Wet garbage large-capacity centralized treatment three-waste-free rapid decomposition system and rapid decomposition method

A centralized treatment, large-capacity technology, applied in the field of wet waste treatment, can solve the problems of high cost, environmental odor, long treatment period, etc., and achieve the effect of low cost, less waste residue and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

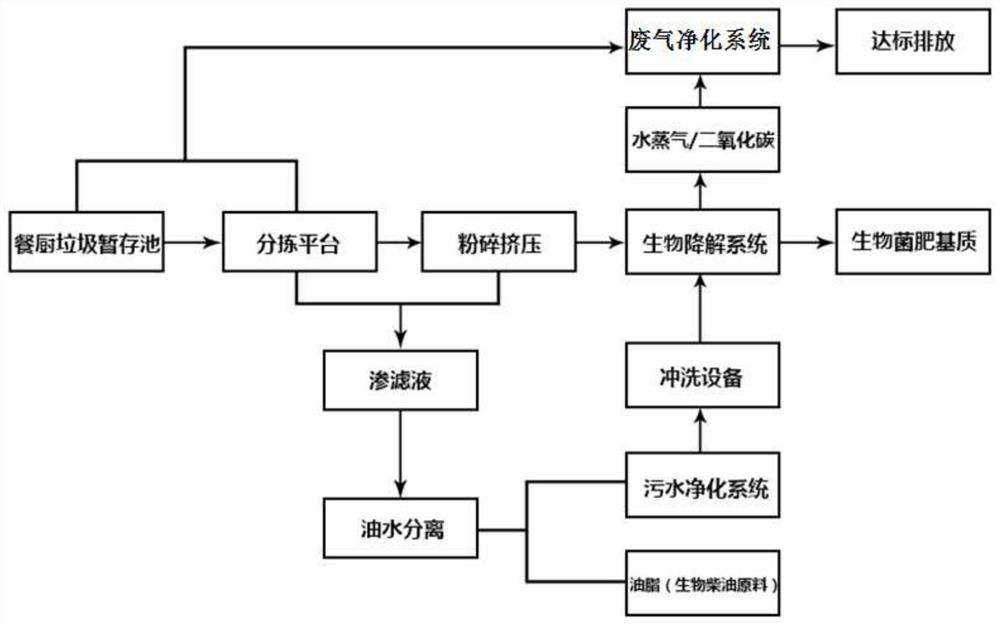

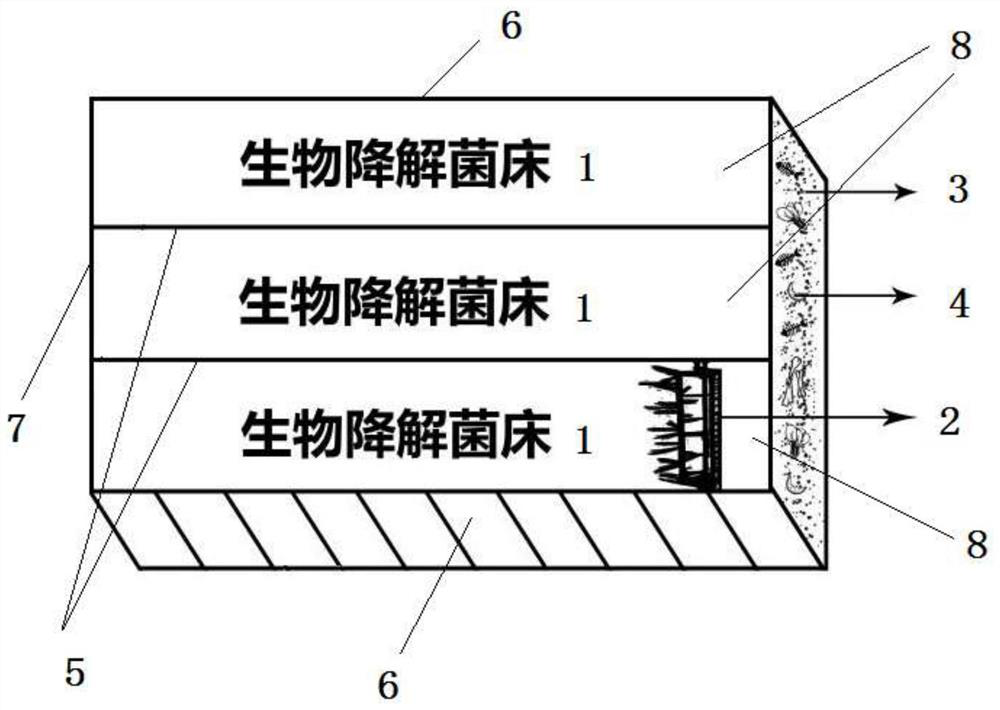

[0045] Such as figure 1 , figure 2 As shown, the present invention is a large-capacity centralized treatment of wet garbage without three wastes rapid decomposition system, which includes sequentially connected wet garbage temporary storage pool, sorting platform, crushing extruder, biodegradation system (biodegradation room), waste gas purification system; the biodegradation system, that is, the biodegradation room is provided with a throwing machine 2 and three biodegradation bacteria beds 1; the biodegradation room is a large rectangular house, and the inside of the house is provided with barrier The wall includes two side retaining walls 6 on the left and right sides and a retaining wall 7 at the back; the front of the house is a material inlet and outlet 8; two parallel long intermediate retaining walls are arranged between the two side retaining walls on the left and right Wall 5, the interior space of the house is divided into three rectangular biodegradable bacteria ...

Embodiment 2

[0053] In the present invention, a large-capacity centralized treatment of wet garbage without the three wastes rapid decomposition system described in the above embodiment 1 is used to perform a rapid decomposition method for the large-capacity centralized treatment of wet garbage without the three wastes, comprising the following steps:

[0054] (1) Build a biodegradable room (wet garbage treatment room, the height of the left and right walls is 1.7-1.8m), and set up a biodegradable bed and a throwing machine in the biodegradable room; spread mixed bacteria on the biodegradable bed Litter (i.e. a mixture of litter and biodegradable flora, the mixing ratio of biodegradable flora and litter is 1:500 by volume, and the height of the mixed bedding layer is 1.4-1.5m; the litter is sawdust , a mixture of plant ash and shredded coconut, the volume ratio of which is 7:1:2; the biodegradable flora is mainly a mixture of Bacillus subtilis, Bacillus pumilus, Bacillus licheniformis, Acin...

Embodiment 3

[0068] Embodiment 3 application embodiment (using the wet garbage of vegetable farm as raw material)

[0069] Wet garbage from vegetable farms (including animal residues such as rotten vegetable leaves, vegetable stalks, intestines and scales left by killing fish and eels, etc.) is used as raw material, and the wet garbage large-capacity centralized treatment described in the above-mentioned embodiment 1 is used. The three-waste rapid decomposition system , according to the wet garbage large-capacity centralized treatment described in the above-mentioned embodiment 2 without the rapid decomposition method of the three wastes, wherein:

[0070] In step (1), the moisture content of wet garbage raw materials in the vegetable market is 80-90%; the biodegradable flora is mainly a mixture of Bacillus subtilis, Bacillus pumilus, Bacillus licheniformis, Acinetobacter calcium acetate, etc.; wherein each The mass ratio of the components is: Bacillus subtilis 10%, Bacillus pumilus 10%, B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com