Magnetic suspension control moment gyroscope high-speed rotor device

A technology for controlling torque gyroscopes and high-speed rotors, which is applied in the directions of space navigation vehicle guidance devices, transportation and packaging, space navigation equipment, etc. and other problems, to meet the needs of aerospace applications, with higher cost and lower power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

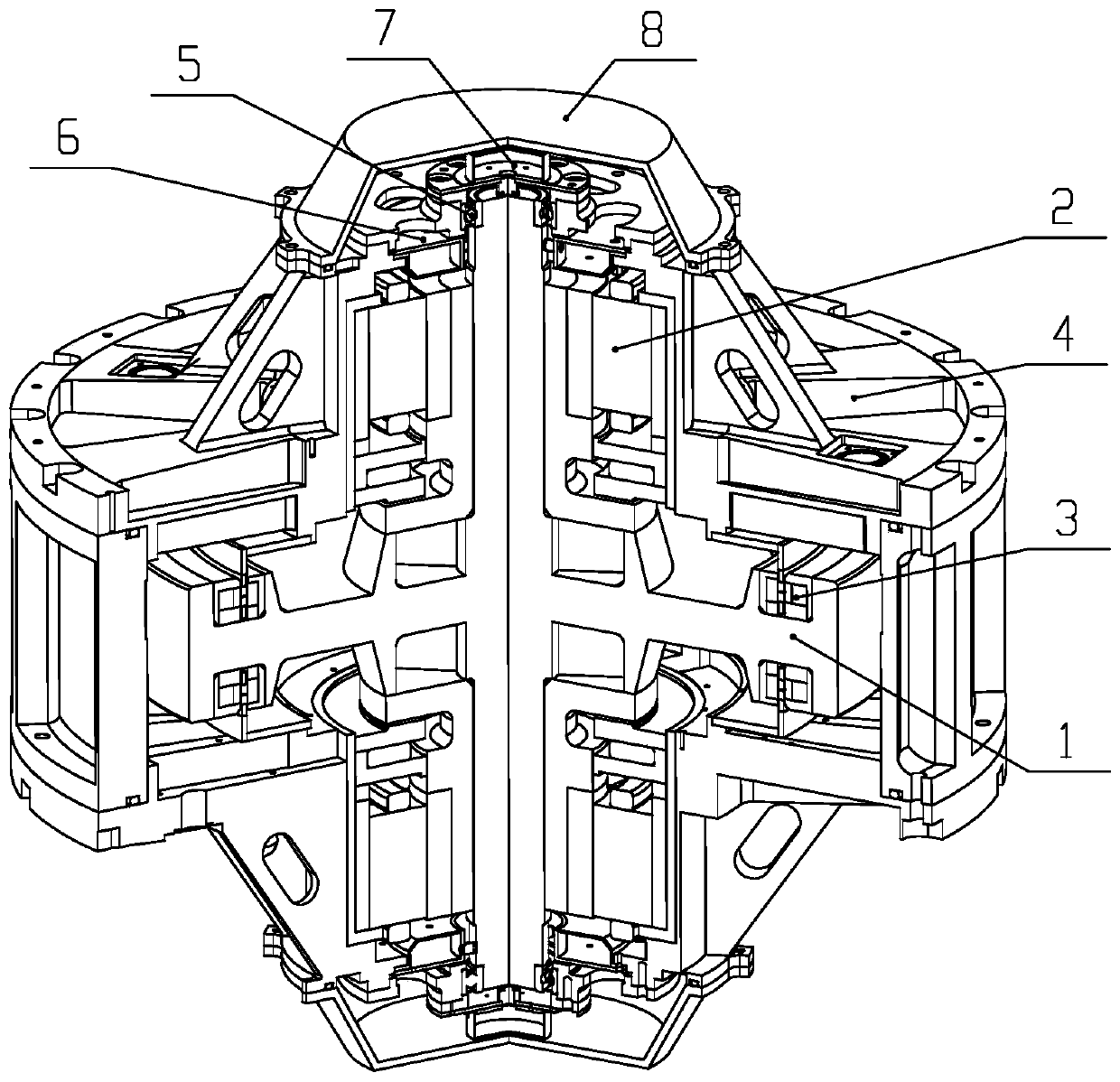

