Slide rail capable of enhancing rigidity modulus

A technology of rigidity modulus and slide rail, which is applied in the special position of the vehicle, vehicle seat, movable seat, etc., can solve problems such as stiffness reduction, noise, and distress, and achieve the effect of improving the mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

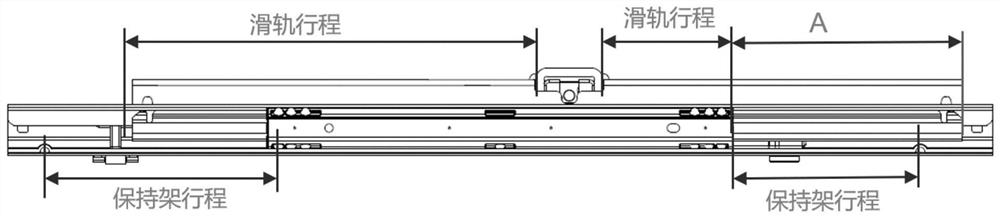

[0043] For the front seat of the car, generally the slide rail and the slide rail stroke are longer, so a longer cage 30 can be matched. Due to the limitation of the length of the upper slide rail, the length of the cage 30 will be limited within a certain range; when the long cage 30 is used, the modal performance of the front end of the slide rail is generally good, but the middle and rear sections of the slide rail do not have the cage 30 Braces, sometimes have issues with poor modality. If the mode is not up to standard, it will cause the parts to resonate, which will lead to problems such as abnormal sound and reduced durability.

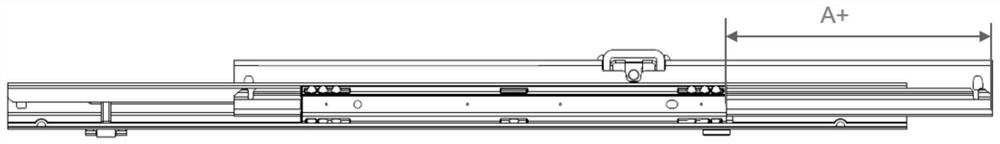

[0044] Based on the above reasons, this embodiment designs a sliding cage 30 based on the cage 30 of the front row seat slide rail, and the second half lengthens the sliding cage 30; The rear section provides additional support for the upper rail, especially in vibration situations, which can effectively improve the mode of the slide rail and ...

Embodiment 2

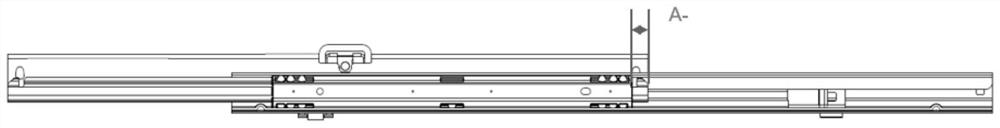

[0058] This embodiment is aimed at the optimization of the slide rails of the short cages 30 in the rear row. The rear stroke of the slide rails in the rear seats of the car is generally short, so the selected cage 30 is relatively short; When the rail is at the design position or the front position of the comfortable stroke, the slide rail will have a problem of poor mode. The root cause is that the rear end of the upper slide rail is in a suspended state and lacks support. The present invention designs an auxiliary support structure used in conjunction with the short cage 30, through the cooperation of the short cage 30 and the new structure, it can always provide support for the upper rail, especially in the case of vibration, which can effectively improve the mode of the slide rail performance. The specific plan is as follows:

[0059] A slide rail with enhanced rigidity modulus, the slide rail is composed of an upper rail assembly 10, a lower rail assembly 20 and a cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com