Car body light-weight design method

A lightweight design and vehicle body technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as optimization and analysis results being restricted, and achieve the effect of meeting the rigidity requirements of the body, avoiding errors, and reducing the weight of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

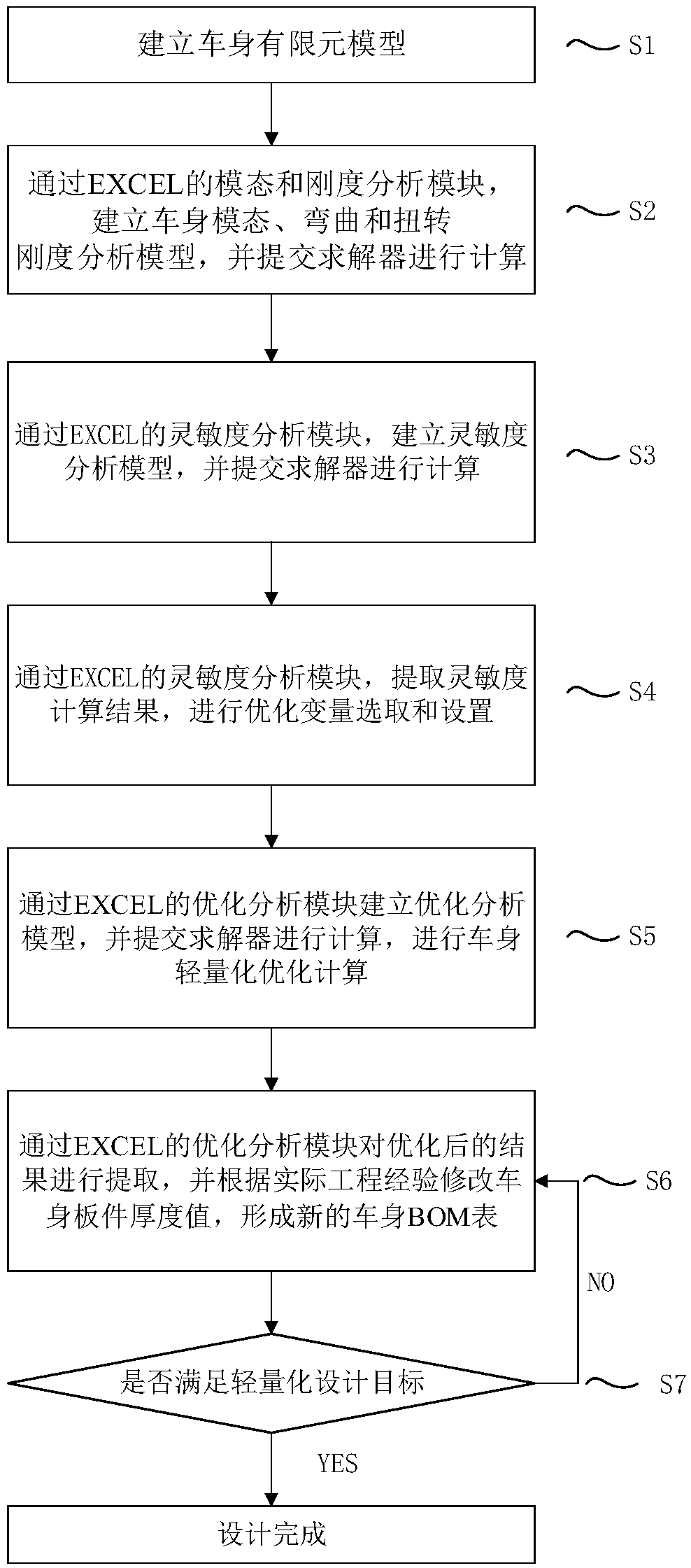

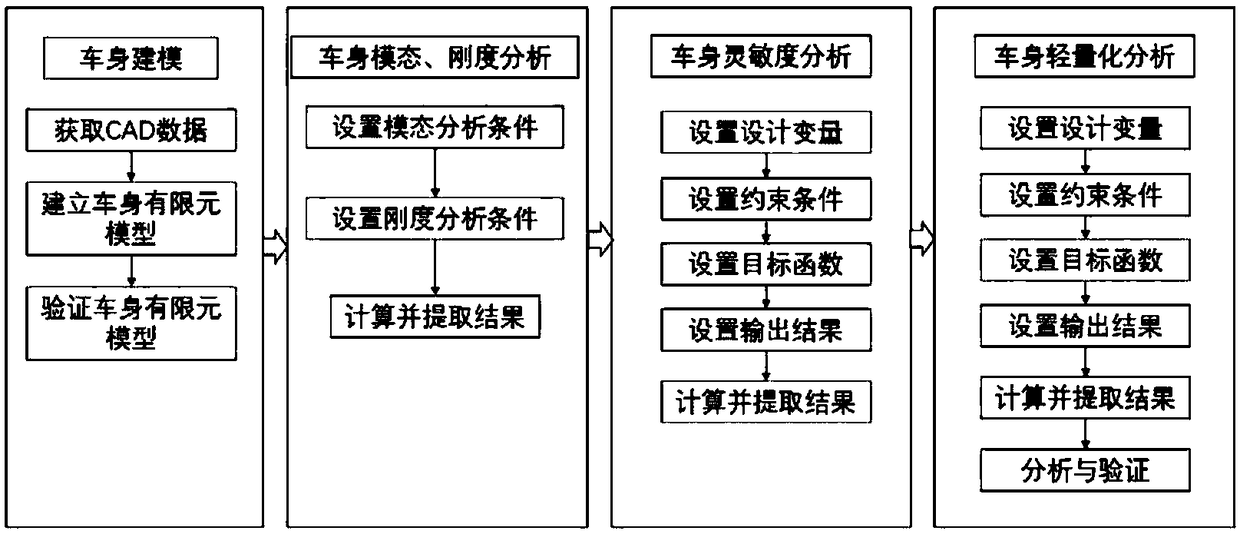

[0031] like figure 1 , figure 2 Shown, a kind of vehicle body lightweight design method, present embodiment mainly adopts finite element analysis software and EXCEL (Microsoft Excel) spreadsheet software to realize design process, comprises the following steps:

