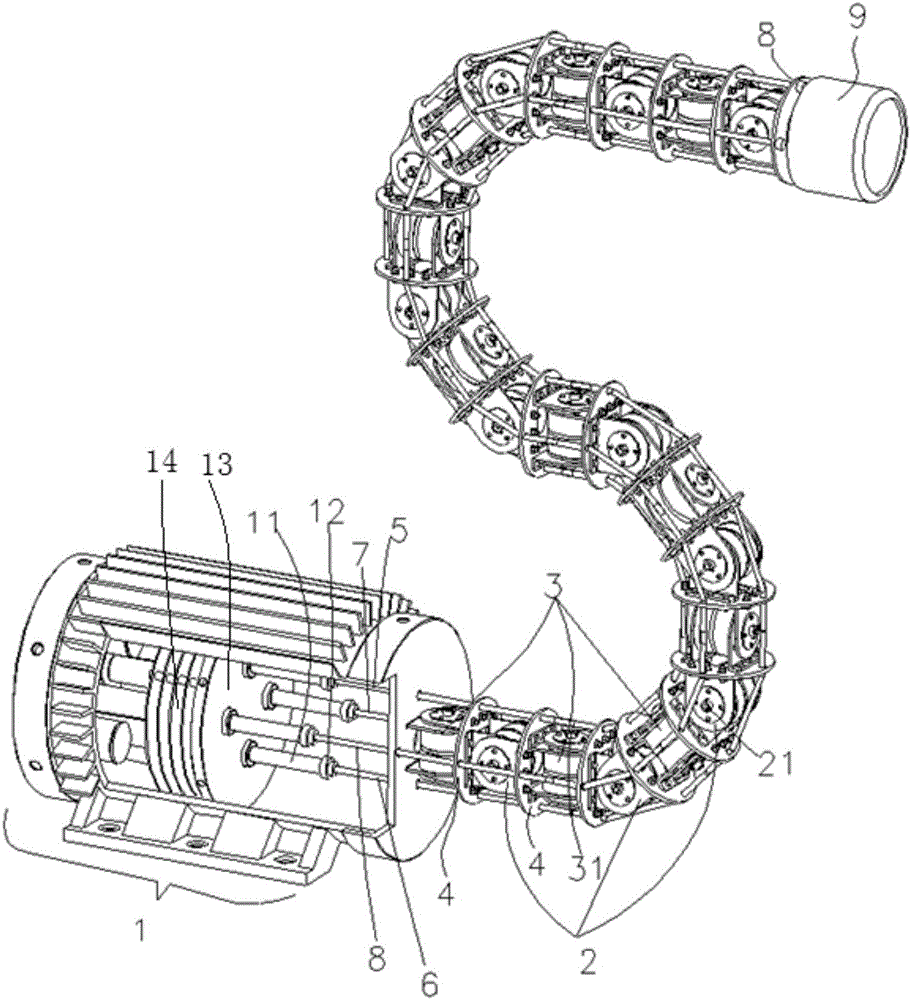

Multi-joint flexible mechanical arm

A mechanical arm and multi-joint technology, applied in the field of robotics, can solve problems such as complex installation structure, high energy consumption, and complex control system, and achieve the effects of good interchangeability, strong flexibility, and many degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

