Skylight reinforcing ring structure and vehicle

A technology for reinforcing rings and sunroofs, applied to vehicle parts, roofs, transportation and packaging, etc., can solve problems affecting the quality of the whole vehicle, decrease in stiffness and modal, deformation of the sunroof or abnormal noise, etc., to improve stiffness and modal, Improve the effect of modality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

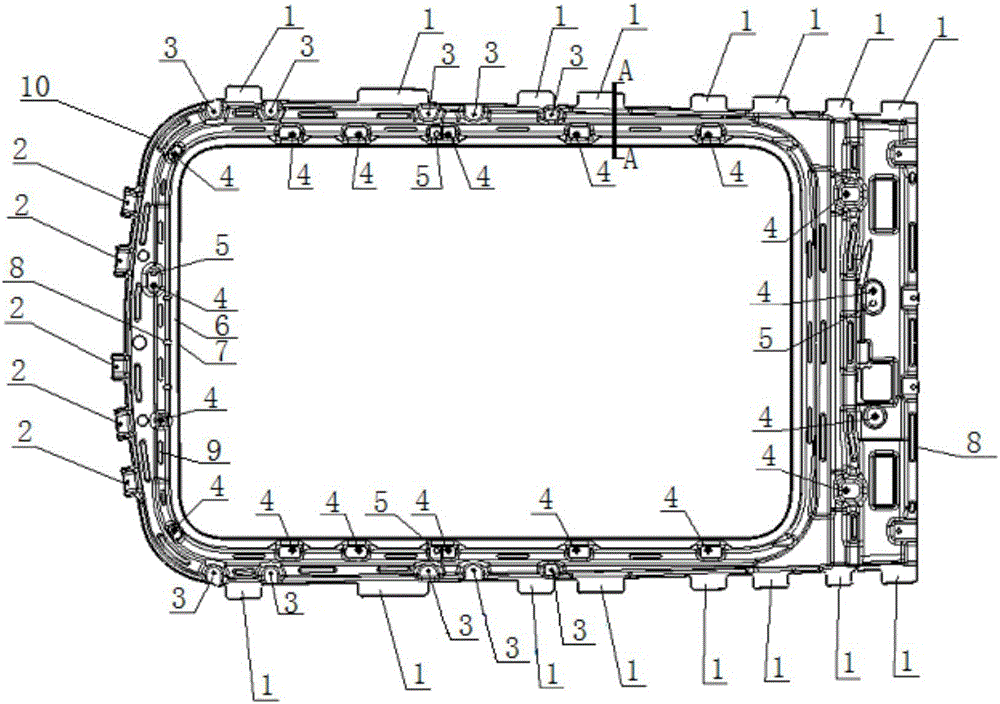

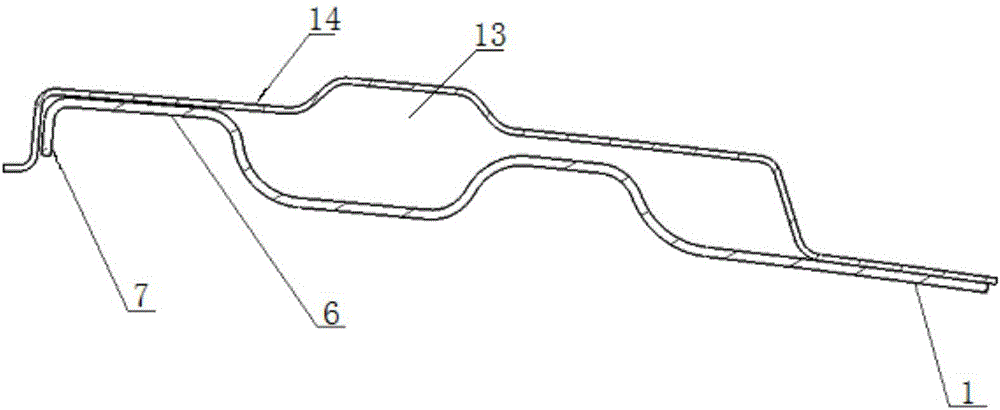

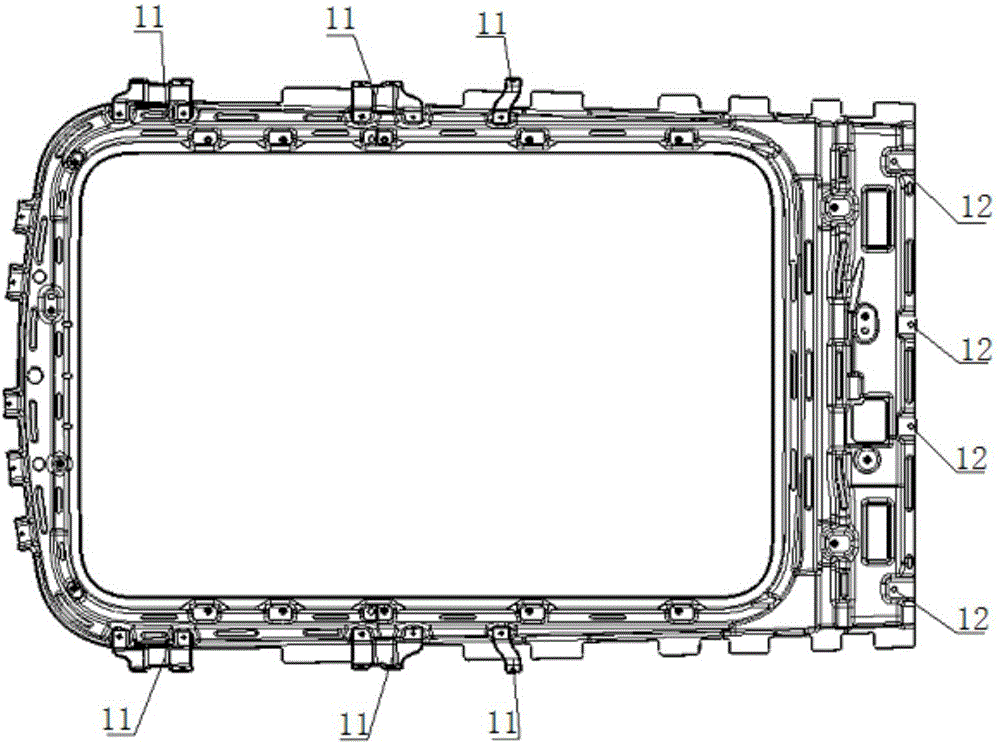

[0023] The core of this specific embodiment is to provide a sunroof reinforcement ring structure, which effectively improves the assembly accuracy of the sunroof while ensuring the rigidity and mode, and solves the problems in the prior art.

[0024] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0025] The skylight reinforcing ring structure provided by this specific embodiment mainly includes: a main body 10, a plurality of overlapping edges 1, a plurality of overlapping platforms 2, a plurality of bosses 3, a plurality of mounting points 4, a plurality of positioning holes 5, and Glue structure 6, flanging structure 7, multiple glue grooves 9. Wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com