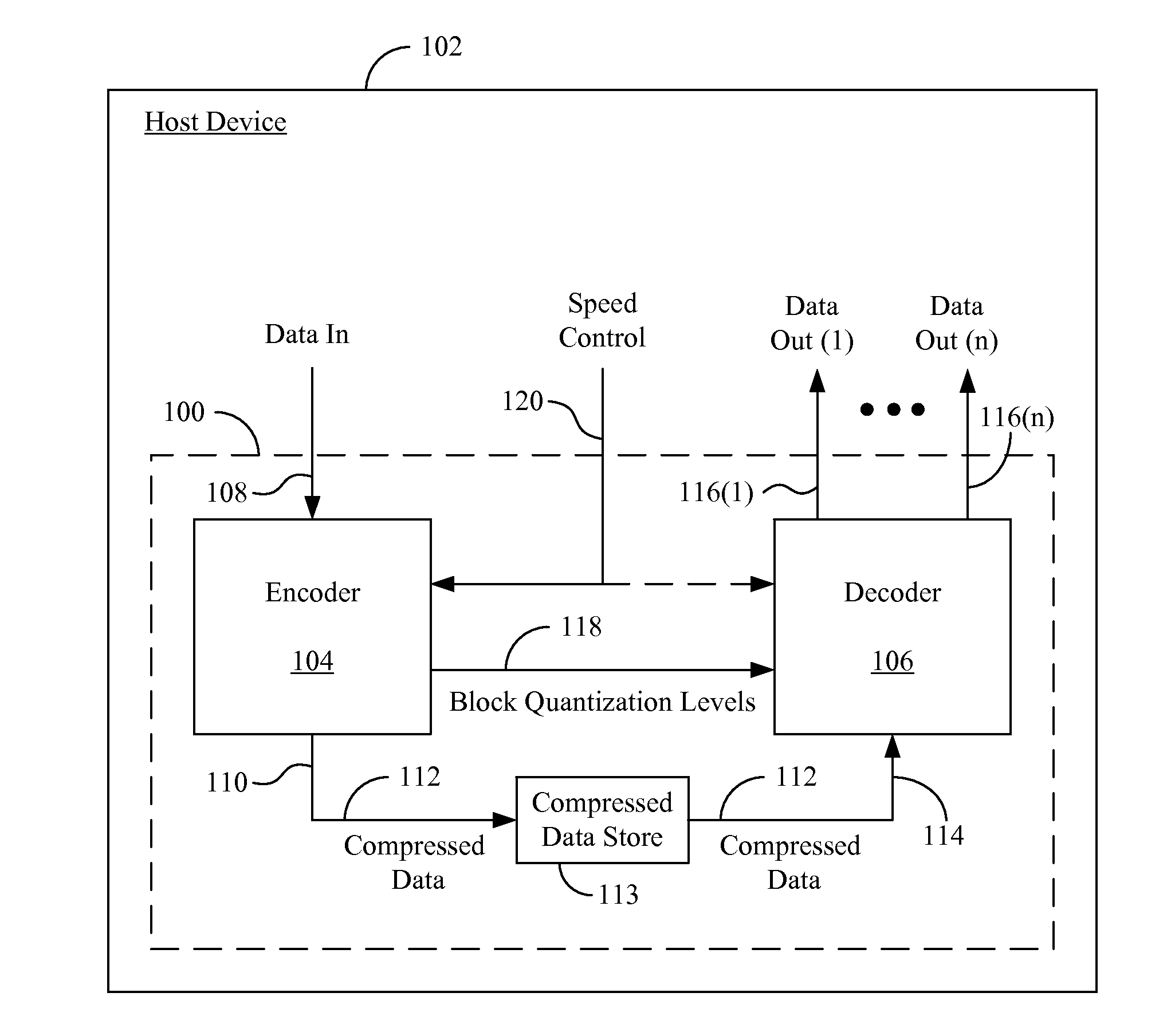

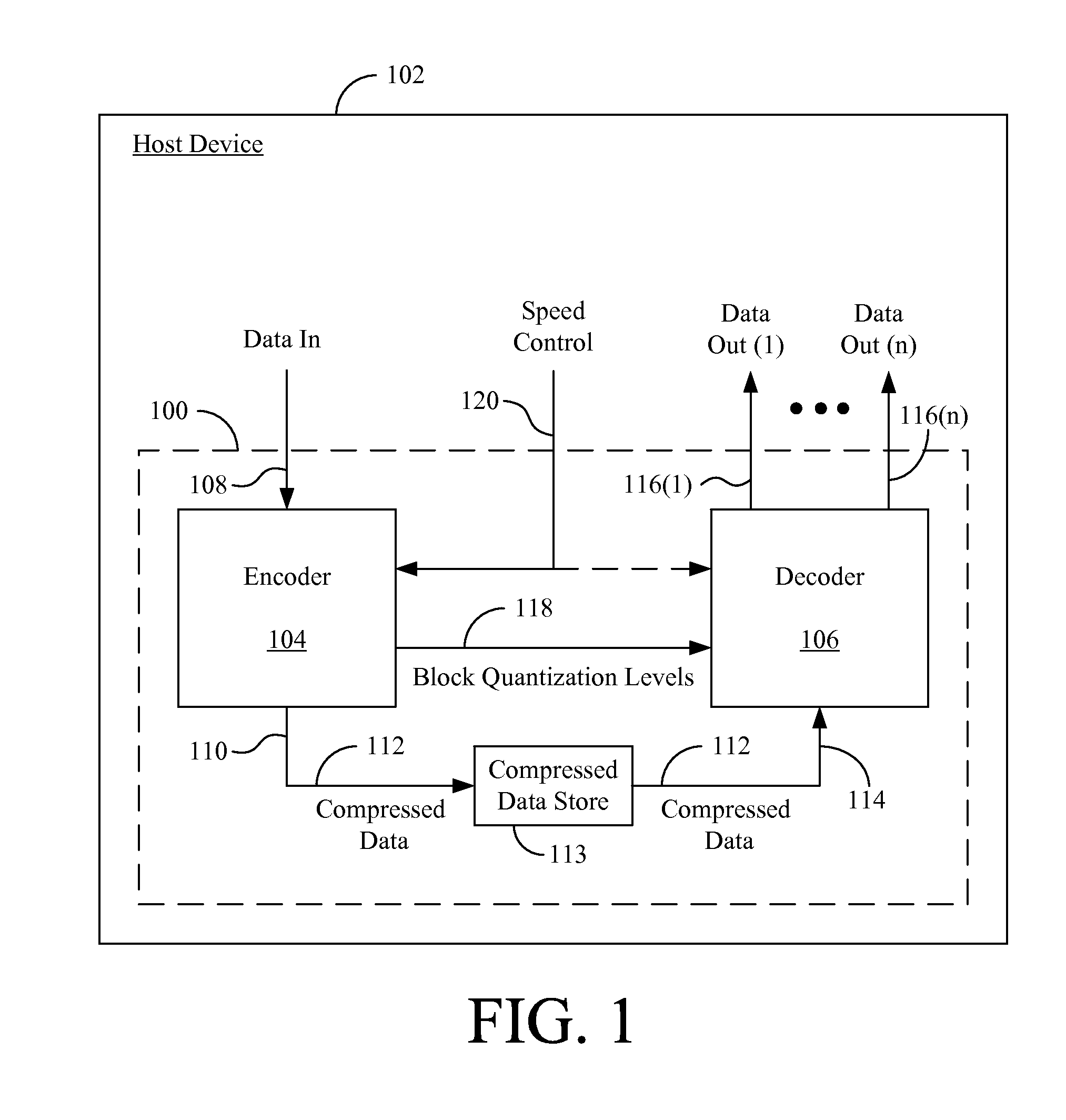

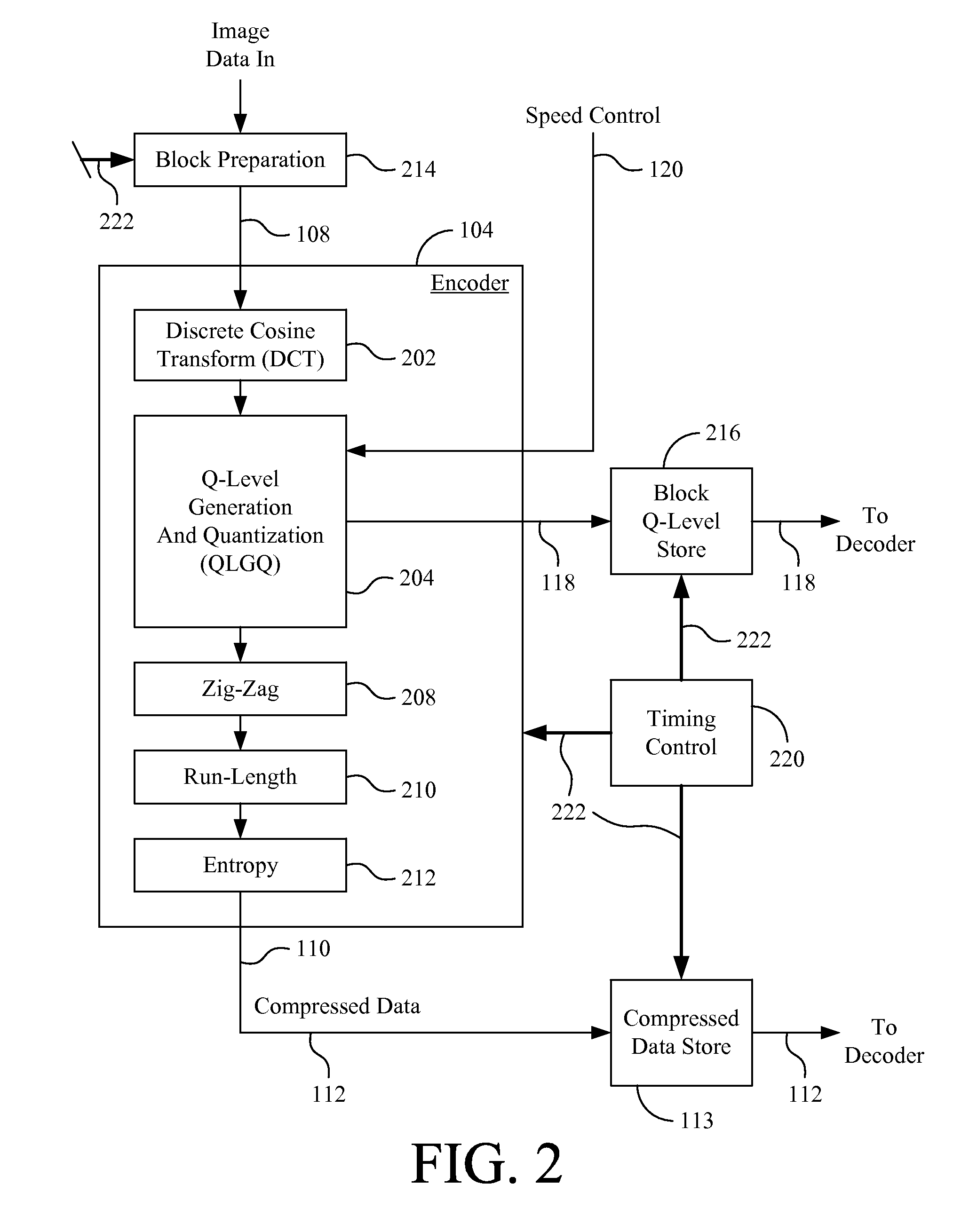

Decoder performance through quantization control

ActiveUS20140023285A1Improves data compressionImproves decoder performanceCharacter and pattern recognitionDigital video signal modificationData compressionJPEG

A codec includes an encoder having a quantization level generator that defines a quantization level specific to a block of values (e.g., transform coefficients), a quantizer that quantizes the block of transform coefficients according to the block-specific quantization level, a run-length encoder, and an entropy encoder. The quantization level is defined to result in at least a predetermined number (k) of quantized coefficients having a predetermined value. The amount of data compression by the encoder is proportional to (k). The codec also includes a decoder having entropy and run-length decoding sections whose throughputs are proportional to (k). The decoder takes advantage of this increased throughput by further decoding coefficients in parallel using a plurality of decoding channels. Methods for encoding and decoding data are also disclosed. The invention is well-suited to quantization, entropy, and / or run-length-based codecs, such as JPEG.

Owner:OMNIVISION TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com