Supercharger engine hot end heat insulating shield assembly

A technology of supercharged engine and heat shield, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of difficulty in ensuring strength and modal requirements, high installation process requirements, and many installation points. The effect of cost control, reduction of processing requirements, and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

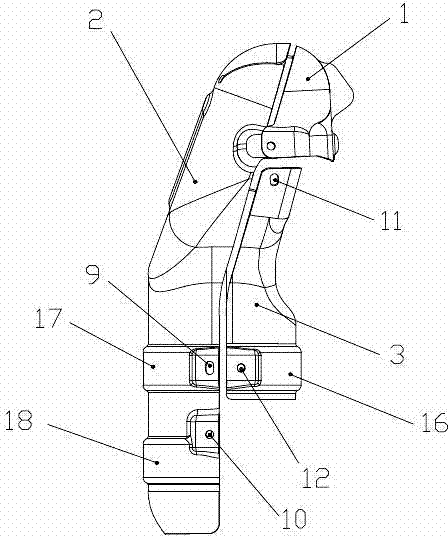

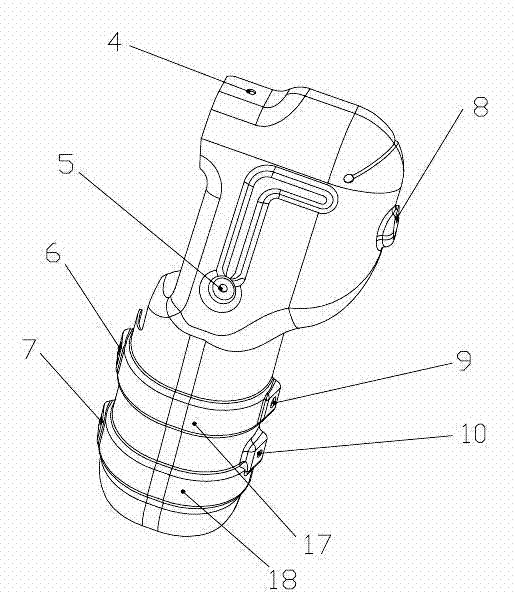

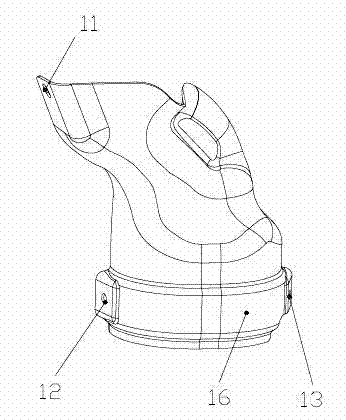

[0017] Such as Figure 1 to Figure 4 The hot end heat shield assembly of the supercharged engine includes an exhaust manifold heat shield (not shown in the figure), a supercharger heat shield 1 and a three-way catalytic converter heat shield, and the supercharger heat shield Both the heat shield 1 and the heat shield of the three-way catalytic converter are layered structures, the upper and lower layers are hot-dipped aluminum plates, and the middle layer is ceramic fiber cardboard; the heat shield of the three-way catalytic converter is installed on the left side of the supercharger 14 by the upper part, The lower part is composed of the three-way catalytic converter upper cover 2 installed on the left side of the three-way catalytic converter 15 and the lower three-way catalytic converter cover 3 installed on the right side of the three-way catalytic converter 15; the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com