Synchronous transmission mechanism for yarn feeder

A technology of synchronous transmission and yarn feeder, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of inconvenient use, complex structure of gear pulleys, and inability to adjust the length of toothed belts, etc. Simple, easy-to-market effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

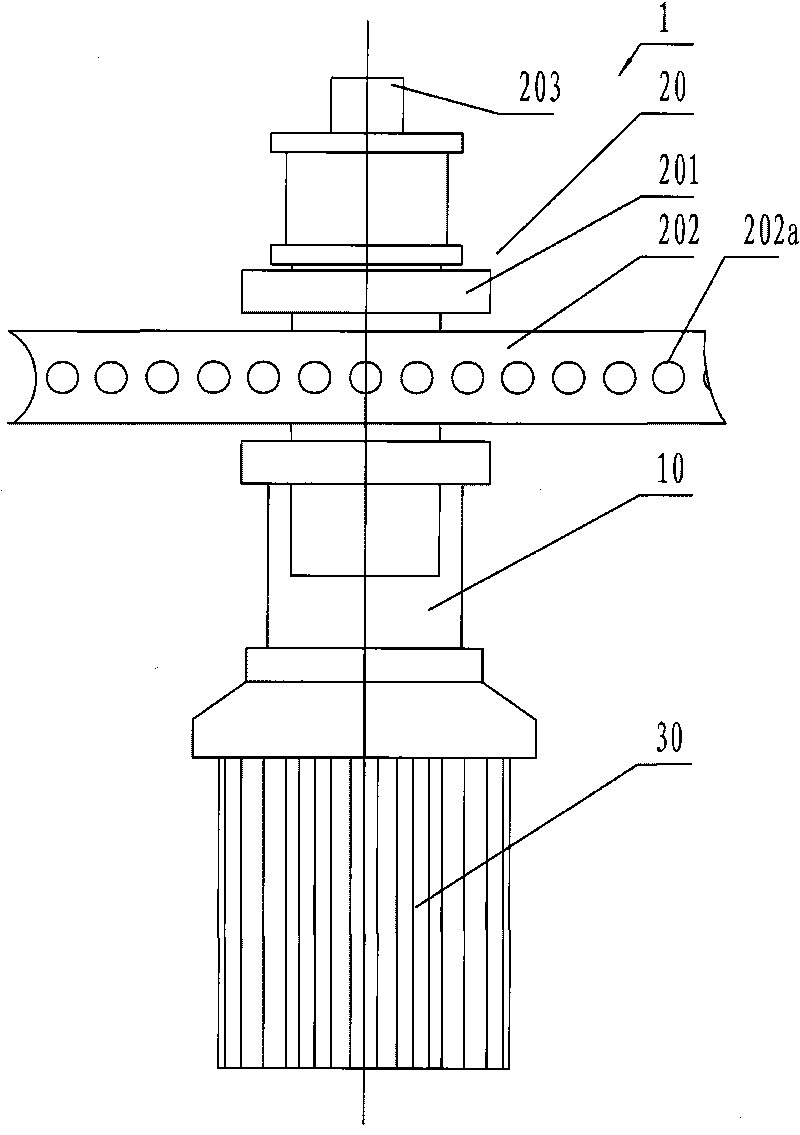

[0020] figure 2 It is a structural schematic diagram of a single yarn feeder in the present invention. Such as figure 2 As shown, a yarn feeder 1 mainly includes a frame 10 , a synchronous transmission mechanism 20 , and a yarn storage device 30 . The synchronous transmission mechanism 20 is mainly composed of transmission wheels 201 of a plurality of yarn feeders arranged in a circle and an endless synchronous belt 202 . The transmission wheel 201 is installed above the yarn storage device 30, and the transmission wheel 201 and the yarn storage device 30 are installed on the frame 10 respectively.

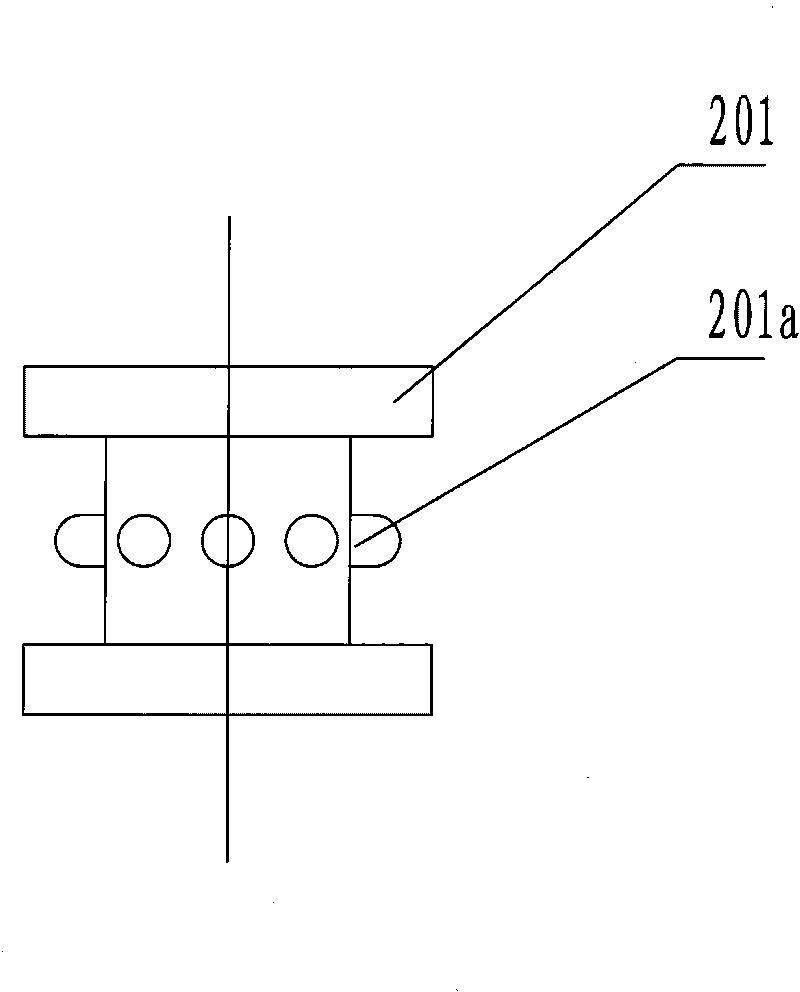

[0021] image 3 It is a structural schematic diagram of the transmission wheel 201, combined with figure 2 and image 3 Viewing, the transmission wheel 201 is provided with a shaft hole (not shown in the figure) in the center, and a transmission shaft 203 and a bearing (not shown in the figure) are arranged in the shaft hole. Through this structure, the transmission wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com