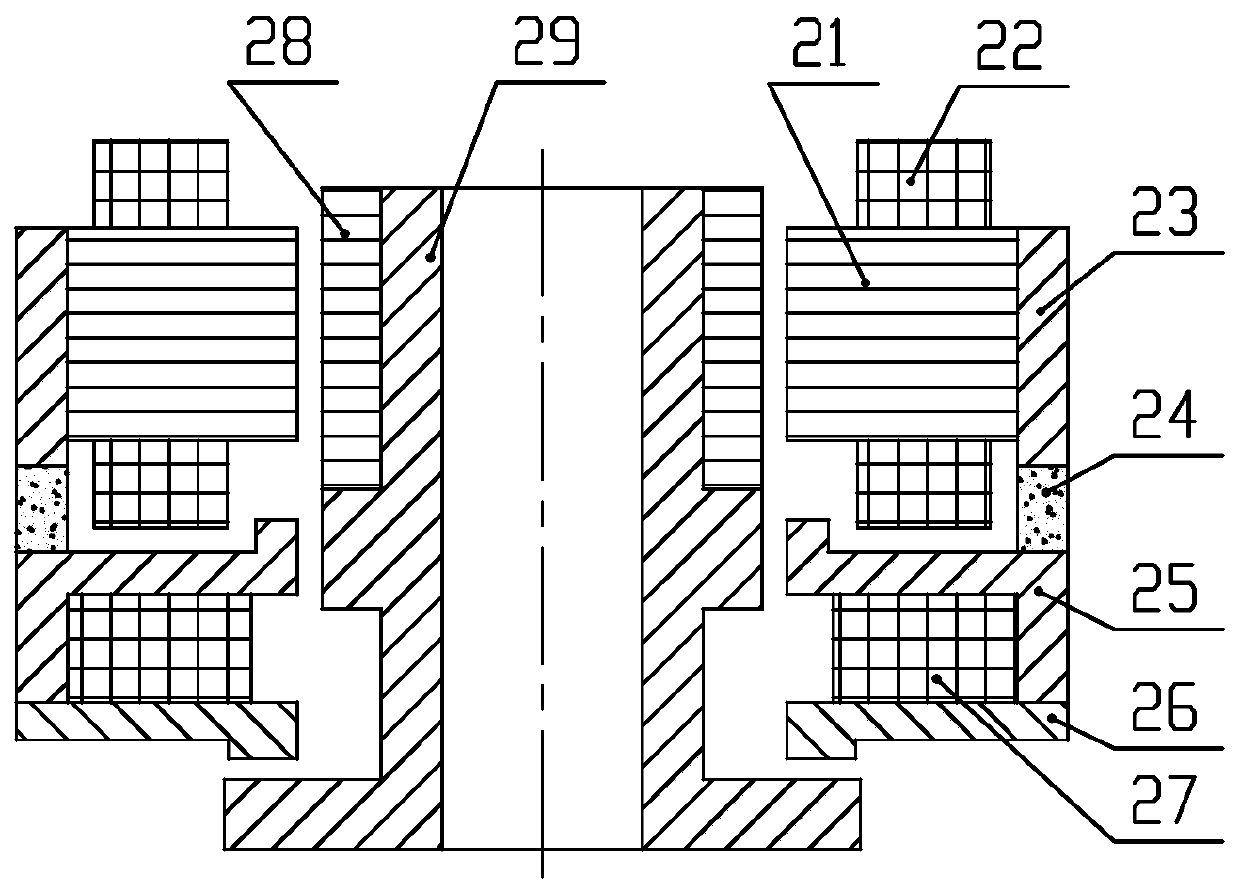

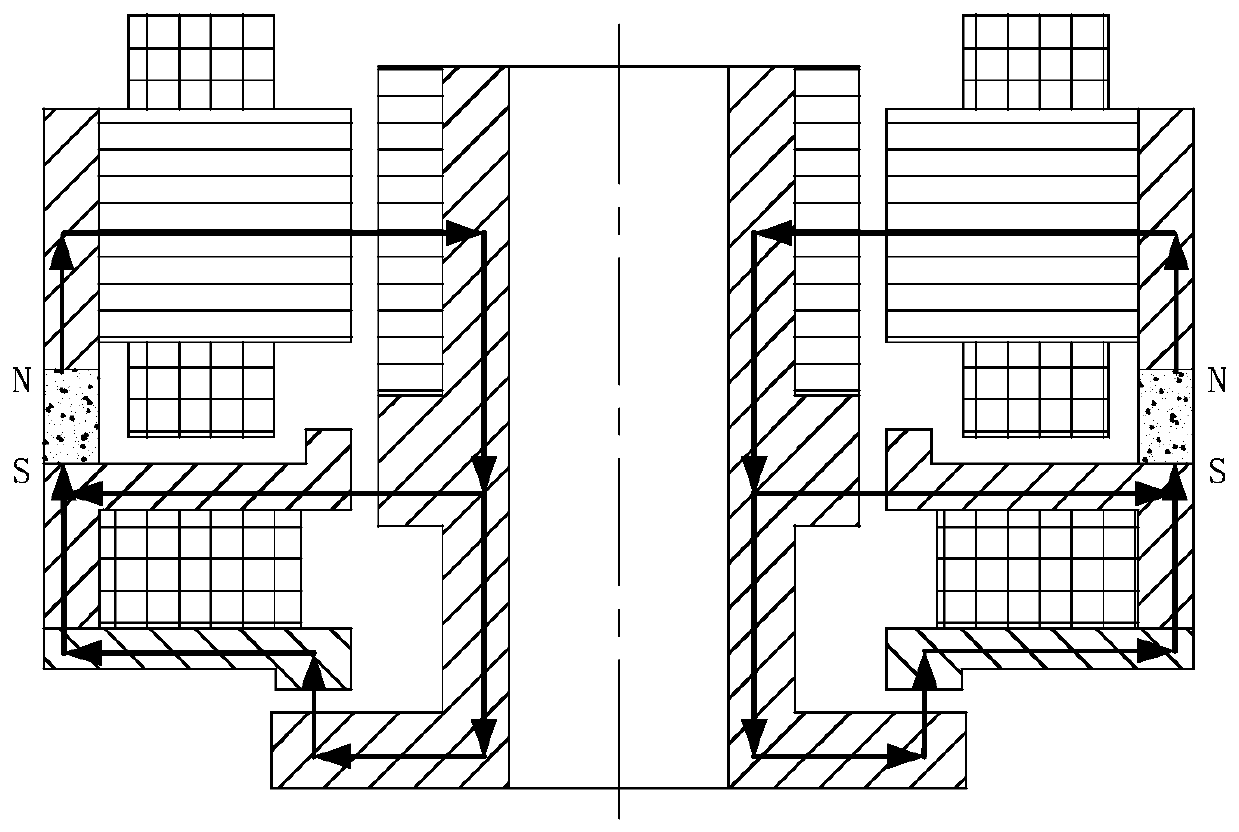

[0021] Such as figure 1 As shown, a magnetic levitation control moment gyro high-speed rotor device is mainly composed of a flywheel 1, a three-degree-of-freedom integrated magnetic bearing 2, a high-speed motor 3, a gyro room 4, a protective bearing 5, a radial displacement sensor 6, and an axial displacement sensor 7 And end cap 8 composition. Among them, the flywheel 1, the rotor part of the high-speed motor 3, the rotor part of the three-degree-of-freedom integrated magnetic bearing 2 constitute the rotor assembly of the device, and the gyro room, the stator part of the high-speed motor, the stator part of the three-degree-of-freedom integrated magnetic bearing and the end cover form the stator assembly. The high-speed motor 3 is used to realize the high-speed rotation of the rotor between the rotor assembly and the stator assembly, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com