Carbon fiber composite material automobile front cover

A composite material and carbon fiber technology, used in vehicle parts, synthetic resin layered products, superstructure sub-assemblies, etc., can solve problems such as lack of overall strength, and achieve the effect of easy process molding, firm structure, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

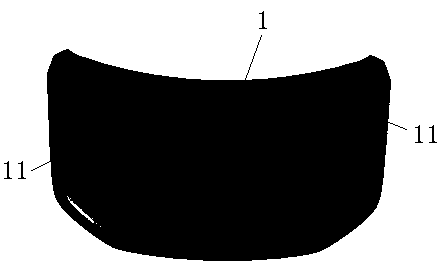

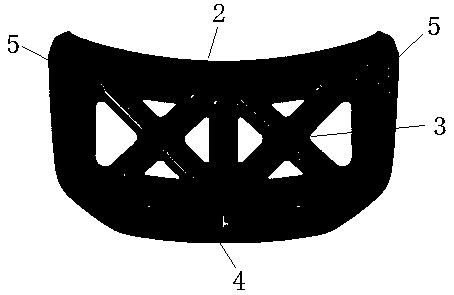

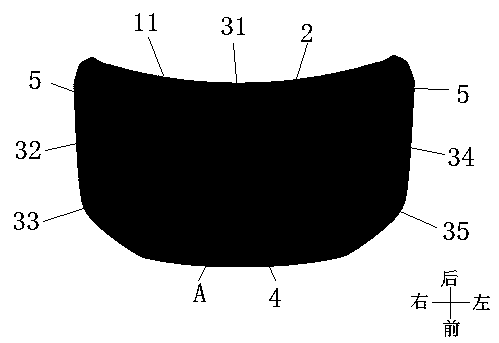

[0025] Embodiment one, see Figure 1 to Figure 4 , the carbon fiber composite car front cover shown, including the outer panel 1 and the inner panel 2 glued together, in order to improve the stability of the connection between the outer panel 1 and the inner panel 2, a connection with the inner panel is provided on the periphery of the outer panel 1 Correspondingly matched glued flanging 11.

[0026] The outer panel 1 and inner panel 2 are made of integrally laminated carbon fiber composite materials; the middle part of the inner panel 2 is provided with a mesh reinforcement part 3, and the inner panel 2 is glued with a locking reinforcement panel 4 and a hinge The fixed support 5, the lock reinforcement plate 4 is located in the middle of the front end of the inner panel 2, and the number of the hinge fixed supports 5 is two, which are respectively arranged at the left and right parts of the inner panel 2 rear end. A reinforcement layer 22 is interposed in the integral layer...

Embodiment 2

[0030] Embodiment 2, a carbon fiber composite car front cover, including an outer panel 1 and an inner panel 2, the outer panel 1 and the inner panel 2 are made of an integrally laminated carbon fiber composite material; the carbon fiber composite material is made of multi-layer The carbon fiber fabric material in the multi-ply direction is the reinforcement, and the epoxy resin is used as the matrix resin. The grade of the carbon fiber fabric material is T300, and the tow of the carbon fiber fabric material is 3K; The edge 11 and the mesh-shaped reinforcing part are connected by epoxy resin structural adhesive, the bonding width is 15 mm, and the bonding thickness is 1 mm; the rest of the structure is the same as that of the first embodiment.

Embodiment 3

[0031] Embodiment 3, a carbon fiber composite car front cover, including an outer panel 1 and an inner panel 2, the outer panel 1 and the inner panel 2 are made of integrally laminated carbon fiber composite materials; the carbon fiber composite material is made of multi-layer The carbon fiber fabric material with multi-ply directions is the reinforcement body, with epoxy resin as the matrix resin, the grade of the carbon fiber fabric material is T700, and the tow of the carbon fiber fabric material is a mixture of 3K, 12K and 50K; the outer plate 1 and the inner plate The glued flange 11 along the periphery of the board 2 and the mesh reinforcement 3 are connected by polyurethane structural glue, the glued width is 25mm, and the glued thickness is 1.5mm; the rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com