[0032] S1. Establish the finite element model of the vehicle body according to the CAD data of the vehicle body, specifically including:

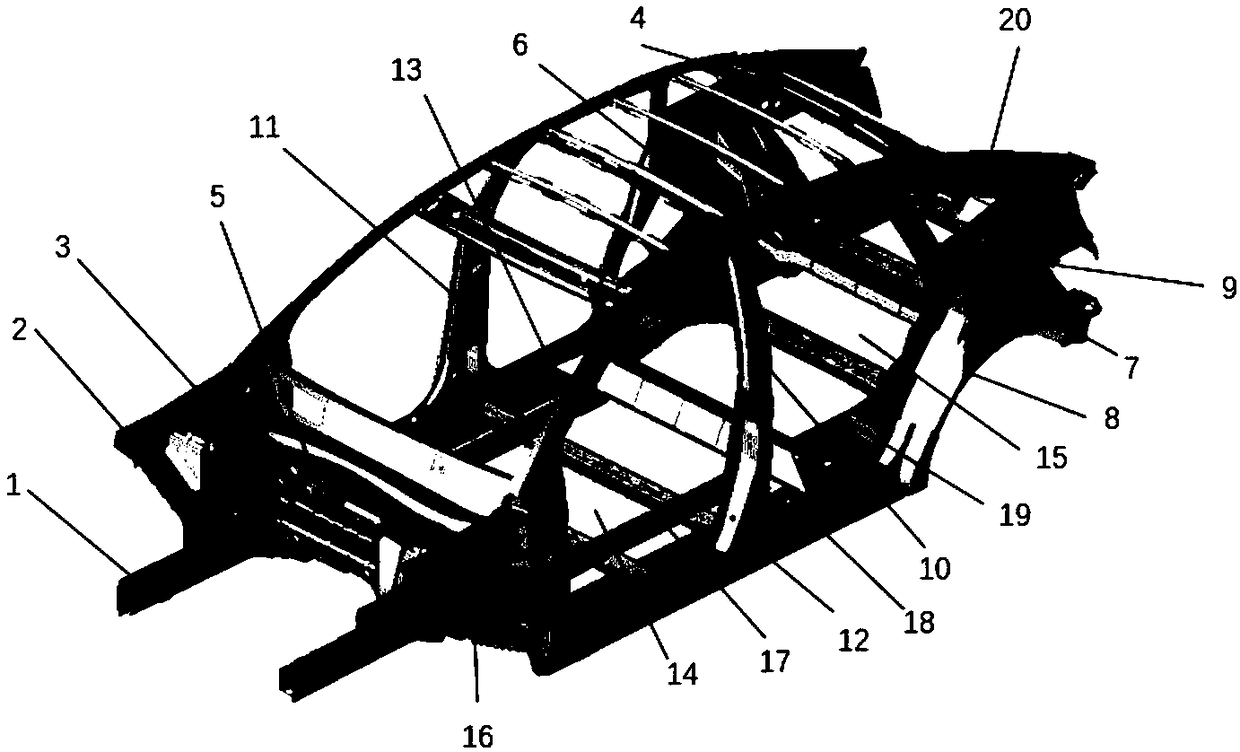

[0033] S11. According to the CAD data of the vehicle body, the finite element model of the vehicle body is established by using the finite element preprocessing software HyperMesh. The finite element model of the vehicle body is as follows: image 3 shown;

[0034] S12. Use the acm and rbe3 units to simulate the solid welding points and connections of the car body, use triangular and quadrilateral mesh elements for mesh division, and perform mesh quality inspection to make the finite element model meet the finite element mesh quality standards, including:

[0035] Aspect ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com