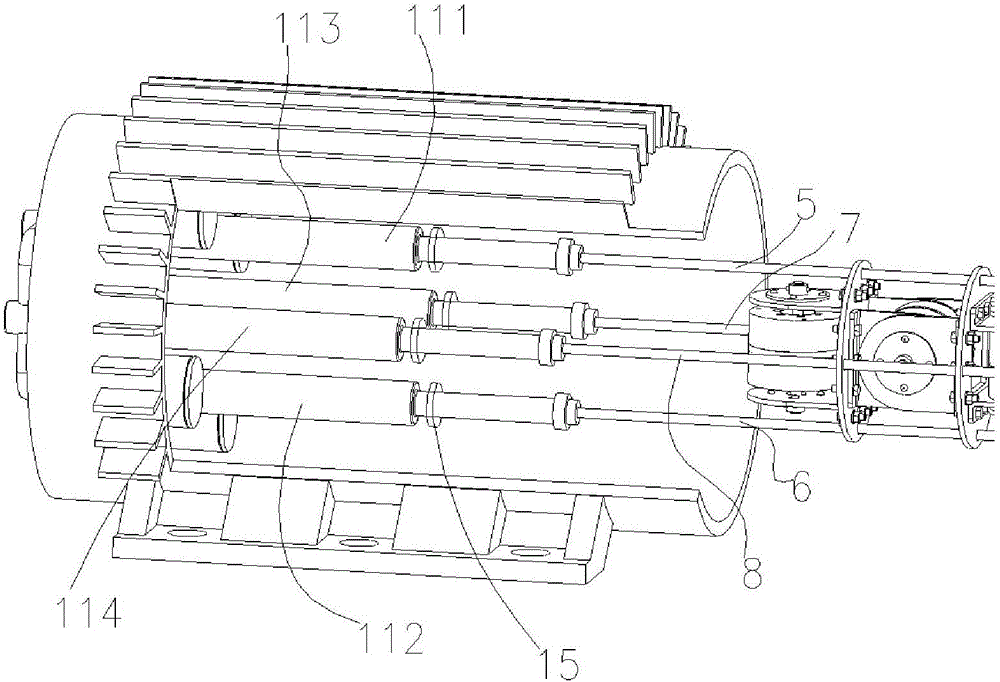

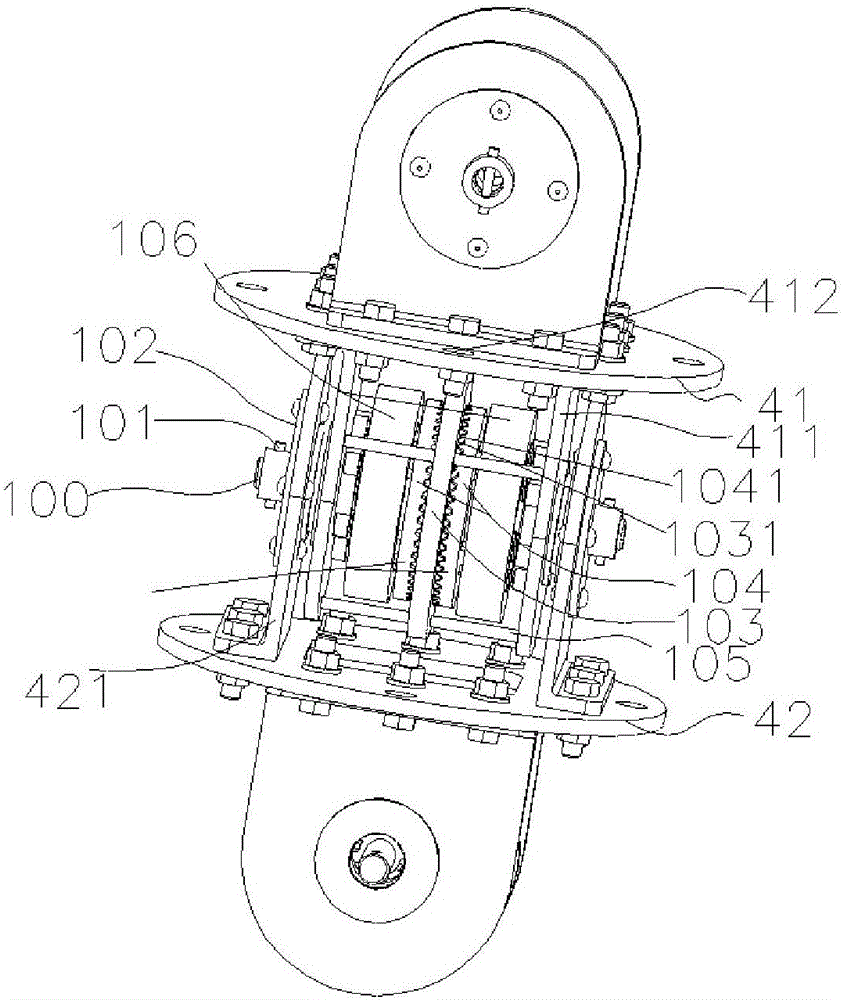

[0022] Hereinafter, embodiments of the multi-joint flexible robot arm of the present invention will be described with reference to the accompanying drawings. Those of ordinary skill in the art can realize that the described embodiments can be modified in various different ways or combinations thereof without departing from the spirit and scope of the present invention. Therefore, the drawings and descriptions are illustrative in nature and are not used to limit the scope of protection of the claims. In addition, in this specification, the drawings are not drawn to scale, and the same reference numerals denote the same parts.

[0023] Most multi-joint manipulators use joint motors to drive the motion of each joint. Therefore, each joint needs a joint motor, which has a complicated installation structure and consumes a lot of electric energy. The present invention provides a mechanical arm that can be driven by an electric push rod. The power source is concentratedly arranged and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com