Automobile engine suspension mounting structure

A technology of automobile engine and installation structure, which is applied in the direction of power plant, vehicle parts, transportation and packaging, etc. It can solve the problems of failure to meet NVH performance requirements, failure of rear suspension cushions, low bracket mode, etc., and achieve low noise, Ingenious design and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

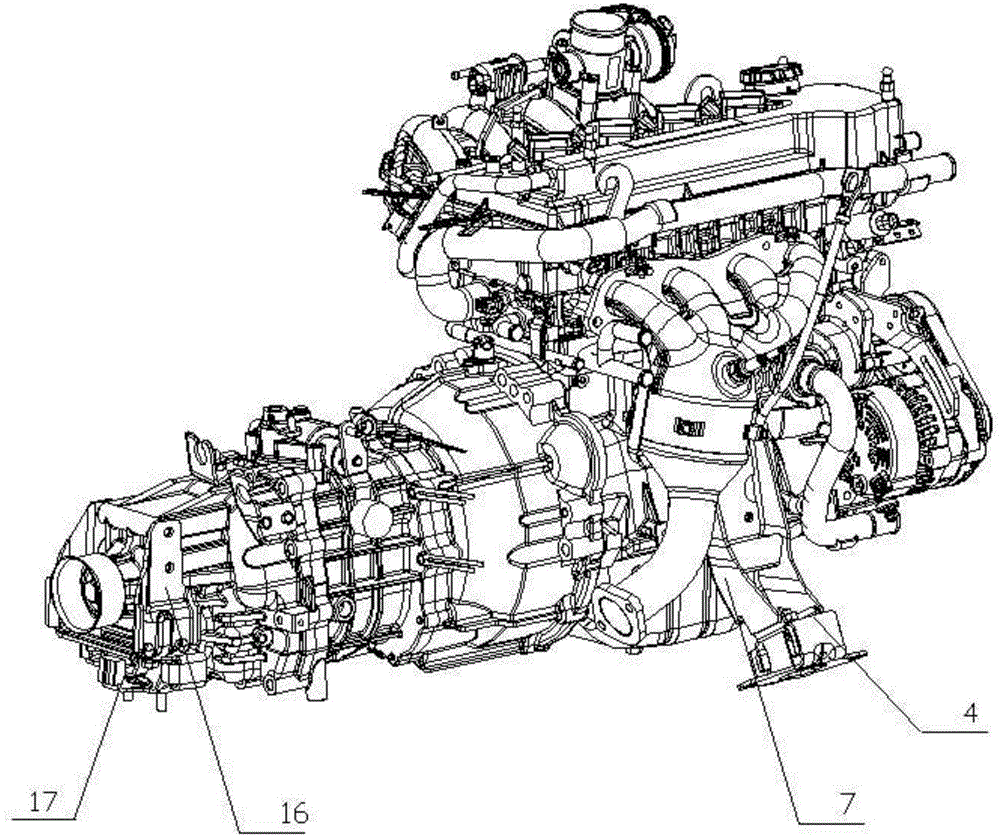

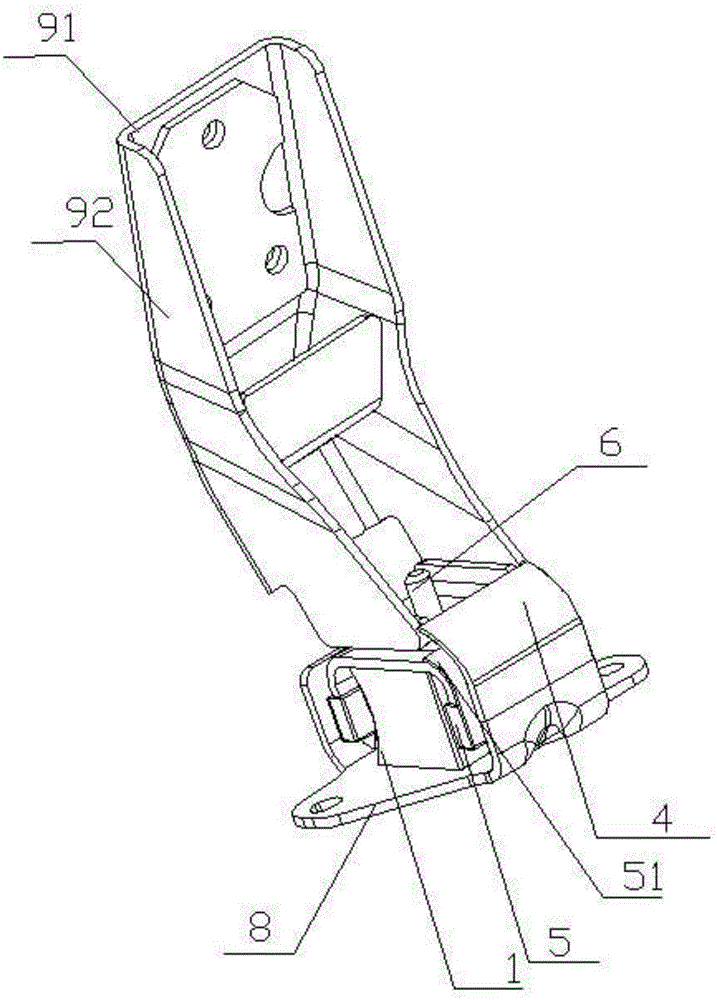

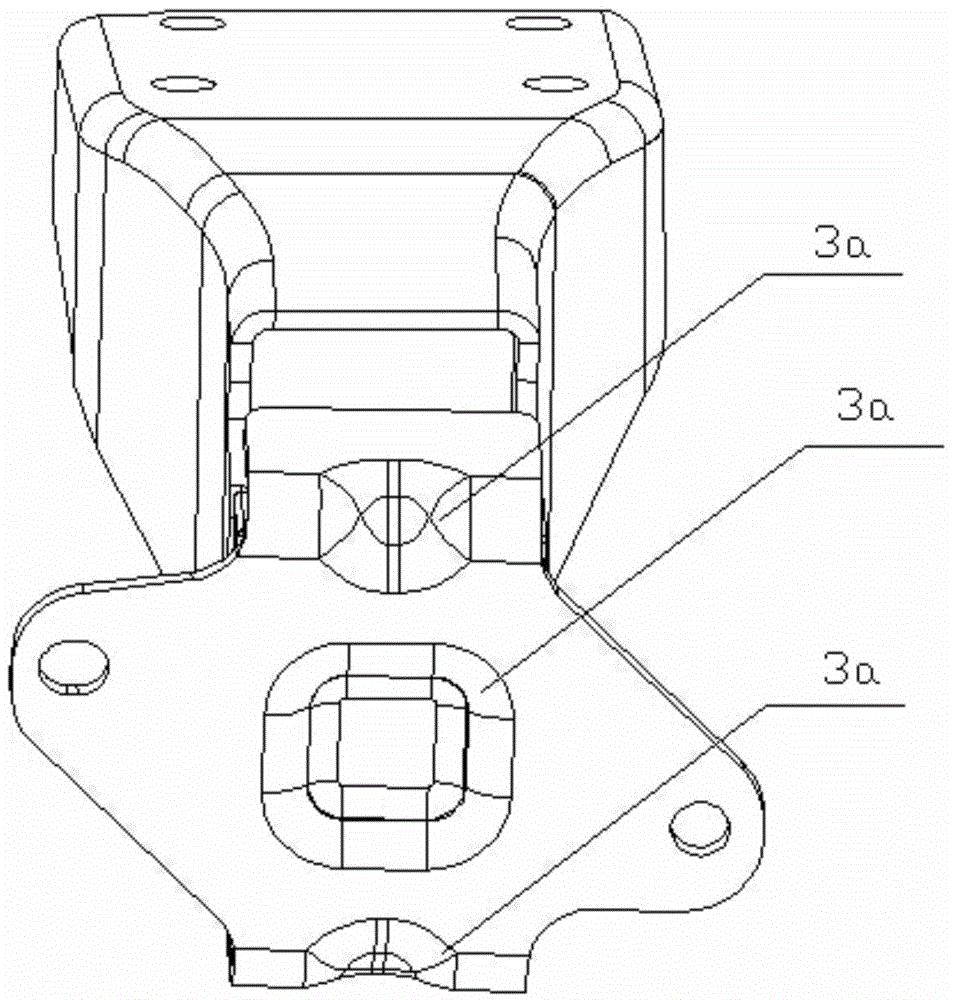

[0039] Such as Figure 1-13 Shown: an automobile engine suspension installation structure of the present invention is composed of a cylinder block, a transmission, a left suspension, a right suspension and a rear suspension. The engine includes a cylinder block, a transmission and other components. This is the prior art, here Do not repeat it. The left and right suspensions are respectively installed on the left and right sides of the cylinder, and the rear suspension is installed on the rear housing of the transmission. The left suspension and the right suspension have the same structure, including the elastic body 1, the upper limit block 2. The lower limit block 3 and the suspension bracket 9 connected with the cylinder by bolts, the rear suspension includes a rear suspension bracket 16 and a rear suspension cushion assembly 17.

[0040] The left and right suspension of the engine is composed of elastic body 1, upper limit block 2, lower limit block 3, limit part 4, rubber sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com