Bilateral drive four-point force press

A bilateral drive and press technology, applied in the field of presses, to achieve the effects of prolonging service life, reducing deformation and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

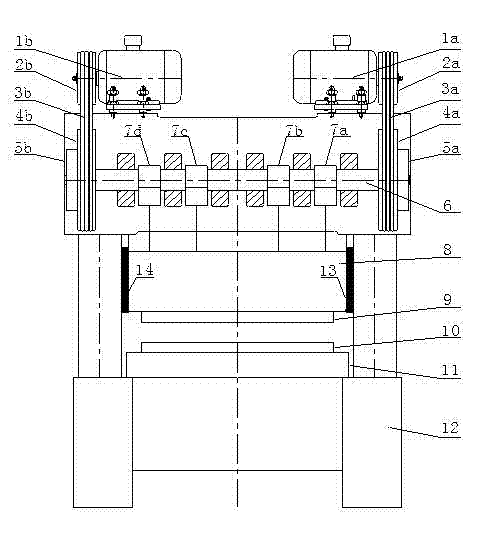

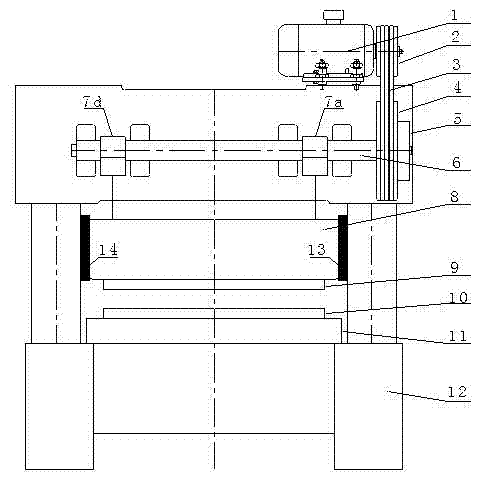

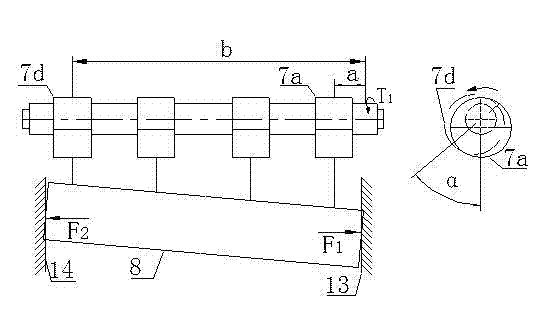

[0023] Such as figure 1 The shown press includes a fuselage 12, a worktable 11 is installed in the fuselage 10, a lower mold 10 of the press mold is installed on the worktable 11, and four eccentric force application points 7a, 7b, 7c and 7d are respectively Installed on the main shaft 6, the slider 8 is connected to the main shaft 6 through four eccentric force application points 7a, 7b, 7c and 7d, and the upper mold 9 of the press mold is installed on the bottom plane of the slider 8, opposite to the lower mold 10, The machining of the workpiece between the upper die and the lower die is completed by the reciprocating motion of the slider between the upper dead center and the lower dead center.

[0024] The first motor 1a and the second motor 1b are installed on the top of the fuselage 12 respectively, and the two motor pulleys 2a and 2b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com