Double-blade and double-faced symmetric machining device of large propellers

A processing device and propeller technology, which is applied in the field of large-scale propeller double-knife double-sided symmetrical processing devices, can solve the problems of large-scale propeller cavitation, high manufacturing cost, and reduced propeller propulsion efficiency, so as to achieve high processing efficiency and processing accuracy, and ensure concealment performance and safety, and the effect of eliminating the cantilever beam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the patent of the present invention is described further.

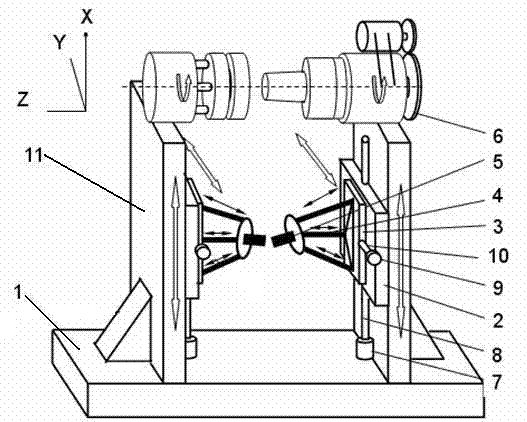

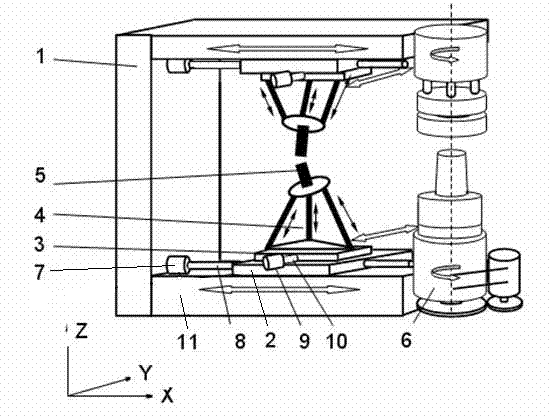

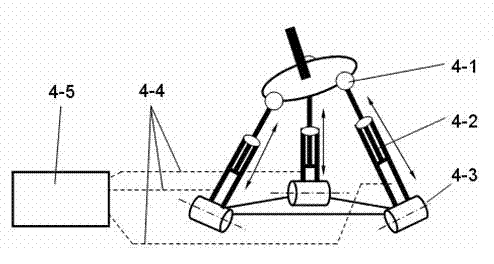

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 The shown large propeller double-knife double-sided symmetrical processing device is provided with a fixed seat 1, and a pair of mutually symmetrical propeller processing devices are arranged on the fixed seat 1. The propeller processing device includes a support frame 11, an X-direction sliding seat 2, and a Y-direction sliding seat. Seat 3, less freedom parallel mechanism 4 and processing tool 5; X-direction drive motor 7 and X-direction slide seat 2 are arranged on the support frame 11, X-direction drive screw 8 is provided on the X-direction slide seat, and X-direction drive motor 7 is connected with the X-direction driving screw 8, and is used to drive the X-direction slide to move along the X direction; the X-direction slide is provided with a Y-direction drive motor 9 and a Y-direction slide 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com